Sandpiper S15 Non-Metallic Operating Manual And Service Instructions

Hide thumbs

Also See for S15 Non-Metallic:

- Service & operating manual (23 pages) ,

- Service & operating manual (34 pages)

Table of Contents

Advertisement

SERVICE & OPERATING MANUAL

Original Instructions

Certified Quality

Quality System

ISO 9001 Certified

Environmental Management System

ISO 14001 Certified

Warren Rupp, Inc.

A Unit of IDEX Corporation

800 N. Main St.,

Mansfield, Ohio 44902 USA

Telephone 419.524.8388

Fax 419.522.7867

SANDPIPERPUMP.COM

© Copyright 2016 Warren Rupp, Inc.

All rights reserved

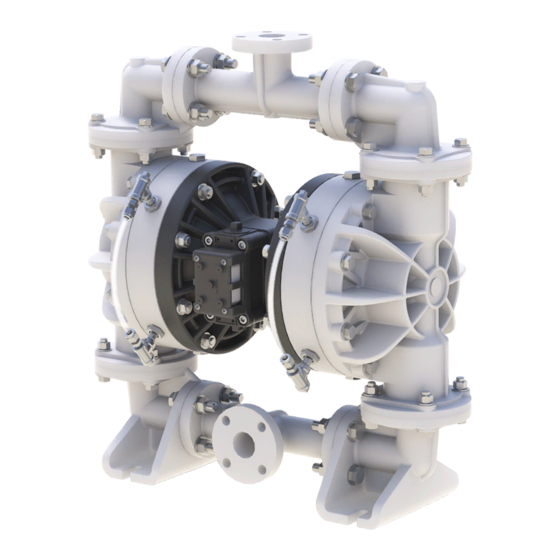

Model S15

Non-Metallic

Design Level 3

.

s a n d p i p e r p u m p

c o m

Advertisement

Table of Contents

Summary of Contents for Sandpiper S15 Non-Metallic

- Page 1 SERVICE & OPERATING MANUAL Original Instructions Certified Quality Model S15 Non-Metallic Design Level 3 Quality System ISO 9001 Certified Environmental Management System ISO 14001 Certified Warren Rupp, Inc. A Unit of IDEX Corporation 800 N. Main St., Mansfield, Ohio 44902 USA Telephone 419.524.8388 Fax 419.522.7867 SANDPIPERPUMP.COM...

-

Page 2: Safety Information

• Equipment is always used to transfer electrically conductive fluids or • Explosive environment is prevented from entering the internal portions of the pump, i.e. dry running For further guidance on ATEX applications, please consult the factory. Model S15 Non-Metallic sandpiperpump s15nmdl3sm-rev0316... -

Page 3: Table Of Contents

SECTION 6: OPTIONAL CONFIGURATIONS ..18 • Solenoid Shifted Air Valve • Dual Port • Electronic Leak Detector Installation Instructions SECTION 7: WARRANTY & CERTIFICATES ..21 • Warranty • CE Declaration of Conformity - Machinery • ATEX Declaration of Conformity Model S15 Non-Metallic sandpiperpump s15nmdl3sm-rev0316... -

Page 4: Explanation Of Nomenclature

II 2D Ex c iaD 20 IP67 T100°C II 2G EEx m c II T5 0, 6 A1, A2, A3, A4 II 2D c IP65 T100°C sandpiperpump • Model S15 Non-Metallic s15nmdl3sm-rev0316 PB 1/4 ATEX Detail Construction Muffler Options Options... -

Page 5: Performance

Performance S15 NON-METALLIC MODEL S15 Non-Metallic Performance Curve SUCTION/DISCHARGE PORT SIZE Performance based on the following: elastomer fitted pump, flooded suction, water at ambient conditions. The use of other materials and varying hydraulic conditions may result in deviations in excess of 5%. -

Page 6: Dimensional Drawings

ON A 3.88 BOLT CIRCLE Note: Porting Flanges are also available with PN10 40mm DIN Bolting Configuration AIR INLET 3/4” NPT S15 Non-Metallic with Spill Containment Dimensions in Inches [ ] in Millimeters. Dimensional tolerance: +/- 1/8"[ ] +/- 3mm DISCHARGE PORT 1 1/2” STANDARD 125# FLANGE CONFIGURATION .62 (4) HOLES EQUALLY SPACED ON A 3.88 BOLT CIRCLE... -

Page 7: Principle Of Pump Operation

MUFFLER source is at a higher level than the pump (flooded suction condition), pipe the exhaust higher than the product source to prevent siphoning spills. 1" DIAMETER AIR EXHAUST PIPING LIQUID LEVEL SUCTION LINE sandpiperpump Model S15 Non-Metallic • s15nmdl3sm-rev0316... -

Page 8: Recommended Installation Guide

To start the pump, slightly open the air shut-off valve. After the pump primes, the air valve can be opened to increase air flow as desired. If opening the valve increases cycling rate, but does not increase the rate of flow, cavitation has occurred. The valve should be closed slightly to obtain the most efficient air flow to pump flow ratio. sandpiperpump • Model S15 Non-Metallic s15nmdl3sm-rev0316... -

Page 9: Troubleshooting Guide

Inspect check valves and seats for wear and proper setting. Replace if necessary. Entrained air or vapor lock in chamber(s). Purge chambers through tapped chamber vent plugs. For additional troubleshooting tips contact After Sales Support at service.warrenrupp@idexcorp.com or 419-524-8388 sandpiperpump Model S15 Non-Metallic • s15nmdl3sm-rev0316... -

Page 10: Composite Repair Parts Drawing

Wetted End Kit (For PTFE Spill Containment Pumps) Neoprene Diaphragms, Neoprene Diaphragms, Neoprene Balls and PTFE Seals PTFE Overlay Diaphragms, PTFE Balls and PTFE Seals 476-255-633 Wetted End Kit FKM Diaphragms, PTFE Balls and PTFE Seals sandpiperpump • Model S15 Non-Metallic s15nmdl3sm-rev0316... -

Page 11: Composite Repair Parts List

Diaphragm 286-005-365 Diaphragm 286-114-000 Diaphragm, One-Piece Bonded PTFE LEGEND: = Items contained within Air End Kits = Items contianed within Wet End Kits Note: Kits contain components specific to the material codes. ATEX Compliant sandpiperpump Model S15 Non-Metallic • s15nmdl3sm-rev0316... -

Page 12: Material Codes

We encourage pump users to recycle worn 363..FKM (Fluorocarbon) 661..EPDM/Santoprene ® out parts and pumps whenever possible, Color coded: YELLOW 666..FDA Nitrile Diaphragm, after any hazardous pumped fluids are PTFE Overlay, Balls, and Seals thoroughly flushed. sandpiperpump • Model S15 Non-Metallic s15nmdl3sm-rev0316... - Page 13 560-078-611 O-Ring 618-003-110 Plug, Pipe 618-003-308 Plug, Pipe 618-025-110 Plug, Boss 618-025-308 Plug, Boss 618-031-110 Threaded Bushing 618-031-308 Threaded Bushing 835-005-110 Tee, Pipe 835-005-308 Tee, Pipe 860-055-606 Tube, Sight 866-060-110 Connector, Tube 560.078.611 O-Ring sandpiperpump Model S15 Non-Metallic • s15nmdl3sm-rev0316...

- Page 14 Sandpiper product line: Outer plate with a threaded curve toward the outer chamber. 15. Loosen the top boss plug (item 46) on the filled stud, diaphragm, and a threaded inner plate.

-

Page 15: Air Distribution Valve Assembly

(Includes all items used on 031-140-001 damage the pump, and void factory warranty. minus items 1-D, 1-F & 1-J) ATEX Compliant * For pumps with stainless brass sleeve and spool set use replace last three digits with 162 sandpiperpump Model S15 Non-Metallic • s15nmdl3sm-rev0316... -

Page 16: Air Valve With Stroke Indicator Assembly

Note: Sleeve and spool (1-A) set is match ground to a specified clearance 031-147-000 Air Valve Assembly sleeve and spools (1-A) cannot be interchanged. (includes all items on 031-146-000 minus 1-D, 1-F, & 1-J) ATEX Compliant sandpiperpump • Model S15 Non-Metallic s15nmdl3sm-rev0316... -

Page 17: Pilot Valve Assembly

Step 3: Remove spool (2-D) from sleeve (2-B), 775-055-000 Spool (With O-Rings) inspect O-Rings (2E), replace if required. 560-023-360 O-Ring (Spool) 675-037-080 Retaining Ring Step 4: Lightly lubricate O-Rings (2-C) and (2-E). Reassemble in reverse order. sandpiperpump Model S15 Non-Metallic • s15nmdl3sm-rev0316... -

Page 18: Intermediate Assembly

Step 8: Clean seal area, lightly lubricate and install new Seal, to prevent siphoning spills. In the event of a diaphragm failure a complete rebuild of the Diaphragm Rod (32). center section is recommended. sandpiperpump • Model S15 Non-Metallic s15nmdl3sm-rev0316... - Page 19 Diaphragm Service Drawing with Overlay Torque: 480 in/lbs Diaphragm Service Drawing, Non-Overlay Torque: 480 in/lbs Field conversion kit 475-256-000 available for conversion from PTFE Overlay to One-Piece bonded Diaphragm Part Description 286-114-000 One-Piece Diaphragm 612-227-150 Plate, Inner Diaphragm sandpiperpump Model S15 Non-Metallic • s15nmdl3sm-rev0316...

-

Page 20: Diaphragm Servicing

Turn the pump over of diaphragm plate assemblies utilized throughout the and thread the second diaphragm / inner plate onto Sandpiper product line: Outer plate with a threaded the diaphragm rod. Turn the diaphragm until the stud, diaphragm, and a threaded inner plate. -

Page 21: Solenoid Shifted Air Valve

(usually 1500 A). A maximum permissible ripple of 20% is valid for Note: Item 37 (Conduit Connector) is not required all magnets of direct-current design. Compressed Air Temperature Range: Maximum Ambient Temperature to plus 50°C sandpiperpump Model S15 Non-Metallic • s15nmdl3sm-rev0316... -

Page 22: Dual Port

The discharge elbows can be rotated in direction at 180° increments. (See arrows and 90°increments and the suction elbows can be rotated optional positioning in the Dual Porting Drawing.) in 180° increments (see optional positioning in the Dual Porting Drawing). sandpiperpump • Model S15 Non-Metallic s15nmdl3sm-rev0316... -

Page 23: Electronic Leak Detector Installation Instructions

¼" pipe tee (item 48). LEAK DETECTION OPTION (MECHANICAL) Follow instructions found elsewhere in this manual, “Filling the Spill Containment Chambers” when installing leak detectors. Mechanical Leak Detector Installation Kit 031-023-110 To install mechanical leak detectors, remove the bottom ¼" NPT pipe plug on the visual sight tube (item 49). Insert leak detector into the ¼" pipe tee (item 48). sandpiperpump Model S15 Non-Metallic • s15nmdl3sm-rev0316... -

Page 24: Declaration Of Conformity

Warren Rupp that bears a Warren Rupp brand shall fail under normal use and service due to a defect in material or workmanship within five years from the date of shipment from Warren Rupp’s factory. Warren Rupp brands include Warren Rupp ,SANDPIPER , MARATHON , PortaPump , SludgeMaster™... - Page 25 EC / EU Declaration of Conformity The objective of the declaration described is in conformity with the relevant Union harmonisation legislation: Directive 94/9/EC (until April 19, 2016) and Directive 2014/34/EU (from April 20, 2016). Manufacturer: Applicable Standard: Warren Rupp, Inc. EN13463-1: 2001 A Unit of IDEX Corportion EN13463-5: 2003...

Need help?

Do you have a question about the S15 Non-Metallic and is the answer not in the manual?

Questions and answers