Summary of Contents for HIMA HIMatrix F60 CPU 01

- Page 1 HIMatrix Safety-Related Controller CPU 01 Manual HIMA Paul Hildebrandt GmbH + Co KG Industrial Automation Rev. 1.01 HI 800 189 E...

- Page 2 HIMA directly. HIMA appreciates any suggestion on which information should be included in the manual. Equipment subject to change without notice. HIMA also reserves the right to modify the written material without prior notice. For further information, refer to the CD-ROM and our website http://www.hima.de and http://www.hima.com.

-

Page 3: Table Of Contents

Pin Assignment of D-sub Connectors FB1 and FB2..........20 3.4.8 Reset Key ......................21 3.4.9 Monitoring the Operating Voltage ................21 Product Data......................22 Certified HIMatrix F60 CPU 01 ................23 HI 800 189 E Rev. 1.01 Page 3 of 40... - Page 4 Table of Contents CPU 01 Start-Up ..............24 Installation and Mounting ..................24 4.1.1 Mounting and Removing the Modules ..............24 4.1.2 Mounting the CPU 01 in Zone 2 ................25 Configuration ......................26 4.2.1 Module Slots......................26 Configuring the Module with SILworX..............26 Configuring a Module Using ELOP II Factory............

-

Page 5: Introduction

CPU 01 1 Introduction Introduction This manual describes the technical characteristics of the module and its use. It also includes instructions on how to install, start up and replace it. Structure and Use of this Manual The content of this manual is part of the hardware description of the HIMatrix programmable electronic system. -

Page 6: Target Audience

ELOP II Factory Table 2: Additional Relevant Documents The latest manuals can be downloaded from the HIMA website www.hima.com. The revision index on the footer can be used to compare the current version of existing manuals with the Internet edition. -

Page 7: Formatting Conventions

CPU 01 1 Introduction Formatting Conventions To ensure improved readability and comprehensibility, the following fonts are used in this document: To highlight important parts Bold: Names of buttons, menu functions and tabs that can be clicked and used in the programming tool. For parameters and system variables Italics: Literal user inputs... -

Page 8: Operating Tips

1 Introduction CPU 01 1.3.2 Operating Tips Additional information is structured as presented in the following example: The text corresponding to the additional information is located here. Useful tips and tricks appear as follows: The tip text is located here. Page 8 of 40 HI 800 189 E Rev. -

Page 9: Safety

CPU 01 2 Safety Safety The following safety information, notes and instructions must be strictly observed. The product may only be used if all guidelines and safety instructions are adhered to. This product is operated with SELV or PELV. No imminent danger results from the product itself. -

Page 10: Residual Risk

2 Safety CPU 01 Residual Risk No imminent danger results from a HIMatrix system itself. Residual risk may result from: Faults in the engineering Faults in the user program Faults in the wiring Safety Precautions Observe all local safety requirements and use the protective equipment required on site. Emergency Information A HIMatrix system is a part of the safety equipment of a site.If a device or a module fails, the site adopts the safe state. -

Page 11: Product Description

61508, IEC 61511 and IEC 62061), Cat. 4 (EN 954-1) and PL e (EN ISO 13849-1). Further safety standards, application standards and test standards are specified in the certificate available on the HIMA website. Module's faults are signaled by the ERR LED located on the front plate, see Chapter 3.4.3. -

Page 12: Type Label

3 Product Description CPU 01 Type Label The type plate contains the following details: Product name Bar code (1D or 2D code) Part no. Production year Hardware revision index (HW Rev.) Firmware revision index (FW Rev.) Operating voltage Mark of conformity Figure 1: Sample Type Label Page 12 of 40... -

Page 13: Assembly

CPU 01 3 Product Description Assembly This chapter describes the layout and function of the plug-in module, and its communication via safeethernet. 3.4.1 Block Diagram Communication System Data Memory in NVRAM. Dual Port RAM Watchdog I/O Bus Module safety related processor system Program Memory Figure 2: Block Diagram... -

Page 14: Front View

3 Product Description CPU 01 3.4.2 Front View CPU 01 STOP PROG FAULT FORCE Figure 3: Front View of CPU 01 Page 14 of 40 HI 800 189 E Rev. 1.01... -

Page 15: Led Indicators

CPU 01 3 Product Description 3.4.3 LED Indicators The light-emitting diodes (LEDs) indicate the operating state of the device. The LEDs are classified as follows: System LEDs Program LEDs Communication LEDs Fieldbus LEDs 3.4.3.1 System Light Emitting Diodes While the system is being booted, all LEDs are lit simultaneously. Color Status Description... -

Page 16: Program Light Emitting Diodes

3 Product Description CPU 01 3.4.3.2 Program Light Emitting Diodes While the system is being booted, all LEDs are lit simultaneously. Color Status Description Green The controller is in the RUN state. The user program is in the RUN or FREEZE state. The controller is not in the RUN state. -

Page 17: Communication Indicators

CPU 01 3 Product Description 3.4.3.3 Communication Indicators Safe communication via safeethernet is signaled by 2 small LEDs integrated in all RJ-45 connectors: Color Status Description Green Full duplex operation Blinking Collision Half duplex operation, no collision Yellow Connection available Blinking Interface activity Table 7:... -

Page 18: Communication

3 Product Description CPU 01 3.4.6 Communication The Ethernet interfaces and fieldbus interfaces of the CPU 01 module are used to communicate with external systems. Each individual Ethernet interface can simultaneously process several protocols. When configuring safety-related communication, observe the instructions specified in the Communication Manual (for SILworX) or the Safety Manual (ELOP II Factory). -

Page 19: Connections For Fieldbus Communication

CPU 01 3 Product Description TCP ports Modbus (can be modified by the user) TCP SR assigned by the user 44818 Ethernet/IP Explicit Messaging Services Table 11: Network Ports (TCP Ports) in Use 3.4.6.3 Connections for Fieldbus Communication The 2 9-pole D-sub connectors can be accessed through the front plate of the module. Designation Hardware/ Fieldbus Protocols... -

Page 20: Pin Assignment Of D-Sub Connectors Fb1 And Fb2

3 Product Description CPU 01 Connection Signal Function - - - - - - 5 V decoupled with diodes RxD/TxD-A Receive/send data A CNTR-A Control signal A DGND Data reference potential 5 V, plus pole supply voltage - - - - - - RxD/TxD-B Receive/send data B... -

Page 21: Reset Key

CPU 01 3 Product Description Connection Signal Function Positive data output Positive data input Common 0 V line - - - - - - - - - - - - Negative data input Negative data output - - - - - - - - - - - - Table 17: Pin Assignment of the D-sub Connectors FB1 and FB2 for INTERBUS... -

Page 22: Product Data

3 Product Description CPU 01 Voltage level Reaction of the CPU 18...28.8 V No reaction < 18.0 V Alarm state (the internal variables are written to) < 13.0 V Shutdown Table 18: Operating Voltage Monitoring The alarm can be evaluated with a PADT loaded with a programming tool, using the Power Supply State system parameter. -

Page 23: Certified Himatrix F60 Cpu 01

CPU 01 3 Product Description Certified HIMatrix F60 CPU 01 HIMatrix F60 CPU 01 EMC, ATEX Zone 2 TÜV IEC 61508 1-7:2000 up to SIL 3 IEC 61511:2004 EN 954-1:1996 up to Cat. 4 TÜV ATEX 94/9/EG EN 1127-1 EN 61508 UL Underwriters ANSI/UL 508, NFPA 70 –... -

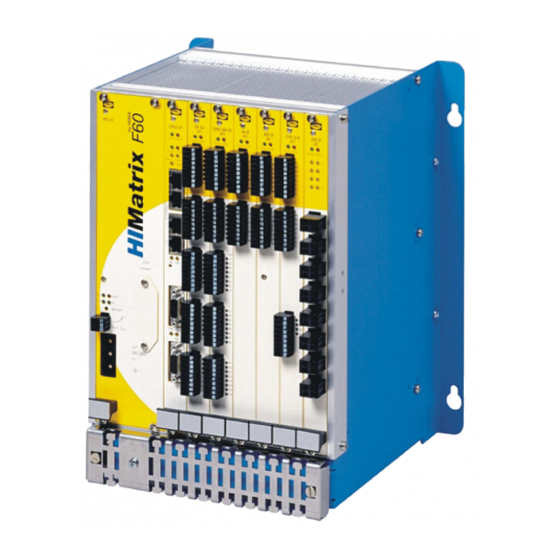

Page 24: Start-Up

4 Start-Up CPU 01 Start-Up To start up the controller, it must be mounted, connected and configured in the programming tool. Installation and Mounting The module is mounted in the subrack of the modular HIMatrix F60 system. 4.1.1 Mounting and Removing the Modules To mount and remove the modules, the connection cable clamp terminals must be unplugged. -

Page 25: Mounting The Cpu 01 In Zone 2

Mounting the CPU 01 in Zone 2 (EC Directive 94/9/EC, ATEX) The device is suitable for mounting in zone 2. Refer to the corresponding declaration of conformity available on the HIMA website. When mounting the device, observe the special conditions specified in the following section. -

Page 26: Configuration

4 Start-Up CPU 01 Configuration The CPU 01 module can be configured using a programming tool, SILworX or ELOP II Factory. Which programming tool should be used depends on the revision status of the operating system (firmware): ELOP II Factory is required for operating system versions prior to 7. SILworX is required for operating system version 7 and beyond. -

Page 27: Configuring A Module Using Elop Ii Factory

CPU 01 4 Start-Up Configuring a Module Using ELOP II Factory The first step is to configure the CPU, refer to the System Manual for the Modular F60 System. Refer to the Safety Manual for the HIMatrix system for more details on how to configure the CPU for safety-related operation. -

Page 28: Operation

5 Operation CPU 01 Operation The module runs within a HIMatrix subrack and does not require any specific monitoring. Handling Handling of the controller during operation is not required. Diagnosis A first diagnosis results from evaluating the LEDs, see Chapter 3.4.3. The device's diagnostic history can also be read using the programming tool. -

Page 29: Maintenance

CPU 01 6 Maintenance Maintenance No maintenance measures are required during normal operation. If a device or module fails, it must be replaced with a faultless device or module of the same type or with an approved replacement model. Only the manufacturer is authorized to repair the device/module. Faults 6.1.1 Operating System Version 6.42 and Beyond... -

Page 30: Maintenance Measures

6.2.1 Loading the Operating System HIMA is continuously improving the operating system of the devices. HIMA recommends to use system downtimes to load a current version of the operating system into the devices. Refer to the release list to check the consequences of the new operation system version on the system! Load the operating system using the programming tool. -

Page 31: Decommissioning

CPU 01 7 Decommissioning Decommissioning Remove the supply voltage to decommission the module. Afterwards pull out the pluggable screw terminal connector blocks for inputs and outputs and the Ethernet cables. HI 800 189 E Rev. 1.01 Page 31 of 40... -

Page 32: Transport

8 Transport CPU 01 Transport To avoid mechanical damage, HIMatrix components must be transported in packaging. Always store HIMatrix components in their original product packaging. This packaging also provides protection against electrostatic discharge. Note that the product packaging alone is not suitable for transmission. Page 32 of 40 HI 800 189 E Rev. -

Page 33: Disposal

9 Disposal Disposal Industrial customers are responsible for correctly disposing of decommissioned HIMatrix hardware. Upon request, a disposal agreement can be arranged with HIMA. All materials must be disposed of in an ecologically sound manner. HI 800 189 E Rev. 1.01... - Page 34 9 Disposal CPU 01 Page 34 of 40 HI 800 189 E Rev. 1.01...

-

Page 35: Appendix

CPU 01 Appendix Appendix Glossary Term Description Address Resolution Protocol: Network protocol for assigning the network addresses to hardware addresses Analog Input COMmunication module Cyclic Redundancy Check Digital Input Digital Output ELOP II Factory Programming tool for HIMatrix systems ElectroMagnetic Compatibility European Norm ElectroStatic Discharge FieldBus... -

Page 36: Index Of Figures

Appendix CPU 01 Index of Figures Figure 1: Sample Type Label Figure 2: Block Diagram Figure 3: Front View of CPU 01 Figure 4: Label for Ex Conditions Page 36 of 40 HI 800 189 E Rev. 1.01... -

Page 37: Index Of Tables

CPU 01 Appendix Index of Tables Table 1: HIMatrix System Variants Table 2: Additional Relevant Documents Table 3: Environmental Requirements Table 4: Part Numbers Table 5: System Light Emitting Diodes Table 6: Indicator Program Light Emitting Diodes Table 7: Indicators for safeethernet Communication Table 8: Indicators for Fieldbus Communication Table 9:... -

Page 38: Index

Appendix CPU 01 Index diagnosis..........28 specifications ........... 22 part numbers..........11 SRS ............11 reset key ..........21 Page 38 of 40 HI 800 189 E Rev. 1.01... - Page 40 HIMA Paul Hildebrandt GmbH + Co KG P.O. Box 1261 68777 Brühl, Germany Tel: +49 6202 709-0 Fax: +49 6202 709-107 E-mail: info@hima.com Internet: www.hima.com (1025)

Need help?

Do you have a question about the HIMatrix F60 CPU 01 and is the answer not in the manual?

Questions and answers