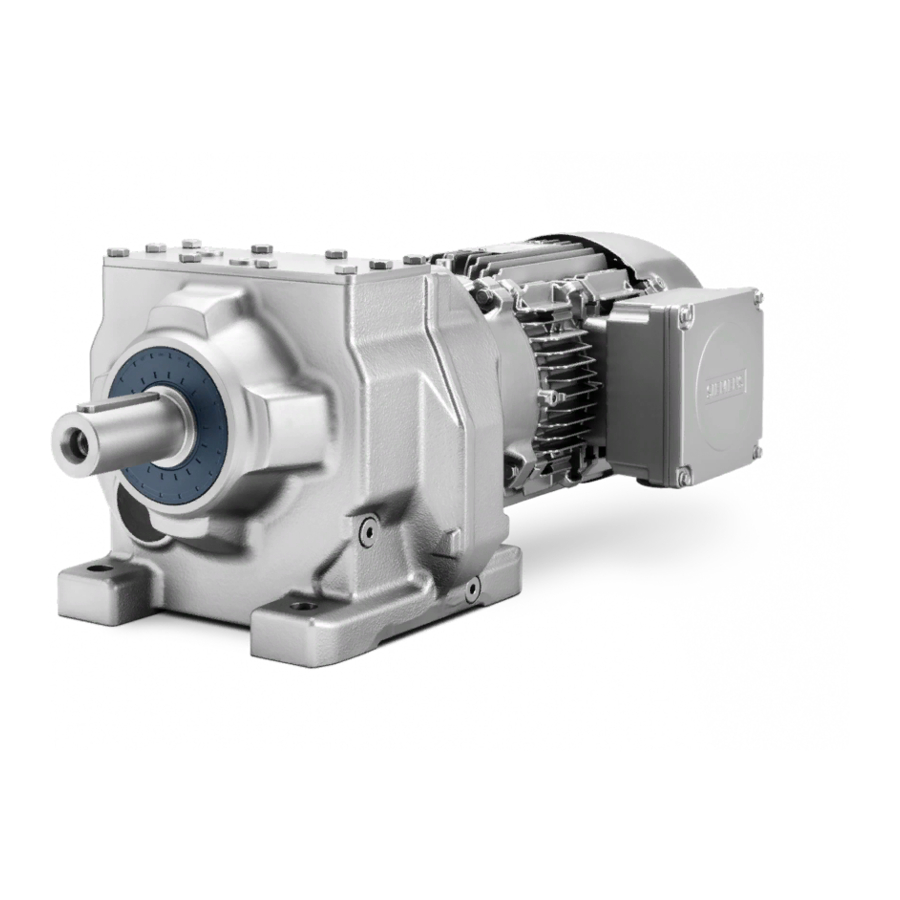

Siemens SIMOGEAR BA 2030 Operating Instructions Manual

Gearbox

Hide thumbs

Also See for SIMOGEAR BA 2030:

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Siemens SIMOGEAR BA 2030

- Page 3 General information and safety notes Technical description Incoming goods, transport, SIMOGEAR and storage Installation Gearbox BA 2030 (2KJ4) Commissioning Operation Operating Instructions Faults, causes and remedies Service and maintenance Disposal Technical data Spare parts Your suggestions 07/2020 A5E50009094A/RS-AL...

- Page 4 Note the following: WARNING Siemens products may only be used for the applications described in the catalog and in the relevant technical documentation. If products and components from other manufacturers are used, these must be recommended or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and maintenance are required to ensure that the products operate safely and without any problems.

-

Page 5: Table Of Contents

Table of contents General information and safety notes ....................7 General information ......................7 Copyright ..........................8 Intended use ........................9 Obligations of the user ......................9 The five safety rules ......................10 Particular types of hazards ....................11 Technical description ........................... 13 General technical description ..................... - Page 6 Table of contents Mounting an input or output element on the gearbox shaft..........30 Removing and installing the protection cover ..............32 Installing and removing the shaft-mounted gearbox............35 4.9.1 General information on installing the shaft-mounted gearbox ..........35 4.9.2 Hollow shaft with feather key ....................

- Page 7 Table of contents Checking the gearbox for leaks ..................75 Replacing the vent valve ....................75 Checking the oil level sensor (optional) ................76 Cleaning the gearbox ......................76 Checking the tightness of fastening bolts ................77 8.10 Inspecting the gearbox ...................... 78 8.11 Replacing the hose of the oil expansion unit ...............

- Page 8 Table of contents BA 2030 (2KJ4) Operating Instructions, 07/2020, A5E50009094A/RS-AL...

-

Page 9: General Information And Safety Notes

General information and safety notes General information Note Siemens AG does not accept any liability for damage and failures that result from the non- observance of these operating instructions. These operating instructions are part of the gearbox delivery. Store the operating instructions near the gearbox. -

Page 10: Copyright

The described gearboxes correspond to the state-of-the-art at the time these operating instructions were printed. Siemens AG reserves the right to change individual components and accessory parts in the interest of further development. The changes serve to improve the performance and safety. -

Page 11: Intended Use

General information and safety notes 1.3 Intended use Intended use The SIMOGEAR gearboxes described in these operating instructions have been designed for stationary use in general engineering applications. Unless otherwise agreed, the gearboxes have been designed for use in plants and equipment in industrial environments. -

Page 12: The Five Safety Rules

Observe the permissible tightening torque of the fastening bolts. Replace damaged bolts with new bolts of the same type and strength class. Siemens AG accepts the warranty only for original spare parts. The manufacturer who installs the geared motors in a plant must include the regulations contained in the operating instructions in its own operating instructions. -

Page 13: Particular Types Of Hazards

General information and safety notes 1.6 Particular types of hazards Particular types of hazards WARNING Extreme surface temperatures Hot surfaces over +55 °C pose a burn risk. Cold surfaces below 0 °C pose a risk of damage due to freezing. Do not touch the gearbox without protection. - Page 14 General information and safety notes 1.6 Particular types of hazards BA 2030 (2KJ4) Operating Instructions, 07/2020, A5E50009094A/RS-AL...

-

Page 15: Technical Description

Technical description General technical description The gearbox is supplied with one, two or three transmission stages. The gearbox is suitable for various mounting positions. Observe the correct oil level. Gearbox housing The housings for sizes 19 and 29 are made of die-cast aluminum. Depending on the gearbox type, the housings of sizes 39 and 49 are made of die-cast aluminum or cast iron. -

Page 16: Shaft Seals

Technical description 2.2 Shaft seals XLplus and VLplus heavy-duty bearing systems ① Grease nipple ② Automatic regreasing device (optional) ③ Screw plug ④ Dry-well oil sight glass (optional) ⑤ Dry-well oil sensor (optional) Figure 2-1 XLplus and VLplus heavy-duty bearing systems The multi-stage helical gearbox sizes 89-169 can be supplied with an XLplus or VLplus heavy- duty bearing system. -

Page 17: Cooling

Technical description 2.3 Cooling Seal for a longer service life (optional) The radial shaft sealing ring with dust lip has an additional buffer axial seal towards the inside of the gearbox. The sealing system has a high degree of reliability as a result of the insensitivity with respect to contaminations in the oil. -

Page 18: Surface Treatment

Technical description 2.5 Surface treatment Surface treatment 2.5.1 General information on surface treatment All paint finishes are sprayed on. WARNING Danger due to electrostatic discharge For paint finishes in explosion group III, the paint can be electrostatically charged as a result of intensive dust accumulation or processes with high levels of electrostatic charging. -

Page 19: Painted Version

Technical description 2.5 Surface treatment 2.5.2 Painted version The corrosion protection system is classified according to the corrosiveness categories in DIN EN ISO 12944-2. Table 2- 2 Paint according to corrosiveness categories Paint system Description Corrosiveness category C1, unpainted for gearbox and motor housings made of aluminum •... - Page 20 Technical description 2.5 Surface treatment Paint system Description Corrosiveness category C4 for high environmental stress 2-component epoxy zinc phosphate base • Indoor and outdoor installation coat, • Chemical plants, swimming pools, wastewater treat- 2-component polyurethane top coat ment plants, electroplating shops, and boathouses above seawater •...

-

Page 21: Primed Version

Technical description 2.5 Surface treatment 2.5.3 Primed version Table 2- 3 Primer according to corrosiveness category Paint system Can be overpainted with Unpainted corrosiveness category C1 Cast iron parts immersion primed, • Synthetic paint, synthetic resin paint, oil paint steel parts primed or zinc-plated, •... - Page 22 Technical description 2.5 Surface treatment BA 2030 (2KJ4) Operating Instructions, 07/2020, A5E50009094A/RS-AL...

-

Page 23: Incoming Goods, Transport, And Storage

Notify the freight company of any damage caused during transport immediately (this is the only way to have damage rectified free of charge). Siemens AG will not accept any claims relating to items missing from the delivery and which are submitted at a later date. -

Page 24: Fastening For Suspended Transport

Incoming goods, transport, and storage 3.2 Transport Different forms of packaging may be used, depending on the size of the gearbox or geared motor and the method of transport. Unless contractually agreed otherwise, the seaworthy packaging complies with HPE Packaging Guidelines (Bundesverband Holzpackmittel Paletten Exportverpackungen e.V., the German Federal Association for wooden packaging, pallets, and export packaging). -

Page 25: Storage

Incoming goods, transport, and storage 3.3 Storage Table 3- 1 Maximum load of the eyebolt on the gearbox Thread size Thread size [kg] [mm] [kg] [mm] 1200 1800 3200 The eyebolt corresponds to DIN 580. Storage 3.3.1 General information for storage WARNING Danger of serious injuries caused by falling objects Danger of damage to the gearbox when stacked... -

Page 26: Storage Up To 36 Months With Long-Term Preservation (Optional)

Incoming goods, transport, and storage 3.3 Storage 3.3.2 Storage up to 36 months with long-term preservation (optional) 3.3.2.1 General notes for storage up to 36 months Store the gearbox or geared motor in dry, dust-free rooms that are maintained at a constant temperature. -

Page 27: Installation

Installation Unpacking NOTICE Transport damage impairs the correct function of the gearbox Never commission faulty gearboxes. Check the gearbox for completeness and for damage. Report any missing parts or damage immediately. Remove and dispose of the packaging material and transport equipment in compliance with regulations. - Page 28 Installation 4.2 General information on installation NOTICE Malfunction resulting from foreign objects The operator must ensure that no foreign objects impair the function of the gearbox. NOTICE Damaged components impair the correct function of the gearbox If any components are damaged, the correct function of the gearbox will no longer be ensured.

-

Page 29: Thread Sizes And Tightening Torques For Fastening Bolts

Installation 4.3 Thread sizes and tightening torques for fastening bolts Thread sizes and tightening torques for fastening bolts The general tolerance for the tightening torque is 10%. The tightening torque is based on a friction coefficient of μ = 0.14. Table 4- 1 Tightening torques for fastening bolts Thread size... -

Page 30: Gearbox With Flange Fastening

K129 K149 169, 189 K169, K189 Gearbox with flange fastening Note Siemens AG recommends an anaerobic adhesive to enhance the friction lock between flange and mounting surface. Table 4- 3 Thread size of the fastening bolt Thread Flange Helical gearbox... - Page 31 Installation 4.5 Gearbox with flange fastening Note the following exceptions: Table 4- 4 Strength class of the fastening bolt for FF/FAF and KF/KAF Gearbox Flange Strength class for motor size size A160 10.9 10.9 A200 10.9 10.9 10.9 A250 10.9 A250 10.9 10.9...

-

Page 32: Gearboxes In Foot Or Flange Version

Installation 4.6 Gearboxes in foot or flange version Gearboxes in foot or flange version NOTICE Impermissible housing loadings caused by incorrectly installed add-on elements Do not subject the gearbox housing to excessive stress by adding add-on elements to the foot or flange. Add-on elements must not transmit forces, torques, and vibrations to the gearbox. - Page 33 Installation 4.7 Mounting an input or output element on the gearbox shaft NOTICE Damage caused by improper handling Bearings, housing, shaft and locking rings are damaged due to improper handling. Do not use impacts or knocks to force the input and output elements to be mounted onto the shaft.

-

Page 34: Removing And Installing The Protection Cover

Installation 4.8 Removing and installing the protection cover Observe the correct mounting arrangement to minimize stress on shafts and bearings due to lateral forces. Correct Incorrect Force Figure 4-2 Mounting arrangement for low stress on shafts and bearings Procedure 1. Use either benzine or solvent to remove the anti-corrosion protection from the shaft ends and flanges or remove the applied protective skin. - Page 35 Installation 4.8 Removing and installing the protection cover ① Screw ③ Flat seal/O-ring ② Protection cover ④ Gearbox housing Figure 4-3 Protection cover for hollow shaft Procedure Premounted protection cover 1. Release the screws ① and remove the protection cover ② together with the flat gasket or O- ring ③.

- Page 36 Installation 4.8 Removing and installing the protection cover Protection cover (supplied loose) When using the plastic protection cover for gearbox F49, the cover must first be brought into the correct shape. When using the plastic protection cover for other gearboxes, it is not necessary to bring the cover into the required shape;...

-

Page 37: Installing And Removing The Shaft-Mounted Gearbox

Installation 4.9 Installing and removing the shaft-mounted gearbox Installing and removing the shaft-mounted gearbox 4.9.1 General information on installing the shaft-mounted gearbox NOTICE Damage to shaft sealing rings caused by solvent Avoid any contact of solvent or benzine with the shaft sealing rings. NOTICE Subjecting stress to the hollow shaft causes bearing failure Skewing or stressing the hollow shaft increases the loading. -

Page 38: Hollow Shaft With Feather Key

Installation 4.9 Installing and removing the shaft-mounted gearbox 4.9.2 Hollow shaft with feather key 4.9.2.1 Mounting the hollow shaft with feather key Not included in the scope of supply ① Machine shaft ⑥ Circlip ② Hollow shaft ⑦ Feather key ③... -

Page 39: Removing The Hollow Shaft With Feather Key

Installation 4.9 Installing and removing the shaft-mounted gearbox 4.9.2.2 Removing the hollow shaft with feather key WARNING Inadequately secured gearbox or geared motors can free themselves Before driving out the machine shaft, fasten a suitably dimensioned means of absorbing load to the gearbox. Slightly pretension the pulling equipment so that the gearbox does not drop onto it when the insert shaft is released. - Page 40 Installation 4.9 Installing and removing the shaft-mounted gearbox Design suggestion for threaded block and disk Gearbox Size Hollow shaft ∅ [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] 19.9 22.5 B, C 19.9 22.5 B, F 24.9 24.9 B, K, F, C 29.9 34.9 39.9...

-

Page 41: Hollow Shaft With Shrink Disk

Installation 4.9 Installing and removing the shaft-mounted gearbox 4.9.3 Hollow shaft with shrink disk 4.9.3.1 Mounting the hollow shaft with shrink disk Greased Absolutely grease-free Not included in the scope of supply ① Machine shaft ② Hollow shaft ③ Bushing Figure 4-7 Mounting the hollow shaft with shrink disk Procedure... - Page 42 Installation 4.9 Installing and removing the shaft-mounted gearbox NOTICE Lubricants in the shrink disk seat impair torque transmission Keep the bore in the hollow shaft and the machine shaft completely grease-free. Do not use impure solvents and soiled cleaning cloths. NOTICE Plastic deformation of the hollow shaft caused by tightening the tightening bolts Plastic deformation of the hollow shaft when tightening the tightening bolts before fitting...

- Page 43 Installation 4.9 Installing and removing the shaft-mounted gearbox Note Coat with a suitable lubricant to prevent frictional corrosion of the contact surface on the customer's machine shaft in the vicinity of the bush. Sizes 19 - 69 Sizes 79 - 189 Greased Absolutely grease-free ①...

-

Page 44: Pulling Off The Shrink Disk

Installation 4.9 Installing and removing the shaft-mounted gearbox Table 4- 7 Tightening torque for the tightening bolt Gearbox size Thread size Strength class Tightening torque [Nm] 19, 29 10.9 39, 49, 69 10.9 79, 89 12.9 12.9 12.9 12.9 169, 189 12.9 4.9.3.3 Pulling off the shrink disk... -

Page 45: Hollow Shaft With Splines

Installation 4.9 Installing and removing the shaft-mounted gearbox 4.9.4 Hollow shaft with splines Not included in the scope of supply ① Machine shaft ② Hollow shaft ③ Hexagon nut ④ Threaded spindle ⑤ Disk ⑥ Locking ring ⑦ Mounting paste Figure 4-9 Mounting the hollow shaft with splines Instead of the nut and threaded spindle shown in the diagram, other types of equipment... -

Page 46: Torque Arms With Shaft-Mounted Gearboxes

Installation 4.9 Installing and removing the shaft-mounted gearbox 4.9.5 Torque arms with shaft-mounted gearboxes 4.9.5.1 General information regarding torque arms Torque arms can absorb the reaction torque and the weight force of the gearbox. NOTICE Dangerous transient torques due to excess backlash Take care to prevent the torque arm causing excessive constraining forces, for example, due to the driven shaft running out-of-true. -

Page 47: Mounting Torque Arms On Bevel Gearboxes And Helical Worm Gearboxes

Installation 4.9 Installing and removing the shaft-mounted gearbox Size Rubber buffer Washer Unten- Tensioned sioned [mm] [mm] [mm] [mm] [mm] [mm] 14.0 10.5 13.5 18.5 12.5 18.5 17.5 27.5 37.5 36.5 47.5 46.5 Procedure 1. Use the washers according to the table above. 2. - Page 48 Installation 4.9 Installing and removing the shaft-mounted gearbox The torque arm can be fitted in various positions, depending on the hole circle pitch. Figure 4-12 Toggle lever design For a toggle lever design, derive the force in the range of 90° ± 20°. Procedure 1.

-

Page 49: Commissioning

Check the oil level before commissioning. Correct the oil quantity when required. Please observe Checking and changing lubricants (Page 60). Siemens AG recommends a complete oil change after a storage time longer than 24 months: • For gearboxes with long-term preservation. -

Page 50: Mount The Oil Expansion Unit

Commissioning 5.3 Mount the oil expansion unit Gearbox in special mounting position The gearbox is intended for a specific rotation angle and is delivered with the correct quantity of oil for this purpose. It is not possible to check the oil level. You will find information regarding oil quantity and type of oil on the rating plate. - Page 51 Commissioning 5.3 Mount the oil expansion unit Procedure 1. Assemble the mounting kit ① - ⑤. 2. Screw on the unit with the screwed connection ⑤ at the uppermost drill hole of the gearbox housing or of the motor bearing shield. 3.

-

Page 52: Installing The Oil Temperature Monitoring Device

The position of the resistance thermometer is defined by Siemens AG. The sensor pocket of the thermometer is installed in the gearbox and closed with a sealing cap. - Page 53 Commissioning 5.4 Installing the oil temperature monitoring device Mounting the sensor for oil temperature monitoring 1476 Sensor pocket ② Intermediate fitting 1477 Sealing cap ③ Sealing element 1475 Resistance thermometer comprising ④ Compression nut ①②③④⑤ ① Sensor ⑤ Sensor cable Figure 5-4 Mounting the sensor for oil temperature monitoring Procedure...

-

Page 54: Options Of The Vlplus Heavy-Duty Bearing System

Commissioning 5.5 Options of the VLplus heavy-duty bearing system Options of the VLplus heavy-duty bearing system 5.5.1 Automatic regreasing device Gearboxes with the VLplus heavy-duty bearing system can be optionally supplied with an automatic regreasing device. The automatic regreasing device can be installed in any position and can be used underwater. ①... - Page 55 Commissioning 5.5 Options of the VLplus heavy-duty bearing system CAUTION Closed lubricator bursts Overpressure will result if the lubricator is not opened and the grease channels are contaminated. At an overpressure of approximately 5 bar, the lubricator will burst at the preset breaking point between the housing and the funnel.

-

Page 56: Dry-Well Version With Oil Sensor

Commissioning 5.5 Options of the VLplus heavy-duty bearing system At an ambient temperature of -10 °C, the actual lubrication time is twice that for the set temperature. At an ambient temperature of +40 °C, the actual lubrication time drops to approximately half that for the set temperature. -

Page 57: Operation

Operation CAUTION Malfunctions can cause injuries or gearbox damages In the event of changes during operation, the drive component must be switched off immediately. Determine the cause of the fault using the fault table (Page 57). Remedy faults or have faults remedied. - Page 58 Operation BA 2030 (2KJ4) Operating Instructions, 07/2020, A5E50009094A/RS-AL...

-

Page 59: Faults, Causes And Remedies

Faults and malfunctions that occur during the warranty period and requiring repair work on the gearbox must be remedied only by Technical Support. If faults occur without a clearly identifiable cause, Siemens AG recommends the services of the Technical Support even after the warranty period has elapsed. - Page 60 Faults, causes and remedies Faults Causes Remedy Oil escapes. Incorrect oil level for the mounting Check the mounting position (Page 84) position being used. and the oil level (Page 62). Gearbox leaks. Checking the gearbox for leaks (Page 75). Overpressure due to lack of venting. Mount the venting as appropriate for the mounting position (Page 84).

-

Page 61: Service And Maintenance

Improper maintenance Only authorized qualified personnel may perform the maintenance and servicing. Only original parts supplied by Siemens AG may be installed. Only qualified personnel may perform the inspection, maintenance and servicing work. Please observe the General information and safety notes (Page 7). -

Page 62: Checking And Changing Lubricants

Service and maintenance 8.2 Checking and changing lubricants Remedy Interval Description of work Carry out a complete inspection Every 12 months. Inspecting the gearbox of the geared motor. (Page 78) Check the friction clutch and After 500 hours, thereafter once Observe the BA 2039 (2KJ4) adjust if necessary. - Page 63 Service and maintenance 8.2 Checking and changing lubricants NOTICE Damage to the gearbox caused by incorrect oil quantities The oil quantity and the position of the sealing elements are determined by the mounting position. After removing the oil level screw, the oil level may not be below the specified fill level. NOTICE Damage to the gearbox due to open oil holes Dirt and damaging atmosphere can penetrate through open oil holes.

-

Page 64: Checking The Oil Level

Service and maintenance 8.2 Checking and changing lubricants Note Gearbox in special mounting position The gearbox is intended for a specific rotation angle and is delivered with the correct quantity of oil for this purpose. It is not possible to check the oil level. You will find information regarding oil quantity and type of oil on the rating plate. -

Page 65: Checking The Oil Level Using The Oil Sight Glass (Optional)

Service and maintenance 8.2 Checking and changing lubricants Procedure 1. Switch off the power supply to the drive component. 2. Unscrew the oil level screw, see Mounting positions (Page 84). Oil escapes if the maximum fill level is above the plug hole. 3. -

Page 66: Changing The Oil

Service and maintenance 8.2 Checking and changing lubricants 3. Unscrew the sealing element at one of the points marked with the symbols listed above. 4. Remove some oil, using a suction pump and a flexible hose, for example. 5. Check the state of the sealing ring on the sealing element. When required, replace the sealing ring. -

Page 67: Draining The Oil

Service and maintenance 8.2 Checking and changing lubricants Note The oil must be warm because insufficient viscosity caused by oil that is too cold impairs correct emptying. If necessary, run the gearbox for 15 to 30 minutes to become warm. 8.2.5.2 Draining the oil Observe the symbols in the diagrams of the Mounting positions (Page 84):... -

Page 68: Filling In Oil

Service and maintenance 8.2 Checking and changing lubricants Note Polyglycol oil has a higher density than mineral oil. Therefore, it sinks down towards the oil drain and the mineral oil floats on top. This makes the required complete draining of mineral oil from the gearbox extremely difficult. -

Page 69: Topping Up With Oil

Service and maintenance 8.2 Checking and changing lubricants Observe the symbols in the diagrams of the Mounting positions (Page 84): Venting Procedure 1. Unscrew the vent plug. 2. Fill the gearbox with fresh oil. Use a filler filter with mesh of max. 25 μm. 3. -

Page 70: Change The Roller Bearing Grease

"Guide values for oil change intervals". For a +80 °C oil sump temperature, the following service life can be expected when observing the properties specified by Siemens AG: Table 8- 4 Service life of the oils... - Page 71 Service and maintenance 8.2 Checking and changing lubricants ① Mineral oil ② Synthetic oil Oil-bath steady-state temperature [°C] Oil change interval in operating hours [h] Figure 8-3 Guide values for oil change intervals Grease service life of roller bearing greases Roller bearings and the clearance in front are filled with sufficient grease.

-

Page 72: Recommended Lubricants

8.2 Checking and changing lubricants 8.2.9 Recommended lubricants The released and recommended lubricants are listed in the table NT 7300 (https://support.industry.siemens.com/cs/ww/en/view/109753864). DANGER Used lubricants only have conditional approval The used lubricants are not or only conditionally approved for use in the foodstuff or pharmaceutical industry. - Page 73 The oil quality must meet the gearbox lubricant requirements specified in the NT 7300 table. The Siemens warranty is otherwise null and void. We recommend the use of one of these gearbox lubricants. These gearbox oils are subject to constant testing and meet the specified requirements.

-

Page 74: Lubrication Of The Xlplus And Vlplus Heavy-Duty Bearing Systems

Service and maintenance 8.3 Lubrication of the XLplus and VLplus heavy-duty bearing systems Operating range Oil grade Permissible oil Ambient temperature designation accord- sump tem- [°C] ing to DIN 51502 perature range during operation [°C] Helical worm gearbox C, bevel gearbox B -20 ...+40 -25 ...+40 -30 ...+40... - Page 75 Service and maintenance 8.3 Lubrication of the XLplus and VLplus heavy-duty bearing systems Regreasing intervals Note The relubrication interval of the bearing depends on the temperature and the load For temperatures above +70 °C, the regreasing interval must be reduced by half for each temperature increase of 15 K.

- Page 76 Service and maintenance 8.3 Lubrication of the XLplus and VLplus heavy-duty bearing systems The grease quantities listed in the table are guide values. Table 8- 7 Grease quantity [g] for relubrication Regreasing interval Grease quantity for size After 6 months After several years without operation Maintenance of the output-side bearing Note...

-

Page 77: Replace Bearings

Service and maintenance 8.4 Replace bearings Replace bearings The bearing service life depends greatly on the operating conditions and so cannot be calculated reliably. In the operating conditions specified by the operator, bearing life can be calculated and indicated on the rating plate. If no information is given, changes in vibration and noise pattern can serve as an indicator that an immediate bearing replacement is necessary. -

Page 78: Checking The Oil Level Sensor (Optional)

Service and maintenance 8.7 Checking the oil level sensor (optional) Checking the oil level sensor (optional) The oil level sensor indicates the oil level only when the gearbox is shut down. Lower the oil level and fill it up again until the oil level sensor gives a switching signal. Please refer to the separate operating instructions for the oil level sensor. -

Page 79: Checking The Tightness Of Fastening Bolts

Service and maintenance 8.9 Checking the tightness of fastening bolts Checking the tightness of fastening bolts Note Replace damaged headless bolts with new bolts of the same type and strength class. Switch off the power supply to the drive component. Check all fastening bolts for tightness using a torque wrench. -

Page 80: Inspecting The Gearbox

Service and maintenance 8.10 Inspecting the gearbox 8.10 Inspecting the gearbox Carry out a scheduled inspection of the gearbox once a year in accordance with the possible criteria listed in General notes about maintenance work (Page 59). Check the gearbox in accordance with the criteria set out in General information and safety notes (Page 7). -

Page 81: Disposal

Disposal Recycling and disposal of SIMOGEAR geared motors For environmentally friendly recycling and disposal of your old device, please con- tact a company certified for the disposal of old electrical and/or electronic devices and dispose of the device in accordance with the regulations in your country. WARNING Incorrect disposal of used oil Incorrect disposal of used oil is a threat to the environment and health. - Page 82 Disposal BA 2030 (2KJ4) Operating Instructions, 07/2020, A5E50009094A/RS-AL...

-

Page 83: Technical Data

Technical data 10.1 Type designation Table 10- 1 Example of the type designation structure Main gearbox Intermediate Input unit helical gearbox (100) Example: Gearbox type Stage Type Size Stage Size Input unit (for motor size) (100) Table 10- 2 Type designation code Gearbox type Helical gearbox Parallel shaft gearbox... -

Page 84: Rating Plate Data

Two-stage Three-stage Input unit Coupling adapter only for fitting a SIEMENS servomotor of the SIMOTICS S-1FK7/1FT7, SIMOTICS M-1PH8, SIMOTICS S-1FK2, and SIMOTICS S-1FL6 series Coupling adapter with flexible coupling for fitting an IEC motor Short adapter with plug-in connection for fitting an IEC motor... -

Page 85: Rating Plate Simogear Geared Motors

Technical data 10.3 Weight 10.2.2 Rating plate SIMOGEAR geared motors Serial number Frequency 1 Purchase order number Rated frequency Type designation Rated voltage Degree of protection Rated current Oil quantity Power factor Oil type Rated power Total transmission ratio Rated speed Frequency 1 Frequency 2 Rated frequency... -

Page 86: Sound Power Level

Technical data 10.4 Sound power level 10.4 Sound power level SIMOGEAR geared motors have noise levels below the permissible noise levels defined for gearboxes in VDI guideline 2159 and for motors in IEC 60034-9. In conjunction with gearboxes, the motor noise values L or L increase on average by 3 dB (A). -

Page 87: Single-Stage Helical Gearboxes

Technical data 10.5 Mounting positions 10.5.2 Single-stage helical gearboxes Figure 10-1 Mounting positions for helical gearbox E, foot-mounted design, sizes 39 - 149 BA 2030 (2KJ4) Operating Instructions, 07/2020, A5E50009094A/RS-AL... - Page 88 Technical data 10.5 Mounting positions Figure 10-2 Mounting positions for helical gearbox EF/EZ, flange-mounted design, sizes 39 - 149 BA 2030 (2KJ4) Operating Instructions, 07/2020, A5E50009094A/RS-AL...

-

Page 89: Two- And Three-Stage Helical Gearbox

Technical data 10.5 Mounting positions 10.5.3 Two- and three-stage helical gearbox Figure 10-3 Mounting positions for helical gearbox D/Z foot-mounted design, sizes 19 - 29 BA 2030 (2KJ4) Operating Instructions, 07/2020, A5E50009094A/RS-AL... - Page 90 Technical data 10.5 Mounting positions Figure 10-4 Mounting positions for helical gearbox D/Z foot-mounted design, sizes 39 - 189 BA 2030 (2KJ4) Operating Instructions, 07/2020, A5E50009094A/RS-AL...

- Page 91 Technical data 10.5 Mounting positions Figure 10-5 Mounting positions for helical gearbox DB/ZB foot / flange-mounted design, size 29 BA 2030 (2KJ4) Operating Instructions, 07/2020, A5E50009094A/RS-AL...

- Page 92 Technical data 10.5 Mounting positions Figure 10-6 Mounting positions for helical gearbox DB/ZB foot / flange-mounted design, sizes 39 - 89 BA 2030 (2KJ4) Operating Instructions, 07/2020, A5E50009094A/RS-AL...

- Page 93 Technical data 10.5 Mounting positions Figure 10-7 Mounting positions for helical gearbox DF/ZF flange-mounted design and DZ/ZZ with housing flange, sizes 19 - 29 BA 2030 (2KJ4) Operating Instructions, 07/2020, A5E50009094A/RS-AL...

- Page 94 Technical data 10.5 Mounting positions Figure 10-8 Mounting positions for helical gearbox DF/ZF flange-mounted design and DZ/ZZ with housing flange, size 39 BA 2030 (2KJ4) Operating Instructions, 07/2020, A5E50009094A/RS-AL...

- Page 95 Technical data 10.5 Mounting positions Figure 10-9 Mounting positions for helical gearbox DF/ZF flange-mounted design, sizes 49 - 189 and DZ/ZZ with housing flange, sizes 49 - 129 BA 2030 (2KJ4) Operating Instructions, 07/2020, A5E50009094A/RS-AL...

-

Page 96: Parallel Shaft Gearbox

Technical data 10.5 Mounting positions 10.5.4 Parallel shaft gearbox Figure 10-10 Mounting positions for parallel shaft gearbox F.AD torque arm-mounted design, size 29 BA 2030 (2KJ4) Operating Instructions, 07/2020, A5E50009094A/RS-AL... - Page 97 Technical data 10.5 Mounting positions Figure 10-11 Mounting positions for parallel shaft gearbox F.AD torque arm-mounted design, sizes 39 - BA 2030 (2KJ4) Operating Instructions, 07/2020, A5E50009094A/RS-AL...

- Page 98 Technical data 10.5 Mounting positions Figure 10-12 Mounting positions for parallel shaft gearbox F.F flange-mounted design and F.Z with housing flange, size 29 BA 2030 (2KJ4) Operating Instructions, 07/2020, A5E50009094A/RS-AL...

- Page 99 Technical data 10.5 Mounting positions Figure 10-13 Mounting positions for parallel shaft gearbox F.F flange-mounted design and F.Z with housing flange, sizes 39 - 189 BA 2030 (2KJ4) Operating Instructions, 07/2020, A5E50009094A/RS-AL...

- Page 100 Technical data 10.5 Mounting positions Figure 10-14 Mounting positions for parallel shaft gearbox F foot-mounted design, size 29 BA 2030 (2KJ4) Operating Instructions, 07/2020, A5E50009094A/RS-AL...

- Page 101 Technical data 10.5 Mounting positions Figure 10-15 Mounting positions for parallel shaft gearbox F. foot-mounted design, sizes 39 - 189 BA 2030 (2KJ4) Operating Instructions, 07/2020, A5E50009094A/RS-AL...

-

Page 102: Bevel Gearbox

Technical data 10.5 Mounting positions 10.5.5 Bevel gearbox Figure 10-16 Mounting positions for bevel gearbox B foot-mounted design, sizes 19 - 29 BA 2030 (2KJ4) Operating Instructions, 07/2020, A5E50009094A/RS-AL... - Page 103 Technical data 10.5 Mounting positions Figure 10-17 Mounting positions for bevel gearbox B foot-mounted design, sizes 39 - 49 BA 2030 (2KJ4) Operating Instructions, 07/2020, A5E50009094A/RS-AL...

- Page 104 Technical data 10.5 Mounting positions Figure 10-18 Mounting positions for bevel gearbox B.F flange-mounted design and B.Z with housing flange, sizes 19 - 29 BA 2030 (2KJ4) Operating Instructions, 07/2020, A5E50009094A/RS-AL...

- Page 105 Technical data 10.5 Mounting positions Figure 10-19 Mounting positions for bevel gearbox B.F flange-mounted design and B.Z with housing flange, sizes 39 - 49 BA 2030 (2KJ4) Operating Instructions, 07/2020, A5E50009094A/RS-AL...

- Page 106 Technical data 10.5 Mounting positions Figure 10-20 Mounting positions for bevel gearbox BAD torque arm-mounted design, sizes 19 - 29 BA 2030 (2KJ4) Operating Instructions, 07/2020, A5E50009094A/RS-AL...

- Page 107 Technical data 10.5 Mounting positions Figure 10-21 Mounting positions for bevel gearbox BAD torque arm-mounted design, sizes 39 - 49 BA 2030 (2KJ4) Operating Instructions, 07/2020, A5E50009094A/RS-AL...

- Page 108 Technical data 10.5 Mounting positions Figure 10-22 Mounting positions for bevel gearbox K. foot-mounted design, sizes 39 - 189 BA 2030 (2KJ4) Operating Instructions, 07/2020, A5E50009094A/RS-AL...

- Page 109 Technical data 10.5 Mounting positions Figure 10-23 Mounting positions for bevel gearbox K.F flange-mounted design and KAZ with housing flange, sizes 39 - 189 BA 2030 (2KJ4) Operating Instructions, 07/2020, A5E50009094A/RS-AL...

- Page 110 Technical data 10.5 Mounting positions Figure 10-24 Mounting positions for bevel gearboxes KAD torque arm-mounted design, sizes 39 - 189 BA 2030 (2KJ4) Operating Instructions, 07/2020, A5E50009094A/RS-AL...

-

Page 111: Helical Worm Gearbox

Technical data 10.5 Mounting positions 10.5.6 Helical worm gearbox Figure 10-25 Mounting positions for helical worm gearbox CAD torque arm-mounted design, size 29 BA 2030 (2KJ4) Operating Instructions, 07/2020, A5E50009094A/RS-AL... - Page 112 Technical data 10.5 Mounting positions Figure 10-26 Mounting positions for helical worm gearbox CAD torque arm-mounted design, sizes 39 - BA 2030 (2KJ4) Operating Instructions, 07/2020, A5E50009094A/RS-AL...

- Page 113 Technical data 10.5 Mounting positions Figure 10-27 Mounting positions for helical worm gearbox CF flange-mounted design and CAZ housing flange, size 29 BA 2030 (2KJ4) Operating Instructions, 07/2020, A5E50009094A/RS-AL...

- Page 114 Technical data 10.5 Mounting positions Figure 10-28 Mounting positions for helical worm gearbox CF flange-mounted design and CAZ housing flange, sizes 39 - 89 BA 2030 (2KJ4) Operating Instructions, 07/2020, A5E50009094A/RS-AL...

- Page 115 Technical data 10.5 Mounting positions Figure 10-29 Mounting positions for helical worm gearbox C. foot-mounted design, size 29 BA 2030 (2KJ4) Operating Instructions, 07/2020, A5E50009094A/RS-AL...

- Page 116 Technical data 10.5 Mounting positions Figure 10-30 Mounting positions for helical worm gearbox C. foot-mounted design, sizes 39 - 89 BA 2030 (2KJ4) Operating Instructions, 07/2020, A5E50009094A/RS-AL...

-

Page 117: Tandem Gearboxes - Intermediate Helical Gearboxes

Technical data 10.5 Mounting positions 10.5.7 Tandem gearboxes - Intermediate helical gearboxes Only operate the gearbox in the mounting position specified on the rating plate. This ensures that the correct quantity of lubricant is provided. The symbols are shown for the standard mounting position. - Page 118 Technical data 10.5 Mounting positions Horizontal operating position Vertical operating position Main gearbox Intermediate helical gearbox On opposite side Figure 10-31 Operating position for tandem gearbox BA 2030 (2KJ4) Operating Instructions, 07/2020, A5E50009094A/RS-AL...

-

Page 119: Oil Quantities

Technical data 10.6 Oil quantities 10.6 Oil quantities NOTICE Damage to the gearbox caused by incorrect oil quantities The oil quantities listed in the tables are guide values for changing the oil. They serve, for example, for lubricant storage and procurement. The precise values depend on the number of stages and transmission ratio of the gearbox. -

Page 120: Helical Gearbox

Technical data 10.6 Oil quantities 10.6.1 Helical gearbox Table 10- 3 Oil quantities [l] for E, EZ, EF , sizes 39 - 149 Type Mounting position E.39 0.45 0.45 E.49 0.95 0.95 E.69 E.89 E.109 E.129 10.7 E.149 10.3 15.5 11.6 Table 10- 4 Oil quantities [l] for D/Z, DB/ZB, DF/ZF, DZ/ZZ, sizes 19 - 189... -

Page 121: Parallel Shaft Gearbox

Technical data 10.6 Oil quantities 10.6.2 Parallel shaft gearbox Table 10- 5 Oil quantities [l] for FD/Z, FD/ZZ, FD/ZA., FD/ZAF., FD/ZAZ., FD/ZAD., sizes 29 - 189 Type Mounting position FD.29 0.35 0.45 0.45 FD.39 0.95 FD.49 FD.69 FD.79 FD.89 FD.109 11.8 FD.129 16.1... -

Page 122: Bevel Gearbox

Technical data 10.6 Oil quantities Type Mounting position FZF39 0.85 0.95 FZF49 FZF69 FZF79 FZF89 FZF109 13.7 13.3 FZF129 21.5 16.7 25.5 15.8 16.5 FZF149 24.5 FZF169 39.5 37.5 37.5 39.5 FZF189 53.5 10.6.3 Bevel gearbox Table 10- 7 Oil quantities [l] for B., sizes 19 - 49 Type Mounting position B.19... - Page 123 Technical data 10.6 Oil quantities Table 10- 9 Oil quantities [l] for KZ, KAF., KAZ., KAD., sizes 39 - 189 Type Mounting position M5-A M6-A M6-B M5-B K.39 0.95 0.95 K.49 0.65 K.69 0.85 K.79 K.89 K.109 11.7 K.129 13.5 17.5 20.5 13.8...

-

Page 124: Helical Worm Gearbox

Technical data 10.6 Oil quantities 10.6.4 Helical worm gearbox Table 10- 11 Oil quantities [l] for C, CA., CAS, CAT, sizes 29 - 89 Type Mounting position C.29 0.15 0.55 0.35 C.39 0.95 0.55 C.49 0.55 C.69 0.75 C.89 Table 10- 12 Oil quantities [l] for CZ, CAF., CAZ., CAD., sizes 29 - 89 Type Mounting position C.29... -

Page 125: Tandem Gearbox - Intermediate Helical Gearbox

Technical data 10.6 Oil quantities 10.6.5 Tandem gearbox - intermediate helical gearbox 10.6.5.1 Two- and three-stage helical gearboxes Note For gearbox "a" in mounting position M4, the oil level is above the oil level hole so that the higher bearings are lubricated. Table 10- 14 Oil quantities [l] for D/Z, DB/ZB, DF/ZF, DZ/ZZ, sizes 29 - 189 Type Mounting position... -

Page 126: Parallel Shaft Gearboxes

Technical data 10.6 Oil quantities 10.6.5.2 Parallel shaft gearboxes Note For gearbox "a" in mounting position M4, the oil level is above the oil level hole so that the higher bearings are lubricated. Table 10- 15 Oil quantities [l] for FD/Z, FD/ZZ, FD/ZA., FD/ZAF., FD/ZAZ., FD/ZAD., sizes 29 - 189 Type Mounting position FZ.29-Z19... - Page 127 Technical data 10.6 Oil quantities Table 10- 16 Oil quantities [l] for FD/ZF, sizes 29 - 189 Type Mounting position FZF29-Z19 0.6 + 0.15 0.9 + 0.5 0.4 + 0.15 0.85 + 0.5 0.5 + 0.15 0.45 + 0.15 FZF29-D19 0.6 + 0.15 0.9 + 0.45 0.4 + 0.15...

-

Page 128: Bevel Gearboxes

Technical data 10.6 Oil quantities 10.6.5.3 Bevel gearboxes Note For gearbox "a" in mounting position M4, the oil level is above the oil level hole so that the higher bearings are lubricated. Table 10- 17 Oil quantities [l] for K, KA, KAS, KAT, sizes 39 - 189 Type Mounting position K.39-Z19... - Page 129 Technical data 10.6 Oil quantities Type Type of construction K.189-Z69 24.5 + 0.65 53 + 2.1 73 + 0.65 94 + 2.95 53.5 + 0.65 59 + 0.65 K.39-D19 0.4 + 0.15 0.9 + 0.45 1.2 + 0.15 1.4 + 0.45 0.95 + 0.15 0.95 + 0.15 K.49-D19...

-

Page 130: Helical Worm Gearboxes

Technical data 10.6 Oil quantities 10.6.5.4 Helical worm gearboxes Table 10- 20 Oil quantities [l] for C, CA., CAS, CAT, sizes 39 - 89 Type Mounting position C.39-Z19 0.3 + 0.15 1.1 + 0.5 0.95 + 0.15 1 + 0.5 0.55 + 0.15 0.6 + 0.15 C.49-Z19... -

Page 131: Spare Parts

Siemens AG states explicitly that only spare parts and optional components supplied by Siemens have been tested and approved by Siemens. If you do not use original spare parts and optional components, Siemens AG excludes every liability and warranty. Siemens AG accepts the warranty only for original spare parts. -

Page 132: Lists Of Spare Parts

Spare parts 11.2 Lists of spare parts 11.2 Lists of spare parts 11.2.1 Helical gearbox E, sizes 39 - 149 BA 2030 (2KJ4) Operating Instructions, 07/2020, A5E50009094A/RS-AL... - Page 133 Spare parts 11.2 Lists of spare parts 1001 Gearbox housing 1160 Shaft sealing ring 1040 Output flange 1210 Bolt 1045 Bolt 1212 1101 Output shaft 1225 Seal 1105 Feather key 1301 Plug-in pinion 1129 Supporting disk 1303 Slip-on pinion 1130 Bearing 1304 Feather key...

-

Page 134: Helical Gearbox D / Z, Sizes 19 - 189

11.2.2 Helical gearbox D / Z, sizes 19 - 189 Note For gearbox sizes 19 and 29, we recommend that Siemens AG replaces the gearbox if service is required. Parts subject to wear are available on request. BA 2030 (2KJ4) - Page 135 Spare parts 11.2 Lists of spare parts 1001 Gearbox housing 1162 O ring 1020 Bearing 1165 Seal 1025 Locking ring 1210 Bolt 1028 Bearing 1212 Nut 1030 Bearing 1225 Seal 1031 Supporting disk 1301 Plug-in pinion 1032 Shim 1303 Slip-on pinion 1034 NILOS sealing ring 1304 Feather key 1035 Locking ring...

-

Page 136: Parallel Shaft Gearbox F, Sizes 29 - 189

11.2 Lists of spare parts 11.2.3 Parallel shaft gearbox F, sizes 29 - 189 Note For gearbox size 29, we recommend that Siemens AG replaces the gearbox if service is required. Parts subject to wear are available on request. BA 2030 (2KJ4) - Page 137 Spare parts 11.2 Lists of spare parts 1001 Gearbox housing 1140 Bearing 1020 Bearing 1141 Supporting disk/shim 1030 Bearing 1143 NILOS sealing ring 1031 Supporting disk 1144 Supporting disk/shim 1032 Shim 1146 Locking ring 1034 NILOS sealing ring 1160 Shaft sealing ring 1035 Locking ring 1161 Shaft sealing ring 1036 Shim...

-

Page 138: Bevel Gearbox B, Sizes 19 - 49

11.2 Lists of spare parts 11.2.4 Bevel gearbox B, sizes 19 - 49 Note For gearbox sizes 19 and 29, we recommend that Siemens AG replaces the gearbox if service is required. Parts subject to wear are available on request. BA 2030 (2KJ4) - Page 139 Spare parts 11.2 Lists of spare parts 1001 Gearbox housing 1130 Bearing 1020 Bearing 1131 Shim 1027 Locking ring / nut 1135 Locking ring 1030 Bearing 1136 Locking ring 1031 Supporting disk 1139 Supporting disk 1032 Shim 1140 Bearing 1035 Locking ring 1144 Supporting disk / shim 1037 Locking ring 1146 Locking ring...

-

Page 140: Bevel Gearbox K, Sizes 39 - 189

Spare parts 11.2 Lists of spare parts 11.2.5 Bevel gearbox K, sizes 39 - 189 BA 2030 (2KJ4) Operating Instructions, 07/2020, A5E50009094A/RS-AL... - Page 141 Spare parts 11.2 Lists of spare parts 1001 Gearbox housing 1133 NILOS sealing ring 1020 Bearing 1135 Locking ring 1021 Supporting disk/shim 1138 Locking ring 1022 Supporting disk/shim 1139 Supporting disk 1025 Locking ring 1140 Bearing 1030 Bearing 1141 Supporting disk/shim 1031 Supporting disk 1143 NILOS sealing ring 1032 Shim...

-

Page 142: Helical Worm Gearbox C, Sizes 29 - 89

11.2 Lists of spare parts 11.2.6 Helical worm gearbox C, sizes 29 - 89 Note For gearbox size 29, we recommend that Siemens AG replaces the gearbox if service is required. Parts subject to wear are available on request. BA 2030 (2KJ4) - Page 143 Spare parts 11.2 Lists of spare parts 1001 Gearbox housing 1132 Supporting disk / shim 1020 Bearing 1135 Locking ring 1025 Locking ring 1138 Locking ring 1027 Locking ring 1139 Supporting disk 1030 Bearing 1140 Bearing 1035 Locking ring 1144 Shim 1036 Supporting disk / shim 1146 Locking ring 1037 Locking ring...

-

Page 144: Xlplus And Vlplus Heavy-Duty Bearing Systems, Sizes 89-169

Spare parts 11.2 Lists of spare parts 11.2.7 XLplus and VLplus heavy-duty bearing systems, sizes 89-169 Figure 11-8 XLplus and VLplus helical gearboxes BA 2030 (2KJ4) Operating Instructions, 07/2020, A5E50009094A/RS-AL... - Page 145 Spare parts 11.2 Lists of spare parts Figure 11-9 VLplus parallel-shaft gearboxes and bevel gearboxes Spare parts list for XLplus and VLplus heavy-duty bearing systems 1040 Output flange 1146 Locking ring 1045 Bolt 1160 Shaft sealing ring 1085 Adapter 1161 Shaft sealing ring 1088 Plug 1166 Shaft sealing ring 1101 Output shaft...

- Page 146 Spare parts 11.2 Lists of spare parts BA 2030 (2KJ4) Operating Instructions, 07/2020, A5E50009094A/RS-AL...

-

Page 147: Your Suggestions

YOUR ideas and suggestions are important. Please forward us your knowledge. Send the completed following preprinted form to: Siemens AG, Quality Management, Bahnhofstr. 40, 72072 Tübingen, Germany or to the e- mail address: sales-sgm.aud@siemens.com Your data...

Need help?

Do you have a question about the SIMOGEAR BA 2030 and is the answer not in the manual?

Questions and answers