Emerson Micro Motion Installation Manual

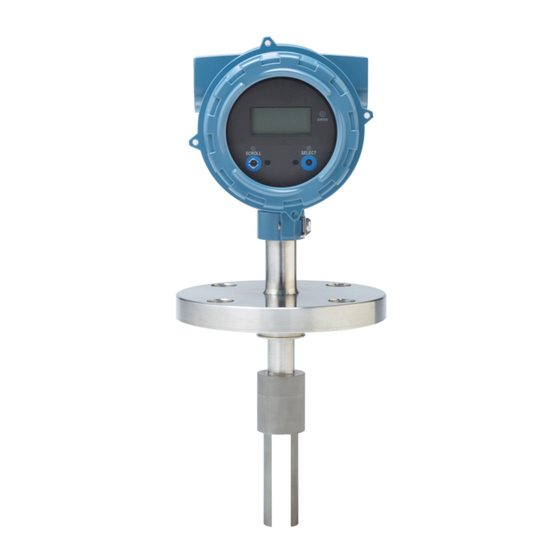

Specific gravity meters / gas specific gravity measurement

Hide thumbs

Also See for Micro Motion:

- Configuration and use manual (212 pages) ,

- User manual (76 pages) ,

- Installation manual (74 pages)

Summary of Contents for Emerson Micro Motion

- Page 1 Installation Manual MMI-20020984, Rev AC March 2018 ® Micro Motion Specific Gravity Meters (SGM) Gas specific gravity measurement...

- Page 2 Micro Motion employees. Micro Motion will not accept your returned equipment if you fail to follow Micro Motion procedures. Return procedures and forms are available on our web support site at www.emerson.com, or by phoning the Micro Motion Customer Service department.

-

Page 3: Table Of Contents

Contents Contents Chapter 1 Planning ...........................1 Installation and commissioning overview ..................1 Installation checklist ........................1 Best practices ..........................2 Recommended installation for specific gravity applications ............3 Power requirements ........................4 Chapter 2 Mounting .........................7 Mount the meter enclosure to a wall ....................7 Connect the gas bypass lines ...................... - Page 4 Contents Micro Motion Specific Gravity Meters...

-

Page 5: Chapter 1 Planning

Wire the meter according to the recommended practices for Chapter 3 your process environment and required approvals. Select the control pressure for the meter. See Micro Motion Specific Gravi‐ ty Meters (SGM): Configuration Purge cycle the meter. and Use Manual Calibrate the meter. -

Page 6: Best Practices

M20 to 1/2-inch NPT adapter (if applicable) 1/2-inch NPT blanking plug 2.5 mm hex key Calibration certificate Safety instructions booklets Micro Motion Product Documentation DVD □ Make sure that all electrical safety requirements are met for the environment in which the meter will be installed. □... -

Page 7: Recommended Installation For Specific Gravity Applications

Recommended installation for specific gravity applications To ensure optimum performance of the meter, Micro Motion recommends that you install the meter inside an enclosure that is mounted to a wall. The following diagram illustrates the recommended installation of the SGM. -

Page 8: Power Requirements

For ATEX installations, you are required to install a coalescing filter and element (as supplied). Power requirements Following are the DC power requirements to operate the meter: • 24 VDC, 0.45 W maximum • Minimum 22.8 VDC with 1000 m (3280 ft) of 0.20 mm (18 AWG) power-supply cable Micro Motion Specific Gravity Meters... - Page 9 Planning • At startup, power source must provide a minimum of 0.5 A of short-term current at a minimum of 19.6 V at the power-input terminals. Power cable recommendations Figure 1-2: Minimum wire gauge (AWG per feet) 22 . 8 V 24 V 3 0 0 6 0 0...

- Page 10 Planning Figure 1-3: Minimum wire area (mm per meter) Minimum wire area (mm Distance of installation Micro Motion Specific Gravity Meters...

-

Page 11: Chapter 2 Mounting

Rotate the display on the transmitter (optional) Mount the meter enclosure to a wall Micro Motion recommends that you install the meter in an enclosure that is mounted to a wall. When you order the meter with an enclosure, the meter and pipework inside the enclosure are configured at the factory to allow for easy installation of the meter in your process pipeline. - Page 12 When lifting or transporting the meter inside the enclosure, be sure not to drop the meter. While the meter enclosure is designed to minimize damage due to shocks, dropping the meter will damage the meter. 2.1.1 Mounting dimensions for a large enclosure Figure 2-2: Mounting dimensions for large enclosure Micro Motion Specific Gravity Meters...

-

Page 13: Connect The Gas Bypass Lines

Mounting Connect the gas bypass lines Once you have mounted the meter, you are ready to connect the gas bypass lines. There are three lines: sample gas input, sample gas output, and pressure relief. Each connector is a 1/4-inch Swagelok bulkhead fitting. These connectors are located on the outside of the enclosure. -

Page 14: Rotate The Display On The Transmitter (Optional)

If the display pins come out of the board stack with the display module, remove the pins and reinstall them. Rotate the display module to the desired position. Insert the sub-bezel pin terminals into the display module pin holes to secure the display in its new position. Micro Motion Specific Gravity Meters... - Page 15 Mounting If you have removed the display screws, line them up with the matching holes on the sub-bezel, then reinsert and tighten them. Place the display cover onto the main enclosure. Turn the display cover clockwise until it is snug. If appropriate, power up the meter.

-

Page 16: Chapter 3 Wiring

Time period signal (TPS) 4–20 mA + HART Time Period Sig- Modbus/RS-485 nal (TPS) Fixed 4–20 mA (tem- Time period sig- Disabled perature) nal (TPS) Processor for remote-mount Model Disabled Disabled Modbus/RS-485 2700 FOUNDATION fieldbus Micro Motion Specific Gravity Meters... -

Page 17: Intrinsically Safe Output Wiring

Wiring Intrinsically safe output wiring Micro Motion provides safety barrier and galvanic isolator installation kits for wiring the meter in a hazardous environment. These kits provide the appropriate barriers or isolators depending on the outputs available and approvals required. Information provided about wiring the safety barriers and galvanic isolators is intended as an overview. - Page 18 (Lcable), must be lower than the maximum allowable inductance (La) specified by the safety barrier. The following equation can then be used to calculate the maximum cable length between the meter and the barrier: Li + Lcable ≤ La Micro Motion Specific Gravity Meters...

- Page 19 Wiring 3.2.2 Wire all intrinsically safe outputs using safety barriers Micro Motion provides a safety barrier installation kit for wiring the meter in a hazardous area. Contact your local sales representative or customer support at flow.support@emerson.com for more information on ordering a barrier kit.

- Page 20 For safety, do not terminate the inner individual screens to earth in a hazardous area. • Use metal cable glands where the cables enter the meter amplifier box. Fit unused cable ports with metal blanking plugs. Micro Motion Specific Gravity Meters...

- Page 21 Wire the intrinsically safe Analog outputs version using galvanic isolators Micro Motion provides a galvanic isolator installation kit specific to wiring the Analog version of the meter in a hazardous area. Contact your local sales representative or Micro Motion Customer Support at flow.support@emerson.com...

- Page 22 For safety, do not terminate the inner individual screens to earth in a hazardous area. • Use metal cable glands where the cables enter the meter amplifier box. Fit unused cable ports with metal blanking plugs. Micro Motion Specific Gravity Meters...

- Page 23 Wire the intrinsically safe Time Period Signal (TPS) or Discrete output version using galvanic isolators Micro Motion provides a galvanic isolator installation kit specific to wiring the Time Period Signal (TPS) and Discrete versions of the meter in a hazardous area. Contact your local sales representative or Micro Motion Customer Support at flow.support@emerson.com...

- Page 24 For safety, do not terminate the inner individual screens to earth in a hazardous area. • Use metal cable glands where the cables enter the meter amplifier box. Fit unused cable ports with metal blanking plugs. Micro Motion Specific Gravity Meters...

-

Page 25: Heater Wiring

Wiring Set the isolator switch settings for the TPS/DO connection (MTL5532 isolator). You must set the isolator switches appropriately for Pins 1 through 5 (see Table 3‐4). The switches are located on the side of the isolator, and must be set to either Off (the up position) or On (the down position). - Page 26 N or L2 NEUTRAl OR LIVE 2 LIVE 1 GROUND A. N or L2 B. L1 C. Ground D. Thermostat E. Black F. Inside junction box G. Heater block H. Red/white stripe White or black Green Micro Motion Specific Gravity Meters...

-

Page 27: Chapter 4 Grounding

The meter must be grounded according to the standards that are applicable at the site. The customer is responsible for knowing and complying with all applicable standards. Prerequisites Micro Motion suggests the following guides for grounding practices: • In Europe, EN 60079-14 is applicable to most installations, in particular Sections 12.2.2.3 and 12.2.2.4. - Page 28 © 2018 Micro Motion, Inc. All rights reserved. The Emerson logo is a trademark and service mark of Emerson Electric Co. Micro Motion, ELITE, ProLink, MVD and MVD Direct Connect marks are marks of one of the Emerson Automation Solutions family of companies. All other marks are property of their respective owners.

Need help?

Do you have a question about the Micro Motion and is the answer not in the manual?

Questions and answers