SICK GM700 Operating Instructions Manual

Tdls analyzer for nh3, hf, hcl or o2

cross-duct version

Hide thumbs

Also See for GM700:

- Operating instructions manual (102 pages) ,

- Addendum to operating instructions (14 pages) ,

- Operating instructions manual (92 pages)

Summary of Contents for SICK GM700

- Page 1 O P E R A T I N G I N S T R U C T I O N S GM700 TDLS Analyzer for NH , HF, HCl or O Cross-Duct Version Installation Operation Maintenance...

- Page 2 Please consult the documentation Hazard by corrosive substances Hazard by voltage Hazard by unhealthy substances Hazard by toxic substances Hazard by laser radiation Hazard by high temperature or hot surface GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG...

-

Page 3: Table Of Contents

GM700 system, Cross-Duct version, layout........ - Page 4 Fitting the GM700 system components ........

- Page 5 9.2.1 Technical data, GM700 system components ....... . 97 GM700 sender/receiver unit dimensions ........99 Purge air fixtures for SR-unit and reflector dimensions .

- Page 6 Contents 8011543 V 3.1 GM700 · Operating Instructions · · © SICK AG...

-

Page 7: Safety Information

Safety Information GM700 Safety Information Main hazards Main operating information Intended use Responsibility of user GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG... -

Page 8: Main Hazards

▸ Do not interrupt protective conductor connections. WARNING: Hot surfaces when enclosure open Pay attention to hot surfaces on the measuring cell when opening the GM700 enclosure. WARNING: Eye injuries possible due to laser radiation Observe all relevant information in these Operating Instructions Main operating information 1. - Page 9 Safety Information WARNING: Toxic and caustic substances in parts in contact with sample gas ● GM700 parts in contact with sample gas can contain toxic and caustic sub- stances depending on the sample gas composition. ● When fitted in the measuring device, the reference cuvette contains the respective gases to be measured.

-

Page 10: Protection Against Laser Radiation

(e.g. cleaning the front window) otherwise the laser beam could be touched or accessed. WARNING: Never open the reflector during operation: This could result in dangerous exposure to radiation. GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG... -

Page 11: Behavior During Purge Air Failure

Laser capacity The laser wavelength varies for the respective measuring components. The laser output capacity is <10 mW on the optical interface (front window) of the GM700 SR-unit. The emitted radiation is harmless to human skin. Behavior during purge air failure 1.2.3... -

Page 12: Disposing Of Device Parts Harmful To The Environment

Printed circuit boards and similar electronic components ▸ Dispose of the permanent cuvette, when fitted, safely because it con- tains low concentrations of HCl or HF. Therefore, do not simply destroy the cuvette. GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG... -

Page 13: Product Overview

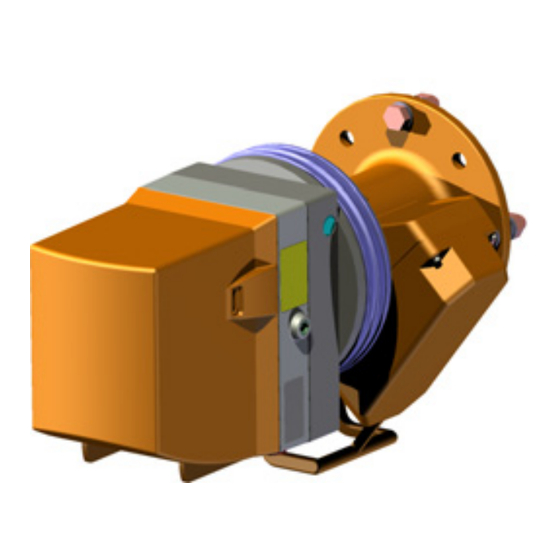

Product Overview GM700 Product Overview Product identification GM700 system, Cross-Duct version, layout Measuring principle GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG... -

Page 14: Product Identification

Operation Measuring Service Evaluation Unit Warnin Ref. conditions Malfunction Hum: wet diag maint Purge air unit SLV 4 (2nd purge air unit depending on application) Inputs/outputs, analog, binary GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG... - Page 15 (purge air unit filter monitor, temperature sensor PT1000, on the SR side) GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG...

-

Page 16: Gm700 Options And Accessories

Product Overview Evaluation unit The evaluation unit in the GM700 measuring system serves as user interface and is responsible for measured value processing and output as well as control and monitoring functions. The EvU can be located in the vicinity of the SR-unit. It can also be located up to about 1000 meters from the sampling point, e.g. -

Page 17: Measuring Principle

(TDLS) or Tunable Diode Laser Absorption Spectroscopy (TDLAS). A laser specially developed for gas analysis is used as light source in the GM700. This laser diode radiates a wavelength with a narrow line width so that an absorption line can be reli- ably scanned. - Page 18 Product Overview GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG...

-

Page 19: Project Planning Information

Project Planning Information GM700 Project Planning Information Project Planning Checklist Initial onsite installation Preparations for electrical installation GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG... -

Page 20: Work Steps From System Selection To Start-Up

● Start-up The actual start-up is carried out by trained personnel or Customer Service. This work is described on §6 ( p. 47). The main activities are adjustment tasks on the GM700 sys- tem related to the application. Project Planning Checklist 3. - Page 21 When working on the zero path; prerequisites: Clean Tools for start-up and ambient atmosphere free from sample gas; weatherproof: maintenance Plan the zero path or order from SICK. GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG...

- Page 22 This is especially important when inserting and removing the SR-unit or reflector. ▸ Accident prevention Applicable (national) regulations on accident prevention must be observed. GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG...

-

Page 23: Initial Onsite Installation

Remove any duct insulation to uncover an area of approx. 800 x 1500 mm (W x H) to prepare the duct for the following work. ▸ Keep the insulation material removed for later refitting resp. provide new suitable insu- lation material. GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG... -

Page 24: Mounting The Flanges With Tube

Mounting the flanges with tube 3.3.3 SICK delivers two flanges with tube with 240 mm total length and 125 mm inner diameter as standard. A version with 500 mm total length is available for installation locations with thicker insulation or for stone stacks. Special versions can be manufactured on request. - Page 25 Anchor the retainer plate with flange with tube welded on securely to the duct. 5 Weld the flange tube on. 6 Optical flange alignment. a) Remove the protective cap from the adjustment tube. GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG...

- Page 26 NOTICE: Observe the GM700 ambient temperature ▸ When the gas duct is hot, insulate the duct and flanges so that the (GM700 p. 67, §) is protected against high temperatures. GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG...

-

Page 27: Assembly Preparation For The Purge Air Unit

The onsite supply and signal cables are laid beforehand to facilitate subsequent installa- tion and start-up of the GM700 system components. Suitable cable ducts resp. empty con- duits are installed for cables already prefabricated and delivered with the GM700 system. - Page 28 Wiring by customer 3 binary outputs 6 x 0.5 mm Prefabricated with plug-in connector(s) 3 analog inputs 3 analog outputs 6 x 0.5 mm 6 x 0.5 mm GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG...

-

Page 29: Can Bus Wiring

– Start with the system internal connections of the GM700. Status and signal cables from the EvU to the connection terminals of the customer's sta- tus/message devices can be added later as required. GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG... - Page 30 Project Planning Information GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG...

-

Page 31: Installation

Installation GM700 Installation Preparations Fitting system components Installing the evaluation unit Electrical connection of system components GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG... -

Page 32: Preparations

Installation Preparations 4. 1 This Section describes the assembly and installation work for the GM700 measuring sys- tem before the actual start-up. Completion of the onsite preinstallation according to p. 19, §3 is assumed. Checking the scope of delivery 4.1.1 ▸... -

Page 33: Fitting System Components

The cable length available from the terminal box to the SR-unit is 4 m.Take the empty conduits laid for the prefabricated cables during onsite preinstallation into account. Figure 11 Fitting the terminal box with power supply unit Mounting holes GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG... -

Page 34: Installing The Evaluation Unit

Attach the evaluation unit at the installation location using the 4 planned fastening brackets with suitable screws. Figure 12 Installing the evaluation unit (sheet metal enclosure version) 4 mounting holes 8 mm Mounting surface Fastening brackets GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG... -

Page 35: Installing The Evaluation Unit - Cast-Metal Enclosure Version

Attach the evaluation unit at the installation location using the 3 planned mounting holes with suitable screws (M8 x 20). Figure 14 Fitting the evaluation unit (cast-metal enclosure) ▸ Close and lock the cover again. GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG... -

Page 36: Electrical Connection Of System Components

WARNING: Endangerment of electrical safety The power cables must be adequately dimensioned. ● The power connection must be made via a circuit-breaker switch. ● The grounding cable must be connected. ● GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG... -

Page 37: Electrical Connection In The Evaluation Unit Evu

Electrical connection in the evaluation unit EvU 4.5.2 Cable laying to the evaluation unit and relevant specifications have already been shown in p. 28, Fig. 10. GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG... - Page 38 The evaluation unit is configured to 230 V AC on delivery. ▸ Plug the respective bridges for 115 resp. 120 V AC as shown on the connection plate of the evaluation unit. GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG...

- Page 39 CAN cable shielding CAN bus cable PG screw fitting on the EvU WARNING: Burns by touching the cable glands The temperature on the cable glands could be >60 °C. GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG...

- Page 40 Installation GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG...

-

Page 41: Handling The Evaluation Unit

Handling the Evaluation Unit GM700 Handling the Evaluation Unit User qualifications Operating elements Menu overview GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG... -

Page 42: User Qualifications

User qualifications 5. 1 This Section describes how to operate the GM700 measuring system with the evaluation unit (EvU). The evaluation unit is available with either a sheet metal enclosure (protection class IP 65) or a cast-metal enclosure (protection class IP 67). The work described in this Section can be carried out by qualified customer operating personnel. -

Page 43: Menu Overview

● Probe, Subst. Analog In Subst. ● –100 ... 2000 °C Pressure Source: ● Probe, Subst. Analog In Subst. ● 600 ...15000 hPa Humidity Subst. ● 0 ... 93.0 percent by volume GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG... - Page 44 ● _ _ _ _ _ _ _ _ ● _ _ _ _ _ _ _ _ Software Revi- ● GMM700-X sion ● XXXXXXX XXXX ● GMM700/DSP ● XXXXXXX XXXX Service ● Not defined GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG...

- Page 45 ● Outputs the complete parameter set via the RS232 Service interface Reset System ● Restarts the measuring system Reset Parameter ● Resets parameters to factory settings Attention: All settings are overwritten! GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG...

- Page 46 Handling the Evaluation Unit GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG...

-

Page 47: Start-Up

Start-up GM700 Start-up Start-up steps overview Mechanical preparationOptical alignment Starting operating mode GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG... -

Page 48: Preparations

● Exact adherence to the application requirements specified in the order ● The possibility, during start-up, to ask the advice of a trained specialist from SICK or the respective sales partner should special questions arise that go beyond the normal scope of the standard procedures described. -

Page 49: Mechanical Preparation

Make sure the supply voltages on the type plates of the GM700 device components comply with the installation conditions. The supply voltage of the GM700 components can be changed between 115 V and 230 V on site by the SICK service personnel when necessary. -

Page 50: Cleaning Optical Interfaces

Set the gap between device flange and purge air fixture to approx. 5 mm so that the cup springs have sufficient pre-loading strength. ▸ Position the zero path near the SR-unit. GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG... -

Page 51: Fitting The Gm700 System Components

2 Fitting the alignment tool SR-unit: ▸ Unlock the enclosure lock of the SR-unit and swing the enclosure out ▸ Remove the hinge bolt and take the enclosure off the device flange. GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG... - Page 52 Position the alignment tool – light source onto the device flange (left side), insert the hinge bolt and swivel the alignment tool in. At the same time, lock properly with the lever. Figure 22 Fitting the alignment tool-light source Locking lever GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG...

- Page 53 ( p. 54, Fig. 25 left). Figure 24 L adjustment to align the flange - purge air attachment (example: reflector flange) Horizontal adjustment Vertical adjustment (screw hidden) Fixing shown here without sealing tape) GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG...

- Page 54 6 Installing the reflector ▸ Attach the reflector to the device flange – Position the reflector head and insert the bolt – Fix the reflector head with the quick-release locks GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG...

-

Page 55: Electrical Connections

Switch the power supply on. Figure 28 Connections on the SR-unit with purge air fixture Temperature sensor PT Low-pressure monitor 1000 SR-unit Connection CAN cable to purge CAN cable air fixture reflector GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG... -

Page 56: Optical Alignment

Using the XY adjustment with internal alignment tool ß back WARNING: Eye injuries possible due to laser radiation ▸ Never open or fold down the reflector during operation. GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG... - Page 57 To do this, adjust the nuts on the device flange so the light spot is positioned in the center of the target. ▸ Only adjust the screws as shown on p. 58, Fig. 31. GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG...

- Page 58 Press button “maint” ▸ Select Adjust Optical Alignment Maintenace Mode Maintenance mode/Optical Alignment is active. P, m xxx.x The EvU display switches to display the measuring chan- nel brightness. back GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG...

-

Page 59: Zero Adjust

The flashing “Malfunction” LED indicates that one or more error messages are pending. ▸ Switch to Diagnosis mode and rectify the problem, p. 85, §8. Starting measuring operation GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG... -

Page 60: Installing The Purge Air Fixtures

Start-up This Section describes the final preparations at the measuring point at which The Ausfüh- rung mit Messlanze GM700 starts measuring operation. The SR-unit and reflector with fit- ted purge air fixture must already be installed at the sampling point. -

Page 61: Sender/Receiver Unit And Reflector Start-Up

Connect the cable connections as described on p. 55, §6.4.3 and p. 28, Fig. 10 and switch the power supply for the sender/receiver unit and reflector unit on. GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG... - Page 62 Switch the power supply on. ▸ Carry out fine alignment according to p. 56, §6.4.4. ▸ Switch back to Measuring mode with button meas Regular measuring operation now starts. GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG...

-

Page 63: Installing Weatherproof Covers (Option)

Place the weatherproof cover on the ground turned over. ▸ Open and unhinge the locks on both sides. ▸ Pull the installation plate upwards and remove from the cover. 2 Installing the cover GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG... - Page 64 Place installation plate (1) from the top on the rubber band of the purge air fixture. Place the mounting ring on the side of purge air fixture (2); see detailed view in Fig. 38. ▸ Re-attach lower mounting ring (3). GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG...

-

Page 65: Evaluation Unit Start-Up

EvU initialization INIT Initializing the SR-unit INITIALISATION Adjusting amplification to changed transmission SIGNAL_ADJUST Measuring mode MEASURING Measuring mode with active tracking of laser wave- MEASURING LL length (line-locking) GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG... -

Page 66: Gas Connections For Oxygen Measurement

● Pressure reducer ● Supply line " with cutting-clamping ring connection (Swagelok) ▸ Fit a pressure reducer on the nitrogen cylinder and secure the gas cylinder against fall- ing over. GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG... -

Page 67: Starting Operating Mode

–22 … 77 –20 … 35 253 … 308 –4 … 95 –10 … 45 263 … 318 14 … 104 0 … 52 273 … 325 32 … 122 GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG... -

Page 68: Starting The Increased Nitrogen Purging For Oxygen Measurement

Make sure the nitrogen cylinder does not run empty. Close off the nitrogen cylinder for safety reasons when the measuring system has been shut down. The device first performs an initializing cycle after the power supply for all GM700 compo- nents (evaluation unit, purge unit) has been switched on. The evaluation unit displays the message “Initialization”. -

Page 69: Maintenance

Maintenance GM700 Maintenance Maintenance intervals Maintenance work on SR-unit and reflector Evaluation unit (EvU) Controlling and tracking the laser working point during measurement GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG... -

Page 70: Maintenance Intervals

The maintenance intervals depend on individual application conditions and should be clar- ified with SICK Service resp. a trained engineer or technician at the local sales partner. If no other specifications have been made, the following recommendation is applicable: ●... -

Page 71: Maintenance Work On Sr-Unit And Reflector

▸ Always switch the GM700 SR-unit off or disconnect the SR-unit CAN cable to the evaluation unit during work on the SR-unit or on the reflector. Otherwise, this could result in dangerous exposure to radiation. -

Page 72: Evaluation Unit (Evu)

If the evaluation unit is mounted outdoors, the following simple checks should be carried out regularly due to the load resulting from changing weather conditions: GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG... -

Page 73: Controlling And Tracking The Laser Working Point During Measurement

For HCI, use a test gas concentration between 500 and 1500 ppm. Connecting the test gas 7.5.1 Figure 44 Test gas connections on the SR-unit (for HF measurements) Test gas inlet Test gas outlet GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG... -

Page 74: Starting The Tracking Procedure

Watch for malfunction messages or warnings on the status LEDs of the EvU. ▸ If malfunctions appear, follow the instructions in the Troubleshooting Table on p. 88 and following pages. GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG... -

Page 75: Filter Box Measurement To Check The Measuring Channels For Nh 3 , Hf Or Hcl

Filter box measurement to check the measuring channels for NH , HF or HCl 7.5.3 The gas filter box serves to check the GM700 with test gases. Requirements Components required: ● Reflector enclosure with gold-plated hollow triple reflector; Part No. 2030206 ●... -

Page 76: Determining The Necessary Test Gas Concentration

Conversion factor depends on the component : 0.758, HF: 0.892, HCl: 1.628 Comp. Required test gas concentration Filter chamber lengths 25 mm 50 mm 75 mm 100 mm 125 mm 150 mm GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG... -

Page 77: Installing The Filter Box

Figure 46 Filter box Bolt Intermediate housing ▸ Swivel the intermediate GM700 enclosure open, remove the bolts and take off the intermediate enclosure. Store safely until filter box measurement is completed. Figure 47 Installing the filter box on the GM700 Bolt... -

Page 78: Carry Out Filter Box Measurement

After about 3 minutes, call Box measuring in menu cal (button cal) and select the option “gas”. ▸ Enter password “1 2 3 4”. ▸ The measuring device now starts a zero adjust and then switches to operating mode “Box measuring”. GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG... - Page 79 ▸ Disassemble the filter box with plate and reflector from the SR-unit and store safely ▸ Refit the SR-unit back onto the sampling point in the correct position. GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG...

-

Page 80: Checking The Gas Analyzer With Test Cell Gmk10

This is the standard case for GM700-2 (HF). A test gas system with hose pump, scales and evaporator is required in addition to the heated test cell GMK10 (example: Hovacal). -

Page 81: Assembly Of The Gm700 Components With The Test Cell Gmk10

Select “Maintenance Mode” and activate maintenance operation Assembly of the GM700 components with the test cell GMK10 7.6.1 Fig. 50 Assembly of the GM700 components and the test cell to a zero path GM700 reflector unit Zero path GMK10 test cell GM700 SR-unit ... -

Page 82: Carrying Out Measurement

1 Step: Checking optical alignment Checking optical alignment p. 56, 6.4.4 CAUTION: It is possible to perform the check of the GM700 with a separate reflector on a zero tube or a similar construction. Independent therefrom, the optical alignment is always performed to the probe position (marking “O, circle”... - Page 83 − Remove the cover of the GMK10 and set the temperature on the temperature controller. If required, see separate Operating Instructions of the temperature controller. Fig. 53 Temperature indicator on GMK10 Temperature indicator Temperature controller GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG...

- Page 84 Terminate the measurement with the “ back” button. Reinstall the GM700 SR and reflector unit to the purge air fixtures at the sampling point and continue Measuring mode. NOTICE: Purge the mesuring system with evaporated distilled water ...

-

Page 85: Troubleshooting And Clearing Malfunctions

Troubleshooting and Clearing Malfunctions GM700 Troubleshooting and Clearing Malfunctions Malfunction categories/possible effects Purge air failure Troubleshooting and clearing malfunctions, evaluation unit GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG... -

Page 86: Malfunction Categories/Possible Effects

Damage to the measuring system itself Depending on the installation conditions and measuring system version, a purge air failure could cause damage to the GM700. Section p. 86, 8.2 describes the necessary emer- gency and protective measures. Purge air failure 8. -

Page 87: Display And Retrieval Of Messages On The Evaluation Unit

Start Diagnosis mode (diag) Plain-text error messages – Call menu Malfunction (resp. Warning ) indicate possible causes ● Relay 1: – Check and clear the specified malfunction. Group malfunction GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG... -

Page 88: Troubleshooting And Clearing Malfunctions, Evaluation Unit

– Only connect the cable between the EvU and SR- Open: 230 V AC unit Plugged: 115 V – Connect the cable to the reflector Fuses: 2.5 AT, 250 V Screw terminals (CAN) for SR-unit GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG... -

Page 89: Error Messages

Error during signal evaluation for temperature and pressure substitute and correct if necessary ● Incorrect parameter values ▸ Restart device, see above ● Hardware defective ▸ If not successful, contact Service GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG... - Page 90 Gas concentration in reference (only for devices with ▸ cuvette too low Contact Service closed cuvette) ▸ Sensor communication Check CAN connection and repair if neces- SR-unit not connected correctly sary GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG...

- Page 91 Clean front window, p. 71, §7.3.2 of SR-unit or reflector contami- ▸ nated Check optical alignment and correct if neces- ● Optical axes alignment too inac- sary, p. 56, §6.4.4 curate GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG...

-

Page 92: Warning Messages

Wait until the temperature has stabilized ▸ Select different ambient temperature range, p. 75, ● Warm-up phase after switch- ing on §7.5.2.1 ▸ ● Ambient temperature too Cool device high GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG... -

Page 93: Further Tips On Troubleshooting

2.5 AT, 250 V Evaluation unit not responding ▸ Check the power supply on the GM700, check the operating voltage set ▸ Check the fuse in the evaluation unit; check the 24 V/5 V supply indicator in the evalu- ation unit, when doing so, remove the plug-in terminal on the cable to the receiver. - Page 94 Troubleshooting and Clearing Malfunctions GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG...

-

Page 95: Technical Data, Expendable And Spare Parts

Technical Data, Expendable and Spare Parts GM700 Technical Data, Expendable and Spare Parts Approvals Accessories, expendable and spare parts GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG... -

Page 96: Approvals

Minimum and maximum measuring range end values are only applicable for single compo- nents. Extremely small or large end values for different components cannot be combined in all cases. GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG... -

Page 97: Technical Data, Gm700 System Components

–40 to +55 °C Power supply 24 V DC, 1.7 A max. (supplied by evaluation unit) Dimensions L x W x H: 239 x 272 x 330 mm Weight 13 kg GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG... - Page 98 115/230 V AC –10%/+6%; 50/60 Hz Power input 50 VA max. Dimensions, weight, protection class Protection class IP 65 / NEMA 4x See dimensional drawing, p. 101 Dimensions GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG...

-

Page 99: Gm700 Sender/Receiver Unit Dimensions

Technical Data, Expendable and Spare Parts GM700 sender/receiver unit dimensions 9 . 3 GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG... -

Page 100: Purge Air Fixtures For Sr-Unit And Reflector Dimensions

Technical Data, Expendable and Spare Parts Purge air fixtures for SR-unit and reflector dimensions 9. 4 Reflector dimensions 9. 5 GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG... -

Page 101: Flanges With Tube Dimensions

1.4571 2017785 ST37 2017786 1.4571 Alternatively, an ANSI flange provided by the customer can be used. 240/500 GM700 evaluation unit, sheet metal enclosure version, dimensions 9 . 7 GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG... -

Page 102: Gm700 Evaluation Unit, Sheet Metal Version, Dimensions

Technical Data, Expendable and Spare Parts GM700 evaluation unit, sheet metal version, dimensions 9. 8 GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG... -

Page 103: Weatherproof Cover For Gm700 Sr-Unit, Dimensions

Technical Data, Expendable and Spare Parts Weatherproof cover for GM700 SR-unit, dimensions 9 . 9 Weatherproof cover for GM700 reflector unit, dimensions 9 . 10 GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG... -

Page 104: Terminal Box Dimensions For Can Bus (Option); Part No. 2020440

Technical Data, Expendable and Spare Parts Terminal box dimensions for CAN bus (option); Part No. 2020440 9. 1 1 GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG... -

Page 105: Accessories, Expendable And Spare Parts

2030739 (plug) Spare parts set, flange mounting kit 2039628 Spare parts set, lever (for alignment tool) 2030742 Spare parts set, clamping ring bolt 2030741 Bulkhead fitting 1/8" 5306073 GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG... -

Page 106: Spare Parts For The Reflector Unit

6 007 488 Protective cap 2 032 031 Plug, purge air unit Spare parts set, flange mounting: 2039628 5 pairs cup springs, spherical washer, nut 3 pcs. per flange required GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG... -

Page 107: Spare Parts For The Evaluation Unit

Cup springs A25 5 700 472 Nut SSI M12 5 700 494 Spherical washer 2 017 329 Hinge pin for GM700 flange fixture 4 023 743 Sealing tape GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG... -

Page 108: Spare Parts Assignment For Sender/Receiver Unit

Laser diode module PCB heater PCB processor Reference cuvette Receiver module for monitor and refer- ence channel Receiver module for measuring channel Optics body module GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG... - Page 109 Technical Data, Expendable and Spare Parts Figure 56 Spare parts assignment for GM700 SR-unit - intermediate enclosure and flange fixture SR-unit – intermediate enclosure Socket Plug Bulkhead fitting CAN cable connector CAN cable connector SR-unit: Flange fixture Fixing set, flange...

- Page 110 Technical Data, Expendable and Spare Parts Assignment of reflector spare parts GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG...

- Page 111 Technical Data, Expendable and Spare Parts GM700 · Operating Instructions · 8011543 V 3.1 · © SICK AG...

- Page 112 E-Mail support@sick.jp 1 (800) 325-7425 – tollfree Magyarország E-Mail info@sickusa.com Phone +36 1 371 2680 E-Mail office@sick.hu Nederland Phone +31 (0)30 229 25 44 More representatives and agencies E-Mail info@sick.nl at www.sick.com SICK AG | Waldkirch | Germany | www.sick.com...

Need help?

Do you have a question about the GM700 and is the answer not in the manual?

Questions and answers