Summary of Contents for MKS 390 Series

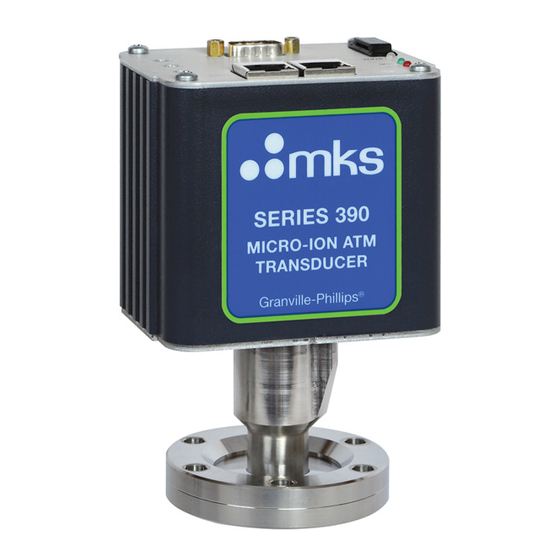

- Page 1 Series 390 Granville-Phillips Series 390 Micro-Ion ATM, ® ® Four-Sensor Combination Vacuum Gauge Module with RS-485 Interface and Analog Output Instruction Manual Instruction manual part number 390001 Revision H - November 2016...

- Page 3 Andover, MA 01810 USA Tel: 978-645-5500 Fax: 978-557-5100 Email: mks@mksinst.com Instruction Manual ® ® © 2016 MKS Instruments, Inc. All rights reserved. Granville-Phillips , Micro-Ion , and ® Conductron are registered trademarks, and mksinst is a trademark of MKS Instruments, Inc. All other trademarks and registered trademarks are the properties of...

- Page 4 ® ® Granville-Phillips Series 390 Micro-Ion ATM, Four-Sensor Combination Vacuum Gauge Module with RS-485 Interface and Analog Output Catalog numbers for Series 390 Micro-Ion ATM Modules Power supply and cable are not included. Analog output only - no display: 390410 - 0 - # # - # Analog output only - with digital display: 390411 - 0 - # # - # RS-485 interface &...

-

Page 5: Table Of Contents

Table of Contents Table of Contents Chapter 1 Before You Begin ........About these instructions . -

Page 6: Calibration

Table of Contents Reading differential pressure ......Micro-Ion gauge OFF ......Micro-Ion gauge degas . - Page 7 Table of Contents Read Micro-Ion gauge emission current ..Calibrate module at atmospheric pressure ..Calibrate module at vacuum pressure ..Set or read atmospheric pressure output .

- Page 8 Table of Contents ® Micro-Ion ATM Module Instruction Manual - 390001...

-

Page 9: Chapter 1 Before You Begin

Before You Begin Chapter 1 Before You Begin These instructions explain how to install, operate, and maintain the About these instructions ® ® Granville-Phillips Micro-Ion ATM vacuum gauge module. The module may have an RS-485 interface and one or two analog outputs. The module with an RS-485 interface may have no trip point relays, two trip point relays, or three trip point relays. -

Page 10: System Grounding

Chapter 1 WARNING Warning statements alert you to hazards or unsafe practices that could result in severe property damage or personal injury due to electrical shock, fire, or explosion. Each warning statement explains what you must do to prevent or avoid the potential result of the specified hazard or unsafe practice. -

Page 11: Operation

Reading and following instructions or maintaining the module. Failure to comply with the instructions violates standards of design, manufacture, and intended use of the module. MKS Instruments, Inc. / Granville-Phillips disclaim all liability for the customer's failure to comply with the instructions. -

Page 12: Definitions Of Terms

The difference between atmospheric pressure and vacuum pressure. Differential pressure zero is the pressure value at which vacuum pressure equals atmospheric pressure. For Customer Service / Technical Support: Customer service MKS Pressure and Vacuum Measurement Solutions ® MKS Instruments, Inc., Granville-Phillips Division 6450 Dry Creek Parkway... -

Page 13: Chapter 2 Installation

Installation Chapter 2 Installation The Micro-Ion ATM Module contains a Micro-Ion gauge (Bayard-Alpert Module components type ionization gauge), a Conductron heat-loss sensor, an atmospheric pressure diaphragm sensor, and a vacuum pressure diaphragm sensor. WARNING Using the module to measure the pressure of flammable or explosive gases can cause a fire or explosion resulting in severe property damage or personal injury. -

Page 14: Installation Procedure

Chapter 2 The module installation procedure includes the following steps: Installation procedure Determine the location of the module on the vacuum chamber. Attach the module’s flange/ fitting to its mating fitting on the vacuum chamber. Assemble and connect the module wiring. Calibrate the module at atmospheric pressure. - Page 15 Installation Figure 2-1 Dimensions Dimensions in (in.) ® Micro-Ion ATM Module Instruction Manual - 390001...

-

Page 16: Step 2 Attach Module To Vacuum Chamber

Chapter 2 Step 2 Attach module to vacuum chamber Attach the module’s flange/fitting to its mating fitting on the vacuum chamber. CAUTION Twisting the module to tighten the fitting to the vacuum chamber can damage the module’s internal connections. • Do not twist the module to tighten the fitting. -

Page 17: Step 3 Assemble And Connect Wiring

Installation Step 3 Assemble and connect wiring Cable is user-supplied. Granville-Phillips does not supply cable. Connecting cable • CE Mark compliance requires metal connector housings and cable with a braided shield. • To prevent ground loops, connect the shield only to the outer shell of the subminiature D connector on the module. - Page 18 Chapter 2 Figure 2-2 Wiring terminals for Micro-Ion ATM module with two analog outputs, and no trip-point relays for Module Catalog # 390410-0-##-# 390411-0-##-# Figure 2-3 Wiring terminals for Micro-Ion ATM module with RS-485 interface, two analog outputs, and no trip-point relays for Module Catalog # 390510-0-##-# 390511-0-##-#...

-

Page 19: Chassis Ground

Installation Chassis Ground WARNING Improper grounding could cause severe product failure or personal injury. Follow ground network requirements for the facility. • Maintain all exposed conductors at earth ground. • Ground the module housing to the vacuum chamber as illustrated below. •... -

Page 20: Step 4 Calibrate Module At Atmospheric Pressure

Chapter 2 Step 4 Calibrate module at atmospheric pressure • To calibrate the module at atmospheric pressure using a momentary switch installed between pins 15 and 5 on the 15-pin connector, see page 31. • To calibrate the module at atmospheric pressure using an RS-485 command, see page 61. -

Page 21: Chapter 3 Operation Overview

Operation Overview Chapter 3 Operation Overview Table 3-1 lists tasks that may be performed if the module has one or two Analog operation analog outputs Table 3-2 lists tasks that may be performed if the module has an RS-485 RS-485 operation interface. - Page 22 Chapter 3 Table 3-2 Commands, tasks, and page references for RS-485 operation Command Task Instructions: Toggle functions to locked or unlocked state Page 41 Unlock interface functions Page 41 Set address offset Page 42 yuiop Set RS-485 communication to default values Page 43 Set baud rate Page 43...

-

Page 23: Automatic Filament Selection

Operation Overview As the vacuum system pumps down from atmosphere, the Conductron Automatic filament selection sensor measures pressure until a sufficiently low pressure level is achieved, then automatically turns ON the Micro-Ion gauge. The filaments in the Micro-Ion gauge can burn out if they turn ON at a pressure that is too high. Tungsten filaments are more likely than yttria-coated iridium filaments to burn out if they turn ON at a pressure that is too high. - Page 24 Chapter 3 ® Micro-Ion ATM Module Instruction Manual - 390001...

-

Page 25: Chapter 4 Analog Operation

Analog Operation Chapter 4 Analog Operation The module may have two analog outputs with no RS-485 interface, two Output functions analog outputs with RS-485 interface, or one analog output with RS-485 interface. If the module has two analog outputs, analog output 1 indicates vacuum pressure, and analog output 2 represents differential pressure. -

Page 26: Led Status Indicator

Chapter 4 • Figure 4-1 illustrates the LED status indicator. The LED behavior indicates LED status indicator the status of the module and Micro-Ion gauge. • Table 4-1 lists states indicated by the LED. Figure 4-1 LED status indicator LED status indicator Table 4-1 LED status indications... -

Page 27: Reading Pressure

Analog Operation Use the module’s 15-pin connector to read voltage that indicates vacuum Reading pressure pressure or differential pressure. • Regardless of the number of analog outputs, the voltage across pins 2 and 12 indicates vacuum pressure. • If the module has two analog outputs, the voltage across pins 1 and 12 indicates differential pressure. -

Page 28: Reading Differential Pressure

Chapter 4 Figure 4-3 Analog output indicating vacuum pressure If the module has two analog outputs, the voltage across pins 1 (analog Reading differential pressure output 2) and 12 (signal common) represents differential pressure, as illustrated in Figure 4-4. Use one of the following equations to calculate differential pressure as a function of voltage: P differential 250 V... - Page 29 Analog Operation Figure 4-4 Pins 1 and 12: Voltage indicating differential pressure Figure 4-5 Analog output indicating differential pressure ® Micro-Ion ATM Module Instruction Manual - 390001...

-

Page 30: Micro-Ion Gauge Off

Chapter 4 When power is supplied to the module, the Conductron sensor is ON. As Micro-Ion gauge OFF pressure decreases to a level that allows the Micro-Ion gauge to operate, the sensor automatically turns the gauge ON. The LED status indicator blinks green when the Micro-Ion gauge is ON. -

Page 31: Calibration

Analog Operation Figure 4-7 Pins 8 and 7: Switch for Micro-Ion gauge degas ON You may install a momentary contact switch between pins 15 (calibration) Calibration and 5 (24 Vdc power ground) to enable calibration at atmospheric or vacuum pressure. See Figure 4-8. Figure 4-8 Pins 15 and 5: Switch for calibration ®... -

Page 32: Atmospheric Pressure Calibration

Chapter 4 Atmospheric pressure calibration and differential pressure zero are Atmospheric pressure calibration performed using N at the factory before the module is shipped. Differential pressure zero is the pressure value at which atmospheric and vacuum pressures are equal. The factory calibration sets the differential pressure zero to approximately 760 Torr (1013 mbar, 1.01 x 10 Pa). -

Page 33: Rs-485 Operation

RS-485 Operation Chapter 5 RS-485 Operation A module with RS-485 communications may have one or two analog Pressure output and relay functions outputs. • If the module has no trip point relays, it has two analog outputs. • If the module has two or three set point relays, it has one analog output. If the unit has one analog output, the output represents vacuum chamber pressure. -

Page 34: Rs-485 Physical Layer

Chapter 5 Table 5-1 Relay trip points and assignments Activation trip point Deactivation trip point Relay (Torr, mbar, or Pa) (Torr, mbar, or Pa) Relay assignment Relay 1 Vacuum pressure Differential pressure Relay 2 Vacuum pressure Differential pressure ... -

Page 35: Operational Tasks

RS-485 Operation Once the module is operating, you may use RS-485 commands to perform Operational tasks the tasks listed in Table 3-2 on page 22. If a command cannot be processed, the module returns one of the error Error responses responses listed in Table 5-3. -

Page 36: Data Timing And Response

Chapter 5 The module communicates using half-duplex mode. Neither the module Data timing and response nor the host can send and receive signals at the same time. The host issues a command then waits for a response from the module. Figure 5-1 illustrates the request and response data timing sequence, including: •... -

Page 37: Rs-485 Commands

RS-485 Operation Table 5-4 Data timing and response delay limits Timing segment Time limit Time T (data processing and response time) ------------ - ¥ Baud µsec Time D (time for module to switch from transmit to receive) Total response time ... -

Page 38: Symbols Used In This Manual

Chapter 5 The ↵ symbol at the end of the command represents the carriage return Symbols used in this manual (CR), which is entered as hex code 0D or, if you’re using a terminal, by simultaneously pressing the “Control” and “M” keys. The response will have a space between the address and the text of the response. - Page 39 RS-485 Operation Table 5-7 RS-485 command set for values not affecting module operation Command Set by command Non-volatile Change after reset Data returned Can be locked Vacuum pressure Differential pressure Pressure unit RPCS Relay state Micro-Ion gauge ON/OFF state Degas ON/OFF state Emission current Filament operation state Module status RS-485 string...

- Page 40 Chapter 5 Table 5-8 RS–485 command set for commands affecting module operation Set by Can be Command command Non-volatile Default Change after reset Data returned locked OFF (0) Confirm OFF (0) Confirm Confirm 19200 baud Confirm yuiop • 19200 baud None •...

-

Page 41: Tlu Toggling Locked Functions

RS-485 Operation In default operating mode, all interface functions are unlocked. Toggling locked functions Use the toggle lock/unlock (TLU) command to lock or unlock any of the interface functions listed in Table 5-9. Table 5-9 Interface functions affected by TLU command Command Interface function Instructions:... -

Page 42: Sa Set Address Offset

Chapter 5 You must assign an address to enable the module to communicate with the Set address offset host. The module may use any address from 0 to 63. The address consists of the hexadecimal switch setting plus the hexadecimal SA (set address offset) value. For example, to set a value of 60 for the address, set the switch to C (12), then send an SA value of (48). -

Page 43: Sb Set Baud Rate

RS-485 Operation The example set baud rate (SB) command sequence sets the baud rate to Set baud rate 2400 baud: Example SB command from host: #01SB2400↵ Response from module: *01 PROGM OK↵ Valid values are 1200, 2400, 4800, 9600, 19200 (default), or 38400 baud. The lower-case yuiop command restores the address offset to 0 and the yuiop Restore RS-485... -

Page 44: Rd Read Vacuum Pressure

Chapter 5 The example read pressure (RD) command causes the module to return a Read vacuum pressure –2 value that indicates vacuum pressure is 1.50 x 10 Example RD command from host: #01RD↵ Example response from module: *01 1.50E–02↵ The returned value is in the pressure unit that you’ve set for the module. If the returned value is not a valid representation of pressure, see page 76. -

Page 45: Process Control Relay

RS-485 Operation The module may have two single-pole double-throw (normally Process control relay trip points open/normally closed) relays or three single-pole single-throw (normally open) relays. Each relay can be independently assigned to vacuum or differential pressure. Each relay has programmable activation and deactivation trip points. - Page 46 Chapter 5 The “A” (activation) and “D” (deactivation) pressure values determine activation and deactivation direction, as listed in Table 5-10. Table 5-10 Activation/deactivation direction Activation versus deactivation Effect on relay operation If A > D Relay activates with increasing pressure (see Figure 5-4) If D >...

- Page 47 RS-485 Operation Figure 5-3 Default behavior of relays activating with decreasing pressure (D > A) Time Deactivate Hysteresis Activate Relay activated Activate Deactivate Figure 5-4 Default behavior of relays activating with increasing pressure (A > D) Time Activate Hysteresis Deactivate Relay activated Activate...

- Page 48 Chapter 5 The plus (+) or minus (–) sign that precedes the pressure value is meaningful only if the relay indicates differential pressure. If the relay is assigned to vacuum pressure, do not enter a + or – sign preceding the “A” and “D” pressure values. •...

-

Page 49: Pcg Set Trip Point Relay Assignments

RS-485 Operation Use the process control gauge (PCG) command to assign any relay to Set trip point relay assignments vacuum pressure or to differential pressure. WARNING Failure to adjust relays for the gas that is being used can cause an explosion due to overpressurization. If relays are re−assigned, do not use the module to measure the pressure of gases other than N or air without adjusting relay... -

Page 50: Rpcs Read Trip Point Relay Status

Chapter 5 The read process control relay status (RPCS) command causes the module RPCS Read trip point relay status to return a numeric value that represents the status of both relays if the module has two relays or all three relays if the module has three relays. RPCS command from host: #01RPCS↵... - Page 51 RS-485 Operation If the Micro-Ion gauge has been turned OFF using the IG0 command or Set or read pressure indication when wiring terminals 3 and 5, use the IGM (ion gauge mode) command to Micro-Ion gauge is OFF enable or disable pressure indications from the Conductron sensor. Example IGM command from host: #01IGM1↵...

-

Page 52: Iod Set Or Read Micro-Ion Gauge Delay On/Off State

Chapter 5 The ion gauge delay (IOD) command reduces the possibility that the Set or read Micro-Ion gauge delay ON/OFF state Micro-Ion gauge filaments will burn out if the gauge turns ON at a pressure that is too high. The IOD command functions by delaying the time at which the Micro-Ion gauge turns ON with decreasing pressure. -

Page 53: Idt Set Or Read Micro-Ion Gauge Delay Time

RS-485 Operation Whether or not the IOD command is set to ON, you may send the ion delay Set or read Micro-Ion gauge delay time time (IDT) command to add to, determine, or read the amount of time the Micro-Ion gauge waits to turn ON after pressure has decreased to a point where the gauge can operate. -

Page 54: Sf Set Micro-Ion Gauge Filament Mode

Chapter 5 The Micro-Ion gauge contains two filaments, and can operate in automatic, Set Micro-Ion gauge filament mode alternating, manual or both-filament mode of operation. The both-filament mode works at low-emission only, and is factory configured. The example set filament (SF) command sets the gauge to manual mode. Example SF command from host: #01SFMAN↵... -

Page 55: Automatic Filament Switching Flow Chart

RS-485 Operation Figure 5-5 Automatic filament switching flow chart NOTE: The Micro-Ion Module is factory configured for either single-filament or both-filament operation at low emission. ® Micro-Ion ATM Module Instruction Manual - 390001... - Page 56 Chapter 5 Figure 5-6 Alternating filament switching flow chart NOTE: The Micro-Ion Module is factory configured for either single-filament or both-filament operation at low emission. ® Micro-Ion ATM Module Instruction Manual - 390001...

- Page 57 RS-485 Operation Figure 5-7 Manual filament switching flow chart NOTE: The Micro-Ion Module is factory configured for either single-filament or both-filament operation at low emission. ® Micro-Ion ATM Module Instruction Manual - 390001...

-

Page 58: Rf Read Micro-Ion Gauge Filament Status

Chapter 5 The read filament (RF) command causes the module to return an example Read Micro-Ion gauge filament status character string indicating filament 1 is operating. RF command from host: #01RF↵ Example response from module: *01 FIL SF1↵ • The “FIL SF1” response means filament 1 is operating. •... -

Page 59: Dgt Set Or Read Micro-Ion Gauge Degas Time

RS-485 Operation The Micro-Ion gauge degas cycle runs for two minutes unless you adjust the Set or read Micro-Ion gauge degas time degas time by sending a degas gauge time (DGT) command. The example DGT command sets the degas time to 60 seconds. Example DGT command from host: #01DGT60↵... - Page 60 Chapter 5 The switch back to low emission current with increasing pressure is 100% greater than the switch to high emission current with decreasing pressure, as illustrated in Figure 5-8. For example, in default mode, the current level –6 –6 switches from low to high emission at 5 x 10 Torr (6.66 x 10 mbar,...

-

Page 61: Re Read Micro-Ion Gauge Emission Current

RS-485 Operation Send the read emission (RE) command to read the Micro-Ion gauge Read Micro-Ion gauge emission current emission current. RE command from host: #01RE↵ Example response from module: *01 4.0MA EM↵ Table 5-14 lists module responses to the RE command. Table 5-14 Responses to RE command Response Description... -

Page 62: Tz Calibrate Module At Vacuum Pressure

Chapter 5 Ordinarily, the Conductron sensor turns the Micro-Ion gauge ON when Calibrate module at –2 –2 vacuum pressure pressure decreases to 2 x 10 Torr (2.66 x 10 mbar, 2.66 Pa). However, if the Conductron sensor calibration has shifted so that the Micro-Ion gauge cannot turn ON, you can recalibrate the module for vacuum pressure. -

Page 63: Atm Set Or Read Atmospheric Pressure Output

RS-485 Operation Use the atmospheric pressure output (ATM) command to set or read the Set or read atmospheric pressure output pressure value that the module will indicate each time the module senses zero differential between atmospheric and chamber pressures. The ATM command followed by the character string “ACTUAL” sets the output to indicate actual atmospheric pressure whenever the module senses zero differential between atmospheric and chamber pressure. - Page 64 Chapter 5 Table 5-15 Module status RS–485 strings Response Cause Solution Module is operating normally. No solution necessary. 00 ST OK Conductron sensor is inoperable. Replace gauge assembly (see page 79). 01 CGBAD Pressure diaphragm sensor is inoperable. 02 DGBAD º...

-

Page 65: Rsx Read Module Status Hexadecimal Bits

RS-485 Operation Send the read status hexadecimal (RSX) command to read hexadecimal bits Read module status hexadecimal bits that indicate the module operating status. RSX command from host: #01RSX↵ Example response from module: *01 000000A0↵ The example response indicates that ambient temperature > 80 º C and a Micro-Ion gauge grid voltage failure has occurred. - Page 66 Chapter 5 Table 5-16 Hexadecimal fatal error bits: Module has stopped operating Fatal error bit Cause Solution 00000001 • Conductron sensor is inoperable. • If Conductron sensor is inoperable, replace gauge assembly • Module electronics failure. (see page 79). 00000002 •...

- Page 67 RS-485 Operation Table 5-17 Hexadecimal warning bits: Module can operate but measurements may be inaccurate Warning bit Cause Solution 00000008 Vacuum pressure diaphragm sensor Pressure readouts will indicate pressure as measured by is inoperable. Conductron sensor. Module will not indicate differential pressure, Micro-Ion gauge failure, or electronics failure.

-

Page 68: Rst Reset Module To Power-Up State

Chapter 5 The reset (RST) command resets the module to power-up status. Reset module to power-up state RST command from host: #01RST↵ Response from module: None Sending the RST command has the same effect as cycling power to the module. Communication is re-enabled two seconds after you’ve sent the RST command. -

Page 69: Chapter 6 Optional Display

Optional Display Chapter 6 Optional Display The optional display is a backlit, 72-dot by 48-dot matrix that can indicate Display capabilities vacuum pressure, differential pressure, and error conditions. Using the RS-485 interface, you can send a set display (SD) command that enables the display to indicate vacuum (absolute) pressure when pressure is less than 250 Torr (333 mbar, 3.33 x 10 Pa) and differential pressure when... -

Page 70: Display Resolution

Chapter 6 Figure 6-2 Optional display indicating differential pressure Two significant + or – sign digits for exponent + or – sign for Exponent positive or negative +2.1 differential pressure “D” for differential TORR Pressure unit pressure –10 –10 –9 Pressure values in the 10 range (such as 6 x 10 ) will appear as “0.6... - Page 71 Optional Display Table 6-2 Error conditions indicated by optional display Error message Cause Solution Module is in startup mode and operating No solution necessary. GAUGE OK normally. Conductron sensor is inoperable. Replace the gauge assembly (see page 79). ERR 01 CGBAD Pressure diaphragm sensor is inoperable.

- Page 72 Chapter 6 ® Micro-Ion ATM Module Instruction Manual - 390001...

-

Page 73: Chapter 7 Maintenance

Maintenance Some minor problems are readily corrected on site. If the product requires Customer Service service, contact the MKS, Granville-Phillips Division Technical Support Department at 1-303-652-4400 or 1-800-776-6543 for troubleshooting help over the phone. If the product must be returned to the factory for service, request a Return Material Authorization (RMA) from Granville-Phillips. -

Page 74: Troubleshooting

Chapter 7 Troubleshooting Because the module contains static-sensitive electronic parts, follow these Precautions precautions while troubleshooting: • Use a grounded, conductive work surface. Wear a high impedance ground strap for personal protection. • Do not operate the module with static sensitive devices or other components removed from the product. -

Page 75: Symptoms, Causes, And Solutions

Maintenance Table 7-1 lists failure symptoms, causes, and solutions indicated by Symptoms, causes, and solutions something other than an RS-485 error message from the module. Table 7-1 Failure symptoms, causes, and solutions Symptom Possible causes Solution Analog output voltage = 0 V Power supply cable is improperly Repair or replace the power supply connected or faulty. -

Page 76: Error Responses

Chapter 7 Table 7-2 lists error responses that the module returns if you enter a RS-485 error responses command improperly or if the module non-volatile memory (NOVRAM) cannot process a command. Table 7-2 Troubleshooting RS–485 error responses Response Possible causes Solution 1. -

Page 77: Micro-Ion Gauge Continuity Test

Maintenance If a problem with pressure measurement is traced to the module, the Micro-Ion gauge continuity test Micro-Ion gauge can be tested with an ohmmeter. This test can detect open filaments or shorts between gauge elements, but may not detect inaccurate pressure measurement associated with vacuum leaks or adsorbed gases within the gauge. - Page 78 Chapter 7 Figure 7-2 Micro-Ion gauge pins Use a digital multimeter to measure the resistance between pins 2 and 3 (the filament pins), and between pins 1 and 2. See Figure 7-2. The readings should be 0.2 Ω. Measure the resistance of filament pins 1, 2, or 3 to any of pins 4, 5, or 6, or the gauge case.

-

Page 79: Replacing The Gauge Assembly

Material Authorization (RMA) from Granville-Phillips. Do not return products without first obtaining an RMA. In some cases a hazardous materials document may be required. The MKS/Granville-Phillips Customer Service Representative will advise you if the hazardous materials document is required. - Page 80 Chapter 7 ® Micro-Ion ATM Module Instruction Manual - 390001...

-

Page 81: Appendix A Specifications & Compliance

Specifications & Compliance Appendix A Specifications & Compliance Pressure Measurement Specifications Atmospheric value is based on calibration at time of use. Absolute Pressure for N or Air Measurements will change with different gases and mixtures. –9 Torr 1 x 10 to atmosphere Absolute Pressure Range –9... - Page 82 Appendix A X-ray Limit X-ray limit is the absolute lowest indication from the gauge. It is not possible to make repeatable measurements near the x-ray limit. –10 Torr < 3 x 10 –10 mbar < 4 x 10 –8 Pascal <...

- Page 83 Specifications & Compliance Backlit, 72-dot by 48-dot matrix can indicate vacuum pressure, differential Optional Display pressure, and error conditions. RS-485 interface enables display to indicate vacuum (absolute) pressure when pressure is < 250 Torr (333 mbar, 3.33 x 10 Pa) and differential pressure when pressure ≥...

- Page 84 Appendix A Optional Trip Point Relays Two single-pole double-throw (normally open/normally closed) or three Relay Type single-pole single-throw (normally open) relays. Each relay can be independently assigned to vacuum or differential pressure. Relay Contact Ratings Maximum 1 A at 30 Vdc, resistive load Minimum 5 mA at 5 Vdc, resistive load Relays Assigned to Vacuum Pressure...

- Page 85 Specifications & Compliance Micro-Ion Sensor 0.02 mA or 4 mA, automatically set Emission Current Use RS–485 commands to set switch point for high and low emission currents. Default control settings –2 2 x 10 Torr with decreasing pressure Gauge ON –2 2.66 x 10 mbar with decreasing pressure...

- Page 86 Appendix A Electrical Connectors 15-pin subminiature D male I/O Connector Power supply requirement is 24 Vdc +10% to –15%, 1 A, 22 W nominal. Power Requirements Maximum inrush current is 2 amps, 48 W, for 0.5 seconds. Power supply must supply at least 2 amps (48 W) of current for at least 0.5 seconds during Micro-Ion sensor start up.

- Page 87 Specifications & Compliance Physical specifications 728.5 g (25.7 oz.) with 2.75-inch ConFlat flange Weight Powder-coated extruded aluminum Case material 304 stainless steel, tantalum, tungsten, yttria-coated iridium, alumina, CuAg Materials exposed to vacuum eutectic, Kovar, gold-plated and nickel-plated Kovar, borosilicate glass Dimensions Dimensions in (in.)

- Page 88 Appendix A ® Micro-Ion ATM Module Instruction Manual - 390001...

-

Page 89: Appendix B Theory Of Operation

Theory of Operation Appendix B Theory of Operation The Micro-Ion ATM vacuum gauge module consists of four separate Module Operation pressure measuring devices: a Micro-Ion gauge (Bayard-Alpert type ionization gauge), a Conductron heat-loss sensor, and two Piezo resistive pressure diaphragm sensors. One Piezo resistive diaphragm sensor measures atmospheric pressure, and one Piezo resistive diaphragm sensor measures vacuum pressure. - Page 90 Appendix B Figure B-2 Auto ranging Actuation Points The functional parts of the Micro-Ion gauge are the filaments (cathodes), Micro-Ion Gauge Operation grid (anode) and ion collectors. These electrodes are maintained by the controller at +30, +180, and 0 volts, relative to ground, respectively. The filaments are heated to such a temperature that electrons are emitted and accelerated toward the grid by the potential difference between the grid and filaments.

- Page 91 Theory of Operation The amount of ion current for a given emission current and pressure depends on the Micro-Ion gauge design. This gives rise to the definition of ionization gauge sensitivity, frequently denoted by “S”: Ion current --------------------------------------------------------------------- - Emission current ¥...

- Page 92 Appendix B ® Micro-Ion ATM Module Instruction Manual - 390001...

-

Page 93: Index

Index Index relay activation pressure 84 RS-485 commands 40 Definitions of terms 12 degas 35, 58, 59, 76, 85 Differential pressure 82 Dimensions 15, 87 About these instructions 9 or air 81 Absolute pressure for N Analog output specifications 82 Appendixes Electrical connectors 86 Specifications 81... - Page 94 Index wiring terminals returning a damaged module 79 module with analog and RS-485 outputs 18 RS-485 error messages 76 module with three trip point relays 18 symptoms, causes, solutions 75 module with two analog outputs 18 troubleshooting 74 module with two trip point relays 18 troubleshooting precautions 74 Filament material 85 Materials exposed to vacuum 87...

- Page 95 Index pressure indication with gauge OFF 51 analog 25 process control 45 RS-485 33 reading differential pressure 28, 44 Pressure reading firmware version 68 differential 28, 44 reading Micro-Ion gauge degas status 58 measurement unit, reading 43 reading Micro-Ion gauge emission current 61 measurement unit, setting 43 reading module status 63 reading differential 69...

- Page 96 Index RST 22, 68 physical 87 RSX 22, 65 power requirements 86 RU 22, 43 pressure measurement 81 SA 22, 42 relay activation pressure 84 SB 22, 43 relay contact ratings 84 SD 22, 43 relay type 84 SER 22, 59 relays assigned to vacuum pressure 84 SF 22, 54 response time 82...

- Page 97 Index symptoms, causes, solutions 75 Vacuum pressure 81 VCR type fitting 16 Weight 87 Wiring assembling and connecting 17 CE Mark compliance 86 gauge ON/OFF 17 ground 19 I/O connector 86 power requirements 86 power supply 17 terminals 17 ® Micro-Ion ATM Module Instruction Manual - 390001...

- Page 98 Index ® Micro-Ion ATM Module Instruction Manual - 390001...

-

Page 100: Customer Service

ATM, ® ® Four-Sensor Combination Vacuum Gauge Module with RS-485 Interface and Analog Output Customer Service / Technical Support: MKS Pressure and Vacuum Measurement Solutions ® MKS Instruments, Inc., Granville-Phillips Division 6450 Dry Creek Parkway Longmont, Colorado 80503 USA Tel: 303-652-4400 Fax: 303-652-2844 Email: mks@mksinst.com...

Need help?

Do you have a question about the 390 Series and is the answer not in the manual?

Questions and answers