Emerson Micro Motion Configuration And Use Manual

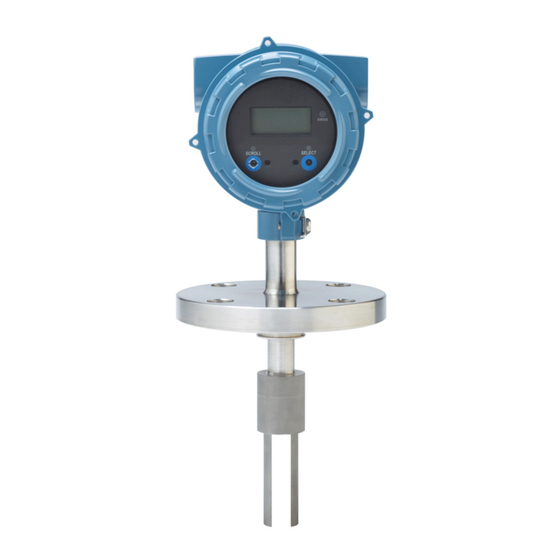

Fork density meters

Hide thumbs

Also See for Micro Motion:

- User manual (76 pages) ,

- Installation manual (74 pages) ,

- Quick start manual (58 pages)

Subscribe to Our Youtube Channel

Summary of Contents for Emerson Micro Motion

- Page 1 Configuration and Use Manual MMI-20020959, Rev AB June 2014 ® Micro Motion Fork Density Meters (FDM) Configuration and Use Manual...

- Page 2 Safety and approval information This Micro Motion product complies with all applicable European directives when properly installed in accordance with the instructions in this manual. Refer to the EC declaration of conformity for directives that apply to this product. The EC declaration of...

-

Page 3: Table Of Contents

Contents Contents Part I Getting Started Chapter 1 Before you begin ......................3 About this manual ........................3 Model codes and device types ..................... 3 Communications tools and protocols ..................4 Additional documentation and resources ..................5 Chapter 2 Quick start ........................7 Power up the transmitter ......................7 Check meter status ........................7 Make a startup connection to the transmitter ................8... - Page 4 Test or tune the system using sensor simulation ................99 Back up transmitter configuration ..................... 99 Enable HART security .......................100 Part III Operations, maintenance, and troubleshooting Chapter 8 Transmitter operation ....................105 Record the process variables ....................105 View process variables ......................105 Micro Motion ® Fork Density Meters (FDM)

- Page 5 Contents 8.2.1 View process variables using the display ..............105 8.2.2 View process variables and other data using ProLink III ..........106 8.2.3 View process variables using the Field Communicator ..........106 View and acknowledge status alerts ..................107 8.3.1 View and acknowledge alerts using the display ............107 8.3.2 View and acknowledge alerts using ProLink III ............109 8.3.3...

- Page 6 Concentration measurement matrices, derived variables, and process variables ..199 Standard matrices for the concentration measurement application ........199 Concentration measurement matrices available by order ............200 Derived variables and calculated process variables ..............202 Micro Motion ® Fork Density Meters (FDM)

-

Page 7: Getting Started

Getting Started Part I Getting Started Chapters covered in this part: • Before you begin • Quick start Configuration and Use Manual... - Page 8 Getting Started Micro Motion ® Fork Density Meters (FDM)

-

Page 9: Before You Begin

Fork Density Meter with Analog Output and Discrete Output • Fork Density Meter with Time Period Signal Output ® For the Fork Density Meter with Foundation Fieldbus, see Micro Motion Fork Density Meters with Foundation Fieldbus: Configuration and Use Manual. Important... -

Page 10: Communications Tools And Protocols

Appendix Micro Motion web site (www.micromo‐ tion.com You may be able to use other communications tools from Emerson Process Management, such as ™ AMS Suite: Intelligent Device Manager, or the Smart Wireless THUM Adapter. Use of AMS or the Smart Wireless THUM Adapter is not discussed in this manual. For more information on the Smart Wireless THUM Adapter, refer to the documentation available at www.micromotion.com. -

Page 11: Additional Documentation And Resources

Micro Motion Fork Density Meters (FDM): Installation Manual Product data sheet Micro Motion Fork Density Meters: Product Data Sheet All documentation resources are available on the Micro Motion web site at www.micromotion.com or on the Micro Motion user documentation DVD. - Page 12 Before you begin Micro Motion ® Fork Density Meters (FDM)

-

Page 13: Chapter 2 Quick Start

Quick start Quick start Topics covered in this chapter: • Power up the transmitter • Check meter status • Make a startup connection to the transmitter Power up the transmitter The transmitter must be powered up for all configuration and commissioning tasks, or for process measurement. -

Page 14: Make A Startup Connection To The Transmitter

To change the communications parameters using ProLink III, choose Device Tools > Configuration > Communications. • To change the communications parameters using the Field Communicator, choose On-Line Menu > Configure > Manual Setup > HART > Communications. Micro Motion ® Fork Density Meters (FDM) - Page 15 Quick start Important If you are changing communications parameters for the connection type that you are using, you will lose the connection when you write the parameters to the transmitter. Reconnect using the new parameters. Configuration and Use Manual...

- Page 16 Quick start Micro Motion ® Fork Density Meters (FDM)

-

Page 17: Part Ii Configuration And Commissioning

Configuration and commissioning Part II Configuration and commissioning Chapters covered in this part: • Introduction to configuration and commissioning • Configure process measurement • Configure device options and preferences • Integrate the meter with the control system • Completing the configuration Configuration and Use Manual... - Page 18 Configuration and commissioning Micro Motion ® Fork Density Meters (FDM)

-

Page 19: Introduction To Configuration And Commissioning

Introduction to configuration and commissioning Introduction to configuration and commissioning Topics covered in this chapter: • Default values • Enable access to the off‐line menu of the display • Disable HART security • Set the HART lock • Restore the factory configuration Default values Default values for your meter are configured at the factory. - Page 20 Power down the meter. Using the strap wrench, loosen the grub screws and remove the transmitter end- cap. Figure 3-1: Transmitter with end-cap removed A. Transmitter end‐cap Using the hex key, remove the safety spacer. Micro Motion ® Fork Density Meters (FDM)

- Page 21 Introduction to configuration and commissioning Figure 3-2: Transmitter with end-cap and safety spacer removed A. Transmitter end‐cap B. Safety spacer Move the HART security switch to the OFF position (up). The HART security switch is the switch on the left. Figure 3-3: HART security switch A.

-

Page 22: Set The Hart Lock

Restore the factory configuration Display Not available ProLink III Device Tools > Configuration Transfer > Restore Factory Configuration Field Communicator Service Tools > Maintenance > Reset/Restore > Restore Factory Configuration Micro Motion ® Fork Density Meters (FDM) - Page 23 Restoring the factory configuration returns the transmitter to a known operational configuration. This may be useful if you experience problems during configuration. Restoring the factory configuration is not a common action. You may want to contact Micro Motion to see if there is a preferred method to resolve any issues.

- Page 24 Introduction to configuration and commissioning Micro Motion ® Fork Density Meters (FDM)

-

Page 25: Configure Process Measurement

View the calibration factors that are stored in the device. Compare them to the factory values. • If the values match, no action is required. • If the values do not match, contact Micro Motion customer service. Configuration and Use Manual... -

Page 26: Calibration Factors

Device Tools > Configuration > Process Measurement > Line Density > Density Unit Field Communicator Configure > Manual Setup > Measurements > Density > Density Unit Overview Density Measurement Unit controls the measurement units that will be used in density calculations and reporting. Micro Motion ® Fork Density Meters (FDM) - Page 27 Configure process measurement Restriction If the API referral application is enabled, you cannot change the density measurement unit here. The density measurement unit is controlled by the API table selection. Procedure Set Density Measurement Unit to the option you want to use. The default setting for Density Measurement Unit is g/cm3 (grams per cubic centimeter).

-

Page 28: Configure Density Damping

Value specifies the time period (in seconds) over which the transmitter will spread changes in the process variable. At the end of the interval, the internal value will reflect 63% of the change in the actual measured value. Micro Motion ® Fork Density Meters (FDM) -

Page 29: Configure Density Cutoff

Configure process measurement Density damping affects all process variables that are calculated from line density. Procedure Set Density Damping to the value you want to use. The default value is 0 seconds. The range is 0 to 60 seconds. Interaction between Density Damping and Added Damping When the mA output is configured to report density, both Density Damping and Added Damping are applied to the reported density value. -

Page 30: Configure Two-Phase Flow Parameters

The default value for Two-Phase Flow Timeout is 0.0 seconds, meaning that the alert will be posted immediately. The range is 0.0 to 60.0 seconds. Micro Motion ® Fork Density Meters (FDM) -

Page 31: Configure Temperature Measurement

Configure process measurement Detecting and reporting two-phase flow Two-phase flow (gas in a liquid process or liquid in a gas process) can cause a variety of process control issues. By configuring the two-phase flow parameters appropriately for your application, you can detect process conditions that require correction. To decrease the occurrence of two-phase flow alerts, lower Two-Phase Flow Low Limit or raise Two-Phase Flow High Limit. -

Page 32: Configure Temperature Damping

Field Communicator Configure > Manual Setup > Measurements > Temperature > Temperature Damping Overview Temperature Damping controls the amount of damping that will be applied to the line temperature value, when the on-board temperature data is used (RTD). Micro Motion ® Fork Density Meters (FDM) -

Page 33: Configure Temperature Input

Configure process measurement Damping is used to smooth out small, rapid fluctuations in process measurement. Damping Value specifies the time period (in seconds) over which the transmitter will spread changes in the process variable. At the end of the interval, the internal value will reflect 63% of the change in the actual measured value. - Page 34 Click Apply. ble in addition to the internal c. Perform the necessary host programming and communica- RTD temperature data. tions setup to write temperature data to the meter at appro- priate intervals. Micro Motion ® Fork Density Meters (FDM)

- Page 35 Configure process measurement Postrequisites If you are using external temperature data, verify the external temperature value displayed in the Inputs group on the ProLink III main window . Need help? If the value is not correct: • Ensure that the external device and the meter are using the same measurement unit. •...

- Page 36 Verify that the host has access to the required data. Verify that the host is writing to the correct register in memory, using the correct data type. • If necessary, apply an offset. Micro Motion ® Fork Density Meters (FDM)

-

Page 37: Configure The Pressure Input

Configure process measurement Configure the pressure input Pressure data is required for several different measurements. The meter does not measure pressure. There are several different methods to obtain pressure data. • Configure the pressure input using ProLink III (Section 4.4.1) •... -

Page 38: Configure The Pressure Input Using The Field Communicator

Set up the pressure input. a. Choose Configure > Manual Setup > Inputs/Outputs > External Device Polling. b. Choose an unused polling slot. c. Set Polling Control to Poll as Primary or Poll as Secondary. Micro Motion ® Fork Density Meters (FDM) -

Page 39: Options For Pressure Measurement Unit

Configure process measurement Option Description Poll as Primary No other HART masters will be on the network. The Field Communicator is not a HART master. Poll as Secondary Other HART masters will be on the network. The Field Communicator is not a HART master. d. -

Page 40: Set Up The Api Referral Application

The API referral application must be enabled before you can perform any setup. If the API referral application was enabled at the factory, you do not need to enable it now. Choose Device Tools > Configuration > Transmitter Options. Micro Motion ® Fork Density Meters (FDM) - Page 41 Configure process measurement If the concentration measurement application is enabled, disable it and click Apply. The concentration measurement application and the API referral application cannot be enabled simultaneously. Enable API Referral and click Apply. Configure API referral using ProLink III The API referral parameters specify the API table, measurement units, and reference values to be used in referred density calculations.

- Page 42 60 °F 0 psi (g) line, jet fuel, aviation fuel, Range: 0 to 85 °API kerosene, heating oils, fuel Unit: SGU 60 °F 0 psi (g) oils, diesel, gas oil) Range: 0.6535 to 1.0760 Micro Motion ® Fork Density Meters (FDM)

- Page 43 Configure process measurement Table 4-4: API tables, process fluids, measurement units, and default reference values (continued) Default reference Default reference Process fluid API table Referred density (API) temperature pressure Unit: kg/m 15 °C 0 kPa (g) Range: 653 to 1075 kg/m³ Liquids with a constant den- Unit: °API 60 °F...

- Page 44 Other HART masters will be on the net- Poll as Secondary work. The Field Communicator is not a HART master. d. Set External Device Tag to the HART tag of the temperature device. e. Click Apply. Micro Motion ® Fork Density Meters (FDM)

- Page 45 Configure process measurement Option Description Setup Digital communica- A host writes temperature data a. Set Line Temperature Source to Fixed Value or Digital Communica- tions to the meter at appropriate in- tions. tervals. This data will be availa- b. Click Apply. ble in addition to the internal c.

-

Page 46: Set Up The Api Referral Application Using The Field Communicator

Set API Table Number to the number that matches the API table units that you want to use for referred density. Your choice also determines the measurement unit to be used for temperature and pressure, and the default values for reference temperature and reference pressure. Micro Motion ® Fork Density Meters (FDM) - Page 47 Configure process measurement Measurement Temperature Default refer- unit for referred measurement Pressure meas- ence tempera- Default refer- density unit urement unit ture ence pressure API Table Number °API °F psi (g) 60 °F 0 psi (g) °API °F psi (g) 60 °F 0 psi (g) °F...

- Page 48 60 °F 0 psi (g) line, jet fuel, aviation fuel, Range: 0 to 85 °API kerosene, heating oils, fuel Unit: SGU 60 °F 0 psi (g) oils, diesel, gas oil) Range: 0.6535 to 1.0760 Micro Motion ® Fork Density Meters (FDM)

- Page 49 Configure process measurement Table 4-5: API tables, process fluids, measurement units, and default reference values (continued) Default reference Default reference Process fluid API table Referred density (API) temperature pressure Unit: kg/m 15 °C 0 kPa (g) Range: 653 to 1075 kg/m³ Liquids with a constant den- Unit: °API 60 °F...

- Page 50 Other HART masters will be on the net- work. The Field Communicator is not a HART master. f. Set External Device Tag to the HART tag of the external tem- perature device. g. Set Polled Variable to Temperature. Micro Motion ® Fork Density Meters (FDM)

- Page 51 Configure process measurement Method Description Setup Digital communica- A host writes temperature data a. Choose Configure > Manual Setup > Measurements > External Inputs tions to the meter at appropriate in- > Temperature. tervals. This data will be availa- b. Set External Temperature to Enable. ble in addition to the internal c.

-

Page 52: Set Up Concentration Measurement

Field Communicator, you can build a custom matrix but you cannot load a matrix from a file. This manual does not discuss building a custom matrix. For information on building a custom matrix, see Micro Motion Enhanced Density Application: Theory, Configuration, and Use. •... -

Page 53: Set Up Concentration Measurement Using Prolink Iii

This section guides you through the tasks required to set up, configure, and implement concentration measurement. Restriction This section does not cover building a concentration matrix. See Micro Motion Enhanced Density Application: Theory, Configuration, and Use for detailed information on building a matrix. Enable the concentration measurement application using ProLink III... - Page 54 Volume Concentration (Density). If your matrix is not set up for Volume Concentration (Density), contact Micro Motion for assistance or for a custom matrix. If you plan to use matrix switching, you must identify the two matrices to be used for switching and load them into Slot 1 and Slot 2.

-

Page 55: Set Reference Temperature Values For Specific Gravity Using Prolink

Configure process measurement Important When you load a matrix, if the temperature unit is not correct, concentration data will be incorrect. The temperature units must match at the time of loading. You can change the temperature unit after the matrix is loaded. Choose Device Tools >... -

Page 56: Set Up Temperature Data For Concentration Measurement Using Prolink

RTD temperature and the external temperature separately. However, the transmitter stores only one alternate temperature value, which may be either an external temperature or the configured fixed value. Accordingly, if you set up polling for temperature in one Micro Motion ® Fork Density Meters (FDM) - Page 57 Configure process measurement area, and digital communications in another, and configure a fixed temperature value in a third, the fixed value will be overwritten by polling and digital communications, and polling and digital communications will overwrite each other. Prerequisites If you plan to poll an external device, the primary mA output must be wired to support HART communications.

-

Page 58: Modify Matrix Names And Labels Using Prolink Iii

Additionally, for certain types of concentration measurement, you can select the calculation method to be used. Choose Device Tools > Configuration > Process Measurement > Concentration Measurement. Micro Motion ® Fork Density Meters (FDM) - Page 59 Configure process measurement The Concentration Measurement window is displayed. It is organized into steps that allow you to perform several different setup and configuration tasks. For this task, you will not use all the steps. Scroll to Step 2, set Matrix Being Configured to the matrix you want to modify, and click Change Matrix.

-

Page 60: Set Up Concentration Measurement Using The Field Communicator

This section guides you through most of the tasks related to setting up and implementing the concentration measurement application. Restrictions • This section does not cover building a concentration matrix. See Micro Motion Enhanced Density Application: Theory, Configuration, and Use for detailed information on building a matrix. •... -

Page 61: Enable The Concentration Measurement Application Using

Configure process measurement Modify concentration measurement operational parameters using the Field Communicator Select the active concentration matrix using the Field Communicator Enable the concentration measurement application using the Field Communicator The concentration measurement application must be enabled before you can perform any setup. - Page 62 If you plan to poll an external device, the primary mA output must be wired to support HART communications. Procedure Choose the method to be used to supply temperature data, and perform the required setup. Micro Motion ® Fork Density Meters (FDM)

- Page 63 Configure process measurement Method Description Setup Internal RTD tem- Temperature data from the on- a. Choose Configure > Manual Setup > Measurements > Density > Tem- perature data board temperature sensor perature. (RTD) is used. b. Set External Temperature to Disable. Polling The meter polls an external de- a.

- Page 64 Each concentration matrix is built for a specific density range and a specific temperature range. If line density or line temperature goes outside the range, the transmitter will extrapolate concentration values. However, extrapolation may Micro Motion ® Fork Density Meters (FDM)

-

Page 65: Using Equations To Calculate Specific Gravity, °Baumé, °Brix, °Plato, And °Twaddell

Configure process measurement affect accuracy. Extrapolation alerts are used to notify the operator that extrapolation is occurring, and can also be used to initiate matrix switching. Each concentration matrix has its own extrapolation alert settings. a. Set Extrapolation Alert Limit to the point, in percent, at which an extrapolation alert will be posted. -

Page 66: Matrix Switching

When matrix switching is enabled, the meter automatically switches between the matrices in Slot 1 and Slot 2 whenever an extrapolation alert is present for the active matrix but would not be generated by the other matrix. For example: Micro Motion ® Fork Density Meters (FDM) - Page 67 Configure process measurement • The matrix in Slot 2 is active, the high-density extrapolation alert is enabled, and matrix switching is enabled. Line density goes above the range of the matrix plus the extrapolation limit. The meter posts an alert, then checks the range of the matrix in Slot 1.

-

Page 68: Measuring Net Mass Flow Rate And Net Volume Flow Rate

Prerequisites To calculate mass flow rate, you must be able to supply volume flow rate data to the meter. Micro Motion ® Fork Density Meters (FDM) - Page 69 Configure process measurement If you plan to poll an external device, the primary mA output must be wired to support HART communications. Procedure Choose Device Tools > Configuration > I/O > Inputs > External Inputs. Set Mass Flow (Calculated) to Enabled and click Apply. Set Mass Flow Rate (Calculated) Unit to the unit in which the mass flow rate will be reported.

-

Page 70: Set Up Flow Rate Measurement Using The Field Communicator

Choose Configure > Manual Setup > Measurements > External Inputs > Volume and set Volume Flow Source to Enabled. Choose the method to be used to supply volume flow rate data, and perform the required setup. Micro Motion ® Fork Density Meters (FDM) - Page 71 Configure process measurement Method Description Setup Polling The meter polls an external de- a. Choose Configure > Manual Setup > Inputs/Outputs > External Device vice for volume flow rate data. Polling. b. Choose an unused polling slot. c. Set Poll Control to Poll as Primary or Poll as Secondary. Option Description No other HART masters will be on the...

- Page 72 Verify that the host is writing to the correct register in memory, using the correct data type. • If necessary, apply an offset. Related information Measuring Net Mass Flow Rate and Net Volume Flow Rate Micro Motion ® Fork Density Meters (FDM)

-

Page 73: Configure Device Options And Preferences

Configure device options and preferences Configure device options and preferences Topics covered in this chapter: • Configure the transmitter display • Enable or disable operator actions from the display • Configure security for the display menus • Configure alert handling •... -

Page 74: Configure The Process Variables And Diagnostic Variables Shown On The Display

For temperature and density process variables, the default value is 2 decimal places. For all other variables, the default value is 4 decimal places. The range is 0 to 5. Micro Motion ® Fork Density Meters (FDM) -

Page 75: Configure The Refresh Rate Of Data Shown On The Display

Configure device options and preferences The lower the precision, the greater the change must be for it to be reflected on the display. Do not set the precision too low or too high to be useful. 5.1.4 Configure the refresh rate of data shown on the display Display OFF-LINE MAINT >... -

Page 76: Enable Or Disable Operator Actions From The Display

To acknowledge alerts from the display, operators must have access to the alert menu. Enable or disable Acknowledge All Alerts as desired. Option Description Enabled (default) Operators can use a single display command to acknowledge all alerts at once. Micro Motion ® Fork Density Meters (FDM) -

Page 77: Configure Security For The Display Menus

Configure device options and preferences Option Description Disabled Operators cannot acknowledge all alerts at once. Each alert must be ac- knowledged separately. Configure security for the display menus Display OFF-LINE MAINT > OFF-LINE CONFG > DISPLAY ProLink III Device Tools > Configuration > Transmitter Display > Display Security Field Communicator Configure >... -

Page 78: Configure Alert Handling

If you set Fault Timeout to 0, fault actions are performed as soon as the alert condition is detected. The fault timeout period begins when the transmitter detects an alert condition. During the fault timeout period, the transmitter continues to report its last valid measurements. Micro Motion ® Fork Density Meters (FDM) -

Page 79: Configure Status Alert Severity

For some alerts, Status Alert Severity is not configurable. • For some alerts, Status Alert Severity can be set only to two of the three options. Micro Motion recommends using the default settings for Status Alert Severity unless you have a specific requirement to change them. Procedure Select a status alert. - Page 80 To Informational or Ignore only Informational A102 Drive Overrange Informational A104 Calibration in Progress To Informational or Ignore only Informational A105 Two-Phase Flow Informational A106 Burst Mode Enabled To Informational or Ignore only Informational Micro Motion ® Fork Density Meters (FDM)

-

Page 81: Configure Informational Parameters

Configure device options and preferences Table 5-1: Status alerts and Status Alert Severity (continued) Alert number Alert title Default severity User can reset severity A107 Power Reset Occurred Informational A113 mA Output 2 Saturated To Informational or Ignore only Informational A114 mA Output 2 Fixed To Informational or Ignore only... - Page 82 The Field Communicator allows you to configure HART Tag and HART Long Tag from this location. These parameters are replicated from Configure > Manual Setup > HART > Communications. These parameters are used in HART communications. Micro Motion ® Fork Density Meters (FDM)

-

Page 83: Integrate The Meter With The Control System

Integrate the meter with the control system Integrate the meter with the control system Topics covered in this chapter: • Configure Channel B • Configure the mA output • Configure the discrete output • Configure an enhanced event • Configure HART/Bell 202 communications •... -

Page 84: Configure The Ma Output

Overview Use mA Output Process Variable to select the variable that is reported over the mA output. Procedure Set mA Output Process Variable as desired. Default settings are shown in the following table. Micro Motion ® Fork Density Meters (FDM) -

Page 85: Prolink Iii

Integrate the meter with the control system Table 6-1: Default settings for mA Output Process Variable Default process variable assign- Device Channel mA output ment FDM mA Channel A Primary mA output Density Channel B Secondary mA output Temperature FDM DO Channel A Primary mA output Density... -

Page 86: Configure Lower Range Value (Lrv) And Upper Range Value (Urv)

URV, you are configuring values for the currently assigned mA output process variable. Ensure that the measurement unit for the configured process variable has been set as desired. Procedure Set LRV and URV as desired. Micro Motion ® Fork Density Meters (FDM) -

Page 87: Configure Added Damping

Integrate the meter with the control system • LRV is the value of mA Output Process Variable represented by an output of 4 mA. The default value for LRV depends on the setting of mA Output Process Variable. • URV is the value of mA Output Process Variable represented by an output of 20 mA. The default value for URV depends on the setting of mA Output Process Variable. -

Page 88: Configure Ma Output Fault Action And Ma Output Fault Level

Configure > Manual Setup > Inputs/Outputs > mA Output 2 > MAO2 Fault Settings > MAO2 Fault Action Overview mA Output Fault Action controls the behavior of the mA output if the transmitter encounters an internal fault condition. Micro Motion ® Fork Density Meters (FDM) - Page 89 Integrate the meter with the control system Note For some faults only: If Fault Timeout is set to a non-zero value, the transmitter will not implement the fault action until the timeout has elapsed. Procedure Set mA Output Fault Action to the desired value. The default setting is Downscale.

-

Page 90: Configure The Discrete Output

Enhanced Event 2 Enhanced Event 2 Enhanced Event 3 Enhanced Event 3 Enhanced Event 4 Enhanced Event 4 Enhanced Event 5 Enhanced Event 5 Site-specific Calibration in Progress Calibration in Progress Calibration in Progress Micro Motion ® Fork Density Meters (FDM) -

Page 91: Configure Discrete Output Polarity

Integrate the meter with the control system Table 6-4: Options for Discrete Output Source (continued) Label Discrete output volt- Option ProLink III Field Communicator State Fault (default) Fault Indicator Fault Site-specific Important This table assumes that Discrete Output Polarity is set to Active High. If Discrete Output Polarity is set to Active Low, reverse the voltage values. -

Page 92: Configure Discrete Output Fault Action

Discrete Output Source to Fault and set Discrete Output Fault Action to None. Procedure Set Discrete Output Fault Action as desired. The default setting is None. Related information Fault indication with the discrete output Micro Motion ® Fork Density Meters (FDM) -

Page 93: Configure An Enhanced Event

Integrate the meter with the control system Options for Discrete Output Fault Action Table 6-6: Options for Discrete Output Fault Action Discrete output behavior Label Polarity=Active High Polarity=Active Low Upscale • Fault: discrete output is ON • Fault: discrete output is OFF (site-specific voltage) (0 V) •... -

Page 94: Configure Hart/Bell 202 Communications

OFF-LINE MAINT > OFF-LINE CONFG > HART ProLink III Device Tools > Configuration > Meter Information Device Tools > Configuration > Communications > Communications (HART) Field Communicator Configure > Manual Setup > HART > Communications Micro Motion ® Fork Density Meters (FDM) -

Page 95: Configure Hart Variables (Pv, Sv, Tv, Qv)

Integrate the meter with the control system Overview Basic HART parameters include the HART address, HART tags, and the operation of the primary mA output. Restrictions • Your device supports HART 7. If you are using HART 5, HART Long Tag is not available. •... - Page 96 Concentration measurement ✓ ✓ ✓ ✓ Specific Gravity ✓ ✓ ✓ ✓ Concentration ✓ ✓ ✓ ✓ Referred Density (Concentration) ✓ ✓ ✓ ✓ Net Mass Flow ✓ ✓ ✓ ✓ Net Volume Flow Micro Motion ® Fork Density Meters (FDM)

-

Page 97: Configure Burst Communications

Integrate the meter with the control system Interaction of HART variables and transmitter outputs The HART variables are automatically reported through specific transmitter outputs. They may also be reported through HART burst mode, if enabled on your transmitter. Restriction One some devices, the PV and the primary mA output are fixed to a specific process variable and cannot be changed. - Page 98 If you change the HART Primary Variable (PV) or Secondary Variable (SV), the process variables assigned to the primary mA output and the secondary mA output (if applicable) are automatically changed to match. The PV cannot be changed on devices with fixed mA output assignments. Micro Motion ® Fork Density Meters (FDM)

- Page 99 Integrate the meter with the control system Configure HART trigger mode Display Not available ProLink III Device Tools > Configuration > Communications > Communications (HART) Field Communicator Configure > Manual Setup > HART > Burst Mode > Burst Message x > Configure Update Rate Overview Trigger mode uses the burst message mechanism to indicate that a process variable has changed.

- Page 100 Trigger Interval begins when the transmitter detects the alert condition. When Trigger Interval expires: • If the alert is still active, the BACK message is broadcast. • If the alert is not active, no message is broadcast. Micro Motion ® Fork Density Meters (FDM)

-

Page 101: Configure Modbus Communications

Integrate the meter with the control system If you set Trigger Interval to 0, the BACK message is broadcast as soon as the alert is detected. Set Retry Rate as desired. Retry Rate controls the rate at which the BACK message is broadcast. •... -

Page 102: Configure Digital Communications Fault Action

Field Communicator Configure > Alert Setup > I/O Fault Actions > Comm Fault Action Overview Digital Communications Fault Action specifies the values that will be reported via digital communications if the device encounters an internal fault condition. Micro Motion ® Fork Density Meters (FDM) -

Page 103: Options For Digital Communications Fault Action

Integrate the meter with the control system Procedure Set Digital Communications Fault Action as desired. The default setting is None. Restrictions • If mA Output Fault Action is set to None, Digital Communications Faut Action should also be set to None. If you do not, the output will not report actual process data, and this may result in measurement errors or unintended consequences for your process. - Page 104 Integrate the meter with the control system Micro Motion ® Fork Density Meters (FDM)

-

Page 105: Completing The Configuration

Completing the configuration Completing the configuration Topics covered in this chapter: • Test or tune the system using sensor simulation • Back up transmitter configuration • Enable HART security Test or tune the system using sensor simulation Display Not available ProLink III Device Tools >... -

Page 106: Enable Hart Security

HART security. Prerequisites • 3 mm strap wrench • 3 mm hex key Procedure Power down the meter. Using the strap wrench, loosen the grub screws and remove the transmitter end- cap. Micro Motion ® Fork Density Meters (FDM) - Page 107 Completing the configuration Figure 7-1: Transmitter with end-cap removed A. Transmitter end‐cap Using the hex key, remove the safety spacer. Figure 7-2: Transmitter with end-cap and safety spacer removed A. Transmitter end‐cap B. Safety spacer Move the HART security switch to the ON position (down). Configuration and Use Manual...

- Page 108 Completing the configuration The HART security switch is the switch on the left. Figure 7-3: HART security switch A. HART security switch B. Unused Replace the safety spacer and end-cap. Power up the meter. Micro Motion ® Fork Density Meters (FDM)

-

Page 109: Part Iii Operations, Maintenance, And Troubleshooting

Operations, maintenance, and troubleshooting Part III Operations, maintenance, and troubleshooting Chapters covered in this part: • Transmitter operation • Measurement support • Troubleshooting Configuration and Use Manual... - Page 110 Operations, maintenance, and troubleshooting Micro Motion ® Fork Density Meters (FDM)

-

Page 111: Chapter 8 Transmitter Operation

View and acknowledge status alerts Record the process variables Micro Motion suggests that you make a record of specific process variable measurements, including the acceptable range of measurements, under normal operating conditions. This data will help you recognize when the process or diagnostic variables are unusually high or low, and may help you diagnose and troubleshoot application issues. -

Page 112: View Process Variables And Other Data Using Prolink Iii

Analog Gauge view or digital view, and you can customize the gauge settings. For more information, see the ProLink III user manual. 8.2.3 View process variables using the Field Communicator Monitor process variables to maintain process quality. Micro Motion ® Fork Density Meters (FDM) -

Page 113: View And Acknowledge Status Alerts

Transmitter operation • To view current values of basic process variables, choose Overview. • To view a more complete set of process variables, plus the current state of the outputs, choose Service Tools > Variables. View and acknowledge status alerts The transmitter posts status alerts whenever a process variable exceeds its defined limits or the transmitter detects a fault condition. - Page 114 Scroll and Select simultaneously for 4 seconds SEE ALARM Select Is ACK ALL enabled? ACK ALL Select Scroll EXIT Select Scroll Active/ unacknowledged alarms? Alarm code NO ALARM Scroll Select Scroll EXIT Select Scroll Micro Motion ® Fork Density Meters (FDM)

-

Page 115: View And Acknowledge Alerts Using Prolink Iii

Transmitter operation Postrequisites • To clear the following alerts, you must correct the problem, acknowledge the alert, then power-cycle the transmitter: A001, A002, A010, A011, A012, A013, A029, A031. • For all other alerts: If the alert is inactive when it is acknowledged, it will be removed from the list. If the alert is active when it is acknowledged, it will be removed from the list when the alert condition clears. -

Page 116: View Alerts Using The Field Communicator

Not cleared; maintained across transmitter that has occurred since the last master reset. power cycles Each record contains: • A count of the number of occurrences • Timestamps for the most recent posting and clearing Micro Motion ® Fork Density Meters (FDM) - Page 117 Transmitter operation Table 8-1: Alert data in transmitter memory (continued) Transmitter action if condition occurs Alert data structure Contents Clearing Recent Alerts 50 most recent alert postings or alert clearings Not cleared; maintained across transmitter power cycles Configuration and Use Manual...

- Page 118 Transmitter operation Micro Motion ® Fork Density Meters (FDM)

-

Page 119: Chapter 9 Measurement Support

Measurement support Measurement support Topics covered in this chapter: • Perform the Known Density Verification procedure • Adjust density measurement with Density Offset or Density Meter Factor • Perform density offset calibration • Adjust temperature measurement with Temperature Offset or Temperature Slope •... -

Page 120: Perform The Known Density Verification Procedure Using Prolink Iii

For problems with Verification Time Period Signal or Drive Gain, ensure that the meter is clean and dry. Then retry the Known Density Verification procedure. If the Known Density Verification procedure continues to fail, contact Micro Motion customer service. 9.1.2 Perform the Known Density Verification procedure using ProLink III The Known Density Verification procedure is used to verify that the meter's current operation matches the factory baseline. -

Page 121: Perform The Known Density Verification Procedure Using The Field Communicator

For problems with Verification Time Period Signal or Drive Gain, ensure that the meter is clean and dry. Then retry the Known Density Verification procedure. If the Known Density Verification procedure continues to fail, contact Micro Motion customer service. 9.1.3 Perform the Known Density Verification procedure using the Field Communicator The Known Density Verification procedure is used to verify that the meter's current operation matches the factory baseline. -

Page 122: Adjust Density Measurement With Density Offset Or Density Meter Factor

Then retry the Known Density Verification procedure. If the Known Density Verification procedure continues to fail, contact Micro Motion customer service. Adjust density measurement with Density Offset or Density Meter Factor You can adjust the reported density measurement by modifying the value for Density Offset or Density Meter Factor. - Page 123 Using the Field Communicator: Configure > Manual Setup > Measurements > Density > Meter Factor The default value for Density Meter Factor is 1.0. The recommended range is 0.8 to 1.2. If your calculated meter factor is outside this range, contact Micro Motion customer service. Configuration and Use Manual...

-

Page 124: Perform Density Offset Calibration

If concentration measurement is enabled, the active matrix is displayed. Activate Scroll to continue. The current reference temperature is displayed. Activate Scroll to move to the next step. Enter the laboratory reference density and save it to the transmitter. Micro Motion ® Fork Density Meters (FDM) -

Page 125: Perform Density Offset Calibration Using Prolink Iii

Measurement support Activate Select to apply the offset, and wait for a few seconds while the calibration process is performed. If the calibration succeeded, the calculated density offset is displayed. If the calibration failed, Density Offset is reset to the original value. •... -

Page 126: Perform Density Offset Calibration Using The Field Communicator

The default value of Density Offset is 0. Restriction Density offset calibration is available only when API referral or concentration measurement is enabled on your meter. If neither of these is enabled, Density Offset must be entered manually. Micro Motion ® Fork Density Meters (FDM) -

Page 127: Adjust Temperature Measurement With Temperature Offset Or Temperature Slope

Although you can set Temperature Offset or Temperature Slope manually, the temperature calibration procedure will generate a pair of offset and slope values that are more accurate for the individual meter. However, temperature calibration can be difficult. Consult Micro Motion before performing a temperature calibration. -

Page 128: Perform Temperature Calibration

Using the Field Communicator: Not available The default value is 1.0. The recommended range is 0.8 to 1.2. If your calculated slope is outside this range, contact Micro Motion customer service. Perform temperature calibration Temperature calibration establishes the relationship between the temperature of the calibration fluids and the signal produced by the sensor. -

Page 129: Perform Temperature Calibration Using The Display

You will not see the effect of the calibration until both the temperature offset calibration and the temperature slope calibration are complete. Important Consult Micro Motion before performing a temperature calibration. Under normal circumstances, the temperature circuit is stable and should not need an adjustment. Procedure Fill the sensor with the low-temperature fluid. -

Page 130: Perform Temperature Calibration Using Prolink Iii

You will not see the effect of the calibration until both the temperature offset calibration and the temperature slope calibration are complete. Important Consult Micro Motion before performing a temperature calibration. Under normal circumstances, the temperature circuit is stable and should not need an adjustment. Procedure... - Page 131 You will not see the effect of the calibration until both the temperature offset calibration and the temperature slope calibration are complete. Important Consult Micro Motion before performing a temperature calibration. Under normal circumstances, the temperature circuit is stable and should not need an adjustment. Procedure...

-

Page 132: Adjust Concentration Measurement With Trim Offset

If the two values are not acceptably close, repeat this procedure. Example: Calculating the trim offset Laboratory value 64.21 °Brix Meter value 64.93 °Brix 64.21 − 64.93 = −0.72 Concentration offset: −0.72 Related information Adjust concentration measurement with Trim Offset and Trim Slope Micro Motion ® Fork Density Meters (FDM) -

Page 133: Adjust Concentration Measurement With Trim Offset And Trim Slope

Measurement support Adjust concentration measurement with Trim Offset and Trim Slope Trim Offset and Trim Slope adjust the meter's concentration measurement to match a reference value. You can adjust concentration measurement by applying the trim offset only, or by applying both the trim offset and the trim slope. - Page 134 50.00 = ( 1.00029 × 49.98 ) + B 50.00 = 49.99449 + B B = 0.00551 Concentration slope (A): 1.00029 Concentration offset (B): 0.00551 Related information Adjust concentration measurement with Trim Offset Micro Motion ® Fork Density Meters (FDM)

-

Page 135: Set Up User-Defined Calculations

Measurement support Set up user-defined calculations Display Not available ProLink III Device Tools > Configuration > User-Defined Calculations Field Communicator Configure > Manual Setup > Measurements > User-Defined Calculations Overview User-defined calculations are used to enhance measurement or to adapt the meter to special process conditions. - Page 136 You may need to convert this value to the configured units before using it in your application or process. Related information Equations used in user‐defined calculations Measurement units used in user‐defined calculations Set up concentration measurement Micro Motion ® Fork Density Meters (FDM)

-

Page 137: Equations Used In User-Defined Calculations

Measurement support 9.8.1 Equations used in user-defined calculations Each user-defined calculation has an equation and a set of user-programmable constants and/or user-specified process variables. Equation 9-1: User-defined calculation 1 (square root) a × ( b + ( X × c )) y=A + B ×... - Page 138 Internal measurement unit Volume Flow (external or calculated) l/sec Line Temperature °C External Temperature °C Board Temperature °C Drive Gain Concentration Line Pressure Bar g Sensor Time Period Microseconds Specific Gravity (concentration measurement) Unitless Micro Motion ® Fork Density Meters (FDM)

-

Page 139: Chapter 10 Troubleshooting

Troubleshooting Troubleshooting Topics covered in this chapter: • Quick guide to troubleshooting • Check power supply wiring • Check grounding • Perform loop tests • Status LED states • Status alerts, causes, and recommendations • Density measurement problems • Temperature measurement problems •... -

Page 140: Check Power Supply Wiring

• If there is no power, continue with this procedure. Before inspecting the power supply wiring, disconnect the power source. Micro Motion ® Fork Density Meters (FDM) -

Page 141: Check Grounding

Reapplying power to the transmitter while the housing cover is removed could cause an explosion. Test the voltage at the terminals. If there is no power, contact Micro Motion customer service. 10.3 Check grounding The sensor and the transmitter must be grounded. -

Page 142: Perform Loop Tests Using The Display

Dots traverse the display while the output is fixed. b. Verify the signal at the receiving device. c. At the transmitter, activate Select. d. Scroll to and select SET OFF. e. Verify the signal at the receiving device. Micro Motion ® Fork Density Meters (FDM) -

Page 143: Perform Loop Tests Using Prolink Iii

If the discrete output readings are reversed, check the setting of Discrete Output Polarity. • If the TPS output readings do not match, contact Micro Motion customer service. 10.4.2 Perform loop tests using ProLink III A loop test is a way to verify that the transmitter and the remote device are communicating properly. -

Page 144: Perform Loop Tests Using The Field Communicator

If the discrete output readings are reversed, check the setting of Discrete Output Polarity. • If the TPS output readings do not match, contact Micro Motion customer service. 10.4.3 Perform loop tests using the Field Communicator A loop test is a way to verify that the transmitter and the remote device are communicating properly. - Page 145 Troubleshooting a. Choose Service Tools > Simulate > Simulate Outputs > mA Output 1 Loop Test or Service Tools > Maintenance > Simulate Outputs > mA Output 2 Loop Test, and select 4 mA. b. Read the mA current at the receiving device and compare it to the transmitter output.

-

Page 146: Status Led States

One or more high-severity alerts are active. A high-severity alert condition affects meas- urement accuracy and output behavior. Re- solve the alert condition before continuing. Related information View and acknowledge status alerts Micro Motion ® Fork Density Meters (FDM) -

Page 147: Status Alerts, Causes, And Recommendations

A001 EEPROM Error The transmitter has detected a • Cycle power to the meter. problem communicating with the • Contact Micro Motion. sensor. A002 RAM Error The transmitter has detected a • Cycle power to the meter. problem communicating with the •... - Page 148 • Evaluate the environment for sources of high electromagnetic interference (EMI) and relocate the transmitter or wiring as necessary. • Contact Micro Motion. A016 Sensor Temperature The value computed for the resist- • Check your process conditions against (RTD) Failure ance of the line RTD is outside lim- the values reported by the device.

- Page 149 Cycle power to the meter. Failure cation between the transmitter and • Replace the display module. the display module. • Contact Micro Motion. A030 Incorrect Board Type The loaded software is not compati- • Contact Micro Motion. ble with the programmed board type.

- Page 150 If it is, unfix the output. • Exit mA output trim, if applicable. • Check whether the output has been set to a constant value via digital communi- cation. Micro Motion ® Fork Density Meters (FDM)

- Page 151 There is a memory error in the dis- • Cycle power to the meter. play) play module. • Replace the display module. • Contact Micro Motion. A136 Incorrect Display An incorrect display module has • Replace the installed display module Type been installed on the device. This with an appropriate display module.

-

Page 152: Density Measurement Problems

Verify the temperature reading from the • Two-phase flow RTD (on-board temperature sensor). • Verify the temperature reading from the external temperature device, if applicable. • Check for two-phase flow. See Section 10.21. Micro Motion ® Fork Density Meters (FDM) -

Page 153: Temperature Measurement Problems

If the temperature measurement is outside the specification, contact Micro Motion. • The temperature of the fluid may be changing rapidly. Allow sufficient time for the sensor to equalize with the process flu- •... -

Page 154: Api Referral Problems

Set the temperature and density units to concentration meas- was configured when the matrix was loa- the units used when the matrix was built, urement after loading then reload the matrix. For custom matri- matrix ces, contact Micro Motion. Micro Motion ® Fork Density Meters (FDM) -

Page 155: Milliamp Output Problems

10.2. • Verify the output wiring. • Check the Fault Action settings. See Section 10.18. • Contact Micro Motion. Loop test failed • Output not powered • Verify that the output loop is powered ex- • Power supply problem ternally. - Page 156 • Verify that the mA output load resistance lower current, but in- is below the maximum supported load correct at higher cur- (see the installation manual for your trans- rent mitter). Micro Motion ® Fork Density Meters (FDM)

-

Page 157: Discrete Output Problems

Check the power supply and power supply wiring. See Section 10.2. • Verify the output wiring. • Contact Micro Motion. Loop test failed • Output not powered • Verify that the output loop is powered ex- • Power supply problem ternally. -

Page 158: Trim Ma Outputs

If you are using a HART/Bell 202 connection, the HART signal over the primary mA output affects the mA reading. Disconnect the wiring between ProLink III and the transmitter terminals when reading the primary mA output at the receiving device. Reconnect to continue the trim. Micro Motion ® Fork Density Meters (FDM) -

Page 159: Trim Ma Outputs Using The Field Communicator

Troubleshooting Check the trim results. If any trim result is less than −200 microamps or greater than +200 microamps, contact Micro Motion customer service. 10.15.2 Trim mA outputs using the Field Communicator Trimming the mA output establishes a common measurement range between the transmitter and the device that receives the mA output. - Page 160 Connect a Field Communicator directly across the resistor and attempt to communicate (poll). If this test fails, the transmitter may need service. Contact Micro Motion. Related information Configure basic HART parameters...

-

Page 161: Check Lower Range Value And Upper Range Value

Troubleshooting 10.17 Check Lower Range Value and Upper Range Value If the process variable assigned to the mA output falls below the configured Lower Range Value (LRV) or rises above the configured Upper Range Value (URV), the meter will post a saturation alert (A100 or A113), then perform the configured fault action. -

Page 162: Check The Cutoffs

You can reduce the occurrence of two-phase flow alerts by setting Two-Phase Flow Low Limit to a lower value, Two-Phase Flow High Limit to a higher value, or Two-Phase Flow Timeout to a higher value. Related information Configure two‐phase flow parameters Micro Motion ® Fork Density Meters (FDM) -

Page 163: Check The Drive Gain

The sensor may need to be reoriented or repositioned. Con- sult the installation manual for your sensor. Drive board or module failure Contact Micro Motion. Vibrating element not free to Ensure that the vibrating element is free to vibrate. vibrate Open drive coil Contact Micro Motion. -

Page 164: Collect Drive Gain Data

Pickoff voltage data can be used to diagnose a variety of process and equipment conditions. Collect pickoff voltage data from a period of normal operation, and use this data as a baseline for troubleshooting. Procedure Navigate to the pickoff voltage data. Micro Motion ® Fork Density Meters (FDM) -

Page 165: Check For Internal Electrical Problems

Possible causes and recommended actions for electrical shorts Possible cause Recommended action Faulty cable Replace the cable. Shorts to the housing created by trapped or damaged wires Contact Micro Motion. Loose wires or connectors Contact Micro Motion. Liquid or moisture inside the housing Contact Micro Motion. 10.25... - Page 166 Troubleshooting Micro Motion ® Fork Density Meters (FDM)

-

Page 167: Appendix A Calibration Certificate

Calibration certificate Appendix A Calibration certificate Sample calibration certificate Your meter was shipped with a calibration certificate. The calibration certificate describes the calibrations and configurations that were performed or applied at the factory. Configuration and Use Manual... - Page 168 TP = Time period (µs ) PASSED t = Temperature (°C) Reference FC V3.0.0.0 Date 09-May-2013 All equipment used for this calibration is calibrated at routine intervals against standards that are traceable to National Standards of Measurement. Micro Motion ® Fork Density Meters (FDM)

-

Page 169: Appendix B Using The Transmitter Display

Using the transmitter display Appendix B Using the transmitter display Topics covered in this appendix: • Components of the transmitter interface • Use the optical switches • Access and use the display menu system • Display codes for process variables •... -

Page 170: Access And Use The Display Menu System

The display will prompt you through this sequence. The Scroll-Select-Scroll sequence is designed to guard against accidental activation of the off-line menu. It is not designed as a security measure. To exit a display menu and return to a higher-level menu: Micro Motion ® Fork Density Meters (FDM) -

Page 171: Enter A Floating-Point Value Using The Display

Using the transmitter display • Activate Scroll until the EXIT option is displayed, then activate Select. • If the EXIT option is not available, activate Scroll and Select simultaneously and hold until the screen returns to the previous display. To exit the display menu system, you can use either of the following methods: •... - Page 172 Enter a floating-point value using exponential notation Exponential notation is used to enter values that are larger than 99999999 or smaller than −9999999. Exponential values entered via the display must be in the following form: SX.XXXEYY. In this string: Micro Motion ® Fork Density Meters (FDM)

- Page 173 Using the transmitter display • S = Sign. A minus sign (−) indicates a negative number. A blank indicates a positive number. • X.XXX = The 4-digit mantissa. • E = The exponent indicator. • YY = The 2-digit exponent. Procedure Switch from decimal notation to exponential notation.

-

Page 174: Display Codes For Process Variables

Volume Flow Rate (External) MAG M Mass Flow Rate (Calculated) API referral RDENS Referred Density (API) Concentration measurement Specific Gravity CONC Concentration NET M Net Mass Flow Rate NET V Net Volume Flow Rate Micro Motion ® Fork Density Meters (FDM) -

Page 175: Codes And Abbreviations Used In Display Menus

Using the transmitter display Codes and abbreviations used in display menus Table B-3: Display codes for measurement units Code Measurement unit Percent %PLATO °Plato %SOL-V % solution by volume %SOL-W % solution by weight °C °Celsius °F °Fahrenheit °K °Kelvin °R °Rankine Atmospheres... - Page 176 INH2O Inches of water at 68 °F INHG Inches of mercury at 0 °C INW4C Inches of water at 4 °C INW60 Inches of water at 60 °F Kilograms KG/D Kilograms per day Micro Motion ® Fork Density Meters (FDM)

- Page 177 Using the transmitter display Table B-3: Display codes for measurement units (continued) Code Measurement unit KG/H Kilograms per hour KG/L Kilograms per liter KG/M2 Kilograms per square meter KG/M3 Kilograms per cubic meter KG/MIN Kilograms per minute KG/S Kilograms per second KG/SCM Kilograms per square centimeter Kilopascals...

- Page 178 Pounds per square inch gauge PSI A Pounds per square inch absolute Standard cubic feet SCFD Standard cubic feet per day SCFH Standard cubic feet per hour SCFM Standard cubic feet per minute Micro Motion ® Fork Density Meters (FDM)

- Page 179 Using the transmitter display Table B-3: Display codes for measurement units (continued) Code Measurement unit SCFS Standard cubic feet per second Seconds Specific gravity units Standard liter SL/D Standard liters per day SL/H Standard liters per hour SL/MIN Standard liters per minute SL/S Standard liters per second Standard cubic meter...

- Page 180 AO 2 SRC mA Output 2 Source API (American Petroleum Institute) APPLY Apply ASCII ASCII AUTO Auto AUTOSCRL Auto Scroll Average BASE Base BDENS Base Density BRD T Board temperature Calibrate or Calibration Calibration result Micro Motion ® Fork Density Meters (FDM)

- Page 181 Using the transmitter display Table B-4: Display codes for menus, controls, and data (continued) Code Definition CALC Calculate CCAI Calculated Carbon Aromaticity Index CH B Channel B CHANGE Change CHMBR Chamber Calculated Ignition Index Carbon monoxide Carbon dioxide CODE? Passcode CONC Concentration CONCENTR...

- Page 182 HART HIDE Hide HIGH High Input/Output K VAL K value K0 calibration factor K1 calibration factor K2 calibration factor Known Density Verification KINV Kinematic viscosity LANG Language LANGUAGE Language LOADING Loading Left pickoff Micro Motion ® Fork Density Meters (FDM)

- Page 183 Output 1 MAO 2 mA Output 2 MASS Mass MBUS Modbus MDIUM Medium MEASR Measurement Micro Motion Millisecond MTR F Meter factor Molecular weight Nitrogen NET M Net mass flow rate NET V Net volume flow rate nSEC Nanoseconds...

- Page 184 Specific gravity Specific gravity SHOW Show Simulate, Simulated SLOPE Slope SPAN Spanish Source SRVIS Secondary referred viscosity STAB Stability START Start STORE Store Software SWREV Software revision TCASE Case temperature TDIFF Tube-Case Temperature Difference Micro Motion ® Fork Density Meters (FDM)

- Page 185 Using the transmitter display Table B-4: Display codes for menus, controls, and data (continued) Code Definition TEMP Temperature Time Period TP A Sensor Time Period (Upper) TP B Sensor Time Period Time Period Signal TYPE Type UCALC User-defined calculation ULTRA Ultra-low UNITS Units...

- Page 186 Using the transmitter display Micro Motion ® Fork Density Meters (FDM)

-

Page 187: Appendix C Using Prolink Iii With The Transmitter

• Connect with ProLink III Basic information about ProLink III ProLink III is a configuration and service tool available from Micro Motion. It runs on a Windows platform and provides complete access to transmitter functions and data. Version requirements The following version of ProLink III is required: v2.4 or later. -

Page 188: Connect With Prolink Iii

These features are documented in the ProLink III manual. They are not documented in the current manual. ProLink III messages As you use ProLink III with a Micro Motion transmitter, you will see a number of messages and notes. This manual does not document all of these messages and notes. Important The user is responsible for responding to messages and notes and complying with all safety messages. -

Page 189: Connect With Prolink Iii Over Modbus/Rs-485

Using ProLink III with the transmitter • Modbus connections, including service port connections, are typically faster than HART connections. • When you are using a HART connection, ProLink III will not allow you to open more than one window at a time. This is done to manage network traffic and optimize speed. - Page 190 To make a ProLink III connection, you can temporarily stop host communications or you can disconnect the cable from the host. Micro Motion ® Fork Density Meters (FDM)

- Page 191 Using ProLink III with the transmitter Figure C-2: Connection over network A. PC B. RS‐232 to RS‐485 converter Ω , 1/2‐watt resistors at both ends of the segment, if necessary C. 120- D. DCS or PLC E. Transmitter with end‐cap removed Note This figure shows a serial port connection.

-

Page 192: Connect With Prolink Iii Over Hart/Bell 202

Removing the end cap while the transmitter is powered up could cause an explosion. To connect to the transmitter in a hazardous environment, use a connection method that does not require removing the transmitter end-cap. Micro Motion ® Fork Density Meters (FDM) - Page 193 Using ProLink III with the transmitter CAUTION! If you connect directly to the mA terminals, the transmitter's mA output may be affected. If you are using the mA output for process control, set devices for manual control before connecting directly to the mA terminals. Prerequisites •...

- Page 194 Note that many PLCs have a built-in 250-Ω resistor. If the PLC is powering the circuit, be sure to take this into consideration. Micro Motion ® Fork Density Meters (FDM)

- Page 195 Using ProLink III with the transmitter Figure C-4: Supply voltage and resistance requirements 1000 Operating range Supply voltage VDC (volts) Note To connect to a point in the local HART loop: a. Attach the leads from the signal converter to any point in the loop, ensuring that the leads are across the resistor.

- Page 196 To meet the resistance requirements, you may use any combination of resistors R1 and R2. Note that many PLCs have a built-in 250-Ω resistor. If the PLC is powering the circuit, be sure to take this into consideration. Micro Motion ® Fork Density Meters (FDM)

- Page 197 Using ProLink III with the transmitter Figure C-6: Supply voltage and resistance requirements 1000 Operating range Supply voltage VDC (volts) Note To connect over a HART multidrop network: a. Attach the leads from the signal converter to any point on the network. b.

- Page 198 Secondary Use this setting if a primary HART host such as a DCS is on the network. Primary Use this setting if no other primary host is on the network. The Field Communicator is a secondary host. Micro Motion ® Fork Density Meters (FDM)

- Page 199 Using ProLink III with the transmitter Click Connect. Need help? If an error message appears: • Verify the HART address of the transmitter, or poll HART addresses 1–15. • Ensure that you have specified the correct port on your PC. •...

- Page 200 Using ProLink III with the transmitter Micro Motion ® Fork Density Meters (FDM)

-

Page 201: Appendix D Using The Field Communicator With The Transmitter

To view the device descriptions that are installed on your Field Communicator: At the HART application menu, press Utility > Available Device Descriptions. Scroll the list of manufacturers and select Micro Motion, then scroll the list of installed device descriptions. -

Page 202: Connect With The Field Communicator

Using the Field Communicator with the transmitter If Micro Motion is not listed, or you do not see the required device description, use the Field Communicator Easy Upgrade Utility to install the device description, or contact Micro Motion. Field Communicator menus and messages Many of the menus in this manual start with the On-Line menu. - Page 203 Using the Field Communicator with the transmitter HART connections are not polarity-sensitive. It does not matter which lead you attach to which terminal. Figure D-1: Field Communicator connection to transmitter terminals A. Field Communicator Ω resistance B. 250–600 C. External power supply D.

- Page 204 To navigate to the Online menu, choose HART Application > Online. Most configuration, maintenance, and troubleshooting tasks are performed from the Online menu. You may see messages related to the DD or active alerts. Press the appropriate buttons to ignore the message and continue. Micro Motion ® Fork Density Meters (FDM)

-

Page 205: Appendix E Concentration Measurement Matrices, Derived Variables, And Process Variables

Standard matrices for the concentration measurement application The standard concentration matrices available from Micro Motion are applicable for a variety of process fluids. These matrices are included in the ProLink III installation. If the standard matrices are not appropriate for your application, you can build a custom matrix or purchase a custom matrix from Micro Motion. -

Page 206: Concentration Measurement Matrices Available By Order

Concentration Proof 50–70C.xml (proof) (Density) Alcohol 160–200 Alcohol 160–200 50–90 °C g/cm³ °C Concentration Proof 50–90C.xml (proof) (Density) Sucrose solution Sucrose 0–40 Brix Sucrose 0–40% 0–100 °C g/cm³ °C Concentration (Brix) 0–100C.xml (Density) Micro Motion ® Fork Density Meters (FDM) - Page 207 Concentration measurement matrices, derived variables, and process variables Table E-2: Concentration matrices, names, ranges, units, and derived variable (continued) Tem- pera- Default ma- Concentra- Tempera- Density ture Derived var- Process fluid Matrix file name trix name tion range ture range unit unit iable...

-

Page 208: Derived Variables And Calculated Process Variables

✓ ✓ ✓ ✓ Mass Concentration The percent mass of solute or of material in (Density) suspension in the total solution, derived from reference density Micro Motion ® Fork Density Meters (FDM) - Page 209 Concentration measurement matrices, derived variables, and process variables Table E-3: Derived variables and calculated process variables (continued) Calculated process variables Density at reference Standard Net vol- tempera- volume Specific Concen- Net mass ume flow Derived Variable Description ture flow rate gravity tration flow rate...

- Page 210 Concentration measurement matrices, derived variables, and process variables Micro Motion ® Fork Density Meters (FDM)

- Page 211 Concentration measurement matrices, derived variables, and process variables Configuration and Use Manual...

- Page 212 © Micro Motion Japan 2014 Micro Motion, Inc. All rights reserved. Emerson Process Management The Emerson logo is a trademark and service mark of Emerson 1-2-5, Higashi Shinagawa Electric Co. Micro Motion, ELITE, ProLink, MVD and MVD Direct Shinagawa-ku Connect marks are marks of one of the Emerson Process Tokyo 140-0002 Japan Management family of companies.

Need help?

Do you have a question about the Micro Motion and is the answer not in the manual?

Questions and answers