Table of Contents

Advertisement

Advertisement

Chapters

Table of Contents

Summary of Contents for Kubota V3300-E2B

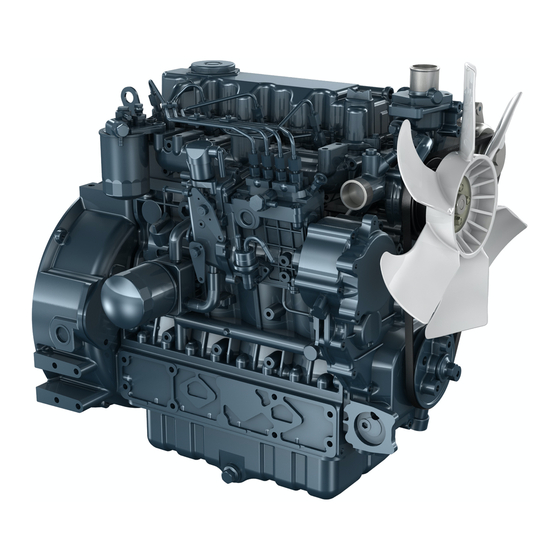

- Page 1 WORKSHOP MANUAL DIESEL ENGINE V3300-E2B,V3300-T-E2B KiSC issued 06, 2006 A...

- Page 2 TO THE READER This Workshop Manual has been prepared to provide servicing personnel with information on the mechanism, service and maintenance of V3300-E2B, V3300-T-E2B. It is divided into three parts, “General”, “Mechanism” and “Servicing”. General Information on the engine identification, the general precautions, maintenance check list, check and maintenance and special tools are described.

- Page 3 V3300-E2B, V3300-T-E2B, WSM SAFETY INSTRUCTIONS SAFETY INSTRUCTIONS SAFETY FIRST This symbol, the industry’s “Safety Alert Symbol”, is used throughout this manual and on labels on the machine itself to warn of the possibility of personal injury. Read these instructions carefully.

- Page 4 V3300-E2B, V3300-T-E2B, WSM SAFETY INSTRUCTIONS SAFETY STARTING • Do not start the engine by shorting across starter terminals or bypassing the safety start switch. • Unauthorized modifications to the engine may impair the function and / or safety and affect engine life.

- Page 5 V3300-E2B, V3300-T-E2B, WSM SAFETY INSTRUCTIONS VENTILATE WORK AREA • If the engine must be running to do some work, make sure the area is well ventilated. Never run the engine in a closed area. The exhaust gas contains poisonous carbon monoxide.

- Page 6 V3300-E2B, V3300-T-E2B, WSM SPECIFICATIONS SPECIFICATIONS Model V3300-E2B V3300-T-E2B Number of Cylinder Type Vertical, water-cooled, 4-cycle diesel engine Bore × Stroke 98 × 110 mm (3.86 × 4.33 in.) Total Displacement 3318 cm (202.48 cu.in.) 44.1 kW / 2600 min (rpm) 53.8 kW / 2600 min...

- Page 7 V3300-E2B, V3300-T-E2B, WSM PERFORMANCE CURVES PERFORMANCE CURVES (1) Brake Horsepower (4) Torque (7) Net Continuous Torque (10) Net Continuous B.H.P. (2) Engine Speed (5) Gross Intermittent Torque (8) Gross Intermittent B.H.P. (11) B.S.F.C. (Net Intermittent) (3) B.S.F.C. (6) Net Intermittent Torque (9) Net Intermittent B.H.P.

- Page 8 V3300-E2B, V3300-T-E2B, WSM PERFORMANCE CURVES (1) Brake Horsepower (4) Torque (7) Net Continuous Torque (10) Net Continuous B.H.P. (2) Engine Speed (5) Gross Intermittent Torque (8) Gross Intermittent B.H.P. (11) B.S.F.C. (Net Intermittent) (3) B.S.F.C. (6) Net Intermittent Torque (9) Net Intermittent B.H.P.

- Page 9 V3300-E2B, V3300-T-E2B, WSM DIMENSIONS DIMENSIONS KiSC issued 06, 2006 A...

-

Page 10: Table Of Contents

GENERAL CONTENTS 1. ENGINE IDENTIFICATION ................G-1 [1] MODEL NAME AND ENGINE SERIAL NUMBER ........ G-1 [2] E2B ENGINE..................... G-1 [3] CYLINDER NUMBER ................G-2 2. GENERAL PRECAUTIONS ................G-3 3. MAINTENANCE CHECK LIST ............... G-4 4. CHECK AND MAINTENANCE ............... G-6 [1] DAILY CHECK POINTS................ -

Page 11: Engine Identification

V3300-E2B, V3300-T-E2B, WSM G GENERAL 1. ENGINE IDENTIFICATION [1] MODEL NAME AND ENGINE SERIAL NUMBER When contacting the manufacture, always specify your engine model name and serial number. The engine model and its serial number need to be identified before the engine can be serviced or parts replaced. -

Page 12: E2B Engine

Phase 2 requirements, we have adopted E2B as a new model name for the engines conforming Tier 2 / Phase 2 regulations. In the after-sale services for V3300-E2B and V3300-T-E2B series engines, only use the dedicated parts for E2B models and carry out the maintenance services accordingly. -

Page 13: General Precautions

Screws, bolts and nuts should be replaced in their original position to prevent reassembly errors. • When special tools are required, use KUBOTA genuine special tools. Special tools which are not frequently used should be made according to the drawings provided. -

Page 14: Maintenance Check List

*Replacing intake air line Replacing battery * The items listed above (* marked) are registered as emission related critical parts by KUBOTA in the U.S.EPA nonroad emission regulation. As the engine owner, you are responsible for the performance of the required maintenance on the engine according to the above instruction. - Page 15 V3300-E2B, V3300-T-E2B, WSM G GENERAL CAUTION • When changing or inspecting, be sure to level and stop the engine. NOTE Lubricating Oil With the emission control now in effect, the CF-4 and CG-4 lubricating oils have been developed for use of a low- sulfur fuel on-road vehicle engines.

-

Page 16: Check And Maintenance

V3300-E2B, V3300-T-E2B, WSM G GENERAL 4. CHECK AND MAINTENANCE [1] DAILY CHECK POINTS Checking Engine Oil Level 1. Level the engine. 2. To check the oil level, draw out the dipstick (1), wipe it clean, reinsert it, and draw it out again. - Page 17 V3300-E2B, V3300-T-E2B, WSM G GENERAL Checking and Replenish Coolant 1. Without recovery tank : Remove the radiator cap (1) and check to see that the coolant level is just below the port. With recovery tank (2) : Check to see that the coolant level lies between FULL (A) and LOW (B).

-

Page 18: Check Points Of Initial 50 Hours

V3300-E2B, V3300-T-E2B, WSM G GENERAL [2] CHECK POINTS OF INITIAL 50 HOURS Changing Engine Oil CAUTION • Be sure to stop engine before changing engine oil. 1. Start and warm up the engine for approx. 5 minutes. 2. Place an oil pan underneath the engine. -

Page 19: Check Point Of Every 50 Hours

V3300-E2B, V3300-T-E2B, WSM G GENERAL Fan Belt Tension 1. Measure the deflection (A), depressing the belt halfway between the fan drive pulley and alternator pulley at specified force 98 N (10 kgf, 22 lbs). 2. If the measurement is not within the factory specifications, loosen the alternator mounting screws and relocate the alternator to adjust. -

Page 20: Check Points Of Every 250 Hours

V3300-E2B, V3300-T-E2B, WSM G GENERAL [4] CHECK POINTS OF EVERY 250 HOURS Fan Belt Tension 1. Measure the deflection (A), depressing the belt halfway between the fan drive pulley and alternator pulley at specified force 98 N (10 kgf, 22 lbs). - Page 21 V3300-E2B, V3300-T-E2B, WSM G GENERAL Cleaning Fuel Filter (Element Type only) 1. Close the fuel cock (3). 2. Unscrew the retaining ring (6) and remove the filter cup (5), and rinse the inside with kerosene. 3. Take out the element (4) and dip it in the kerosene to rinse.

-

Page 22: Check Points Of Every 500 Hours

V3300-E2B, V3300-T-E2B, WSM G GENERAL Checking Battery Electrolyte Level 1. Check the battery electrolyte level. 2. If the level is below than lower level line (2), and the distilled water to pour level of each cell. (1) Upper Level Line... - Page 23 V3300-E2B, V3300-T-E2B, WSM G GENERAL Replacing Fan Belt 1. Remove the alternator. 2. Remove the fan belt (1). 3. Replace new fan belt. 4. Install the alternator. 5. Check the fan belt tension. 10.0 to 12.0 mm / 98 N Deflection (A) Factory spec.

- Page 24 V3300-E2B, V3300-T-E2B, WSM G GENERAL Anti-Freeze • There are two types of anti-freeze available: use the permanent type (PT) for this engine. • Before adding anti-freeze for the first time, clean the radiator interior by pouring fresh, soft water and draining it a few times.

-

Page 25: Check Point Of Every 1000 Hours

V3300-E2B, V3300-T-E2B, WSM G GENERAL [6] CHECK POINT OF EVERY 1000 HOURS Checking Valve Clearance IMPORTANT • Valve clearance must be checked and adjusted when engine is cold. 1. Remove the head cover. 2. Align the 1TC mark of flywheel and the convex of flywheel housing timing windows so that the first piston (gear case side) comes to the compression top dead center. -

Page 26: Check Points Of Every 1 Or 2 Months

V3300-E2B, V3300-T-E2B, WSM G GENERAL [7] CHECK POINTS OF EVERY 1 OR 2 MONTHS Recharging CAUTION • When the battery is being activated, hydrogen and oxygen gases in the battery are extremely explosive. Keep open sparks and flames away from the battery at all times, especially when charging the battery. - Page 27 V3300-E2B, V3300-T-E2B, WSM G GENERAL Battery Specific Gravity 1. Check the specific gravity of the electrolyte in each cell with a hydrometer. 2. When the electrolyte temperature differs from that at which the hydrometer was calibrated, correct the specific gravity reading following the formula mentioned in (Reference).

-

Page 28: Check Points Of Every 1500 Hours

V3300-E2B, V3300-T-E2B, WSM G GENERAL [8] CHECK POINTS OF EVERY 1500 HOURS CAUTION • Check the injection pressure and condition after confirming that there is nobody standing in the direction the fume goes. • If the fume from the nozzle directly contacts the human body, cells may be destroyed and blood poisoning may be caused. - Page 29 V3300-E2B, V3300-T-E2B, WSM G GENERAL Nozzle Holder 1. Secure the nozzle retaining nut (7) with a vise. 2. Remove the nozzle holder (1), and take out parts inside. (When reassembling) • Assemble the nozzle in clean fuel oil. • Install the push rod (4), noting its direction.

-

Page 30: Check Points Of Every 3000 Hours

V3300-E2B, V3300-T-E2B, WSM G GENERAL [9] CHECK POINTS OF EVERY 3000 HOURS Checking Turbocharger (Turbine Side) 1. Check the exhaust port (3) and inlet port (5) side of turbine housing (1) to see if there is no exhaust gas leak. - Page 31 V3300-E2B, V3300-T-E2B, WSM G GENERAL Injection Timing 1. Make sure of matching the injection timing align mark (1) of the injection pump unit and the plate (gearcase), as shown in the illustration. 2. Remove the injection pipes. 3. Remove the stop solenoid.

- Page 32 5. Set the speed control lever to the maximum speed position. 6. Run the starter to increase the pressure. 7. If the pressure can not reach the allowable limit, replace the pump with new one or repair with a Kubota-authorized pump service shop. (Fuel Tightness of Delivery Valve) 1.

-

Page 33: Check Points Of Every 1 Year

V3300-E2B, V3300-T-E2B, WSM G GENERAL [10] CHECK POINTS OF EVERY 1 YEAR Changing Engine Oil CAUTION • Be sure to stop engine before changing engine oil. 1. Start and warm up the engine for approx. 5 minutes. 2. Place an oil pan underneath the engine. -

Page 34: Check Points Of Every 2 Years

V3300-E2B, V3300-T-E2B, WSM G GENERAL [11] CHECK POINTS OF EVERY 2 YEARS Replacing Fan Belt 1. Remove the alternator. 2. Remove the fan belt (1). 3. Replace new fan belt. 4. Install the alternator. 5. Check the fan belt tension. - Page 35 V3300-E2B, V3300-T-E2B, WSM G GENERAL Changing Radiator Coolant (L.L.C.) (Continued) (Anti-freeze) • There are two types of anti-freeze available: use the permanent type (PT) for this engine. • Before adding anti-freeze for the first time, clean the radiator interior by pouring fresh, soft water and draining it a few times.

- Page 36 V3300-E2B, V3300-T-E2B, WSM G GENERAL Replacing Fuel Hose and Clamp Bands 1. Loosen the clamp (2) and remove the fuel hose (3). 2. Replace new fuel hose (3) and new clamp (2). 3. Tighten the clamp (2). CAUTION • Stop the engine when attempting the check and change prescribed above.

-

Page 37: Special Tools

V3300-E2B, V3300-T-E2B, WSM G GENERAL 5. SPECIAL TOOLS Diesel Engine Compression Tester Code No: 07909-30208 (Assembly) 07909-31251 (G) 07909-30934 (A to F) 07909-31271 (I) 07909-31211 (E and F) 07909-31281 (J) 07909-31231 (H) Application: Use to measure diesel engine compression and diagnosis of need for major overhaul. - Page 38 V3300-E2B, V3300-T-E2B, WSM G GENERAL NOTE • The following special tools are not provided, so make them referring to the figure. Injection Pump Pressure Tester Application: Use to check fuel tightness of injection pumps. Pressure gauge full scale : More than 29.4 MPa...

- Page 39 V3300-E2B, V3300-T-E2B, WSM G GENERAL Small End Bushing Replacing Tool Application: Use to press out and to press fit the small end bushing. [Press out] 157 mm (6.181 in.) 14.5 mm (0.571 in.) 120 mm (4.7244 in.) 30.0 mm dia. (1.1811 in. dia.) 32.95 mm dia.

- Page 40 V3300-E2B, V3300-T-E2B, WSM G GENERAL Gear Case Oil Seal Replacing Tool Application: Use to press fit the oil seal. 148.8 mm (5.8582 in.) 50 mm (1.9685 in.) 18.8 mm (0.7401 in.) 13.7 to 13.9 mm (0.5394 to 0.5472 in.) 11 mm (0.433 in.) 18 mm dia.

- Page 41 V3300-E2B, V3300-T-E2B, WSM G GENERAL Valve Guide Replacing Tool Application: Use to press out and press fit the valve guide. Intake valve guide 225 mm (8.86 in.) 70 mm (2.76 in.) 45 mm (1.77 in.) 20 mm dia. (0.79 in dia.) 11.7 to 11.9 mm dia.

- Page 42 V3300-E2B, V3300-T-E2B, WSM G GENERAL Auxiliary Socket for Fixing Crankshaft Sleeve Application: Use to fix the crankshaft sleeve of the diesel engine. Rmax = 12.5 S 94.5 to 95.0 mm dia. (3.7205 to 3.7402 in. dia.) 40 mm dia. (1.5748 in. dia.) 30 mm dia.

- Page 43 V3300-E2B, V3300-T-E2B, WSM G GENERAL Balancer Bushing Replacing Tool 1 Components Parts 1) Shaft 498 mm (19.61 in.) 318.8 to 319.2 mm (12.5512 to 12.5669 in.) 102.8 to 103.2 mm (4.0472 to 4.0630 in.) 60 mm (2.36 in.) 8 mm (0.31 in.) 5 mm (0.20 in.)

- Page 44 V3300-E2B, V3300-T-E2B, WSM G GENERAL 3) Piece 2 Chamfer 0.1 mm (0.004 in.) 1 mm (0.04 in.) Chamfer 1mm (0.04 in.) 54.3 to 54.4 mm dia. (2.1378 to 2.1417 in. dia.) 34.025 to 34.05 mm dia. (1.3396 to 1.3406 in. dia.) 48.5 mm dia.

- Page 45 V3300-E2B, V3300-T-E2B, WSM G GENERAL Balancer Replacing Tools 3, 4, 5 Application: Use to press fit the bushing. NOTE • This special tool is not provided, so make it referring to the figure. Name of Part Q’ty. Bracket Flange Nut...

- Page 46 V3300-E2B, V3300-T-E2B, WSM G GENERAL 2) Shaft 44 mm dia. (1.73 in. dia.) 12 mm (0.47 in.) Chamfer 1 mm (0.04 in.) 3 mm (0.12 in.) 3 mm (0.12 in.) 30 mm (1.18 in.) 38 mm (1.50 in.) 35 mm (1.38 in.) M12 ×...

- Page 47 V3300-E2B, V3300-T-E2B, WSM G GENERAL 4) Joint 1 M12 × P1.25 Chamfer 1 mm (0.04 in.) 30 mm dia. (1.18 in. dia.) 13 mm dia. (0.51 in. dia.) Chamfer 3 mm (0.12 in.) 3 mm (0.12 in.) 45 mm (1.77 in.) 75 mm (2.95 in.)

- Page 48 V3300-E2B, V3300-T-E2B, WSM G GENERAL 7) Piece 3 26 mm (1.02 in.) 18 mm (0.71 in.) 16.5 to 17.0 mm (0.6496 to 0.6693 in.) 1.5 mm (0.06 in.) 53.0 to 53.2 mm dia. (2.0866 to 2.0945 in dia.) 49.55 to 49.75 mm dia. (1.9508 to 1.9587 in dia.) 16 mm (0.63 in.)

- Page 49 V3300-E2B, V3300-T-E2B, WSM G GENERAL Engine Stand Application: Use to support engine. 480 mm (18.90 in.) 50 mm (1.97 in.) 108.5 mm (4.272 in.) 262.5 mm (10.33 in.) 12.5 mm (0.492 in.) 237.5 mm (9.350 in.) 142.5 mm (5.610 in.) 95 mm (3.74 in.)

- Page 50 V3300-E2B, V3300-T-E2B, WSM G GENERAL Jig for Governor Connecting Rod Application: Use for connecting the governor connecting rod to the rack pin of the fuel injection pump assembly. 1 mm radius (0.0394 in. radius) Chamfer 0.2 mm (0.0079 in.) Chamfer 2 mm (0.0787 in.) 35 mm dia.

- Page 51 MECHANISM CONTENTS 1. FEATURE ......................M-1 2. ENGINE BODY ....................M-2 [1] CYLINDER BLOCK................... M-2 [2] HALF-FLOATING HEAD COVER ............M-2 [3] CYLINDER HEAD ..................M-3 [4] PISTON AND PISTON RINGS ............... M-3 [5] BUILT-IN DYNAMIC BALANCER (BALANCER MODEL ONLY)..M-4 3.

-

Page 52: Feature

E-TVCS VERSION-II. Thus, this engine achieves high combustion efficiency and complies with various regulations of exhaust gas. Based upon the conventional model, Kubota developed a unique governor system and various new mechanisms which reduces exhaust emission, noise and vibration and realize durability and high torque. -

Page 53: Engine Body

V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE 2. ENGINE BODY [1] CYLINDER BLOCK This engine employs separate type crankcases - the crankcase 1 (1) with combustion part and the crankcase 2 (2) which supports the crankcase 1 (1) and reduces noise. Since it is a hanger type, you can easily assemble / disassemble it. -

Page 54: Cylinder Head

It also employs Kubota’s unique combustion chamber with multiple injection grooves. Besides the conventional cross port system, it employs the forced cooling method between valves to eliminate heat distortion, thus enabling durable and reliable configuration. -

Page 55: Built-In Dynamic Balancer (Balancer Model Only

V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE [5] BUILT-IN DYNAMIC BALANCER (BALANCER MODEL ONLY) Engine are sure to vibrate by piston’s reciprocation. Theoretically, three-cylinder engines are much less prone to cause vibration than four-cylinder ones (second inertia, etc.). However, any engine has many moving parts in addition to its pistons and cannot be completely free from vibration. -

Page 56: Lubricating System

V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE 3. LUBRICATING SYSTEM [1] OIL COOLER V3 series engine has a water-cooled oil cooler that not only cools hot oil, but also warms the cool engine oil shoftly after start up. As shown in the figure, the oil flows inside the... -

Page 57: Cooling System

V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE 4. COOLING SYSTEM [1] THERMOSTAT Conventional thermostatically-controlled valves (outlet water temperature control type) open against the flow of coolant. In this design, the pressure (steam pressure + water pump’s discharge pressure) affects the open/close performance of such valve. In other words,... -

Page 58: Bottom Bypass System

V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE [2] BOTTOM BYPASS SYSTEM Bottom bypass system is introduced in V3 series for improving the cooling performance of the radiator. While the temperature of coolant in the engine is low, the thermostat is held closed and the coolant is allowed to flow through the bypass pipe and to circulate in the engine. -

Page 59: Fuel System

DIESEL ENGINE 5. FUEL SYSTEM [1] GOVERNOR The engine employs the separated fuel injection pump in combination with Kubota’s own small multi- function mechanical governor, which enable more dependability. It also employs the torque limiting mechanism to control the maximum peak torque so that it complies with the regulations of exhaust gas. - Page 60 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE At Idling Turn the speed control lever (6) clockwise to idle the engine. It tensions the governor spring (3) to pull the fork lever 2 (1). When the fork lever 2 is pulled, it moves the torque spring pin (7) and the fork lever 1 (5) in the direction of the arrow A to restrain the weight.

- Page 61 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE To stop engine When the stop solenoid is turned off, the spring tension of the solenoid is released, the rod extrudes and the stop lever moves the control rack in the direction of the arrow B which stops the engine.

-

Page 62: Turbocharger System

V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE 6. TURBOCHARGER SYSTEM [1] BOOST COMPENSATOR The boost compensator is controlled by the boost pressure of the control mechanism which controls transient smoke caused by oversupply of fuel when the engine starts and accelerates. When the boost pressure is lower than working pressure of the boost actuator (1), it prevents oversupply of fuel to reduce transient smoke. - Page 63 SERVICING CONTENTS 1. TROUBLESHOOTING ..................S-1 2. SERVICING SPECIFICATIONS ..............S-5 3. TIGHTENING TORQUES ................S-12 [1] TIGHTENING TORQUES FOR GENERAL USE SCREWS, BOLTS AND NUTS....................S-12 [2] TIGHTENING TORQUES FOR SPECIAL USE SCREWS, BOLTS AND NUTS....................S-13 4. CHECKING, DISASSEMBLING AND SERVICING........S-15 [1] CHECKING AND ADJUSTING ...............S-15 (1) Engine Body..................S-15 (2) Lubricating System ................S-17 (3) Cooling System...................S-17...

-

Page 64: Troubleshooting

V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE 1. TROUBLESHOOTING Reference Symptom Probable Cause Solution Page Engine Does Not No fuel Replenish fuel Start Air in the fuel system Vent air Water in the fuel system Change fuel and – repair or replace fuel... - Page 65 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE Reference Symptom Probable Cause Solution Page Engine Revolution Is Fuel filter clogged or dirty Replace G-11, 12 Not Smooth Air cleaner clogged Clean or replace G-10, 23 Fuel leak due to loose injection pipe retaining nut...

- Page 66 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE Reference Symptom Probable Cause Solution Page Deficient Output Incorrect injection timing Adjust S-20 Engine’s moving parts seem to be seizing Repair or replace – Injection pump malfunctioning Repair or replace S-21, 42 Deficient nozzle injection...

- Page 67 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE Reference Symptom Probable Cause Solution Page High Oil Pressure Different type of oil Use specified type of 4, G-11 Relief valve defective Replace S-46 Engine Overheated Engine oil insufficient Replenish G-6, 8 Fan belt broken or elongated...

-

Page 68: Servicing Specifications

V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE 2. SERVICING SPECIFICATIONS ENGINE BODY Item Factory Specification Allowable Limit Cylinder Head Surface Flatness – 0.05 mm 0.0020 in. Top Clearance V3300-E2B 0.72 to 0.90 mm – 0.0283 to 0.0354 in. V3300-T-E2B 0.92 to 1.10 mm –... - Page 69 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE ENGINE BODY (Continued) Item Factory Specification Allowable Limit Valve Stem to Valve Guide Clearance (Intake) 0.055 to 0.085 mm 0.1 mm 0.0022 to 0.0033 in. 0.0039 in. Valve Stem O.D. (Intake) 6.960 to 6.975 mm –...

- Page 70 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE ENGINE BODY (Continued) Item Factory Specification Allowable Limit Rocker Arm Shaft to Rocker Arm Clearance 0.016 to 0.045 mm 0.15 mm 0.0006 to 0.0018 in. 0.0059 in. Rocker Arm Shaft O.D. 15.973 to 15.984 mm –...

- Page 71 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE ENGINE BODY (Continued) Item Factory Specification Allowable Limit Timing Gear Idle Gear 1 to Crank Gear Backlash 0.049 to 0.193 mm 0.22 mm 0.0019 to 0.0076 in. 0.0087 in. Idle Gear 1 to Cam Gear Backlash 0.049 to 0.189 mm...

- Page 72 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE ENGINE BODY (Continued) Item Factory Specification Allowable Limit Piston Ring Gap Top Ring 0.30 to 0.45 mm 1.25 mm 0.0118 to 0.0177 in. 0.0492 in. Second Ring 0.30 to 0.45 mm 1.25 mm 0.0118 to 0.0177 in.

- Page 73 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE LUBRICATING SYSTEM Item Factory Specification Allowable Limit Engine Oil Pressure At Idle Speed – 49 kPa 0.5 kgf/cm 7 psi At Rated Speed 196 to 392 kPa 147.1 kPa 2.0 to 4.0 kgf/cm 1.5 kgf/cm 28 to 57 psi 21.3 psi...

- Page 74 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE FUEL SYSTEM Item Factory Specification Allowable Limit Injection Timing V3300-E2B 0.19 to 0.23 rad – (11 to 13 °) before T.D.C. V3300-T-E2B 0.11 to 0.14 rad – (6 to 8 °) before T.D.C. Pump Element Fuel Tightness –...

-

Page 75: Tightening Torques

V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE 3. TIGHTENING TORQUES Screws, bolts and nuts must be tightened to the specified torque using a torque wrench, several screws, bolts and nuts such as those used on the cylinder head must be tightened in proper sequence and the proper torque. -

Page 76: Tightening Torques For Special Use Screws, Bolts And Nuts

V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE [2] TIGHTENING TORQUES FOR SPECIAL USE SCREWS, BOLTS AND NUTS NOTE • For “*” marked screws, bolts and nuts on the table, apply engine oil to their threads and seats before tightening. • The letter “M” in Size x Pitch means that the screw, bolt or nut dimension stands for metric. The size is the nominal outside diameter in mm of the threads. - Page 77 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE Item Size x Pitch N·m kgf·m ft-lbs Governor housing mounting screw M6 x 1.0 9.8 to 11.3 1.00 to 1.15 7.23 to 8.32 Anti-rotation nut M5 x 0.8 2.8 to 4.0 0.29 to 0.41 2.1 to 3.0 Balancer shaft set screw M8 x 1.25...

-

Page 78: Checking, Disassembling And Servicing

V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE 4. CHECKING, DISASSEMBLING AND SERVICING [1] CHECKING AND ADJUSTING (1) Engine Body Compression Pressure 1. After warming up the engine, stop it and remove the air cleaner, the muffler and all nozzle holders. 2. Install a compression tester (Code No: 07909-30208) for diesel engines to nozzle holder hole. - Page 79 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE Checking Valve Clearance IMPORTANT • Valve clearance must be checked and adjusted when engine is cold. 1. Remove the head cover. 2. Align the 1TC mark of flywheel and the convex of flywheel housing timing windows so that the first piston (gear case side) comes to the compression top dead center.

- Page 80 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE (2) Lubricating System Engine Oil Pressure 1. Remove the oil switch and set a pressure tester (Code No. 07916-32032). 2. Start the engine. After warming up, measure the oil pressure of both idling and rated speeds.

- Page 81 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE Fan Belt Damage and Wear 1. Check the fan belt for damage. 2. If the fan belt is damaged, replace it. 3. Check if the fan belt is worn and sunk in the pulley groove.

- Page 82 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE Thermostat Valve Opening Temperature 1. Push down the thermostat valve and insert a string between the valve and the valve seat. 2. Place the thermostat and a thermostat in a container with water and gradually heat the water.

- Page 83 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE (4) Fuel System Injection Timing 1. Make sure of matching the injection timing align mark (1) of the injection pump unit and the plate (gearcase), as shown in the illustration. 2. Remove the injection pipes.

- Page 84 5. Set the speed control lever to the maximum speed position. 6. Run the starter to increase the pressure. 7. If the pressure can not reach the allowable limit, replace the pump with new one or repair with a Kubota-authorized pump service shop. 13.73 MPa...

- Page 85 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE CAUTION • Check the nozzle injection pressure and condition after confirming that there is nobody standing in the direction the fume goes. • If the fume from the nozzle directly contacts the human body, cells may be destroyed and blood poisoning may be caused.

-

Page 86: Electrical System

V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE Nozzle Holder 1. Secure the nozzle retaining nut (7) with a vise. 2. Remove the nozzle holder (1), and take out parts inside. (When reassembling) • Assemble the nozzle in clean fuel oil. • Install the push rod (4), noting its direction. - Page 87 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE Battery Specific Gravity 1. Check the specific gravity of the electrolyte in each cell with a hydrometer. 2. When the electrolyte temperature differs from that at which the hydrometer was calibrated, correct the specific gravity reading following the formula mentioned in (Reference).

- Page 88 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE Motor Test CAUTION • Secure the starter to prevent it from jumping up and down while testing the motor. 1. Disconnect the battery negative cable from the battery. 2. Disconnect the battery positive cable from the battery.

- Page 89 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE Alternator on Unit Test (Before testing) • Before alternator on unit test, check the battery terminal connections, circuit connection, fan belt tension, charging indicator lamp, fuses on the circuit, and abnormal noise from the alternator.

-

Page 90: Turbocharger

V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE Engine Stop Solenoid 1. Remove the engine stop solenoid from the engine. 2. Connect the jumper leads from the pulling coil P terminal to the switch (3), and from switch (3) to the battery positive terminal. -

Page 91: Disassembling And Assembling

V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE [2] DISASSEMBLING AND ASSEMBLING (1) Draining Oil and Coolant Draining Engine Oil 1. Start and warm up the engine for approx. 5 minutes. 2. Place an oil pan underneath the engine. 3. Remove the drain plug (1) to drain oil. - Page 92 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE CAUTION • While the engine is running and or just after it stops, the turbocharger is hot, be careful not to touch the turbocharger. NOTE • When detaching and attaching the turbocharger assembly, be very careful not to allow dust, dirt and other foreign matter in the oil pipes.

-

Page 93: Cylinder Head And Valves

V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE (3) Cylinder Head and Valves Cylinder Head Cover and Nozzle Holder 1. Remove the injection pipes (3) and overflow pipes (2). 2. Remove the glow plugs (1). 3. Remove the nozzle holder assembly (4) and copper gaskets (5). - Page 94 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE Rocker Arm and Push Rod 1. Remove the rocker arm (3) as a unit. 2. Remove the push rods (1). 3. Remove the bridge arm (4). (When reassembling) • When putting the push rods onto the tappets (2), check to see if their ends are properly engaged with the grooves.

- Page 95 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE Cylinder Head and Tappet 1. Loosen the pipe band, and remove the water return pipe (1). 2. Disconnect the fuel pipe (2) first and then the fuel filter (3). 3. Remove the IN. / EX. Manifold.

- Page 96 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE Selecting Cylinder Head Gasket Replacing the Cylinder Head Gasket 1. Make sure the notch mark (a), (b) or (c) of cylinder head gasket (1) in advance. 2. Replace the same notch mark (a), (b) or (c) as the original cylinder head gasket (1).

-

Page 97: Thermostat

V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE (4) Thermostat Thermostat Assembly 1. Remove the thermostat cover mounting screws, and remove the thermostat cover (1). 2. Remove the thermostat assembly (3). (When reassembling) • Apply a liquid gasket (Three Bond 1215 or equivalent) only at the thermostat cover side of the gasket (2). -

Page 98: Injection Pump Unit

V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE (6) Injection Pump Unit Injection Pump Unit (Removing the fuel injection pump unit) 1. Detach the gear cover for the fuel injection pump unit from the gearcase. 2. Place the piston of the 4th cylinder at the top dead center in the compression stroke. - Page 99 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE Injection Pump Unit (Continued) (Reassembling the fuel injection pump unit) 1. Place the piston of the 4th cylinder at the top dead center in the compression stroke. Fix the flywheel with the flywheel stopper. 2. Place the injection pump gear (1) back into the gear case position.

- Page 100 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE Governor Housing Assembly 1. Remove the injection pump unit from the engine. (See the “Injection Pump Unit”.) 2. Remove the governor lubricating pipe (3). 3. Remove the stop solenoid (1). 4. Detach the sight cover (2) from the injection pump unit.

- Page 101 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE Governor Fork Lever Assembly 1. Pull off the governor fork lever shaft (1) with the extra bolt (Dia : 4 mm, Pitch : 0.7 mm, Length : more than 25 mm) (2). 2. Unhook the governor spring (3) at the governor fork lever (4) side.

- Page 102 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE Governor Lever 1. Remove the speed control lever (1) and the return spring (2). 2. Remove the governor lever assembly (4) from the governor housing. 3. Remove the start spring (5) and the stop spring (3).

- Page 103 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE Fuel Camshaft and Governor Weight 1. Separate the governor housing assembly from the injection pump unit. (See the “Injection Pump Unit”.) 2. Remove the governor sleeve (1). 3. Remove the injection pump assembly (2). 4. Remove the cover (3).

- Page 104 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE Fuel Camshaft and Governor Weight (Continued) (When reassembling) • Fix the fuel camshaft with lock bolts as the key way of fuel camshaft (10) is upward. • Install the injection pump assembly to the injection pump housing.

- Page 105 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE Replacing Injection Pump Assembly (If necessary) • The injection pump can be replaced with the crankshaft in whatever position. 1. Disconnect all injection pipes (1). 2. Disconnect the fuel pipe (6) and fuel overflow pipe (4).

- Page 106 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE Installing Procedure of Injection Pump Assembly 1. Install the fuel injection pump assembly (1) in its unit (2), and hook the governor connecting rod to the rack pin of the fuel injection pump assembly. 2. Place the service jig (3) in the stop solenoid mounting hole of the fuel injection pump unit.

- Page 107 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE Installing Procedure (Continued) 1. Move the stop lever (1) and visually check to see if the fuel injection pump control rack comes smoothly back to the start position by the counter force of the start spring.

-

Page 108: Water Pump And Oil Cooler

V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE (7) Water Pump and Oil Cooler Water Pump 1. Remove the pipe band and the water pipe (1). 2. Remove the water pump (2). (When reassembling) • When mounting the water pump, take care not to forget mounting the O-ring and not to let it out of position. -

Page 109: Gear Case And Timing Gears

V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE (8) Gear Case and Timing Gears Gear Case Cover 1. Remove the gear case cover. (When reassembling) • Confirm that the liquid gasket coating surface is free of water, dust and oil in order to maintain sealing effect. - Page 110 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE Idle Gear 1 and Idle Gear 2 (for Balancer Model) 1. Remove the idle gear mounting screw (1). 2. Draw out the idle gear (2) and (3). (When reassembling) • When install the idle gear (2) and (3), be sure to place the 4th...

-

Page 111: Piston And Connecting Rod

V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE Plate (Gear Case) 1. Remove the three plate mounting screws (1). Detach the plate (2). (When reassembling) • Apply Three Bond 1217D adhesive or equivalent over the shaded zones on both sides of the gasket that will be sandwiched between the crankcase and plate. - Page 112 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE Connecting Rod Cap 1. Remove the connecting rod screws (1) from connecting rod cap. 2. Remove the connecting rod caps. (When reassembling) • Align the marks (a) with each other. (Face the marks toward the injection pump.)

- Page 113 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE Piston Ring and Connecting Rod 1. Remove the piston rings using a piston ring tool. 2. Put the fan shaped concave (8) on the piston as shown in figure. 3. Remove the piston pin (7), and separate the connecting rod (6) from the piston (5).

-

Page 114: Flywheel And Crankshaft

V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE (10) Flywheel and Crankshaft Flywheel 1. Install the stopper to the flywheel so that the flywheel does not turn. NOTE • Do not use an impact wrench. Serious damage will occur. 2. Detach the flywheel screws. - Page 115 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE Flywheel Housing 1. Remove the flywheel housing. (When reassembling) • Tighten the flywheel housing mounting screws with even force on the diagonal line. • Make sure the crank cases 1 and 2 are clean. Install them in position, referring to the flywheel housing’s contoured face.

- Page 116 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE Crankshaft 1. Remove the main bearing case. 2. Remove the crankshaft. (When reassembling) • Reassemble the main bearing case having the same number as the one engraved on the crankcase, and set the casting mark “F / W SIDE”...

-

Page 117: Starter

V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE (11) Starter Disassembling Motor 1. Disconnect the solenoid switch (3). 2. Remove the 2 through screws (9) and the 2 brush holder lock screws. Take out the rear end frame (13) and the brush holder (12). - Page 118 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE Rotor 1. Remove the 4 screws and detach the bearing retainer. 2. Temporarily install the nut on the pulley screw, and detach the rotor. W1074920 Brush 1. When the rotor is detached, the 2 brushes are found to stretch out of the shaft hole.

-

Page 119: Servicing

V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE Bearing at Slip Ring Side 1. Lightly secure the rotor (1) with a vise to prevent damage, and remove the bearing (2) with a puller (3). (1) Rotor (3) Puller (2) Bearing W1019701 [3] SERVICING... - Page 120 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE Cylinder Head Surface Flatness 1. Clean the cylinder head surface. 2. Place a straightedge on the cylinder head’s four sides (A), (B), (C) and (D) and two diagonal (E) and (F) as shown in the figure.

- Page 121 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE Valve Recessing 1. Clean the cylinder head, the valve face and seat. 2. Insert the valve into the valve guide. 3. Measure the valve recessing with a depth gauge. 4. If the measurement exceeds the allowable limit, replace the valve.

- Page 122 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE Clearance between Valve Stem and Valve Guide 1. Remove carbon from the valve guide section. 2. Measure the valve stem O.D. with an outside micrometer. 3. Measure the valve guide I.D. of the cylinder head at the most wear part as shown in the figure below with a small hole gauge.

- Page 123 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE Correcting Valve and Valve Seat NOTE • Before correcting the valve and seat, check the valve stem and the I.D. of valve guide section, and repair them if necessary. • After correcting the valve seat, be sure to check the valve recessing.

- Page 124 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE Free Length and Tilt of Valve Spring 1. Measure the free length (B) with vernier calipers. If the measurement is less than the allowable limit, replace it. 2. Put the spring on a surface plate, place a square on the side of the spring, and check to see if the entire side is contact with the square.

- Page 125 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE Push Rod Alignment 1. Place the push rod on V blocks. 2. Measure the push rod alignment. 3. If the measurement exceeds the allowable limit, replace the push rod. 0.25 mm Push rod alignment Allowable limit 0.0098 in.

-

Page 126: Timing Gears

V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE (2) Timing Gears Timing Gear Backlash 1. Set a dial indicator (lever type) with its tip on the gear tooth. 2. Move the gear to measure the backlash, holding its mating gear. 3. If the backlash exceeds the allowable limit, check the oil clearance of the shafts and the gear. - Page 127 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE Camshaft Alignment 1. Support the camshaft with V block on the surface plate and set a dial indicator with its tip on the intermediate journal at right angle. 2. Rotate the camshaft on the V blocks and get the misalignment (half of the measurement).

- Page 128 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE Oil Clearance between Idle Gear Shaft 1, 2 and Idle Gear 1, 2 Bushing 1. Measure the idle gear shaft O.D. with an outside micrometer. 2. Measure the idle gear bushings I.D. with an inside micrometer, and calculate the oil clearance.

-

Page 129: Piston And Connecting Rod

V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE Oil Clearance of Balancer Shaft Journal 1. Measure the balancer shaft journal O.D. with an outside micrometer. 2. Measure the cylinder block bore I.D. (A), (B) for balancer shaft with an inside micrometer. 3. If the clearance exceeds the allowable limit, replace the balancer shaft. - Page 130 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE Replacing Small End Bushing (When removing) 1. Press out the used bushing using a small end bushing replacing tool. (When installing) 1. Clean a new small end bushing and bore, and apply engine oil to them.

-

Page 131: Crankshaft

V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE Clearance between Piston Ring and Groove 1. Remove carbon from the ring grooves. 2. Measure the clearance between the ring and the groove with a feeler gauge or depth gauge. 3. If the clearance exceeds allowable limit, replace the ring since compression leak and oil shortage result. - Page 132 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE Crankshaft Alignment 1. Support the crankshaft with V block on the surface plate and set a dial indicator with its tip on the intermediate journal at right angle. 2. Rotate the crankshaft on the V block and get the misalignment (half of the measurement).

- Page 133 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE Oil Clearance between Crankpin and Crankpin Bearing (Continued) IMPORTANT • STD size crankpin bearing. To replace it with a specific STD service part, make sure the crankpin bearing has the same ID color as the connecting rod.

- Page 134 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE Oil Clearance between Crankshaft Journal and Crankshaft Bearing 1. Clean the crankshaft journal and crankshaft bearing. 2. Put a strip of press gauge on the center of the journal. IMPORTANT • Never insert the press gauge into the oil hole of the journal.

-

Page 135: Cylinder

V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE (5) Cylinder Cylinder Wear 1. Measure the I.D. of the cylinder at the six positions (see figure) with a cylinder gauge to find the maximum and minimum I.D.’s. 2. Get the difference (Maximum wear) between the maximum and the minimum I.D.’s. -

Page 136: Starter

V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE Clearance between Outer Rotor and Pump Body 1. Measure the clearance between the outer rotor and the pump body with a feeler gauge. 2. If the clearance exceeds the allowable limit, replace the oil pump rotor assembly. - Page 137 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE Commutator and Mica 1. Check the contact face of the commutator for wear, and grind the commutator with emery paper if it is slightly worn. 2. Measure the commutator O.D. with an outside micrometer at several points.

-

Page 138: Alternator

V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE Armature Coil 1. Check the continuity across the commutator and armature coil core with an ohmmeter. 2. If it conducts, replace the armature. 3. Check the continuity across the segments of the commutator with an ohmmeter. - Page 139 V3300-E2B, V3300-T-E2B, WSM DIESEL ENGINE Rotor 1. Measure the resistance across the slip rings with an ohmmeter. 2. If the resistance is not the factory specification, replace it. 3. Check the continuity across the slip and core with an ohmmeter.

- Page 140 EDITOR : KUBOTA FARM & INDUSTRIAL MACHINERY SERVICE, LTD. 64, ISHIZU-KITAMACHI, SAKAI-KU, SAKAI-CITY, OSAKA, 590-0823, JAPAN PHONE : ( 81 ) 72-241-1129 : ( 81 ) 72-245-2484 E-mail : ksos-pub@kubota.co.jp Printed in Japan 2005. 12, S, EI, EI, e Code No.9Y011-02912 KUBOTA Corporation 2004.

Need help?

Do you have a question about the V3300-E2B and is the answer not in the manual?

Questions and answers

какой зазор должен быть между поршнем и цилиндром