Summary of Contents for SteelMax D3X RS

- Page 1 The tools of innovation. OPERATOR’S MANUAL DRILLING MACHINE WITH ELECTROMAGNETIC BASE 15335 E. Fremont Drive, Centennial, CO 80112 1– 87STEELMAX, FAX 303 – 690 – 9172 www.steelmax.com sales@steelmax.com...

-

Page 2: Table Of Contents

4.3. Quick change arbor MT3 x 19 mm Weldon ...............23 4.4. Pipe attachment DMP 501 ..................23 5. WIRING DIAGRAM ......................24 6. D3X RS EXPLODED DRAWINGS AND PARTS LIST ............25 7. DECLARATION OF CONFORMITY .................31 8. QUALITY CERTIFICATE....................32 9. WARRANTY CARD ......................33... -

Page 3: General Information

A safety chain protects the machine from dropping in case of a power loss. The D3X RS has a swivel base and thus is capable to be rotated in a range of ±15° and to be moved out up to 15 mm (0.6’’) without moving the electromagnetic base. - Page 4 D3X RS 312 mm (12.3’’) 412 mm (16.2’’) D3X RS Operator’s Manual...

-

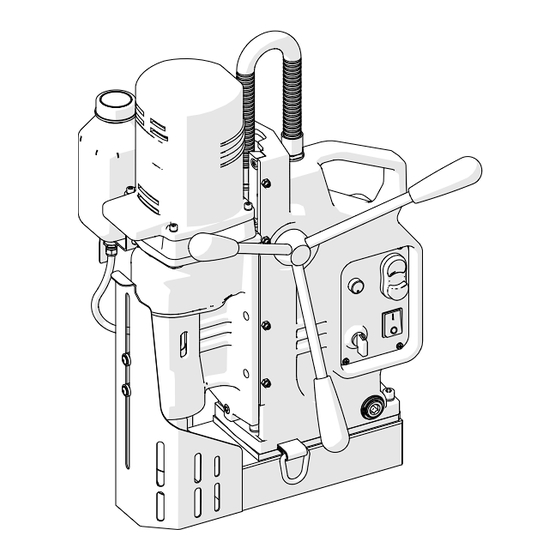

Page 5: Design

Electromagnetic base the swivel base ON/OFF switch Electromagnetic base Swivel base Lug for safety chain Fig. 1. View of the D3X RS 1.4. Equipment included The drilling machine is supplied including the following elements. Drilling machine 1 unit Metal box... -

Page 6: Safety Precautions

Never use arbors without a spring. 18. Never use near flammable liquids or gases, or in explosive environments. 19. Using the machine on surfaces that are rusty, covered with a thick paint layer, uneven, or not rigid is prohibited. D3X RS Operator’s Manual... - Page 7 32. Never leave the machine unattended during operation. 33. Remove from the worksite and store in a secure and dry location when not in use, previously removing the tool from the holder. D3X RS Operator’s Manual...

-

Page 8: Startup And Operation

(drill bit, tap chuck) to the right (4) until it slips into place. Finally, firmly tap the arbor (drill bit, tap chuck) into place using a mallet (5). Fig. 2. Installing the arbor, drill bit, or tap chuck D3X RS Operator’s Manual... - Page 9 3) into the opening above the arbor (drill bit, tap chuck), hold the carrying handle with one hand, and then tap the drift using a mallet (4). Fig. 3. Removing the arbor, drill bit, or tap chuck D3X RS Operator’s Manual...

-

Page 10: Installing, Removing, And Operating The Annular Cutter

4, and then use the 5 mm hex wrench to tighten both set screws. To remove the cutter, loosen the screws 4 using the 5 mm hex wrench. Fig. 4. Installing the annular cutter D3X RS Operator’s Manual... - Page 11 Annular cutters are designed to make only through holes shown in Fig. 6. When drilling incomplete through holes the pilot pin must not be used. Incomplete through holes Complete through holes Fig. 6. Types of holes to make with annular cutters D3X RS Operator’s Manual...

-

Page 12: Installing And Removing The Screw Tap

(tap no. 1) into the proper adapter (1, Fig. 7), and then install the adapter into the tap chuck (2). Install screw taps with a MT3 shank through a MT sleeve. To remove the screw tap, unlock it and remove from the adapter. Fig. 7. Installing the screw tap D3X RS Operator’s Manual... -

Page 13: Installing And Removing The Cooling System

Hang the cooling system bottle on the screws (1, Fig. 8), and then attach the bottle hose to the hose fitting (2). To remove the bottle, proceed in reverse order. Fig. 8. Installing the cooling system D3X RS Operator’s Manual... -

Page 14: Control System Of The Electromagnetic Base Holding Force

D3X RS 3.5. Control system of the electromagnetic base holding force The D3X RS drilling machine incorporates a holding force control system to monitor the clamping of the electromagnetic base to the surface. The force value depends on several factors, such as type, thickness, flatness, and roughness of the surface, presence of paint, rust, or other contaminants, fluctuations of supply voltage, and the wear of the electromagnetic base bottom. - Page 15 The fluid should fill the system and begin flowing from the inside of the cutter. Because the cooling system works by means of gravitation, use a cooling paste when working in horizontal or inverted positions. D3X RS Operator’s Manual...

-

Page 16: Positioning The Machine Precisely

10 mm hex wrench to unlock the eccentric shaft (1, Fig. 10), set the body in desired position, and then lock the shaft (2). 15° 15 mm 15° Fig. 10. Positioning the D3X RS precisely D3X RS Operator’s Manual... -

Page 17: Drilling

In such a case, to restart the machine, press the red MOTOR button, retract the tool from the workpiece, and then press the green MOTOR button (the electromagnetic base must remain powered). D3X RS Operator’s Manual... -

Page 18: Tapping

After the work is finished and the motor is stopped, set the gear II, and then run the machine for a while without load, which will improve lubricity. Next, turn off the motor and the electromagnetic base, and then unplug the machine from the power source. D3X RS Operator’s Manual... -

Page 19: Adjusting The Gib Clearance

Next, use the 4 mm hex wrench to tighten the gib screws: central screw (6), adjacent screws, and then top and bottom screws. Finally, use the 8 mm combination wrench to tighten the nuts (7), while countering the set screws using the 2.5 mm hex wrench (8). D3X RS Operator’s Manual... - Page 20 D3X RS Fig. 11. Adjusting the gib clearance D3X RS Operator’s Manual...

-

Page 21: Replacing The Motor Brushes

(6) and the brush (7). If the length of the brush is less than 5 mm (0.2’’), replace both brushes with new ones. To install brushes, proceed in reverse order. After the replacement, run the motor without load for 20 minutes. Fig. 12. Replacing the brushes D3X RS Operator’s Manual... -

Page 22: Accessories

D3X RS 4. ACCESSORIES 4.1. Pressure cooling system Capacity of 2 liters. Part number: UKL-0440-16-00-00-0 4.2. Arbor MT3 x 32 mm Weldon Required when drilling diameter is more than 60 mm (2.3’’). Part number: UCW-0191-00-00-00-0 D3X RS Operator’s Manual... -

Page 23: Quick Change Arbor Mt3 X 19 Mm Weldon

D3X RS 4.3. Quick change arbor MT3 x 19 mm Weldon Part number: UCW-0285-03-00-02-0 4.4. Pipe attachment DMP 501 Designed for pipes with diameters of 150–500 mm (6–20’’). Part number: PDS-0111-03-00-01-0 D3X RS Operator’s Manual... -

Page 24: Wiring Diagram

D3X RS 5. WIRING DIAGRAM D3X RS Operator’s Manual... -

Page 25: D3X Rs Exploded Drawings And Parts List

D3X RS 6. D3X RS EXPLODED DRAWINGS AND PARTS LIST 12 13 12 13 ITEM PART NUMBER DESCRIPTION Q-TY KLN-0103-00-00-00-0 WEDGE MT3 UCW-0173-00-00-00-0 ARBOR ASSY AMT3-U19/3-3 LNC-0223-00-01-00-0 SAFETY CHAIN 1.5 M (5 FT) UKL-0399-11-00-00-0 COOLING SYSTEM DZW-0400-07-00-00-0 SPOKE HANDLE ASSY... - Page 26 PUSH SPRING WKR-000415 CROSS RECESSED PAN HEAD SELF-TAPPING SCREW 3.5x13 WKR-000150 CROSS RECESSED COUNTERSUNK HEAD SCREW M4x10 WKR-000184 CROSS RECESSED PAN HEAD SCREW M4x12 WKR-000395 HEX SOCKET ROUND HEAD SCREW WITH FLANGE M5x20 PDK-000043 SPRING WASHER 4.1 D3X RS Operator’s Manual...

- Page 27 WZK-0400-03-02-00-0 START-STOP WIRE SET PRC-000007 START-STOP SWITCH WZK-0473-03-04-00-0 LEFT-RIGHT SWITCH WIRE SET DLW-000007 CABLE GLAND WITH STRAIN RELIEF PG11 PDK-000060 EXTERNAL TOOTH LOCK WASHER 4.3 BLO-000023 START-STOP CONTACT BLOCK WKR-000193 CROSS RECESSED PAN HEAD SCREW M4x8 D3X RS Operator’s Manual...

- Page 28 D3X RS 48 11 D3X RS Operator’s Manual...

- Page 29 STATOR – 120V OBD-000024 UPPER HOUSING PRS-000018 INTERNAL RETAINING RING 28w SPR-000042 BRUSH SPRING SCZ-000033 BRUSH – 230V SCZ-000034 BRUSH – 115V WKR-000524 TORX PAN HEAD TAPPING SCREW 4x25 SRB-000286 HEXAGON BOLT M5x76 LOZ-000055 BALL BEARING 8x22x7 D3X RS Operator’s Manual...

- Page 30 INTERNAL RETAINING RING 62w PRS-000077 SEAL 35x55x10 PRS-000081 SEAL 35x56x12 WKR-000450 CROSS RECESSED PAN HEAD SCREW M5x10 LOZ-000034 BALL BEARING 10x26x8 LOZ-000028 BALL BEARING 25x47x12 LOZ-000051 BALL BEARING 35x62x14 – SMR-000001 GREASE LUBRIPLATE BP1 0.48 kg D3X RS Operator’s Manual...

-

Page 31: Declaration Of Conformity

PROMOTECH sp. z o.o. ul. Elewatorska 23/1 15-620 Białystok Poland declare with full responsibility that: D3X RS Drilling Machine with Electromagnetic Base is manufactured in accordance with the following standards: EN 50144-1 • • EN 55014 : 2004/108/EC, 2006/95/EC, 2006/42/EC. -

Page 32: Quality Certificate

D3X RS 8. QUALITY CERTIFICATE Machine control card Drilling Machine with Electromagnetic Base □ D3X RS 115 V □ D3X RS 230 V Serial number ........................ Spindle radial runout ...................... Slide to base travel perpendicularity ................Spindle axis to base perpendicularity ................ -

Page 33: Warranty Card

9. WARRANTY CARD WARRANTY CARD No..............in the name of Manufacturer warrants the D3X RS Drilling Machine with Electromagnetic Base to be free of defects in material and workmanship under normal use for a period of 12 months from the date of sale. - Page 34 21mm 0.8268 SM-AC-21-M-1 SM-AC-21-M-2 22mm 0.8661 SM-AC-22-M-1 SM-AC-22-M-2 23mm 0.9055 SM-AC-23-M-1 SM-AC-23-M-2 24mm 0.9449 SM-AC-24-M-1 SM-AC-24-M-2 25mm 0.9843 SM-AC-25-M-1 SM-AC-25-M-2 26mm 1.0230 SM-AC-26-M-1 SM-AC-26-M-2 28mm 1.1020 SM-AC-28-M-1 SM-AC-28-M-2 29mm 1.1410 SM-AC-29-M-1 SM-AC-29-M-2 31mm 1.2200 SM-AC-31-M-1 SM-AC-31-M-2 D3X RS Operator’s Manual...

Need help?

Do you have a question about the D3X RS and is the answer not in the manual?

Questions and answers