Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Quantum LTO-8 HH SAS

- Page 1 Technical Reference Manual Quantum LTO-8 HH SAS User’s Guide 6-68132-03 Rev A...

- Page 2 MediaShield, Optyon, Pocket-sized. Well-armored, SDLT, SiteCare, SmartVerify, StorageCare, Super DLTtape, and Vision are trademarks of Quantum. LTO and Ultrium are trademarks of HP, IBM, and Quantum in the U.S. and other countries. All other trademarks are the property of their respective companies.

-

Page 3: Table Of Contents

Contents Chapter 1 Preface Safety notices ..........2 Danger notice . - Page 4 Contents Cartridge Compatibility ........15 Speed Matching .

- Page 5 Contents Updating firmware ........30 Updating Firmware through the Host Interface .

- Page 6 Contents Function Code P: Post Error Reporting Enabled ... 64 Function Code U: Post Error Reporting Disabled ... 64 Chapter 5 Media Data Cartridge.

- Page 7 Contents Pre-Call Checklist ......... 89 Appendix A Error Codes and Messages Appendix B...

- Page 8 Contents viii QuantumLTO-8 HH SAS User’s Guide...

-

Page 9: Preface

Chapter 1 Preface This guide describes how to install and use the Quantum LTO-8 Tape Drive in the following chapters: Chapter 2, Introduction describes the product, discusses supported servers, operating systems, and device drivers, and lists hardware specifications. Chapter 3, Installation gives unpacking, set up, and configuration information. -

Page 10: Safety Notices

Chapter 1: Preface Safety notices Appendix B, Tape Alert Flags describes where to find information on TapeAlert messages that are supported and that may aid during problem determination. Safety notices Observe the safety notices when using this product. These safety notices contain danger and caution notices. -

Page 11: Performing The Safety Inspection Procedure

Use care when lifting, removing, or installing this part or unit. Sample caution notices follow: Caution: The battery is a lithium ion battery. To avoid possible explosion, do not burn. Exchange only with the Quantum- approved part. Recycle or discard the battery as instructed by local regulations. -

Page 12: Tape Drive Ac Grounding Inspection

Chapter 1: Preface Tape drive AC grounding inspection 7 Check the cover of the tape drive for sharp edges, damage, or alterations that expose its internal parts. 8 Check the cover of the tape drive for proper fit. It should be in place and secure. -

Page 13: Class I Laser Product

Chapter 1: Preface Class I Laser Product Class I Laser Product The product may contain a laser assembly that complies with the performance standards set by the U.S. Food and Drug Administration for a Class I laser product. Class I laser products do not emit hazardous laser radiation. - Page 14 Chapter 1: Preface Rack Safety • An electrical outlet that is not correctly wired could place hazardous voltage on the metal parts of the system or the devices that attach to the system. It is the responsibility of the customer to ensure that the outlet is correctly wired and grounded to prevent an electrical shock.

- Page 15 Chapter 1: Preface Rack Safety • Ensure that the heaviest devices are installed in the bottom of the rack cabinet. • Ensure that there are no empty U-levels between devices installed in the rack cabinet below the 32U level. • If the rack cabinet you are relocating is part of a suite of rack cabinets, detach the rack cabinet from the suite.

-

Page 16: Power Cords

Quantum product. To avoid electrical shock, always use the power cord and plug with a properly grounded outlet. Quantum power cords used in the United States and Canada are listed by Underwriter’s Laboratories (UL) and certified by the Canadian Standards Association (CSA). -

Page 17: Battery Return Policy

Chapter 1: Preface Product Recycling and Disposal equipment (WEEE). The Directive determines the framework for the return and recycling of used appliances as applicable throughout the European Union. This label is applied to various products to indicate that the product is not to be thrown away, but rather reclaimed upon end of life per this Directive. -

Page 18: End Of Life (Eol) Plan

Chapter 1: Preface End of Life (EOL) Plan accumulators. Customer participation is important to minimize any potential effects of batteries and accumulators on the environment and human health due to the potential presence of hazardous substances. For California: Perchlorate Material - special handling may apply. See http://www.dtsc.ca.gov/ hazardouswaste/perchlorate. -

Page 19: Introduction

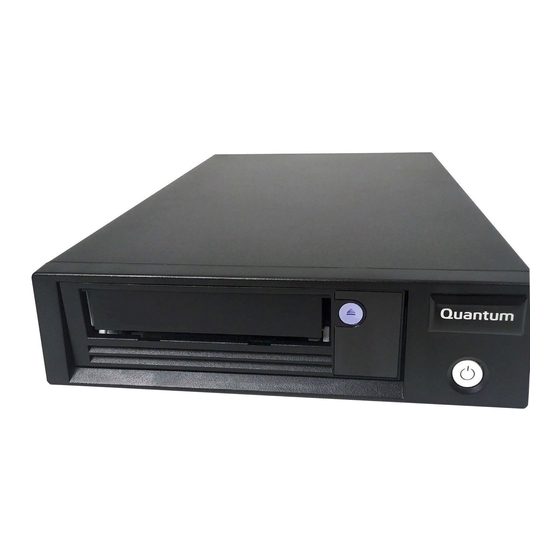

It is the sixth generation in the Ultrium series of products, and is available with a Serial Attached SCSI interface (SAS). This model incorporates the Linear Tape-Open (LTO) Quantum Ultrium 8 Half-High Tape Drive. View of the drive Figure 2 QuantumLTO-8 HH SAS User’s Guide... -

Page 20: Drive Features

Chapter 2: Introduction Drive Features Drive Features The drive offers the following features: • Native storage capacity of 12000 GB per cartridge (30000 GB at 2.5:1 compression when using Ultrium 8 cartridges) • Ability to use LTO-7 media in M8 format to expand capacity to 9000 •... -

Page 21: Front Panel Of The Drive

Chapter 2: Introduction Front Panel of the Drive Front Panel of the Drive Front panel Figure 3 element descriptions 1 Cartridge unload button 2 Ready light (green) 3 Encryption light (white) 4 Fault light (amber) 5 Single Character Display (SCD) 6 SCD dot 7 Drive power button QuantumLTO-8 HH SAS User’s Guide... -

Page 22: Rear Panel Of The Drive

Chapter 2: Introduction Rear Panel of the Drive Rear Panel of the Drive Drive rear panel Figure 4 element descriptions 1 Power receptacle 2 Fan vent 3 SAS connectors 4 Ethernet connector (for drive status and service only) Drive Performance If you run applications that are highly dependent on tape-processing speed, take advantage of the significant performance improvements provided by this tape drive. -

Page 23: Cartridge Compatibility

SAS bus capabilities, and system or application software. Cartridge Compatibility The LTO-8 uses the Quantum LTO Ultrium 12000 GB Data Cartridge and is compatible with the cartridges of its predecessors, the Quantum Ultrium Tape Drive Generation 7. The drive performs the following functions: •... -

Page 24: Speed Matching

Chapter 2: Introduction Speed Matching Speed Matching To improve system performance, the drive uses a technique called speed matching to dynamically adjust its native (uncompressed) data rate to the slower data rate of a server. With speed matching, the drive operates at different speeds when reading or writing the Ultrium 7. -

Page 25: Channel Calibration

1200 GB. Encryption The Quantum LTO-8 Tape Drive supports host Application Managed Encryption (AME), using T10 encryption methods. Data encryption is supported with LTO Ultrium 4 and later Data Cartridges only. -

Page 26: Inhibiting Firmware Down-Leveling

Inhibiting Firmware Down-Leveling Application-managed encryption is supported on AIX, Windows Server, Linux, and Solaris. Encryption requires the latest device drivers available on the web site: http://www.quantum.com/serviceandsupport. Inhibiting Firmware Down-Leveling The drive provides the capability to prevent loading and installing drive... -

Page 27: Supported Operating Systems

Sales Representative. Ethernet Port The Quantum LTO-8 Tape Drive has a single 1 Gbps Ethernet port on the rear panel, with a RJ45 connector. The Default IP address is 169.254.0.3, but the drive’s IP address can be changed as needed. -

Page 28: Ibm Spectrum Archive

Users can run any application designed for disk files against tape data without concern for the fact that the data is physically stored on tape. For more information on LTFS, visit http://www.quantum.com/ serviceandsupport. Specifications The sections below give the physical, power, and environmental specifications for the drive. -

Page 29: Power Specifications

Chapter 2: Introduction Specifications Power specifications Power Measurements Drive AC line current 100 to 240 Vac Line frequency 50 to 60 Hz, auto-ranging Line current at 100 Vac 0.48 A Line current at 240 Vac 0.20 A Other specifications Specification Measurement Maximum altitude for operating and storage 3048 m (10,000 ft) - Page 30 Chapter 2: Introduction Specifications QuantumLTO-8 HH SAS User’s Guide...

-

Page 31: Installation

Chapter 3 Installation This is a customer setup unit. It is the customer's responsibility to install this product. Avoiding Drive Damage on page 24 Unpack the Drive on page 24 Verify the Shipment on page 25 Inspect the Power Cord and Outlet on page 25 Position the Tape Drive on page 26... -

Page 32: Avoiding Drive Damage

Chapter 3: Installation Avoiding Drive Damage Avoiding Drive Damage To avoid static electricity damage when handling the drive, use the following precautions: • Limit your movement. Movement can cause static electricity to build around you. • Always handle the drive carefully. Never touch exposed circuitry. •... -

Page 33: Verify The Shipment

• Optional Rack Mount Kit • The Quantum LTO-8 Tape Drive Quick Reference (6-68101-01) • The Quantum LTO-8 HH SAS User’s Guide 6-68132-03 (this guide) • SAS cables are not part of the ship group. They must be ordered separately. -

Page 34: Position The Tape Drive

Chapter 3: Installation Position the Tape Drive Position the Tape Drive Position the unit so it is convenient to the server. The only restrictions are the length of the power cord and the length of the cable to the server. Recommended locations are: •... - Page 35 Chapter 3: Installation Connect the SAS Interface Cable To connect the cable: 1 Ensure the tape drive is powered OFF. 2 Since there are several types of SAS connectors, verify the SAS cable has the correct connectors for the SAS host adapter and for the tape drive.

-

Page 36: Connect Power

Chapter 3: Installation Connect Power Figure 6 Example of connecting the SAS device to two servers 1 Tape drive 4 SAS host adapter card 2 SAS connectors 5 Servers 3 SAS cables 4 Ensure the host adapter and the server are configured correctly for a SAS bus operation. -

Page 37: Run Drive Diagnostics

Chapter 3: Installation Run Drive Diagnostics characters. Each segmented character represents a test performed during the POST. When the POST finishes, the SCD momentarily lights all segmented characters and then goes blank. Run Drive Diagnostics Run the Standalone Diagnostic (see Function Code 1: Run Drive Diagnostics on page 48). -

Page 38: Updating Firmware

• A firmware update (FUP) tape cartridge For instructions on obtaining a new firmware image, visit http:// www.quantum.com/serviceandsupport. To update the firmware, refer to the following sections. Updating Firmware Use xTalk SW to update your drive firmware. Refer to xTalk User Guide through the Host for more details, http://www.quantum.com/serviceandsupport. - Page 39 Chapter 3: Installation Updating firmware The SCD presents a series of random characters during the firmware download and update. The SCD briefly displays 8, then becomes blank (not lit) when the firmware download and update is complete and there are no errors. An error code will be displayed if a firmware download or update error has been detected.

- Page 40 Chapter 3: Installation Updating firmware QuantumLTO-8 HH SAS User’s Guide...

-

Page 41: Operations

Chapter 4 Operations Operating the drive involves using the following front panel items: • Power Button • Single-character Display (SCD) • SCD Dot • Ready and Fault status lights • Unload Button • Encryption status light Operating modes The drive functions in the following modes: •... -

Page 42: Power Button

Chapter 4: Operations Power Button copy to tape, copy to flash memory, and erase flash). For more information, see Diagnostic and Maintenance Functions on page 45. The Unload button is used to switch between modes. For more information, see Unload Button on page 40. -

Page 43: Scd Dot

Chapter 4: Operations Status Lights The SCD is blank during normal operation. SCD Dot If a drive dump is present while the drive is in maintenance mode, a single dot illuminates in the lower right corner of the SCD (see 6 in Figure 3 on page 13). - Page 44 Chapter 4: Operations Status Lights Mode Ready LED (green) Fault LED (amber) Power-On / Reset Initialization random segments Note: The white Encryption status light will be on when the tape drive has a cartridge loaded and all data on this cartridge is encrypted (excluding the label).

- Page 45 Chapter 4: Operations Status Lights If green amber Ready Fault Encryption Status Status Status SCD Dot Light is Light is Light is and SCD is Meaning Flashing On/Off The drive is reading from the tape, (once per writing to the tape, rewinding the second) tape, locating data on the tape, loading the tape, or unloading the...

- Page 46 Chapter 4: Operations Status Lights If green amber Ready Fault Encryption Status Status Status SCD Dot Light is Light is Light is and SCD is Meaning On/Off On/Off On/Off Displaying On/Off During power on, or a drive reset, random the drive front panel will display segments/ drive progress as follows: Blank/...

- Page 47 Chapter 4: Operations Status Lights If green amber Ready Fault Encryption Status Status Status SCD Dot Light is Light is Light is and SCD is Meaning Flashing Displaying An error occurred and the drive or (once error code media may require service, or it may require cleaning.

-

Page 48: Unload Button

Chapter 4: Operations Unload Button Unload Button The Unload button (1 in Figure 3 on page 13) performs the following functions: Table 4 Functions that the Unload button performs Unload button Function How to Initiate the Function Rewind the tape into the cartridge Press the Unload button once. -

Page 49: Inserting A Tape Cartridge

Chapter 4: Operations Inserting a Tape Cartridge Unload button Function How to Initiate the Function Force a drive dump (part of the Caution: If the drive detects a permanent error and displays an maintenance mode) error code, it automatically forces a drive dump (also known as a save of the firmware trace). - Page 50 Chapter 4: Operations Inserting a Tape Cartridge 3 Grasp the cartridge so that the write-protect switch faces you (see 1 Figure 7 on page 42). 4 Slide the cartridge into the tape load compartment. Note: If the cartridge is already in an ejected position and you want to reinsert it, remove the cartridge then insert it again.

-

Page 51: Removing A Tape Cartridge

Chapter 4: Operations Removing a Tape Cartridge Removing a Tape Cartridge To remove a tape cartridge: 1 Ensure that the drive is powered-on. 2 Press the Unload button. The drive rewinds the tape and partially ejects the cartridge. The Ready light flashes while the tape rewinds, then goes out before the cartridge partially ejects. -

Page 52: Cleaning The Drive Head

Note: The drive will automatically eject an expired cleaning cartridge. The Quantum LTO Ultrium Cleaning Cartridge is valid for 50 uses. Cleaning the Tape Drive Clean the exterior surface of the tape drive with a damp towel. If a liquid all-purpose cleaner is used, apply it to the towel. -

Page 53: Diagnostic And Maintenance Functions

Chapter 4: Operations Diagnostic and Maintenance Functions Diagnostic and Maintenance Functions The drive can: • Run diagnostics • Test write and read functions • Test a suspect tape cartridge • Update firmware • Perform other diagnostic and maintenance functions The drive must be in maintenance mode to perform these functions. Caution: Maintenance functions cannot be performed concurrently with read or write operations. - Page 54 Chapter 4: Operations Diagnostic and Maintenance Functions Function Code Diagnostic or Maintenance Function Instructions Location Update Tape Drive Firmware from Function Code 2: Update Drive FUP Tape: Loads updated firmware Firmware from FUP Tape on page 50 from a firmware update (FUP) tape. Create FUP Tape: Copies its firmware Function Code 3: Create FUP Tape update (FUP) data to a customer-...

- Page 55 Chapter 4: Operations Diagnostic and Maintenance Functions Function Code Diagnostic or Maintenance Function Instructions Location Clear Error Code Log: Erases the Function Code A: Clear Error Code Log contents of the error code log. on page 57 Insert Cartridge into Tape Drive: This Function Code C: Insert Cartridge into function cannot be selected by itself, Tape Drive...

-

Page 56: Entering Maintenance Mode

Chapter 4: Operations Diagnostic and Maintenance Functions Entering Maintenance The drive must be in maintenance mode to run drive diagnostics or Mode maintenance functions. To place the unit in maintenance mode: 1 Make sure that no cartridge is in the drive. 2 Press the Unload button three times within two seconds. -

Page 57: Function Code 0: Maintenance Mode

Chapter 4: Operations Diagnostic and Maintenance Functions Function Code 0: Function Code 0 makes the drive available for running drive diagnostics Maintenance Mode or maintenance functions. 1 Place the drive in Maintenance Mode. For instructions, see Entering Maintenance Mode on page 48. 2 To exit Maintenance Mode, see Exiting Maintenance Mode page 48. -

Page 58: Function Code 2: Update Drive Firmware From Fup Tape

Chapter 4: Operations Diagnostic and Maintenance Functions 2 Press the Unload button once per second until 1 appears in the SCD. (If you cycle past the desired code, press the Unload button once per second until the code reappears.) 3 Press and hold the Unload button for three or more seconds, then release it to select function 1. -

Page 59: Function Code 3: Create Fup Tape

Codes and Messages. Push the Unload button to eject the cartridge. The drive exits Maintenance Mode after the cartridge is removed. Contact Quantum Technical Support for problem determination or machine replacement. Function Code 3: Create Function Code 3 copies the drive's firmware update (FUP) data to a FUP Tape scratch data cartridge. -

Page 60: Function Code 4: Force A Drive Dump

Chapter 4: Operations Diagnostic and Maintenance Functions • If the tape drive creates the FUP tape successfully, it rewinds and unloads the new tape, exits Maintenance Mode, and the tape is ready to use. • If the tape drive fails to create the FUP tape, it displays an error code. - Page 61 Chapter 4: Operations Diagnostic and Maintenance Functions Note: If you inserted an invalid tape cartridge, error code J or 7 appears in the SCD. If you inserted a write-protected cartridge, or the media has read-only compatibility, error code P appears in the SCD.

-

Page 62: Function Code 6: Run Host Interface Wrap Test

Chapter 4: Operations Diagnostic and Maintenance Functions • If the copy operation fails, an error code appears in the SCD. To determine the error, locate the code in Appendix A, Error Codes Messages. The tape drive unloads the tape cartridge and exits Maintenance Mode after the cartridge is removed. -

Page 63: Function Code 7: Run Rs-422 Wrap Test

Chapter 4: Operations Diagnostic and Maintenance Functions 5 Press and hold the Unload button for three or more seconds, then release it to select one of the above functions. The drive automatically starts the test. If you cycle past the desired code, press the Unload button once per second until the code reappears. -

Page 64: Function Code 8: Unmake Fup Tape

Chapter 4: Operations Diagnostic and Maintenance Functions release. When the diagnostic ends, 0 temporarily appears in the SCD, and the tape drive exits Maintenance Mode. • If an error is detected, the Fault light flashes and the drive posts an error code to the SCD. To determine the error, locate the code in Appendix A, Error Codes and Messages. -

Page 65: Function Code 9: Display Error Code Log

Chapter 4: Operations Diagnostic and Maintenance Functions Messages. The tape drive then unloads the FUP tape, and exits Maintenance Mode after the cartridge is removed. Function Code 9: Function Code 9 displays the last ten error codes, one at a time (the Display Error Code Log codes are ordered;... -

Page 66: Function Code C: Insert Cartridge Into Tape Drive

Chapter 4: Operations Diagnostic and Maintenance Functions Function Code C: Insert This function cannot be selected by itself, but is part of other Cartridge into Tape maintenance functions (such as Run Tape Drive Diagnostics and Create FUP Tape) that require a tape cartridge to be inserted. Drive Function Code E: Test Approximate Run Time = 15 minutes per loop... -

Page 67: Function Code F: Write Performance Test

Chapter 4: Operations Diagnostic and Maintenance Functions • If no error is detected, the diagnostic will loop and begin again. To stop the loop, press the Unload button for one second and release. When the diagnostic ends, 0 temporarily appears in the SCD, and the tape drive exits Maintenance Mode. -

Page 68: Function Code H: Test Head

Chapter 4: Operations Diagnostic and Maintenance Functions 3 Press and hold the Unload button for three or more seconds, then release it to select the function. The SCD changes to a flashing C. 4 Insert a scratch (blank) data cartridge. The SCD changes to a flashing F and the tape drive runs the tests. -

Page 69: Function Code J: Fast Read/Write Test

Chapter 4: Operations Diagnostic and Maintenance Functions Note: If you inserted an invalid tape cartridge, error code J or 7 appears in the SCD. If you inserted a write-protected cartridge, or the media has read-only compatibility, error code P appears in the SCD. - Page 70 Chapter 4: Operations Diagnostic and Maintenance Functions Code F: Write Performance Test on page 59. If the Write Performance Test fails, replace the media and exit maintenance mode. Press the Unload button to stop the diagnostic and exit maintenance mode. Pressing the Unload button once will abort the test at the end of the current test loop.

-

Page 71: Function Code L: Load/Unload Test

Chapter 4: Operations Diagnostic and Maintenance Functions Function Code L: Load/ Approximate Run Time = 30 seconds per loop Unload Test Total Number of Loops = 10 Function Code L tests the drive's ability to load and unload a tape cartridge. -

Page 72: Function Code P: Post Error Reporting Enabled

Chapter 4: Operations Diagnostic and Maintenance Functions drive by pressing and holding the Unload button for 10 seconds. Function Code P: Post When Post Error Reporting is enabled, deferred-check conditions are Error Reporting reported to the host and temporary errors are reported in the sense data. - Page 73 Chapter 4: Operations Diagnostic and Maintenance Functions 3 Exit Maintenance Mode if you do not want to change the current setting for Post Error Reporting. For instructions, see Exiting Maintenance Mode on page 48. 4 To disable Post Error Reporting, Press and hold the Unload button for three seconds while P appears in the SCD.

- Page 74 Chapter 4: Operations Diagnostic and Maintenance Functions QuantumLTO-8 HH SAS User’s Guide...

-

Page 75: Media

• WORM (Write Once, Read Many) Cartridge • Cleaning cartridge To ensure that your Quantum Ultrium Tape Drive conforms to Quantum's specifications for reliability, use only Quantum LTO Ultrium tape cartridges. You may use other LTO-certified data cartridges, but they may not meet the standards of reliability that are established by Quantum. - Page 76 Chapter 5: Media The Quantum LTO Figure 8 Ultrium Data Cartridge LTO cartridge memory Cartridge door Leader Pin Write-protect Switch Label area Insertion guide QuantumLTO-8 HH SAS User’s Guide...

-

Page 77: Data Cartridge

Chapter 5: Media Data Cartridge Data Cartridge The different generations of Quantum Ultrium data cartridges can be identified by color: Type Color Ultrium 8 Burgundy Ultrium 8 WORM Burgundy and Silvery gray Ultrium 7 M8 Format Purple Ultrium 7 Purple... - Page 78 Chapter 5: Media Data Cartridge Data Native Data Cartridge Capacity Recording Format Ultrium 8 12000 GB (30000 GB Reads and writes data on 6656 at 2.5:1 compression) tracks, 32 tracks at a time Ultrium 7 9000 GB (22500 GB Reads and writes data on 5376 M8 format at 2.5:1 compression) tracks, 32 tracks at a time...

-

Page 79: Cartridge Compatibility

20,000 (20k) Ultrium 2 10,000 (10k) Ultrium 1 5000 (5k) Cartridge Compatibility Table 7 Ultrium cartridge compatibility with Ultrium tape drives Quantum LTO Ultrium Data Cartridges Quantum Ultrium 12000 GB 6000 GB 2500 GB 1500 GB 800 GB 400 GB... -

Page 80: Capacity Scaling

SCSI command For information SET CAPACITY. about this command, refer to the Quantum System Storage Ultrium Tape Drive SCSI Reference. WORM (Write Once, Read Many) Cartridge Certain records retention and data security applications require a Write Once, Read Many (WORM) method for storing data on tape. -

Page 81: Data Security On Worm Media

If it does not match, a media Error Code 7 will post on the drive's single-character display (SCD). Requirements for To add WORM capability to your Quantum LTO Ultrium 8 drive(s), you WORM Capability need to use: • Quantum Ultrium 8 12000 GB WORM tape cartridges... -

Page 82: Cleaning Cartridge

• Quantum Ultrium 7 6000 GB WORM tape cartridges Cleaning Cartridge A specially labeled Quantum LTO Ultrium Cleaning Cartridge is used to clean the drive head. The drive itself determines when a head needs to be cleaned. It alerts you by the SCD flashing a C. To clean the head... -

Page 83: Lto-8 Type M Format

LTO-7 drive. A new bar code media identifier is used with M formatted LTO-7 tapes. The last two characters of the bar code are "M8". Quantum strongly recommends that M formatted media are labelled with M8 bar code labels. - Page 84 Guidelines for Using Bar Code Labels Apply the following guidelines whenever using bar code labels: • Use only Quantum-approved bar code labels. • Do not reuse a label or reapply a used label over an existing label. • Before you apply a new label, remove the old label by slowly pulling it at a right angle to the cartridge case.

-

Page 85: Write-Protect Switch

Chapter 5: Media Bar Code Labels • Verify that the label is smooth and parallel, and has no roll-up or roll-over. The label must be flat to within 0.5 mm (0.02 in.) over the length of the label and have no folds, missing pieces, or smudges. •... -

Page 86: Handling Cartridges

Incorrect handling or an incorrect environment can damage cartridges or their magnetic tape. To avoid damage to your tape cartridges and to ensure the continued high reliability of your Quantum LTO Ultrium Tape Drives, use the following guidelines. Provide Training •... -

Page 87: Provide Proper Acclimation And Environmental Conditions

Chapter 5: Media Handling Cartridges • Place the cartridge in polyethylene plastic wrap or bags to protect it from dust, moisture, and other contaminants. • Double-box the cartridge (place it inside a box, then place that box inside the shipping box) and add padding between the two boxes. -

Page 88: Handle The Cartridge Carefully

Chapter 5: Media Handling Cartridges Figure 12 Checking for gaps in the seams of a cartridge • Check that the leader pin is properly seated. • If you suspect that the cartridge has been mishandled but it appears usable, copy any data onto a good cartridge immediately for possible data recovery. -

Page 89: Examples Of Cartridge Problems

Perform the following steps: 1 Look for cartridge mishandling. 2 Use the Quantum Leader Pin Reattachment Kit (part number 08L9129) to correctly seat the pin. Then, immediately use data recovery procedures to minimize chances of data loss. -

Page 90: Disposing Of Tape Cartridges

Chapter 5: Media Disposing of Tape Cartridges Table 8 Environment for operating, storing, and shipping LTO media Environmental Specifications Operational Archival Environmental Factor Operating Storage Storage Shipping Temperature 10 to 45°C 16 to 32°C 16 to 25°C -23 to 49°C (50 to 113°F) (61 to 90°F) (61 to 77°F) - Page 91 Chapter 5: Media Disposing of Tape Cartridges offset 90 degrees from each other to accomplish complete erasure in one pass for higher throughput. Degaussing makes the cartridge unusable. If you burn the cartridge and tape, ensure that the incineration complies with all applicable regulations.

- Page 92 Chapter 5: Media Disposing of Tape Cartridges QuantumLTO-8 HH SAS User’s Guide...

-

Page 93: Troubleshooting

Single- character Display (SCD) on page 34. Please review the Pre-Call Checklist on page 89 before calling Quantum Technical Support. Procedure 1: Determining Firmware Level and Capturing Drive Dump Customers are responsible for updating Firmware. For optimum performance, the customer must obtain the latest level of firmware for... -

Page 94: Procedure 2: Inspecting A Cartridge For Damage

Chapter 6: Troubleshooting Procedure 2: Inspecting a Cartridge for Damage Note: The xTalk utility can be used to either update drive firmware to the latest level or to capture drive dumps from a drive which may be experiencing problems. Procedure 2: Inspecting a Cartridge for Damage If the cartridge fails to load or unload properly, perform the following steps: 1 Check that the leader pin is attached and properly seated by... -

Page 95: Procedure 3: Checking Sas Host Connections

Chapter 6: Troubleshooting Procedure 3: Checking SAS Host Connections Note: If a cartridge is dropped and appears to externally be undamaged, there may still be internal damage that will not become obvious until an attempt is made to write or read data to/from the tape. -

Page 96: Resolving Problems Reported By The Server

SARS detects are reported as TapeAlert flags on the server (see Quantum LTO Ultrium Tape Drive SCSI Reference). Caution: If you insert the Quantum LTO Ultrium Data Cartridge into another manufacturer's drive, the SARS data in the cartridge memory may become lost or invalid. - Page 97 Quantum Technical Support. Ensure that the total SAS cable length does not exceed 5.5m (18 ft). Perform the following steps before you place a call to Quantum Technical Support. Where instructions refer you to the web, visit http://www.quantum.com/serviceandsupport. 1 Perform a general checkup of the hardware and connections: •...

- Page 98 Chapter 6: Troubleshooting Pre-Call Checklist • Function Code E: Test Cartridge & Media on page 57 to determine whether a suspect cartridge and its magnetic tape are acceptable. • Function Code F: Write Performance Test on page 58 to ensure that the drive can read from and write to tape. •...

- Page 99 Appendix A Error Codes and Messages If the drive detects a permanent error, it will display the error code on the SCD and flash the Ready light (Ready light will be Off). • Make note of the SCD error code prior to removing a cartridge or clearing the SCD error code.

- Page 100 Appendix A: Error Codes and Messages Table 9 Error codes on the Single-character Display Error Code Cause and Action No error occurred and no action is required. This code displays when diagnostics have finished running and no error occurred. Note: The Single-character Display is blank during normal operation of the tape drive. Temperature problem.

- Page 101 2 Power the tape drive off and on, then retry the operation that produced the error. 3 If the problem persists, download new firmware and retry the operation. 4 If the problem persists, send the drive dump that you collected in step 1 to your Quantum Support Center.

- Page 102 Appendix A: Error Codes and Messages Error Code Cause and Action Tape drive or media error. The tape drive determined that an error occurred, but it cannot isolate the error to faulty hardware or to the tape cartridge. Ensure the tape cartridge is the correct media type: •...

- Page 103 Appendix A: Error Codes and Messages Error Code Cause and Action For Problems with Reading Data: If the problem occurred while the tape drive was reading data from the tape, perform one of the following procedures: • If another tape drive is available, insert the cartridge into the other unit and retry the operation: •...

- Page 104 Appendix A: Error Codes and Messages Error Code Cause and Action Media error. The tape drive determined an error occurred because of a faulty tape cartridge or an invalid tape cartridge. Ensure the tape cartridge is the correct media type: •...

- Page 105 Appendix A: Error Codes and Messages Error Code Cause and Action Interface problem. The tape drive determined that a failure occurred in the tape drive's hardware or in the host bus. See Chapter 6, Troubleshooting. If 8 was displayed while running Function Code 6: Run Host Interface Wrap Test on page 53:...

- Page 106 Appendix A: Error Codes and Messages Error Code Cause and Action Degraded operation. The tape drive determined that a problem occurred which degraded the operation of the tape drive, but it did not restrict continued use. If the problem persists, determine whether the problem is with the drive or the media.

- Page 107 1 Check the host application to ensure the host application is providing the correct encryption key. • Refer to the Quantum LTO Ultrium Tape Drive SCSI Reference documentation for the Sense Data returned for an encryption operation. • Retry the encryption operation after the host application problems have been resolved.

- Page 108 Appendix A: Error Codes and Messages QuantumLTO-7 HH SAS User’s Guide...

- Page 109 TapeAlert flags from a tape drive through the host interface. The server reads the flags from Log Sense Page 0x2E. Refer to the Quantum LTO Ultrium Tape Drive SCSI Reference for the list of TapeAlert flags that are supported by this tape drive.

- Page 110 Appendix B: Tape Alert Flags QuantumLTO-7 HH SAS User’s Guide...

- Page 111 A circuit board that adds function to a computer. Adjustment. alphanumeric Pertaining to a character set that contains letters, numerals, and usually other characters, such as punctuation marks. alter To change. Quantum LTO-7 HH SAS User’s Guide...

- Page 112 A laser device specialized for scanning and reading bar codes and converting them into either the ASCII or EBCDIC digital character code. bezel Decorative and safety cover. Quantum LTO-7 HH SAS User’s Guide...

- Page 113 (cm) One one-hundredth of a meter (0.01 m). Approximately 0.39 inch. channel command An instruction that directs a data channel, control unit, or device to perform an operation or set of operations. char Character. Check. Quantum LTO-7 HH SAS User’s Guide...

- Page 114 A tape cartridge dedicated to storing data. Contrast with cleaning cartridge. data check A synchronous or asynchronous indication of a condition caused by invalid data or incorrect positioning of data. Direct current. Quantum LTO-7 HH SAS User’s Guide...

- Page 115 A mechanism for moving magnetic tape and controlling its movement. Data security erase. Digital signal processor. EBCDIC Extended binary-coded decimal interchange code. Edge connector. Engineering change. Error correction code. EEPROM Electrically erasable programmable read-only memory. Electronics Industries Association. Quantum LTO-7 HH SAS User’s Guide...

- Page 116 Proprietary code that is usually delivered as microcode as part of an operating system. Firmware is more efficient than software loaded from an alterable medium and more adaptable Quantum LTO-7 HH SAS User’s Guide...

- Page 117 (Gbit) 1 000 000 000 bits. gigabyte (GB) 1 000 000 000 bytes. Gigabit Interface Converter (GBIC) Converts copper interface to optic interface. Ground. hertz (Hz) Unit of frequency. One hertz equals one cycle per second. Hexadecimal. Quantum LTO-7 HH SAS User’s Guide...

- Page 118 The part used to convert a 68-pin connector to a 50-pin D- shell connector. intervention required Manual action is needed. INTRO Introduction. Input/output. Input/output processor. Initial program load. ITST Idle-time self-test. Quantum LTO-7 HH SAS User’s Guide...

- Page 119 A computer network within a limited area. Light-emitting diode. Linear Tape-Open (LTO) A type of tape storage technology developed by the Quantum Corporation, Hewlett-Packard, and Certance. LTO technology is an “open format” technology, which means that its users will have multiple sources of product and media.

- Page 120 Pertaining to the bar code on the bar code label of the Quantum Ultrium Tape Cartridge, a 2-character code, L1, that represents information about the cartridge. L identifies the cartridge as one that can be read by devices which incorporate LTO technology;...

- Page 121 Loss of data because a receiving device is unable to accept data at the rate it is transmitted. parameter A variable that is given a constant value for a specified application and that may denote the application. p bit Parity bit. Parity check. Quantum LTO-7 HH SAS User’s Guide...

- Page 122 Reference. Register. Retention The process or function of tightening the tape onto the cartridge, if it is sensed that the tape has a loose wrap on the cartridge. Request for price quotation. Quantum LTO-7 HH SAS User’s Guide...

- Page 123 - Ultra SCSI: Uses an 8- or 16-bit bus, and supports data rates of 20 or 40 MBps. - Ultra2 SCSI: Uses an 8- or 16-bit bus and supports data rates of 40 or 80 MBps. Quantum LTO-7 HH SAS User’s Guide...

- Page 124 UART Universal asynchronous receiver/transmitter. unload Prepare the tape cartridge for removal from the drive. utility programs A computer program in general support of the processes of a computer; for instance, a diagnostic program. Quantum LTO-7 HH SAS User’s Guide...

- Page 125 A character string that is convenient for some purpose to consider as an entity. External register. External register address register. Quantum LTO-7 HH SAS User’s Guide...

- Page 126 Glossary Quantum LTO-7 HH SAS User’s Guide...

Need help?

Do you have a question about the LTO-8 HH SAS and is the answer not in the manual?

Questions and answers