Sandpiper S30 Operating And Service Manual

Metallic design level 1

Hide thumbs

Also See for S30:

- Service & operation manual (38 pages) ,

- Operating & service manual (24 pages) ,

- Service & operating manual (24 pages)

Table of Contents

Advertisement

SERVICE & OPERATING MANUAL

SANDPIPER

A WARREN RUPP PUMP BRAND

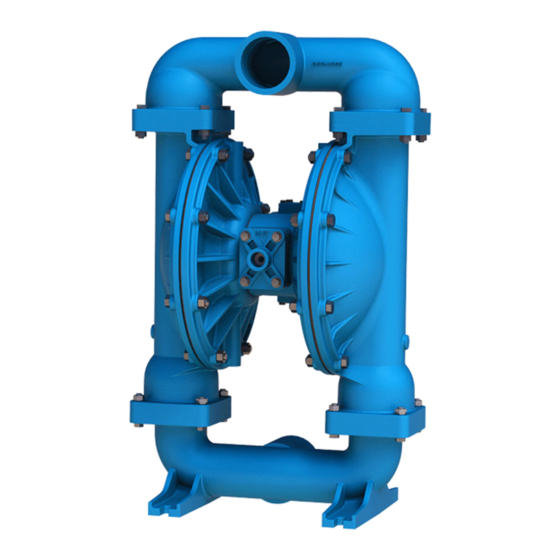

Model S30 Metallic Design Level 1

Model S30 Metallic Design Level 1

Model S30 Metallic Design Level 1

Model S30 Metallic Design Level 1

Model S30 Metallic Design Level 1

Table of Contents

Engineering Data and Temperature Limitations .................................................. 1

Explanation of Pump Nomenclature .................................................................... 2

Performance Curve ............................................................................................... 3

Flange Dimensions .............................................................................................. 4

Metric Flange Dimensions ................................................................................... 5

Demensions ......................................................................................................... 6

Metric Demensions ............................................................................................... 7

Principle of Pump Operation ................................................................................ 8

Installation and Start-Up ....................................................................................... 8

Air Supply ............................................................................................................. 8

Air Valve Lubrication ............................................................................................. 8

Air Line Moisture .................................................................................................. 8

Air Inlet and Priming ............................................................................................. 8

Between Uses ...................................................................................................... 8

Installation Guide .................................................................................................. 9

Troubleshooting .................................................................................................. 10

Warranty ............................................................................................................. 10

Recycling ............................................................................................................ 11

Important Safety Information .............................................................................. 11

Material Codes ................................................................................................... 12

Composite Repair Parts Drawing ...................................................................... 14

Available Service and Conversion Kits .............................................................. 14

Composite Repair Parts List .............................................................................. 15

**Air Distribution Valve Assembly Drawing and Parts List ................................. 16

Air Distribution Valve Servicing .......................................................................... 17

WARREN RUPP

, INC. • A Unit of IDEX Corporation • P .O. Box 1568, Mansfield, Ohio 44901-1568 USA • Telephone (419) 524-8388 • Fax (419) 522-7867 • www.warrenrupp.com

®

520-222-000

1/04 Rev C

®

U.S. Patent #

5,996,627; 6,241,487

Other U.S. Patents

Applied for

**Air Distribution Valve w/Stroke Indicator Servicing ......................................... 19

**Solenoid Shifted Air Valve Drawing ................................................................ 20

**Solenoid Shifted Air Valve Parts List ............................................................... 20

**Solenoid Shifted Air Distribution Valve Option ................................................ 21

Diaphragm Service Drawing, with Overlay ........................................................ 22

Diaphragm Service Drawing, Non-Overlay ....................................................... 22

Diaphragm Servicing .......................................................................................... 23

Overlay Diaphragm Servicing ............................................................................ 23

Actuator Plunger Servicing ................................................................................. 24

Check Valve Servicing ........................................................................................ 25

Check Valve Drawing ......................................................................................... 25

Optional Muffler Configurations ......................................................................... 26

Optional Muffler Configuration Drawing ............................................................ 26

Pumping Hazardous Liquids .............................................................................. 27

Converting Pump for Piping Exhaust Air ............................................................ 27

Converted Exhaust Illustration ........................................................................... 27

**RuppTech® Leak Detection Options & Drawing ............................................. 28

**RuppTech® Electronic Leak Detector Installation .......................................... 28

**RuppTech® Mechanical Leak Detector Installation ....................................... 28

**RuppTech® Pulse Output Kit Drawing ............................................................ 29

**RuppTech® Pulse Output Kit Options ............................................................. 29

Grounding the Pump .......................................................................................... 30

**Note: Not ATEX Compliant

I M2 c/b T5

II 2GD b T5

CE

©Copyright 2004 Warren Rupp, Inc. All rights reserved.

Advertisement

Table of Contents

Summary of Contents for Sandpiper S30

-

Page 1: Table Of Contents

II 2GD b T5 5,996,627; 6,241,487 A WARREN RUPP PUMP BRAND Other U.S. Patents Model S30 Metallic Design Level 1 Model S30 Metallic Design Level 1 Model S30 Metallic Design Level 1 Model S30 Metallic Design Level 1 Model S30 Metallic Design Level 1... -

Page 3: Engineering Data And Temperature Limitations

Polypropylene 180°F 32°F 82°C 0°C For specific applications, always consult The Warren Rupp Chemical Resistance Chart ® SANDPIPER pumps are designed to be powered only by compressed air. 520-222-000 1/04 Rev C Model S30 Metallic Design Level 1 Page 1... -

Page 4: Explanation Of Pump Nomenclature

Explanation of Pump Nomenclature S30 Metallic · Design Level 1· Ball Valve Check Diaphragm/ Check Non-Wetted Shipping MODEL Pump Pump Valve Design Wetted Check Valve Valve Material Porting Pump Pump Weight Brand Size Type Level Material Materials Seat Options Options... -

Page 5: Performance Curve

Performance Curve, S30 Metallic Design Level 1 20(34) 40(68) 60(102) 80(136) 100(170) Displacement Per Stroke: .94 gallons 3.56 liters Flow Capacity: 0 to 235 gallons per minute 120(204) 0 to 889 liters per minute 140(238) 220 240 U.S. Gallons per minute... -

Page 6: Flange Dimensions

Aluminum 31 3/4 Stainless Steel 30 27/32 4 7/32 35 25/32 Air Inlet 3/4" NPT Mesh Muffler 16 5/8 Sound Dampening Muffler 16 5/8 Metal Muffler 16 1/8 520-222-000 1/04 Rev C Model S30 Metallic Design Level 1 Page 4... -

Page 7: Metric Flange Dimensions

For Optional Piping Exhaust Air In Submerged Applications DIMENSION Encapsulated Muffler Pulse Output Kit Aluminum Stainless Steel Mesh Muffler Sound Dampening Muffler Air Inlet 3/4" NPT Metal Muffler 520-222-000 1/04 Rev C Model S30 Metallic Design Level 1 Page 5... -

Page 8: Demensions

29 31/32 2 11/32 17 9/64 32 1/16 Aluminum Stainless Steel 30 3/16 2 9/16 17 23/64 32 9/32 Mesh Muffler 17 3/16 Sound Dampening Muffler 17 3/16 Metal Muffler 16 3/4 520-222-000 1/04 Rev C Model S30 Metallic Design Level 1 Page 6... -

Page 9: Metric Demensions

Air In Submerged Available With Applications 3" BSP Tapered Connection Air Inlet DIMENSION 3/4" NPT Encapsulated Muffler Pulse Output Kit Aluminum Stainless Steel Mesh Muffler Sound Dampening Muffler Metal Muffler 520-222-000 1/04 Rev C Model S30 Metallic Design Level 1 Page 7... -

Page 10: Principle Of Pump Operation

Water in the air supply can be chamber exhausts. When the spool desired performance. When the air reduced by using a point-of-use air dryer 520-222-000 1/04 Rev C Model S30 Metallic Design Level 1 Page 8... -

Page 11: Installation Guide

020-051-000 Filter/Regulator 020-051-001 Lubricator CAUTION The air exhaust should be piped to an area for safe disposition of the product being pumped, in the event of a diaphragm failure. 520-222-000 1/04 Rev C Model S30 Metallic Design Level 1 Page 9... -

Page 12: Troubleshooting

SERVICE MANUAL. PERFORMANCE CURVE. Pump is What to Check: Blocked discharge line. cavitating the fluid by fast cycling. Corrective Action: Check for obstruction or closed discharge line valves. 520-222-000 1/04 Rev C Model S30 Metallic Design Level 1 Page 10... -

Page 13: Recycling

Wear ear and eye protection. certificates visit: www.warrenrupp.com area for safe disposition. 520-222-000 1/04 Rev C Model S30 Metallic Design Level 1 Page 11... -

Page 14: Material Codes

ATOFINA Oil Impregnated 604 ..PTFE 374 ..Carboxylated Nitrile Chemicals, Inc. Warren Rupp, SANDPIPER, Portapump, Tranquilizer and SludgeMaster are registered tradenames of Warren Rupp, Inc. 520-222-000 1/04 Rev C Model S30 Metallic Design Level 1 Page 12... - Page 15 520-222-000 1/04 Rev C Model S30 Metallic Design Level 1 Page 13...

-

Page 16: Composite Repair Parts Drawing

110/120VAC or 220/240VAC Kit 475-198-009 110/120VAC Intrinsically Safe Kit 032-040-000 110VAC 032-037-000 220VAC 475-198-010 220/240VAC Intrinsically Safe Kit Note: Pumps equipped with these components are not ATEX compliant 520-222-000 1/04 Rev C Model S30 Metallic Design Level 1 Page 14... -

Page 17: Composite Repair Parts List

518-143-156 Manifold, Suction (for other muffler options see pg. 26) 518-143-156E Manifold, Suction 3" BSPT Note: Pumps equipped with these components are not ATEX compliant 518-143-010 Manifold, Suction 520-222-000 1/04 Rev C Model S30 Metallic Design Level 1 Page 15... -

Page 18: Air Distribution Valve Assembly Drawing And Parts List

(items 1-F) that set (item 1-B). void factory warranty. 520-222-000 1/04 Rev C Model S30 Metallic Design Level 1 Page 16... -

Page 19: Air Distribution Valve Servicing

(items 1-F) that set (item 1-B). 520-222-000 1/04 Rev C Model S30 Metallic Design Level 1 Page 17... -

Page 20: Air Distribution Valve W/Stroke Indicator Assembly Drawing And Parts List

Clip, Safety 560-001-360 O-Ring For Pumps with Alternate Mesh, Sound Dampening Mufflers or Piped Exhaust: 031-147-000 Air Valve Assembly (includes all items on 031-146-000 minus 1-D, 1-F, & 1-J). 520-222-000 1/04 Rev C Model S30 Metallic Design Level 1 Page 18... -

Page 21: Air Distribution Valve W/Stroke Indicator Servicing

1) and gasket (item 18) to the pump. inspect for scratches or wear. Connect the compressed air line to the pump. Remove the safety clip. The pump is now ready for operation. 520-222-000 1/04 Rev C Model S30 Metallic Design Level 1 Page 19... -

Page 22: Solenoid Shifted Air Valve Drawing

(Connector not required for explosion proof coil; coil is integral with valve) 893-098-001 Solenoid Valve, NEMA 7/9, 24VDC 893-098-002 Solenoid Valve, NEMA 7/9, 24VAC/12VDC 893-098-003 Solenoid Valve, NEMA 7/9, 120VAC 893-098-004 Solenoid Valve, NEMA 7/9, 220VAC 520-222-000 1/04 Rev C Model S30 Metallic Design Level 1 Page 20... -

Page 23: Solenoid Shifted Air Distribution Valve Option

SANDPIPER pump, with one exception. This option provides a way to precisely control and monitor pump speed. BEFORE INSTALLATION Before wiring the solenoid, make certain it is compatible with your system voltage. 520-222-000 1/04 Rev C Model S30 Metallic Design Level 1 Page 21... -

Page 24: Diaphragm Service Drawing, With Overlay

Diaphragm Service Drawing, Diaphragm Service Drawing, with Overlay Non-Overlay 520-222-000 1/04 Rev C Model S30 Metallic Design Level 1 Page 22... -

Page 25: Diaphragm Servicing

32) until the inner diaphragm plate is flush Install 1/4 - 20UNC fastener into tapped hole. (see the drawing at far right). to the end of the rod. Insert rod into pump. 520-222-000 1/04 Rev C Model S30 Metallic Design Level 1 Page 23... -

Page 26: Actuator Plunger Servicing

Push the plungers in as far as they will To remove the bushings (item 7), first remove the retaining rings (item 31) using flat screwdriver. NOTE: It is recommended that new retaining rings be installed. 520-222-000 1/04 Rev C Model S30 Metallic Design Level 1 Page 24... -

Page 27: Check Valve Servicing

The pump can now be reassembled, reconnected and returned to operation. METALLIC SEATS with Non-Metallic Two o-rings (or conductive PTFE Seats seals) (item 27) are required for metallic seats. 520-222-000 1/04 Rev C Model S30 Metallic Design Level 1 Page 25... -

Page 28: Optional Muffler Configurations

**Configuration C 530-027-000 Sound Dampening Muffler screws directly into the Air Valve body. This muffler is equipped with a porous plastic element. Configuration A Configuration B and C 520-222-000 1/04 Rev C Model S30 Metallic Design Level 1 Page 26... -

Page 29: Pumping Hazardous Liquids

(item 1) has 1" NPT the pump comes equipped threads for piped exhaust. with a standard metal muffler 1" DIAMETER AIR EXHAUST PIPING LIQUID LEVEL SUCTION LINE Illustration #3 520-222-000 1/04 Rev C Model S30 Metallic Design Level 1 Page 27... -

Page 30: Rupptech® Leak Detection Options & Drawing

Mechanical Leak Detector Kit 031-023-110 Insert the leak detectors into the bottom part in the inner chambers. LEAK DETECTORS 520-222-000 1/04 Rev C Model S30 Metallic Design Level 1 Page 28... -

Page 31: Rupptech® Pulse Output Kit Drawing

See the individual kits listed on the Pump Repair Parts List for further information. Exhaust Port or Auxiliary Muffler Setup Pulse Output Kit Integral Muffler Setup Muffler Cap Pulse Output Kit 520-222-000 1/04 Rev C Model S30 Metallic Design Level 1 Page 29... -

Page 32: Grounding The Pump

Take action to prevent static sparking. Fire or explosion can result, especially when handling flammable liquids. The pump, piping, valves, containers or other miscellaneous equipment must be grounded. 520-222-000 1/04 Rev C Model S30 Metallic Design Level 1 Page 30...

Need help?

Do you have a question about the S30 and is the answer not in the manual?

Questions and answers