Table of Contents

Advertisement

Quick Links

Advertisement

Chapters

Table of Contents

Summary of Contents for Afag LTM-V-100

- Page 1 Assembly & Operating Instructions Linear-Transport-Module LTM-V-100 LTM-V-180 Translation of the Original Assembly Instructions EN LTM-V-100/180 Order no.: 20190611 Assembly instructions EN LTM-V-100 / LTM-V-180 Edition 03/2020 Rev. 2.0 1-60 ...

- Page 2 Your Afag team © Subject to modifications The linear transport modules from Afag Automation AG have been built according to the state-of-the-art. Due to the constant technical development and improvement of our products, we reserve the right to make technical changes at any time.

-

Page 3: Table Of Contents

Safety signs on the LTM or the working environment ....... 17 Warning signs ................... 17 Mandatory signs ................17 Technical data ....................18 LTM-V-100-XXXX / LTM-V-180-XXXX ............ 18 Workpiece carrier load ................20 Transport, packaging and storage ..............21 General....................21 Safety instructions for transport ............... - Page 4 Measures to be taken after maintenance work ........50 Repair work .................... 50 spare and wear parts lists ............... 50 Toothed belt..................51 Side guides ..................52 4 – 60 Assembly instructions EN LTM-V-100 / LTM-V-180 Edition 03/2020 Rev. 2.0 ...

- Page 5 10.1 Safety instructions for decommissioning, dismantling and disposal ..53 10.2 Decommissioning ................... 53 10.3 Disassembly ................... 53 10.4 Disposal....................54 Declaration of incorporation ................55 Assembly instructions EN LTM-V-100 / LTM-V-180 Edition 03/2020 Rev. 2.0 5-60 ...

-

Page 6: General

NOTICE This safety note points out a potentially dangerous situation which, if not avoided, can cause substantial damage to property and the environment. 6 – 60 Assembly instructions EN LTM-V-100 / LTM-V-180 Edition 03/2020 Rev. 2.0 ... - Page 7 Warning - Magnetic field Warning - back injury due to heavy lifting. Warning - Risk of injury as a result of parts being flung out! Warning -high noise levels Assembly instructions EN LTM-V-100 / LTM-V-180 Edition 03/2020 Rev. 2.0 7-60 ...

-

Page 8: Additional Symbols

Wear parts (e.g. shock absorbers) are excluded from the warranty.* The warranty covers the replacement or repair of defective Afag parts. Further claims are excluded. However, a customer has a right to a defect-free product. This does also apply to defective accessories and wear parts. -

Page 9: Liability

No changes shall be made to the LTM unless described in this instruction manual or approved in writing by Afag Automation AG. Afag Automation AG accepts no liability for unauthorized changes or improper assembly, installation, commissioning, operation, maintenance or repair work. -

Page 10: Safety Instructions

2.2 Intended use The linear transport modules of the LTM-V-100 and LTM-V-180 series have been specially designed for fast workpiece carrier transport and continuous operation. The linear transport modules are integrated into automation systems. -

Page 11: Obligations Of The Operator And The Personnel

The operating company shall be solely responsible for such damage, and Afag Automation AG does not accept any liability for damages caused by improper use. 2.4 Obligations of the operator and the personnel... -

Page 12: Obligations Of The Personnel

Authorized persons who due to their specialized professional training, expertise and experience are capable of identifying risks and preventing possible hazards arising from the use of the machine. 12 – 60 Assembly instructions EN LTM-V-100 / LTM-V-180 Edition 03/2020 Rev. 2.0 ... -

Page 13: Personal Protective Equipment (Ppe)

Hearing protectors are required to protect the personnel against excessive noise levels to prevent noise-induced hearing loss. Assembly instructions EN LTM-V-100 / LTM-V-180 Edition 03/2020 Rev. 2.0 13-60 ... -

Page 14: Safety And Protection Equipment

No changes may be made to the LTM which have not been described in these assembly instructions or approved in writing by Afag Automation AG. Afag Automation AG accepts no liability for unauthorised changes or improper assembly, installation, commissioning, maintenance or repair work. -

Page 15: General Hazards / Residual Risks

The operating company is responsible for ensuring that the permissible noise levels are observed. If the noise level exceeds 85 dB(A) in normal operation, the operator must wear hearing protectors at the workplace. Assembly instructions EN LTM-V-100 / LTM-V-180 Edition 03/2020 Rev. 2.0 15-60 ... -

Page 16: Danger Due To High Temperatures

The due diligence obligations of the operating company include ensuring that the personnel carrying out maintenance work is appropriately trained and qualified. 16 – 60 Assembly instructions EN LTM-V-100 / LTM-V-180 Edition 03/2020 Rev. 2.0 ... -

Page 17: Safety Signs On The Ltm Or The Working Environment

Warning - Risk of hand and finger injuries due to uncontrolled movements of components. Mandatory signs Observe assembly instructions and other applicable documents! Switch off before starting maintenance or repair work! Assembly instructions EN LTM-V-100 / LTM-V-180 Edition 03/2020 Rev. 2.0 17-60 ... -

Page 18: Technical Data

Technical data Technical data 3.1 LTM-V-100-XXXX / LTM-V-180-XXXX LTM-V Speed up to 180 cycles/min Repeatability +/- 0.1 mm Feed lengths 10, 20, 30, 40, 60, 80, 90, 120, 180, 240 mm or continuous operation Feed time From 0.1 sec. depending on feed length and workpiece carrier load... - Page 19 Usable length L1* [mm] 1320 1920 2520 3120 3720 Use length value to which the elongation factor 1.00135 must be applied. Dimension of workp. carrier [mm] [mm] Assembly instructions EN LTM-V-100 / LTM-V-180 Edition 03/2020 Rev. 2.0 19-60 ...

-

Page 20: Workpiece Carrier Load

100 Nm 100 Nm Max forces Fx 100 N 100 N Max forces Fy 500 N 500 N Max forces Fz 5000 N 5000 N 20 – 60 Assembly instructions EN LTM-V-100 / LTM-V-180 Edition 03/2020 Rev. 2.0 ... -

Page 21: Transport, Packaging And Storage

Only lift the LTM with a suitable lifting device (crane, forklift). Also observe the safety instructions in chap. 2 „Safety instructions“ in this manual. Assembly instructions EN LTM-V-100 / LTM-V-180 Edition 03/2020 Rev. 2.0 21-60 ... -

Page 22: Scope Of Delivery And Accessories

This is the zero position of each workpiece carrier. The reference sensor is already mounted at factory for the delivery test. 22 – 60 Assembly instructions EN LTM-V-100 / LTM-V-180 Edition 03/2020 Rev. 2.0 ... -

Page 23: Transport

Lift the load and transport it to the unloading point. Transport by crane is completed. To incorporate the LTM into an assembly system, proceed in the same way. Assembly instructions EN LTM-V-100 / LTM-V-180 Edition 03/2020 Rev. 2.0 23-60 ... -

Page 24: Packaging

Clean the LTM and protect the blank metal parts against corrosion using the appropriate means. Cover the LTM completely and protect against dirt and dust. 24 – 60 Assembly instructions EN LTM-V-100 / LTM-V-180 Edition 03/2020 Rev. 2.0 ... -

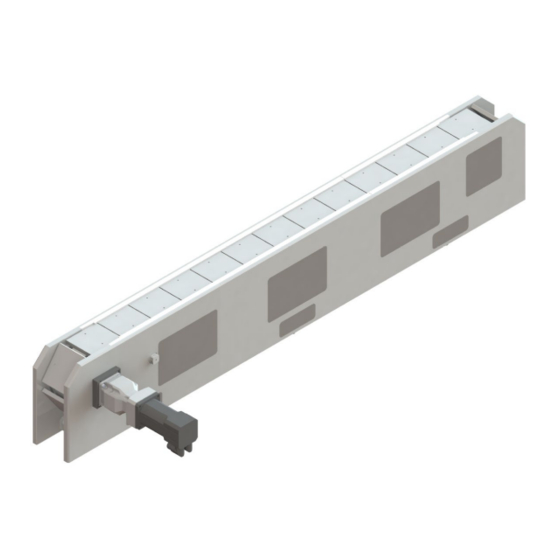

Page 25: Structure And Description

Linear transport module Drive module Middle module Deflector module Workpiece carriers Cover of clamping device Maintenance opening Attachment kit Planetary gear Motor Recess for fastening and lifting straps Assembly instructions EN LTM-V-100 / LTM-V-180 Edition 03/2020 Rev. 2.0 25-60 ... -

Page 26: Product Description

8. Attachment kit 3. Deflector module 9. Gear 4. Workpiece carriers 10. Motor 5. Drive unit 11. Sensor 6. Toothed belt 12. Clamping device 26 – 60 Assembly instructions EN LTM-V-100 / LTM-V-180 Edition 03/2020 Rev. 2.0 ... -

Page 27: Fields Of Application

Integration into an assembly system where high cycle rates are required As stand-alone machine for high output For use in the food industry (after consultation with Afag) Fig. 5 Example of application linear transport module on assembly line... -

Page 28: Installation, Assembly & Setting

Use suitable assembly and transport equipment. Also observe the safety instructions in chap. 2 „Safety instructions“ in this manual. 28 – 60 Assembly instructions EN LTM-V-100 / LTM-V-180 Edition 03/2020 Rev. 2.0 ... -

Page 29: Views Of The Ltm (General View And Engine/Gearbox Installation)

6. Cover of clamping device Assembly kit consisting of: Gear adapter and clamping set Multi-stage planetary gear unit Servo motor Fig. 7 Overview motor and gearbox installation Assembly instructions EN LTM-V-100 / LTM-V-180 Edition 03/2020 Rev. 2.0 29-60 ... -

Page 30: Attachment And Tightening Torque

Bottom view of the LTM The through bores (ø 10.5 mm) for mounting the linear transport module are located on the bottom of the side cheeks! 30 – 60 Assembly instructions EN LTM-V-100 / LTM-V-180 Edition 03/2020 Rev. 2.0 ... -

Page 31: Tightening Torques For Screws

Galvanized blue, oiled or greased Value Tightening torques 2.6 – 3.3 Nm 5.2 – 6.5 Nm 9.0 – 11.3 Nm 21.6 – 27.3 Nm 43.0 – 54.0 Nm Assembly instructions EN LTM-V-100 / LTM-V-180 Edition 03/2020 Rev. 2.0 31-60 ... -

Page 32: Integration Of The Linear Transport Module

Switch the control unit off before starting work and lock to prevent access by unauthorized personnel. Only connect or disconnect the cables when the control is switched off. 32 – 60 Assembly instructions EN LTM-V-100 / LTM-V-180 Edition 03/2020 Rev. 2.0 ... -

Page 33: Integration Of The Ltm Into An Assembly System

Without an additional safety device, personnel may be injured by flying parts ejected from the LTM. When integrating a LTM into an assembly system, the customer must provide an appropriate enclosure or safety barrier. Assembly instructions EN LTM-V-100 / LTM-V-180 Edition 03/2020 Rev. 2.0 33-60 ... -

Page 34: Gearbox Change And Motor Attachment

Turn the screws back into the clamping threads. Remove the 4 screws (Fig. 12, 2). Remove the gear adapter including gear and motor. The gear/motor is disassembled 34 – 60 Assembly instructions EN LTM-V-100 / LTM-V-180 Edition 03/2020 Rev. 2.0 ... -

Page 35: Assembly Of The Gear / Motor

6.6 Attachment of external drives The linear transport module can be fitted with a drive concept other than that offered by Afag Automation. For this purpose, the following prerequisites must be met: The diameter of the gear drive shaft must be 40 mm. This value is based on the size of the appropriate attachment set. -

Page 36: Motor Control

Brake + Brake - Thermo switches Thermo switches Fig. 15 Electrical interfaces If you are using a third-party controller or an Afag SE-Power servo controller, please read the accompanying documentation. 36 – 60 Assembly instructions EN LTM-V-100 / LTM-V-180 Edition 03/2020 Rev. -

Page 37: Setting And Retrofitting

Installation, assembly & setting We recommend the use of the Afag standard cables listed in the accessories list. The motor plugs are turned as follows: Loosen the screws (Fig. 16, 1) on the plug. Turn the plug. Tighten the screws (Fig. 16, 1). -

Page 38: General Safety Instructions For Adjustment And Retrofitting Work

Adjustment and conversion work may only be carried out by qualified personnel! Also observe the safety instructions in chap. 2 „Safety instructions“ in this manual. 38 – 60 Assembly instructions EN LTM-V-100 / LTM-V-180 Edition 03/2020 Rev. 2.0 ... -

Page 39: Toothed Belt Tension

Tension the toothed belt with the tensioning screw (Fig. 17, 1), observing the adjustment dimension. Perform the operation on both sides of the LTM. The tension of the toothed belt is adjusted. Assembly instructions EN LTM-V-100 / LTM-V-180 Edition 03/2020 Rev. 2.0 39-60 ... -

Page 40: Changing The Workpiece Carrier

The measurement was carried with an optical instrument pointing the crosshairs at the workpiece carriers. Setting and measuring of the LTM was carried out with the Afag standard drive. The measuring curve shows the deviation from the target position in running direction, measured optically on the crosshairs on the workpiece carrier. -

Page 41: Commissioning

Commissioning must only be carried out in setup/jog mode. Ensure that there are no persons or loose tools in the danger area. Risk of injury from deflection modules and drive modules Assembly instructions EN LTM-V-100 / LTM-V-180 Edition 03/2020 Rev. 2.0 41-60 ... -

Page 42: Commissioning Procedure

The reference offset value can be saved in the servo-controller or the programmable logic controller (PLC). The servo-controller Afag SE-Power offers the possibility to save the offset value in the controller via the PLC. 42 – 60 Assembly instructions EN... -

Page 43: Programming

LTM. When using the Afag SE-Power servo-controller, please refer to the enclosed quick installation guide. You will also find the quick installation guide on the Internet at www.afag.com. CAUTION Risk of injury due to flying parts ejected from the LTM! There is a risk of injury from flying parts ejected from the LTM, if incorrect acceleration and deceleration values are entered into the PLC. -

Page 44: Fault Elimination

5. Do not put the LTM back into operation until the fault has been eliminated. 6. After the fault, check whether the LTM is still functional and whether there are any other hazards. 44 – 60 Assembly instructions EN LTM-V-100 / LTM-V-180 Edition 03/2020 Rev. 2.0 ... -

Page 45: Tables Fault Causes And Remedy

Check correct functioning as described in chapter “7Commissioning”. Motor disconnection Check motor cable Drive defective Have the drive replaced by an Afag AG service technician Assembly instructions EN LTM-V-100 / LTM-V-180 Edition 03/2020 Rev. 2.0 45-60 ... - Page 46 Marked play in the side guides Have Afag AG service technicians Excessive play replace the guides Ball bearing of drive shaft or Have ball bearings replaced by Afag Ball bearing deflection rollers defective AG service technicians Gearbox is defective ...

-

Page 47: Maintenance And Repair

Maintenance work on the linear transport module with attachments and superstructures may only be carried out in set-up or jog mode. Make sure that there are no persons or tools in the working area of LTM. Assembly instructions EN LTM-V-100 / LTM-V-180 Edition 03/2020 Rev. 2.0 47-60 ... -

Page 48: Maintenance Activities And Maintenance Intervals

The intervals refer to a normal operating environment. If the LTM is to be operated in an environment with abrasive dusts or corrosive or aggressive vapours, gases or liquids, the approval of Afag Automation AG must be obtained in advance. -

Page 49: Overview Maintenance Plan

Check LTM for excessive noise levels, if necessary, determine cause and eliminate Safety signs (warning Check Monthly [Off] symbols) Check the safety label for good legibility and possible damage, replace if necessary Assembly instructions EN LTM-V-100 / LTM-V-180 Edition 03/2020 Rev. 2.0 49-60 ... -

Page 50: Further Maintenance

Afag Automation AG offers a reliable repair service. We recommend that you have any repairs carried out by Afag Ag service technicians. Please note that Afag does not assume any warranty for LTM that have not been replaced or repaired by Afag! 9.6 spare and wear parts lists... -

Page 51: Toothed Belt

Tensioning of the toothed belt is not necessary. After a short running-in phase a constant belt tension is guaranteed. The toothed belts are not covered by the Afag Automation AG warranty! CAUTION Danger of injury! Risk of injury from improperly performed work when replacing the timing belt. -

Page 52: Side Guides

CAUTION Danger of injury! Risk of injury from improperly performed work when replacing the side guides. The side guides may only be replaced by trained Afag Automation AG personnel! Ordering the side guides: When ordering the side guides, please specify the LTM type for which the spare parts are intended. -

Page 53: Decommissioning, Disassembly, Disposal

The linear transport modules may only be removed from a system when the control is switched off and secured with a lockout device. Before disassembly unplug the cables of the motor! Assembly instructions EN LTM-V-100 / LTM-V-180 Edition 03/2020 Rev. 2.0 53-60 ... -

Page 54: Disposal

Electronic parts, electrical scrap, auxiliary and operating materials must be disposed of by approved specialist companies. Information on proper disposal can be obtained from the responsible local authorities. 54 – 60 Assembly instructions EN LTM-V-100 / LTM-V-180 Edition 03/2020 Rev. 2.0 ... -

Page 55: Declaration Of Incorporation

The relevant technical documentation was created according to Annex VII, Part B of the above-mentioned Directive. Authorised representative for compiling the technical documentation: Niklaus Röthlisberger, Product Manager, Afag Automation AG, CH-4950 Huttwil, Germany Place/Date: Huttwil, 01.03.2020 Siegfried Egli Niklaus Röthlisberger... - Page 56 Obligations of the personnel ......12 Technical data ........... 25, 29 Operation ............44 Operator ............12 Warning against hot surfaces ......17 Warning signs ..........17 56 – 60 Assembly instructions EN LTM-V-100 / LTM-V-180 Edition 03/2020 Rev. 2.0 ...

- Page 57 Fig. 19 Example measurement report ....................40 Fig. 20 LTM maintenance points ......................49 Fig. 21 Installation position (1) of the toothed belt (exemplary illustration) ..........51 Assembly instructions EN LTM-V-100 / LTM-V-180 Edition 03/2020 Rev. 2.0 57-60 ...

- Page 58 58 – 60 Assembly instructions EN LTM-V-100 / LTM-V-180 Edition 03/2020 Rev. 2.0 ...

- Page 59 Assembly instructions EN LTM-V-100 / LTM-V-180 Edition 03/2020 Rev. 2.0 59-60 ...

- Page 60 60 – 60 Assembly instructions EN LTM-V-100 / LTM-V-180 Edition 03/2020 Rev. 2.0 ...

Need help?

Do you have a question about the LTM-V-100 and is the answer not in the manual?

Questions and answers