Festo VTEM Description, Function, Parameterisation

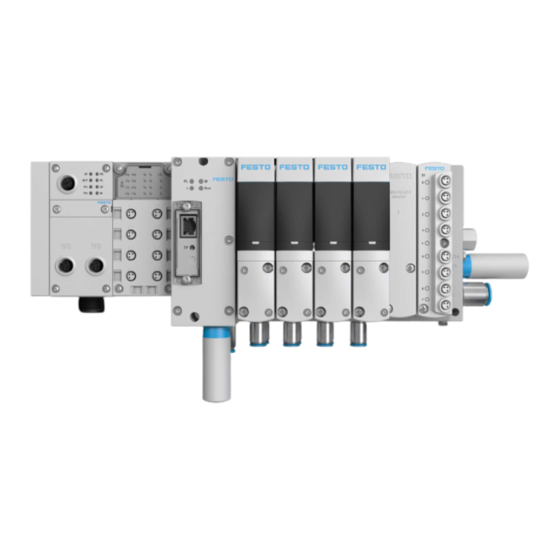

Motion terminal

Hide thumbs

Also See for VTEM:

- Manual (106 pages) ,

- Original instructions manual (64 pages) ,

- Description (12 pages)

Summary of Contents for Festo VTEM

- Page 1 VTEM Motion Terminal Description | Function, Parameterisation 8102588 8102588 2019-03b [8102590]...

- Page 2 ® ® ® ® POWERLINK , FIREFOX , INTERNET EXPLORER , MICROSOFT EDGE , MODBUS , PI PROFIBUS ® ® PROFINET , Sercos III are registered trademarks of the respective trademark owners in certain coun- tries. Festo — VTEM — 2019-03b...

-

Page 3: Table Of Contents

Behaviour during import..................22 Motion Apps......................... 23 2.4.1 Motion App ID......................23 2.4.2 Licences........................23 2.4.3 Parameter....................... 23 2.4.3.1 System parameters....................24 2.4.3.2 Application parameters...................29 2.4.3.3 Tuning parameter....................30 2.4.3.4 Sensor parameters....................30 2.4.3.5 Teach-in data......................31 Festo — VTEM — 2019-03b... - Page 4 Actual value 1 and 2 (actual value 1, actual value 2)..........72 Teach-in run........................73 2.7.1 Prerequisites for starting the teach-in run.............. 73 2.7.2 Default values......................73 2.7.2.1 Selection of the teach-in run mode................ 73 2.7.2.2 Controlling the manual teach-in run............... 74 2.7.3 Return values......................75 Festo — VTEM — 2019-03b...

- Page 5 Diagnostics channel in transfer mode..............81 2.8.3.1 Errors and warnings....................81 2.8.3.2 Structure of the malfunction message..............82 2.8.3.3 Structure of the VTEM diagnostic memory.............. 83 2.8.3.4 Behaviour when an error occurs................84 2.8.3.5 Readout of a malfunction list.................. 84 2.8.3.6 Acknowledging errors.....................

- Page 6 4.1.3 Approvals....................... 101 4.1.4 Input modules......................101 Supported peripherals....................102 Supported CPX bus nodes..................... 102 List of supported drives....................102 Licences........................103 Festo — VTEM — 2019-03b...

-

Page 7: About This Document

Application Note Malfunction codes VTEM Tables with all application-relevant malfunction codes www.festo.com/sp VTEM Expert knowledge è è è Application Note Supported drives VTEM List of all drives released for the Festo Motion Termin- al (VTEM) www.festo.com/sp VTEM Expert è è è knowledge. -

Page 8: Product Version

The product version can be identified from the product labelling or with the help of appropriate soft- ware from Festo. Appropriate software for determining the product version can be found in the Festo Support Portal è www.festo.com/sp. Information on using the software can be found in the integrated Help function. -

Page 9: Product Labelling

Motion Terminal (è 1, 4). Scanning the Data Matrix Code with an appropriate device opens the Festo Support Portal with information appropriate for the product. Alternatively, the Product Key (11-digit alphanumeric code on the product labelling) can be entered in the search field of the Support Portal. - Page 10 C: Normally closed 6 Data Matrix Code 7 Revision 8 Serial number Fig. 4 Label on valve Label on controller 1 Serial number 2 Order code 3 Product key 4 Data Matrix Code Fig. 5 Festo — VTEM — 2019-03b...

-

Page 11: Function

Function General The Motion Terminal VTEM provides a range of pneumatic open-loop and closed-loop control func- tions that are executed in the form of Motion apps (MA). Parameters and setpoint values for executing a Motion App can be specified. The Motion App converts these specifications into control commands at the corresponding valve. -

Page 12: Motion Terminal Controller Ctmm-S1-C

The terminal CPX and the CPX module CTMM-S1-C can be parameterised with the operator unit (CPX- MMI), the Festo Maintenance Tool (CPX-FMT) software or the higher-level system. Further information about parameterisation of the CPX system and its modules can be found in the description of the CPX terminal (è... - Page 13 – Error message at the CPX field bus nodes – Malfunction message in the VTEM diagnostic memory Both types of monitoring can also be activated respectively for the entire CPX terminal. For details, see system description of the CPX terminal 1.1 Applicable documents).

-

Page 14: Manifold Rail

Required specifications è 2.4.3.4 Sensor parameters: – Sensor type – Sensor orientation (for position sensors on the analogue input module CTMM-S1-A-...) 2.1.1.6 Cover plate VABBP1127T Vacant valve or module positions must be sealed with a cover plate. Festo — VTEM — 2019-03b... -

Page 15: Valves

0. The number (address) of a valve is given by the slot on which it is mounted. 2.1.2 Display components For behaviour of display components and diagnostics options see è 2.8.1 LED display components. 2.1.2.1 Controller 1 CPX-specific LEDs 2 Ethernet-specific LED Fig. 9 LED displays on the controller Festo — VTEM — 2019-03b... -

Page 16: Valve

Ethernet connection/data traffic (gree- Link/Traffic Tab. 6 Ethernet-specific LED 2.1.2.2 Valve 1 LED display on valve (red/blue) Fig. 10 LED display on valve Meaning (red) Valve error (blue) Operation/update Tab. 7 LED display on valve Festo — VTEM — 2019-03b... -

Page 17: Input Modules

Ethernet connection to the controller of the Motion Terminal (è 2.3 WebConfig user interface). 2.1.4 Connecting components 2.1.4.1 Electrical Functional earth connection Connect the earth terminal with low impedance to the earth potential. 1 Functional earth connection Fig. 12 Functional earth connection Festo — VTEM — 2019-03b... - Page 18 For additional information è Guidelines and standards for security in information technology, e. g. IEC 62443, ISO/IEC 27001. Input modules CTMM...D... CTMM...A... +24 V U +24 V U 0 V U Input Input 0 V U n. c. Tab. 9 Festo — VTEM — 2019-03b...

-

Page 19: Pneumatic

More information can be found in Specialist knowledge è www.festo.com/sp. For an operating pressure of under 3 bar, the negative pressure monitoring must be deactivated via the corresponding CPX module parameters (è... -

Page 20: Definition Of The Direction Of Movement/Position Of The Drive

Firmware design: è Tab. 2 Product version. An update of the device to a new Firmware design is carried out with the aid of the Festo Field Device Tool (FFT) (see Quick Guide for the Motion Terminal VTEM è 1.1 Applicable documents). The device will subsequently function in accordance with the factory settings. -

Page 21: Manual Override

Subnet address: 255.255.0.0 • Password for activating edit mode: vtem The password can be changed via the WebConfig interface. Operation of the WebConfig interface is described in the “Motion Terminal VTEM, WebConfig interface” Quick Guide è www.festo.com/sp. 2.3.1 Manual override To enable testing of the functionality of a connected drive, the WebConfig interface has a "manual override"... -

Page 22: Behaviour During Export

– Transferring input module parameterisation data between device variants of different length (e. g. from 4+2 to 8+2, from 8+2 to 4+2, from 4+2 to 2+1, ...) is not possible. Festo — VTEM — 2019-03b... -

Page 23: Motion Apps

Motion App #01 “Directional control valve functions”, which is part of the basic equipment of the Motion Terminal, is described in this document: è 2.6 Motion App #01: Directional control valve functions. Additional Motion apps are each described in separate documentation è www.festo.com/sp. 2.4.1 Motion App ID Each Motion App has a unique ID. -

Page 24: System Parameters

Function Information on adding to your available licences can be found in the Festo catalogue è www.festo.com/sp. 2.4.3 Parameter The basic conditions for operating a Motion App are set using system and app-specific parameters. There is a distinction here between 4 types of parameters: –... - Page 25 … … Tab. 14 Tube length at (4) Tube internal diameter at (2) Value range Digit value Digit range 2 11 mm 1 mm 200 1100 × 0.01 mm … … Tab. 15 Tube internal diameter at (2) Festo — VTEM — 2019-03b...

- Page 26 Drive type The Festo drives supported by the Motion Terminal are shown in a list. The list contains a value for the “drive type” parameter for each drive. The default value must be replaced with the value of the con- nected drive type before using a corresponding Motion App.

- Page 27 (4) pressurised, port (2) exhausted, switching position 14). The specified value for the mounting position relates to the position of the plane on which the load is moved, and therefore differs depending on the selected drive è Tab. 18 Drive type. Festo — VTEM — 2019-03b...

- Page 28 Value range [20 27] or [40 47] and [50 57] or [80 87] and [90 97] … … … … … 1) dependent on valve and linkage Tab. 25 Sensor input for end position sensing, advanced Festo — VTEM — 2019-03b...

-

Page 29: Application Parameters

(è 2.4.3.6 Parameter sets). This means that, for example, the “mass during retracting” can be defined differently for different Motion Apps on the same valve. Not all Motion Apps use application parameters. The parameters required to run a Motion App must be transferred before starting the Motion App. Festo — VTEM — 2019-03b... -

Page 30: Tuning Parameter

Sensor parameters The properties of the sensors connected to the inputs of the input modules are defined using the fol- lowing parameters. The reading and writing of the sensor parameters takes place via a dedicated Festo — VTEM — 2019-03b... -

Page 31: Teach-In Data

App can be found in the description of the respective Motion App. There is also an option for transferring teach-in data and the related parameters to another Motion Terminal by exporting this data to a configuration file (è 2.3.3 Export/import of parameterisation and settings). Festo — VTEM — 2019-03b... -

Page 32: Setpoint And Actual Values

Tab. 32 Setpoint and actual values The setpoint and actual values are specific to the individual Motion Apps. The structure of the process data is described in section (è 2.5 Communication between PLC and Motion Terminal). Festo — VTEM — 2019-03b... -

Page 33: Communication Between Plc And Motion Terminal

– Reading of system data and measurement values (è 2.5.4.2 Information on the status of the Motion Terminal (information channel)). – Reading of diagnostic information and acknowledging errors (è 2.8.3 Diagnostics channel in transfer mode). Festo — VTEM — 2019-03b... -

Page 34: Structure Of The Output Data (Pdo)

This section is allocated the same function in every operating mode and is of central importance for the control of the Motion Terminal. Allocation of the other sections depends on the current operating mode of the valve. Festo — VTEM — 2019-03b... - Page 35 Setpoint values for executing a Motion App are specified using the bytes 5 … 4 (PDO) (setpoint value 2) and 3 … 2 (PDO) (setpoint value 1). The exact function is specific to the Motion App and can be found in the description of the Motion App. Festo — VTEM — 2019-03b...

-

Page 36: Structure Of The Input Data (Pdi)

2.5.3.5 Feedback in the case of invalid output data. è Reserved Not used. Feedback for command "62" (acknowledge error) is "61" (valve inactive). Transfer mode active 2.5.4 Transfer mode è Tab. 38 Operating mode of the valve Festo — VTEM — 2019-03b... - Page 37 The active Motion App is reporting a warning that is present in the diagnostic memory of the Motion Terminal. Tab. 40 Indicating warnings For how to deal with warnings and errors (è 2.8 Diagnostics options). Festo — VTEM — 2019-03b...

-

Page 38: Running A Motion App

Value 4000 5000 0 0 0 0 1 1 1 1 1 1 0 0 0 0 1 0 Tab. 41 Assignment of the output data (PDO) for sample operation of the Motion App #02 Festo — VTEM — 2019-03b... -

Page 39: Controlling A Motion App

Status of the Motion App (app state): è Tab. 44 Information on invalid output data – Actual value 1 (actual value 1): (PDI byte 3 … 2 => current pressure [mbar] at port (2)) – Actual value 2 (actual value 2): (PDI byte 5 … 4 => current pressure [mbar] at port (4)) Festo — VTEM — 2019-03b... -

Page 40: Transfer Mode

Motion App. licence file invalid Licence file is invalid. no valve detected No valve detected on the valve slot addressed. valve self calibration running Valve self-calibration process in operation. Tab. 44 Information on invalid output data Festo — VTEM — 2019-03b... -

Page 41: Structure Of The Process Data In Transfer Mode

Tab. 46 Detailed view of the "Command" section of the output data (PDO) Byte 0 The valve is set to transfer mode using the valve mode (valve mode, PDO byte 0, Bits 5 … 0) with value "63". The bits 7 … 6 in byte 0 (PDO) are ignored in transfer mode. Festo — VTEM — 2019-03b... - Page 42 Tab. 52 Meaning of the indices è per addressed target and channel) 1) Values that are not listed are reserved and cannot be used. Tab. 47 Available channels More information on the parameter sets: (è 2.4.3.6 Parameter sets). Festo — VTEM — 2019-03b...

- Page 43 Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 index addressed target Tab. 50 Detailed view of the "Parameters" section of the output data (PDO) Festo — VTEM — 2019-03b...

- Page 44 Temperatures Proximity signals (via digital sensors on input module) Positions (via analogue sensors on input module) – – addressed target is not used in this channel Tab. 51 Meaning of the addressed targets per channel Festo — VTEM — 2019-03b...

- Page 45 Position of the most recent diagnostic message of type “error” Position of the earliest diagnostic message of type “error” Number of diagnostic messages in the diagnostic memory Tab. 52 Meaning of the indices per addressed target and channel Festo — VTEM — 2019-03b...

- Page 46 Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 index addressed target Tab. 55 Detailed view of the "Parameters" section of the input data (PDI) Festo — VTEM — 2019-03b...

-

Page 47: Information On The Status Of The Motion Terminal (Information Channel)

Hardware revision valve 2 Hardware revision valve 3 Hardware revision valve 4 Hardware revision valve 5 Hardware revision valve 6 Hardware revision valve 7 Hardware revision input module 1 Hardware revision input module 2 Tab. 56 Hardware information Festo — VTEM — 2019-03b... - Page 48 Firmware version valve 3, major number Firmware version valve 3, minor number Firmware version valve 3, patch number Bootloader version valve 3, major number Bootloader version valve 3, minor number Bootloader version valve 3, patch number Festo — VTEM — 2019-03b...

- Page 49 Firmware version input module 1, minor number Firmware version input module 1, patch number Bootloader version input module 1, major number Bootloader version input module 1, minor number Bootloader version input module 1, patch number Festo — VTEM — 2019-03b...

- Page 50 Firmware version input module 2, minor number Firmware version input module 2, patch number Bootloader version input module 2, major number Bootloader version input module 2, minor number Bootloader version input module 2, patch number Tab. 57 Software information Festo — VTEM — 2019-03b...

- Page 51 Pressure at valve 5, air port (2) (absolute) 0.001 bar Pressure at valve 5, air port (2) (relative) 0.001 bar Pressure at valve 5, air port (4) (absolute) 0.001 bar Pressure at valve 5, air port (4) (relative) 0.001 bar Pressure at valve 6, air port (2) (absolute) 0.001 bar Festo — VTEM — 2019-03b...

- Page 52 Pressure at valve 6, air port (4) (relative) 0.001 bar Pressure at valve 7, air port (2) (absolute) 0.001 bar Pressure at valve 7, air port (2) (relative) 0.001 bar Pressure at valve 7, air port (4) (absolute) 0.001 bar Pressure at valve 7, air port (4) (relative) 0.001 bar Tab. 58 Pressure values Festo — VTEM — 2019-03b...

- Page 53 Temperature at valve 6, air port (2) 0.1 °C Temperature at valve 6, air port (4) 0.1 °C Temperature at valve 7, air port (2) 0.1 °C Temperature at valve 7, air port (4) 0.1 °C Tab. 59 Temperatures Festo — VTEM — 2019-03b...

- Page 54 Interpreted value from proximity sensor at input module 1, port 6 Raw value from proximity sensor at input module 1, port 7 Interpreted value from proximity sensor at input module 1, port 7 Raw value from proximity sensor at input module 2, port 0 Festo — VTEM — 2019-03b...

- Page 55 Raw value from proximity sensor at input module 2, port 6 Interpreted value from proximity sensor at input module 2, port 6 Raw value from proximity sensor at input module 2, port 7 Interpreted value from proximity sensor at input module 2, port 7 Tab. 60 Proximity signals Festo — VTEM — 2019-03b...

- Page 56 Interpreted value from position sensor at input mod- 0.1 mm ule 1, port 6 Raw value from position sensor at input module 1, 0.001 mA port 7 Interpreted value from position sensor at input mod- 0.1 mm ule 1, port 7 Raw value from position sensor at input module 2, 0.001 mA port 0 Festo — VTEM — 2019-03b...

- Page 57 Interpreted value from position sensor at input mod- 0.1 mm ule 2, port 6 Raw value from position sensor at input module 2, 0.001 mA port 7 Interpreted value from position sensor at input mod- 0.1 mm ule 2, port 7 Tab. 61 Positions Festo — VTEM — 2019-03b...

-

Page 58: Feedback In The Case Of Invalid Output Data

Invalid value in section "value" invalid combination Invalid combination of values in various sections access denied, data in use The addressed data is currently being used by another valve Tab. 62 Assigning invalid information Festo — VTEM — 2019-03b... -

Page 59: Saving Settings As Persistent Data

Motion Terminal. Otherwise, the teach-in run must be executed again after restarting the Motion Terminal (è 2.7.6 Validity of teach-in data based on parameter changes). Festo — VTEM — 2019-03b... - Page 60 Save process is completed. saving not possible Save process cannot be executed. – Repeat the process. – If the problem persists, contact Festo Support. saving failed Save process failed. – Repeat the process. – If the problem persists, contact Festo Support.

- Page 61 Value Bit 9 Bit 8 Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 value … (ignored) Tab. 65 Content of output data for saving as persistent data Festo — VTEM — 2019-03b...

- Page 62 Bit 9 Bit 8 Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 value = 2 (saving successful) Tab. 66 Content of input data if save process is successful Festo — VTEM — 2019-03b...

-

Page 63: Motion App #01: Directional Control Valve Functions

(è 2.6.6.1 Status of the Motion App (app state)), the assignment of sensor inputs to the Motion App (to the valve) must be carried out via the WebConfig interface or using the higher-order controller (è 2.6.3 System parameters used). Festo — VTEM — 2019-03b... -

Page 64: System Parameters Used

(valve terminal with 4 valve slots and 2 slots for input modules) 80 87 and 90 97 … … (valve terminal with 8 valve slots and 2 slots for input modules) Tab. 69 Sensor input for end position sensing, retracted Festo — VTEM — 2019-03b... -

Page 65: Application Parameters Used

Operation in compatibility mode for a fast change between Motion Apps. Higher internal air con- sumption, but no waiting time when changing to other Motion Apps. Selected operating mode Value of parameter Controlled 0 (standard setting) Regulated Tab. 71 Operating mode Festo — VTEM — 2019-03b... -

Page 66: Default Values

The switching status at the air ports (2) and (4) of the valve is controlled using bits 7 … 6 in byte 0 (PDO) and is dependent on the valve type defined. Possible switching statuses: – Closed (G) – Pressurised (B) – Exhausted (E) Festo — VTEM — 2019-03b... - Page 67 1) The symbol in this column replaces the full bridge in the circuit diagram for the valve VEVM and therefore represents the function in the switched status of the valve with corresponding setpoint value (right columns). Tab. 74 Valve type 4/3 B Festo — VTEM — 2019-03b...

- Page 68 1) The symbol in this column replaces the full bridge in the circuit diagram for the valve VEVM and therefore represents the function in the switched status of the valve with corresponding setpoint value (right columns). Tab. 76 Valve type 2 × 3/2 O Festo — VTEM — 2019-03b...

- Page 69 1) The symbol in this column replaces the full bridge in the circuit diagram for the valve VEVM and therefore represents the function in the switched status of the valve with corresponding setpoint value (right columns). Tab. 78 Valve type 3/2 O + 3/2 G Festo — VTEM — 2019-03b...

- Page 70 1) The symbol in this column replaces the full bridge in the circuit diagram for the valve VEVM and therefore represents the function in the switched status of the valve with corresponding setpoint value (right columns). Tab. 80 Valve type 2 × 2/2 G Festo — VTEM — 2019-03b...

-

Page 71: Setpoint Value 1 And 2 (Setpoint Value 1, Setpoint Value 2)

Switching position at the air ports (2) and (4) The switching position at the air ports (2) and (4) of the valve is given by bits 6 … 5 (4) and bits 4 … 3 (2) in byte 1 (PDI). Festo — VTEM — 2019-03b... -

Page 72: Actual Value 1 And 2 (Actual Value 1, Actual Value 2)

Exhausted – – – Error 1) If the problem persists, contact Festo Support. Tab. 83 Switching position at the air ports Warnings Warnings in the diagnostic memory of the valve are shown via bit 7 in byte 1 (PDI). Value Description There are no warnings from the active Motion App. -

Page 73: Teach-In Run

After defining the application parameter 255, you must exit transfer mode. The valve can now be switched to the “teach-in run” mode (60). 2.7.2 Default values 2.7.2.1 Selection of the teachin run mode The teach-in run mode (automatic/manual) is specified using bits 7 ... 6 in byte 0 (PDO). Festo — VTEM — 2019-03b... -

Page 74: Controlling The Manual Teach-In Run

1) The symbol in this column replaces the full bridge in the circuit diagram for the valve VEVM and therefore represents the function in the switched status of the valve with corresponding setpoint value (right columns). Tab. 87 Controlling the manual teach-in run Festo — VTEM — 2019-03b... -

Page 75: Return Values

(2) and (4) are pressurised. A connected drive will move during this step. The teach-in run status then changes to the value "14" (completed) (è 2.7.3.2 Status of teach-in run). Festo — VTEM — 2019-03b... -

Page 76: Manual Teach-In Run

When this option is activated, it is crucial that the user ensures that the actuated parameter changes in combination with the existing teach-in data cannot lead to undesired behaviour of the drive. Festo — VTEM — 2019-03b... -

Page 77: Diagnostics Options

2.8.1 LED display components 2.8.1.1 Controller LED PL (green) Meaning Measure – Voltage is present. No error. Voltage is not present. Check connection of the power sup- ply. Tab. 91 LED display PL (Power Load) Festo — VTEM — 2019-03b... - Page 78 Access to WebConfig interface is not Read and remedy error via PLC, CPX- possible or only conditionally. FMT or FFT. Switch on operating supply voltage off and back on. EL/SEN Tab. 94 LED display SF (System Failure) Festo — VTEM — 2019-03b...

-

Page 79: Valve

Valve has no power supply. If the power supply of the terminal is switched on, switch off power sup- ply and check valve to ensure it is seated properly. Tab. 96 LED indicator valve status Festo — VTEM — 2019-03b... -

Page 80: Analogue Input Module

Switch on operating supply voltage off and back on. Tab. 98 LED display module error, digital LED (green) Meaning Measure – Logic 1 (signal is present). – Logic 0 (signal not present). Tab. 99 LED display input status, digital Festo — VTEM — 2019-03b... -

Page 81: Diagnostic Interface

By means of the transfer mode, the Motion Terminal provides diagnostic information which, independ- ent of the CPX error number, enables more precise analysis of the cause of the malfunction. 2.8.3.1 Errors and warnings The Motion Terminal distinguishes between 2 classes of malfunction: – Error – Warning Festo — VTEM — 2019-03b... -

Page 82: Structure Of The Malfunction Message

A list of malfunction codes with a description of the possible cause and appropriate remedial meas- ures can be found in the application note "Malfunction Code VTEM" (è 1.1 Applicable documents). Malfunction subcodes that can be used by the user to remedy errors are given here also. -

Page 83: Structure Of The Vtem Diagnostic Memory

Tab. 102 Classification of malfunction 2.8.3.3 Structure of the VTEM diagnostic memory The diagnostic memory of the Motion Terminal consists of several malfunction lists that each refer to a valve slot and can be read out in transfer mode via the process data section. Malfunctions that only affect one of the valves are entered in their malfunction list;... -

Page 84: Behaviour When An Error Occurs

Addressing of data transfer (addressed target): 0 (PDO byte 2 => 0) – Index (index): position of the malfunction list with the value that is to be read out (è Example of a malfunction list). (PDO byte 3 => 1 … 40, 253 … 255) Festo — VTEM — 2019-03b... - Page 85 If inactive errors are acknowledged via the WebConfig interface, while the transfer mode channel 31 is active on the PLC side the display on the WebConfig interface will differ from the data that are received from the PLC. Festo — VTEM — 2019-03b...

-

Page 86: Acknowledging Errors

3. Set operating mode of valve (valve mode, PDO byte 0, bits 5 … 0) to the value "62" ("acknow- ledge error"). Status of the valve changes to "ready" (value 1). Acknowledgement deletes all entries in the malfunction list for this valve slot. Festo — VTEM — 2019-03b... -

Page 87: Parameterisation

Parameterisation In this chapter, parameterisation refers to the transfer of system, application and tuning parameters from the higher-order controller (PLC) to the Motion Terminal VTEM. The transfer mode of the Motion Terminal is used to transfer the parameter values (è 2.5.4 Transfer mode). -

Page 88: Sequence

If a system parameter is outside the valid value range for a Motion App to be started because it was set for another Motion App or with addressed target = 0, an error is reported when an attempt is made to start the Motion App. Festo — VTEM — 2019-03b... -

Page 89: Reading Out System, Application And Tuning Parameters

The values of system, application and tuning parameters are read out using the transfer mode (è 2.5.4 Transfer mode). 3.2.1 Requirements – The Motion Terminal boot procedure is completed. – There are no Motion Apps currently running on the valve in question (valve state ≠ "2" (running)). Festo — VTEM — 2019-03b... -

Page 90: Sequence

60 for reading out parameters for the teach-in run (è 2.7.1 Prerequisites for starting the teach-in run) – Index (index): ID of the parameter with the value that is to be read out (PDO byte 3 => … 255 The "Value" section is ignored. Festo — VTEM — 2019-03b... - Page 91 Bit 9 Bit 8 Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 value = … (ignored) Tab. 108 Example of reading out the application parameter "Travel time, advancing" Festo — VTEM — 2019-03b...

-

Page 92: Setting Sensor Parameters

Sensor parameters are set using the transfer mode (è 2.5.4 Transfer mode). 3.3.1 Requirements – The Motion Terminal boot procedure is completed. – There are no Motion Apps running on any of the valves (valve state ≠ "2" (running)). Festo — VTEM — 2019-03b... -

Page 93: Sequence

Addressing of data transfer (addressed target): 1 … 2 (number of input module) (PDO byte 2 => … 2 – Index (index): ID of the sensor parameter to be set (PDO byte 3 => 1 … 212 – Value (value): value to be written to the parameter (PDO bytes 5 … 4) (è Tab. 30 Sensor parameters). Festo — VTEM — 2019-03b... - Page 94 = 2003 (SDAP-MHS-M160-...) Tab. 110 Example of setting the sensor parameter "sensor type" The values are displayed in the corresponding sections of the input data (PDI) for confirmation (è Tab. 53 Structure of the input data (PDI)). Festo — VTEM — 2019-03b...

-

Page 95: Save Parameterisation As Persistent Data

Transfer control (transfer control): 1 (download) (PDO byte 1, bits 7 … 5 => 001 – Addressing of data transfer (addressed target): 0 (PDO byte 2 => 0) – Index (index): 1 (PDO byte 3 => 1) - – Value (value): number of the parameter set that should be actively switched (PDO bytes 5 … 4) Festo — VTEM — 2019-03b... -

Page 96: Example

Bit 9 Bit 8 Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 value = 4 Tab. 111 Example of output data for changing the active parameter set Festo — VTEM — 2019-03b... - Page 97 Tab. 112 Example of input data with selected parameter set Once the active parameter set has been changed, its parameterisation and teach-in data will be provided for the operation of every Motion App subsequently started. Festo — VTEM — 2019-03b...

-

Page 98: Technical Appendix

Switching time off [ms] C value [l/s*bar] 2 Standard nominal flow rate [l/min] Pressurisation (6 bar against 5 bar) Standard nominal flow rate [l/min] Exhausting (6 bar against 5 bar) Flow direction Non-reversible Tab. 113 Characteristic valve values Festo — VTEM — 2019-03b... - Page 99 IP65 (fully mounted and unused connections sealed) Relative humidity 0 90 … Vibration and shock resistance Assembly instructions CPX-VTEM è 1) Degree of protection IP65 is not ensured when using the Ethernet connection. Tab. 116 Environmental conditions Festo — VTEM — 2019-03b...

-

Page 100: Power Supply

Digital input module (plus own [mA] consumption of the sensors) Functional earth (FE) Via functional earth connection of the CPX terminal and functional earth connection at the VTEM ter- minal strip Tab. 119 Power supply Festo — VTEM — 2019-03b... -

Page 101: Approvals

Signal 0 [V DC] 5 £ Signal 1 [V DC] 11 ³ Tab. 122 Digital input module Analogue input module CTMM…A… Interface M8, 4-pin Behaviour Current input 4 20 mA … Compatible sensors SDAP-MHS-M...-1L-A-E-0.3-M8 Tab. 123 Analogue input module Festo — VTEM — 2019-03b... -

Page 102: Supported Peripherals

List of supported drives è www.festo.com/sp è VTEM è Expert knowledge This list contains all Festo drives approved for the Motion Terminal and the corresponding value that must be entered in the “drive type” system parameter (ID 20) in order to be able to operate the respective drive with a Motion App. -

Page 103: Licences

Public Domain Certification libev https://opensource.org/licenses/BSD-2-Clause – libiniparser https://opensource.org/licenses/MIT libnl LGPL https://www.gnu.org/licenses/lgpl-2.1 libtool https://opensource.org/licenses/BSD-3-Clause linux https://www.gnu.org/licenses/gpl-2.0 – https://opensource.org/licenses/MIT – luafilesystem https://opensource.org/licenses/MIT https://www.gnu.org/licenses/gpl-2.0 mkimage 2.0+ https://www.gnu.org/licenses mtdutils https://www.gnu.org/licenses/gpl-2.0 sysroot LGPL https://www.gnu.org/licenses/lgpl-2.1 – zlib Zlib https://zlib.net/zlib_license.html Tab. 125 Licences Festo — VTEM — 2019-03b... - Page 104 Copyright: Festo AG & Co. KG Ruiter Straße 82 73734 Esslingen Germany Phone: +49 711 347-0 Fax: +49 711 347-2144 Reproduction, distribution or sale of this document or communic- e-mail: ation of its contents to others without express authorization is service_international@festo.com...

Need help?

Do you have a question about the VTEM and is the answer not in the manual?

Questions and answers