Table of Contents

Advertisement

SERVICE & OPERATING MANUAL

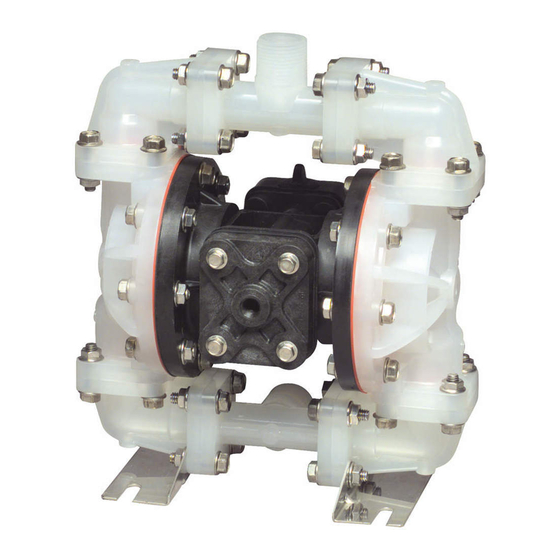

Model S07

Non-Metallic Design Level 1

Table of Contents

Engineering Data and Temperature Limitations .......................................................1

Explanation of Pump Nomenclature .........................................................................2

Performance Curve ..................................................................................................3

Performance Curve, Trihedral Model .......................................................................4

Dimensions: S07 Non-Metallic .................................................................................5

Metric Dimensions: S07 Non-Metallic.......................................................................6

Principle of Pump Operation.....................................................................................7

Installation and Start-up............................................................................................7

Air Supply .................................................................................................................7

Air Valve Lubrication .................................................................................................7

Air Line Moisture.......................................................................................................7

Air Inlet and Priming .................................................................................................7

Between Uses ..........................................................................................................7

Installation Guide ......................................................................................................8

Troubleshooting ........................................................................................................9

Warranty ...................................................................................................................9

Important Safety Information ..................................................................................10

Material Codes ....................................................................................................... 11

Composite Repair Parts Drawing ...........................................................................12

Overlay Option Drawing .........................................................................................12

Available Service and Conversion Kits ...................................................................12

Composite Repair Parts List ...................................................................................13

Air Valve Assembly Drawing and Parts List ............................................................14

Air Valve Assembly Servicing .................................................................................15

Air Valve with Stroke Indicator Drawing and Parts List ...........................................16

Air Valve with Stroke Indicator Servicing ................................................................17

Pilot Valve Servicing, Assembly Drawing and Parts List .......................................18

WARREN RUPP

s07nmdl1sm-rev0513

, IDEX AODD, Inc. • A Unit of IDEX Corporation • 800 N. Main St., P.O. Box 1568, Mansfield, Ohio 44901-1568 USA

®

Telephone (419) 524-8388 • Fax (419) 522-7867 • www.warrenrupp.com

U.S. Patent #

400,210

5,996,627;

6,241,487

Solenoid Shifted Valve Drawing and Parts List ......................................................19

Solenoid Shifted Air Distribution Valve Option ........................................................20

Intermediate Assembly Drawing .............................................................................21

Intermediate Assembly Servicing ...........................................................................21

Modular Check Ball Valve Drawing ........................................................................22

Modular Check Ball Valve Servicing .......................................................................22

Modular Trihedral Check Valve Option Drawing and Parts List ..............................23

Modular Trihedral Check Valve Servicing ...............................................................24

Diaphragm Service Drawing, Non-Overlay.............................................................25

Diaphragm Service Drawing with Overlay .............................................................25

Diaphragm Servicing, Overlay Diaphragm Servicing ............................................26

Dual Port Option Drawing .......................................................................................27

Dual Porting Options ..............................................................................................28

Dual Porting of both suction and discharge ends of the pump ...............................28

Single Porting of the suction and dual porting of the pump discharge ...................28

Dual Porting of the suction and single porting of the pump discharge ...................28

Single Port Suction Repair Parts List .....................................................................29

Single Port Discharge Repair Parts List .................................................................29

Dual Port Suction and Discharge Repair Parts List ................................................29

Pumping Hazardous Liquids...................................................................................30

Converting the Pump for Piping the Exhaust Air ....................................................30

Exhaust Conversion Drawing .................................................................................30

Converted Exhaust Illustration................................................................................30

Pulse Output Kit Drawing, Option ...........................................................................31

Optional Muffler Configurations Drawing ................................................................32

CE Declaration of Conformity .................................................................................33

©Copyright 2013 Warren Rupp, Inc. All rights reserved.

Advertisement

Table of Contents

Summarization of Contents

Engineering, Performance, and Construction Data

Intake/Discharge Pipe Size

Specifies thread sizes for pump inlet and discharge connections.

Capacity

Indicates the flow rate range of the pump in gallons and liters per minute.

Air Valve

Describes the air valve design, noting its lube-free and stall-free characteristics.

Solids-Handling

Details maximum particle size the pump can handle by valve type.

Heads Up To

States maximum head pressure pump can achieve in PSI and feet of water.

Displacement/Stroke

Specifies the volume of fluid displaced per pump stroke.

S07 Non-Metallic Dimensions

Dimensions in Inches

Provides dimensional data for the pump in inches with a specified tolerance.

S07 Non-Metallic Metric Dimensions

Dimensions in Millimeters

Provides dimensional data for the pump in millimeters with a specified tolerance.

Principle of Pump Operation

Installation and Start-Up

Guidelines for placing and connecting the pump for initial operation.

Air Supply

Details requirements for air pressure, capacity, and line connection.

Air Valve Lubrication

Information on whether lubrication is needed and how to apply it.

Air Line Moisture

Discusses the impact of water in compressed air and its mitigation.

Air Inlet and Priming

Instructions on how to start the pump and achieve priming.

Between Uses

Recommendations for pump care when not in use, especially in freezing conditions.

Composite Repair Parts Drawing

Available Service and Conversion Kits

Lists available kits for servicing and upgrading the pump.

Air Distribution Valve Assembly Drawing

Standard Air Valve Assembly Parts List

Lists components and quantities for the main air valve assembly.

Air Distribution Valve Servicing

Disassembly of Standard Air Valve

Steps for taking apart the air valve assembly.

Reassembly of Standard Air Valve

Instructions for putting the air valve assembly back together.

Air Valve with Stroke Indicator Assembly Drawing, Parts List

Air Valve with Stroke Indicator Assembly Parts List

Lists components for the air valve assembly with stroke indicator.

Air Distribution Valve with Stroke Indicator Option Servicing

Disassembly of Air Valve with Stroke Indicator

Steps for disassembling the air valve with stroke indicator.

Reassembly of Air Valve with Stroke Indicator

Steps for reassembling the air valve with stroke indicator.

Pilot Valve Servicing, Assembly Drawing & Parts List

Pilot Valve Assembly Parts List

Lists components for the pilot valve assembly.

Disassembly of the Pilot Valve

Instructions for disassembling the pilot valve.

Re-assembly of the Pilot Valve

Instructions for reassembling the pilot valve.

Re-install the Pilot Valve Assembly into the Intermediate

Steps for reinstalling the serviced pilot valve assembly.

Solenoid Shifted Air Valve Drawing

Solenoid Shifted Air Valve Parts List

Lists parts for the solenoid shifted air valve.

Solenoid Shifted Air Distribution Valve Option

Operation

Explains how the solenoid shifted option controls pump speed.

Before Installation

Pre-installation checks for the solenoid option.

Intermediate Drawing

Actuator Plunger Servicing

Service procedures for the actuator plunger.

Plunger Bushing, O-Ring, and Retaining Ring Servicing

Service procedures for plunger bushings, O-rings, and retaining rings.

Modular Check Ball Valve Drawing

Modular Check Ball Valve Servicing

Steps for servicing the modular check ball valve.

Re-assemble the Modular Check Valves

Instructions for reassembling the modular check ball valves.

Modular Trihedral Check Valve Servicing

Re-assemble the Valves

Instructions for reassembling the trihedral valves.

Suction End Valves

Installation of check valves on the suction end.

Discharge End Valves

Installation of check valves on the discharge end.

Diaphragm Service Drawings

Diaphragm Orientation

Illustrates the correct orientation for diaphragm installation.

Diaphragm Servicing

Overlay Diaphragm Servicing

Specific servicing instructions for overlay diaphragms.

One Piece Diaphragm Servicing (Bonded PTFE with integral plate)

Servicing instructions for one-piece bonded diaphragms.

Dual Porting Options

Dual Porting of Both Suction and Discharge Ends of the Pump

How to convert the pump for dual porting on both suction and discharge.

Single Porting of the Suction and Dual Porting of the Pump Discharge

How to convert the pump for single suction and dual discharge porting.

Dual Porting of the Suction and Dual Porting of the Pump Discharge

How to convert the pump for dual suction and dual discharge porting.

Single Port Suction Repair Parts List

Single Port Discharge Repair Parts List

Parts list for single port discharge configurations.

Pumping Hazardous Liquids

Converting the Pump for Piping the Exhaust Air

Steps to pipe the pump's exhaust air away from the unit.

Pulse Output Kit Drawing

Pulse Output Kit Option

Describes the pulse output kit and its function.

Need help?

Do you have a question about the S07B1P1PPNS000 and is the answer not in the manual?

Questions and answers