Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for WAGNER PROTEC GM 1-530

- Page 1 Translation of the Original Operating Manual For professional use. Version 07/2017 Always follow the information in this manual, particularly the safety instructions and the warning instructions. Store the manual in a safe place. PROTEC GM 1-350 PROTEC GM 1-530 Airless manual gun B_5040...

-

Page 2: Table Of Contents

Processible Working Materials Misuse IDENTIFICATION Explosion protection identification Identification "X" Use in areas subject to explosion hazards Example Type Plate: PROTEC GM 1-530 BASIC SAFETY INSTRUCTIONS Safety instructions for the operator Safety instructions for staff DESCRIPTION Components Mode of operation... -

Page 3: About These Instructions

VERSION 07/2017 ORDER NUMBER DOC 2349369 OPERATING MANUAL ACCESSORIES 12.1 Nozzle for nozzle holder PT-HD GM1 12.2 Nozzle for nozzle holder WAGNER Tip 7/8 UNF 12.3 Nozzle for anti-contact guard 7/8 UNF SPARE PARTS 13.1 How to order spare parts? 13.2... -

Page 4: Languages

2356567 Norwegian 2356568 Dutch 2356570 Finnish 2356571 Czech 2356572 Japanese 2358025 Turkish 2388104 Supplement for WAGNER Tip nozzle holder: Service manual: Language Order No. Language Order No. German, English, French, Spanish, 1088951 German 2355505 Italian, Dutch English 2355506 Additional languages on request or at: www.wagner-group.com... -

Page 5: Correct Use

WAGNER explicitly prohibits any other use! The device may only be operated under the following conditions: Use the device only to work with the products recommended by WAGNER. Only operate the device as a whole. Do not deactivate safety fixtures. -

Page 6: Identification

Remove deposits from the surfaces to maintain conductivity. USE IN AREAS SUBJECT TO EXPLOSION HAZARDS Safe handling of WAGNER spray devices Mechanical sparks can form if the device comes into contact with metal. In an explosive atmosphere: Do not knock or push the device or components and tools against steel or rusty iron. -

Page 7: Example Type Plate: Protec Gm 1-530

VERSION 07/2017 ORDER NUMBER DOC 2349369 OPERATING MANUAL EXAMPLE TYPE PLATE: PROTEC GM 1-530 Designation Wagner Int. AG PROTEC CH-9450 Altstaetten GM 1-530 II 2G X 1 Wagner International AG Serial-No. XXXXX MAX WPR MAX TEMP 2 Serial number MM/JJ 530 bar 85 °C... -

Page 8: Safety Instructions For Staff

VERSION 07/2017 ORDER NUMBER DOC 2349369 OPERATING MANUAL 4.1.2 A SAFE WORK ENVIRONMENT Hazard due to dangerous fluids or steam! Severe or fatal injuries due to explosion hazard or inhalation, swallowing or contact with the skin or eyes. Ensure that the floor in the working are is static dissipative in accordance withEN 61340-4-1 (resistance must not exceed 100 MΩ). - Page 9 - In the event of functional faults, remedy the fault as described in the "Troubleshooting" chapter. If needed, the liquid ejection devices must be checked by experts (e.g., WAGNER service technician) at least every 12 months for their work-safe condition in accordance with DGUV regulation 100-500 Chapter 2.29 and Chapter 2.36.

- Page 10 VERSION 07/2017 ORDER NUMBER DOC 2349369 OPERATING MANUAL 4.2.3 GROUND THE UNIT Hazard due to electrostatic charge! Explosion hazard and damage to the device. Friction, flowing liquids and air or electrostatic coating processes create charges. Flames or sparks can form during discharge. Correct grounding of the entire spraying system prevents electrostatic charges.

- Page 11 VERSION 07/2017 ORDER NUMBER DOC 2349369 OPERATING MANUAL 4.2.5 CLEANING AND FLUSHING Hazard due to cleaning and flushing Explosion hazard and damage to the device. Preference should be given to non-flammable cleaning and flushing agents. When carrying out cleaning work with flammable cleaning agents, make sure that all equipment and resources (e.g., collection tank, funnel, transport cart) are conductive or static dissipative and grounded.

- Page 12 Hazard due to improper maintenance and repair! Danger to life and equipment damage. Only a WAGNER service center or a suitably trained person may carry out repairs and replace parts. Do not change or modify the device; if change is necessary, contact WAGNER.

-

Page 13: Description

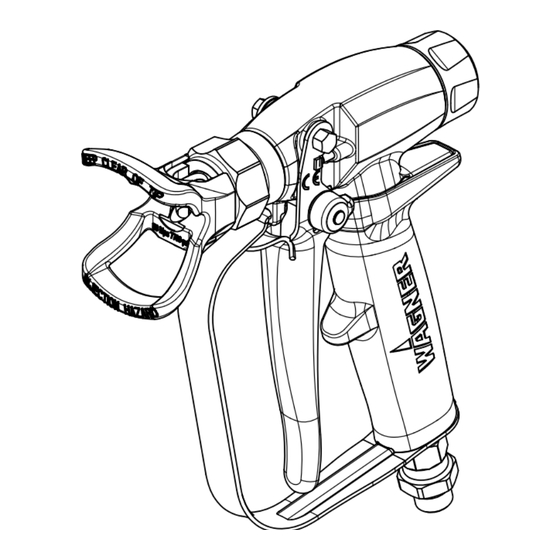

VERSION 07/2017 ORDER NUMBER DOC 2349369 OPERATING MANUAL DESCRIPTION COMPONENTS B_5042 Designation Designation A Preload nut E Nozzle holder B Trigger locking device Reversible nozzle (not included in scope of delivery) C Product connection with swivel joint G Gun housing D Trigger H Guard bracket MODE OF OPERATION... -

Page 14: Included Items

Field of application 2349286 PROTEC GM 1-350 35 MPa; 350 bar; 5075 psi, NPSM1/4" product connection 2349287 PROTEC GM 1-530 53 MPa; 530 bar; 7700 psi, NPSM1/4" product connection The standard equipment for spray guns includes: Order No. Designation 2355332... -

Page 15: Assembly And Commissioning

The system shown in the figure is only one example of an Airless spraying system. Your WAGNER distributor would be happy to assist you in creating a spraying system solution that meets your individual needs. -

Page 16: Grounding

VERSION 07/2017 ORDER NUMBER DOC 2349369 OPERATING MANUAL 6.3.1 VENTILATION OF THE SPRAY BOOTH Operate the device in a spray booth approved for the working materials. -or- Operate the device on an appropriate spraying wall with the ventilation (extraction) switched on. Observe national and local regulations for the exhaust air speed. -

Page 17: Commissioning

Push in nozzle. Screw the entire nozzle holder onto the spray gun. Tighten nozzle holder using a size 30 wrench (SW 30). - Nozzle holder WAGNER Tip 7/8 UNF: Insert seal in nozzle holder, screw nozzle holder onto spray gun and push in nozzle according to supplement WAGNER Tip (For Order No., see Chapter 1.3). -

Page 18: Operation

VERSION 07/2017 ORDER NUMBER DOC 2349369 OPERATING MANUAL OPERATION TRAINING THE OPERATING STAFF The operating staff must be qualified to operate the entire system. The operating staff must be familiar with the potential risks associated with improper behavior as well as the necessary protective devices and measures. Before work commences, the operating staff must receive appropriate system training. - Page 19 3. Point the spray gun at the ground. Remove the nozzle from the opening on the nozzle holder in accordance with supplement WAGNER Tip (For Order No., see Chapter 1.3). 4. Place new nozzle in the opening on the nozzle holder in accordance with supplement WAGNER Tip (For Order No., see Chapter 1.3).

- Page 20 When loosening the nozzle, always keep the spray gun pointed at the ground. Loosen nozzle by ¾ rotation. 4. Turn the nozzle 180° in accordance with supplement WAGNER Tip (For Order No., see Chapter 1.3). 5. Briefly trigger the spray gun so that the pressure eliminates the clog.

- Page 21 - Nozzle vertical – spray jet horizontal 5. Tightly fasten union nut. See also WAGNER Tip (For Order No., see Chapter 1.3). Anti-contact guard 7/8 UNF 1. Relieve the pressure on the spray gun and product pressure generator in accordance with Chapter 7.2.2.

-

Page 22: Cleaning And Maintenance

VERSION 07/2017 ORDER NUMBER DOC 2349369 OPERATING MANUAL CLEANING AND MAINTENANCE CLEANING 8.1.1 CLEANING STAFF Cleaning work should be undertaken regularly and carefully by qualified and trained staff. They should be informed of specific hazards during their training. The following hazards may arise during cleaning work: - Health hazard from inhaling solvent vapors - Use of unsuitable cleaning tools and aids 8.1.2 FLUSHING AND CLEANING THE SPRAY GUN... -

Page 23: Maintenance

Incorrect maintenance/repair! Danger to life and equipment damage. Only a WAGNER service center or a suitably trained person may carry out repairs and replace parts. Only repair and replace parts that are listed in the "Spare parts" chapter and that are assigned to the unit. - Page 24 Yearly or as required In accordance with DGUV regulation 100-500 Chapter 2.29 and 2.36: – The liquid ejection devices should be checked by an expert (e.g., WAGNER service technician) for their safe working conditions as required and at least every 12 months.

- Page 25 1. Flush and clean the spray gun as described in Chapter 8.1.2. 2. Ensure that the system has been relieved of pressure and that the spray gun is secured. 3. Replace the seal in accordance with supplement WAGNER Tip (For Order No., see Chapter 1.3). Anti-contact guard 7/8 UNF...

- Page 26 VERSION 07/2017 ORDER NUMBER DOC 2349369 OPERATING MANUAL 2. Ensure that the system has been relieved of pressure and that the spray gun is secured. 3. Unscrew anti-contact guard Remove nozzle seal. 4. Insert new nozzle seal. Screw the entire anti-contact guard onto the spray gun. Tighten the anti-contact guard with a size 27 wrench (SW 27).

-

Page 27: Troubleshooting

VERSION 07/2017 ORDER NUMBER DOC 2349369 OPERATING MANUAL TROUBLESHOOTING Functional fault Cause Remedy See Chapter Insufficient product Nozzle too small. Select larger nozzle. output Product pressure too low. Increase product pressure. Gun filter or high-pressure Clean or replace filter. 8.2.7 filter clogged at pump Nozzle is clogged. -

Page 28: 10 Repair Work

VERSION 07/2017 ORDER NUMBER DOC 2349369 OPERATING MANUAL 10 REPAIR WORK 10.1 REPAIR STAFF Repair work should be undertaken carefully by qualified and trained personnel. They should be informed of specific hazards during their training. The repairs must be carried out in accordance with the corresponding service manual (For Order No., see Chapter 1.3). - Page 29 Nozzle holder / anti-contact guard: see Chapter 13.2 12.1 NOZZLE FOR NOZZLE HOLDER PT-HD GM1 Nozzle table WAGNER Profi Tip HD In order to determine the order number of a nozzle, please select the number Order No. from the table and replace the three xxx.

- Page 30 VERSION 07/2017 ORDER NUMBER DOC 2349369 OPERATING MANUAL 12.2 NOZZLE FOR NOZZLE HOLDER WAGNER TIP 7/8 UNF Nozzle table WAGNER Tip In order to determine the order number of a nozzle, please select the number Order No. from the table and replace the three xxx.

- Page 31 Incorrect maintenance/repair! Danger to life and equipment damage. Only a WAGNER service center or a suitably trained person may carry out repairs and replace parts. Only repair and replace parts that are listed in the "Spare parts" chapter and that are assigned to the unit.

- Page 32 VERSION 07/2017 ORDER NUMBER DOC 2349369 OPERATING MANUAL 13.2 SPARE PARTS LIST PROTEC GM 1-350/530 3 Nm; 2.2 lbft 70 Nm; 51.6 lbft 16 Nm ; 11.8 lbft B_06730...

- Page 33 2371335 Seal Nozzle holder PT-HD GM1 2353549 for Profi Tip HD 1006xxx and PROTEC Tip 556xxx Nozzle holder WAGNER Tip 7/8 UNF 2371338 for WAGNER Tip 1088xxx Anti-contact guard 7/8 UNF 2371336 for Standard Tip 90xxx (not for Standard Tip plus) 9992590 Loctite®...

-

Page 34: Version 07/2017 Order Number Doc

The manufacturer will not be held liable or will only be held partially liable if third-party accessories or spare parts have been used. With genuine WAGNER accessories and spare parts, you have the guarantee that all safety regulations are complied with. - Page 35 Identification: II 2G X EU Declaration of Conformity The EU Declaration of Conformity is enclosed with this product. If needed, further copies can be ordered through your WAGNER dealer by specifying the product name and serial number. Order number: 2355332...

- Page 36 Order No. 2349369 Version 07/2017 Germany Phone Telefax E-mail ts-liquid@wagner-group.com Switzerland Phone Telefax More contact addresses: www.wagner-group.com Subject to changes without notice...

Need help?

Do you have a question about the PROTEC GM 1-530 and is the answer not in the manual?

Questions and answers