Summary of Contents for Esu LokSound micro V4.0

- Page 1 LokSound V4.0 Instruction Manual 3 . E d i t i o n , F e b r u a r y 2 0 1 2 LokSound V4.0 LokSound micro V4.0 P/N 51972...

-

Page 2: Table Of Contents

5.1.1. LokSound V4.0 Decoders – An overview ....7 6.9.3. Purpose of AUX3 and AUX4 ........19 5.1.2. LokSound V4.0 ............6 6.9.4.1. LokSound with 21MTC Interface ......19 5.1.3. LokSound micro V4.0 ..........7 6.9.5. Suitable Smoke Generators ........19 5.2. General Properties of all Decoders.........8 6.9.6. Connecting a wheel sensor ........20 5.2.1. - Page 3 Contents 8.2.1. Programming with DCC Systems ......28 10.7.2. AC Analogue Operation ........38 8.2.2. Programming with the ESU ECoS ......29 11. Motor Control ............39 8.2.3. Programming with Märklin® 6021 ......29 11.1. Adjusting Load Compensation ........39 8.2.3.1. Changing the Programming Mode ......29 11.1.1.

-

Page 4: Declaration Of Conformity

13.3. Manual notching (Diesel only) ........53 13.4. Synchronizing the steam chuff (Steam only) ....53 We, ESU electronic solutions ulm GmbH & Co KG, Industriestrasse 13.4.1. Minimum distance of steam chuffs ......54 5, D-89081 Ulm, declare in sole responsibility that the products to 13.5. -

Page 5: Important Notes - Please Read This Chapter First

• Make sure that no wires are squeezed or cut by the model’s transmission parts when reassembling the engine. Copyright 1998 - 2012 by ESU electronic solutions ulm GmbH & Co KG. Electri- • Any power supply must be protected by a fuse or circuit breaker cal characteristics and dimensions are subject to change without prior notice. -

Page 6: How This Manual Helps You

How this manual helps you 4. How this manual helps you 5. Introduction – The LokSound Family This manual is divided into several chapters that show you step-by- 5.1. The Members of the LokSound Family step how to install a LokSound decoder. All LokSound V4.0 decoders have been completely redeveloped Chapter 5 provides an overview over the characteristics of each on the basis of their predecessors´... -

Page 7: Loksound V4.0 Decoders - An Overview

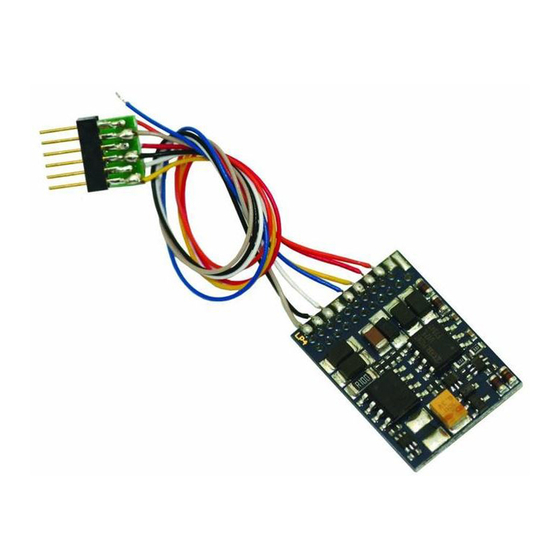

5.1.3. LokSound micro V4.0 Due to its manifold lighting and sound functions and its adapt- The LokSound micro V4.0 is a small power pack: Despite its small ability to different applications, it is the perfect all-rounder for your dimensions it supports beside DCC also Motorola® and Selectrix®... -

Page 8: General Properties Of All Decoders

255 addresses and 28 speed steps in Mo- torola® mode. With the appropriate command station such as the ESU ECoS, you can expand the system limits of the Motorola® system considerably. Furthermore, all LokSound V4.0 decoder support RailComPlus®. -

Page 9: Sound Functions

E.M.F (load compensa- Due to unique load compensation by ESU, there are no visible tion), speed step dependant. jerks between speed steps – even in 14-speed-step-mode. -

Page 10: Functions For Electric Locomotives

Length of sound is up to you. Owners of the ESU ECoS enjoy an even more comfortable method 5.2.3.4. LokProgrammer of programming: you can read all possible settings in plain text on All sounds of the LokSound decoders can be exchanged, trans- the large display and easily adjust them –... -

Page 11: Installing The Decoder

To hold the Right track connection decoder in place use double sided adhesive tape or some (just a Figure 1: LokSound V4.0 & LokSound micro V4.0 - NEM652 little) hot glue. 6.3. Locomotives with 8-pin NEM 652-Interface • Insert the plug of the decoder in such a way that pin 1 of the plug... -

Page 12: Locomotives With 6-Pin Nem 651-Interface

Right track connection Insertion of the decoder with Left track connection black connector to the bottom locomotive pcb Headlight white (e.g. Brawa) Rearlight yellow (Side view) Figure 2: LokSound micro V4.0 - NEM651 & Next18 Figure 3: LokSound V4.0 - 21MTC... -

Page 13: Locomotives With 21Mtc Interface

Installing the Decoder 6.5. Locomotives with 21MTC Interface 6.5.1. Connecting C-Sine motors („SoftDrive-Sinus“) Some LokSound decoders are available with a variant of the The LokSound decoder cannot drive the newer Märklin® models 21MTC interface as per Fig. 3. Installation in locomotives with this with C-Sine motors (also called „SoftDrive-Sinus“) directly. -

Page 14: Wiring Diagram For Loksound

DC motor brown orange orange grey green AUX1 grey black black white yellow blue left track gelb right track connection weiß connection decoder back decoder front Licht Licht hinten vorne Figure 5: Wiring Diagram for LokSound micro V4.0 (wiring example) - Page 15 (no content for the present)

-

Page 16: Colour Coding By Märklin

Please check all connections with an Ohmmeter. Search for short circuits, particularly between the motor leads and the wheel contacts. Description Märklin® colour ESU colour (according to NMRA DCC standard) AC: Power pick up show («Schleifer») (Center rail) DC: Right track connection AC: Outside rails brown... -

Page 17: Connecting Universal Motors With Hamo-Conversions

4 – 16 Ohms. We recom- Figure 9: Parallel wiring of two speakers mend to use the 4 Ohms impendance by ESU as they are tuned to LokSound V4.0 decoders. However, we advise against using the previous 100 Ohm impedance speakers since the sound volume 6.9. -

Page 18: Overload Protection Of Function Outputs (Blinking)

Installing the Decoder Please make sure that the load does not exceed the permitted 6.9.1.1. Suitable Light Bulbs maximum current and there are no short circuits. The outputs Only install bulbs rated 16V or higher and with a nominal current of the LokSound have protection but if an external voltage is draw, that does not exceed 50 mA. -

Page 19: Connecting The Light Outputs, Aux1 And Aux2

In terms of their functionality, AUX3 and AUX4 are equal to chassis of the locomotive (as in most locomotives by Märklin® the other outputs. ESU offers an appropriate adapater board (art. as well as in most older locomotives by Fleischmann® and no. -

Page 20: Connecting A Wheel Sensor

Based on the type of sensor IC you use, this may result decoder. In this case, you must wire a relay (ESU No. 51963) into in double the amount of steam chuffs you want to have. In this the circuit or you slightly reduce the „Brightness“... -

Page 21: Reed Switch Sensor

However, you may not run this locomotive on AC layouts any- more. Risk of destruction! Disconnect / remove the capacitor prior to programming with Reed switch the ESU LokProgrammer! Input 6.10.2. Optional “PowerPack” You can solder a powerful energy buffer to all LokSound V4.0 H0 decoders. - Page 22 Installing the Decoder • The PowerPack only operates in digital mode. It automatically 100Ω,1/4 Watts turns off on analogue layouts. Rev 40 Rev 41 (2012) • It may take up to two minutes to fully charge the capacitor („GoldCap“). Therefore, the time bridged with the energy buffer 2200uF depends on the current draw of your locomotive and the charge- 1N4007...

-

Page 23: Initial Operation

LokSound V4.0 7.2.1. DCC operation LokSound V4.0 LokSound micro V4.0 F1 switches the sound on/off F2 switches the whistle/signal horn The remaining function keys are used differently depending on Remove any capacitors that are wired into the track feeders (e.g. -

Page 24: Auto-Detection Of Dcc Speed Steps

28-speed step mode. In conjunction with suitable command stations (e.g.: ESU ECoS, in „Motorola® 28“ Should you change the speed step setting during operation then mode) this leads to smoother control of your locomotives. No you must interrupt the power to the decoder for a short moment changes are required on the decoder. -

Page 25: Selectrix® Mode

Since load compensation requires about 3 – 4 Volts as „base volt- age“ you must turn the throttle further than normal (=locomo- LokSound V4.0 tives without decoder) before the locomotive starts moving. LokSound micro V4.0 7.3.2. Analogue AC Operation LokSound V4.0 You may operate the LokSound with any Selectrix® compatible command station with access to the functions „lights“... -

Page 26: Decoder Settings (Programming)

Programming 8. Decoder Settings (Programming) Chapter 8 covers setting various parameters of the LokSound de- coder. Should you not be familiar with the handling of CVs please take the time to read these occasionally quite complex instruc- tions. After an introduction into the world of parameters in chapter 8.1, we explain in the following section 8.2 how to change various parameters in DCC mode and with Märklin®... -

Page 27: Configuration Variables (Cvs)

Most CVs contain numbers: CV 1 for instance contains the lo- LokSound V4.0 comotive address. This can be any number between 1 and 127. LokSound micro V4.0 While most CVs expect numbers to be entered, some others are rather like a „collection point“ of various „switches“, that admin- ister different functions in one CV (mainly „on“... -

Page 28: Programming With Dcc Systems

„Write value 7 in CV 3!“. Each decoder receiving this command will execute it. ESU counts the bits from 0 to 7 as laid out in the standards while others (e.g.: Lenz®) count the bits from 1 to 8. -

Page 29: Programming With The Esu Ecos

(alternately pull the mains plug of the transformer). Press the „Stop“ button in order to switch off The owners of an ESU ECoS can comfortably program LokSound the track voltage. Enter the current decoder address. If you do not decoders. -

Page 30: Programming With The Märklin® Mobile Station

You access the long mode by entering the value 07 in CV 07 while LokSound V4.0 in the short mode. The decoder confirms the change to the long LokSound micro V4.0 mode by slowly flashing lights. • Enter the hundred-digit and the ten-digit (decade) of the CV that you want to change. Example: If you want to adjust CV 124, you enter „12“. -

Page 31: Programming With The Märklin® Central Station

LokProgrammer. Address Saves the CV number that 0-99 You can access all properties of ESU decoders with the LokPro- should be actually programmed grammer. Since this works independently form the data format it in units and tens also works for mfx®... -

Page 32: Programming With The Roco® Lokmaus Ii

Saves the value of the CV that 0-99 LokSound V4.0 sould be actually programmed in untis and tens LokSound micro V4.0 Example: You wish to programm CV 317 with value 120. Proceed as follows: The ROCO® LokMaus II is generally one of the most successful • Programm the value of the CV number in hundreds in CV 96. In DCC command stations. -

Page 33: Address Settings

If you want to use your LokSound with the long address it is practical to program this address directly with your digital system: most modern digital systems (e.g. ESU ECoS, Bachmann E-Z Com- mand® Dynamis®) have a menu for programming long addresses. -

Page 34: Adapting The Driving Characteristics

10.2. Starting Voltage, Maximum and Medium Speed LokSound V4.0 10.1. Acceleration and Deceleration LokSound micro V4.0 Acceleration and brake time can be set independently from each other. Therefore, you could for instance program a short accelera- tion and a much longer brake time. -

Page 35: Speed Curve

10.4. Changing between Operating Modes analogue track voltage. You may change from a digital to an analogue sector of your lay- This mode is not available for the LokSound micro V4.0! out „on-the-fly“ at any time. 10.4.3. Changing from Analogue to Digital (directional bit) -

Page 36: Changing From Digital To Digital

LokSound V4.0 Frequently, this function serves for stopping a train in front of a LokSound micro V4.0 red signal. If a LokSound detects a brake command, it will slow down with the programmed deceleration and then stop. After this enforced stop, the locomotive will accelerate again as per the programmed values in CV 3. -

Page 37: Selectrix® Diode Brake Sector

All command stations and boosters age and will stop the train (CV 27 = Value 24). by ESU and Lenz® garantuee a symmetrical output. We don´t rec- ommend to use other boosters for the ABC technique. -

Page 38: Linear Brake Distance

LokSound V4.0 the locomotive stopps at the correct position in the end. Figure 17 shows this quite clearly. LokSound micro V4.0 In DC analogue mode you can adjust the starting speed with CV 125 and the maximum speed with CV126. -

Page 39: Motor Control

Unfortunately, the motors available in the market have consider- LokSound V4.0 able variations due to tolerances. This is even true for the same LokSound micro V4.0 type. Therefore, LokSound decoders enable you to adapt load compensation to the motor with CVs 53, 54 and 55. If the recom- mended values above do not lead to acceptable results, you can further optimise them. -

Page 40: Reference Voltage

Motor Control • Increase the value by 5 starting with the default value for motors 11.1.2.4. Parameter “K slow” with very small or no flywheels. Together with the LokSound V4.0 decoder an additional CV 52 • Reduce the value by 5 starting with the default value for motors has been introduced which seperately determines the gain control with large flywheels. considerably for the whole slow driving sector in speed step 1. Test again and repeat this procedure until you arrive at the desired If you are not satisfied with the driving behaviour when the lo- result. -

Page 41: Turning Off Load Compensation

11.4. Dynamic Drive Control: Up and Down the Hill LokSound V4.0 LokSound V4.0 LokSound micro V4.0 LokSound micro V4.0 You can also switch off load compensation by writing the value 0 Dynamic Drive Control of your LokSound decoder enables you in CV 56 („Control Influence“). -

Page 42: Function Outputs

You can allocate the functions freely to any function button. ESU uses the so-called and once more extended „Mapping“ for the LokSound V4.0 decoder. It has the advantage that you can link each output to any button. -

Page 43: Function Mapping Chart

You want to switch AUX3 with the F8 key, either when you drive 12.2.2. Function Mapping Chart forwards and backwards. With the help of the ESU adapter board Please refer to the chart on page 40/41 to get an overview of the 51968 you added a light bulb to AUX3. -

Page 44: Special Effects On Function Outputs

Function outputs 12.3. Special Effects on Function Outputs • Gyra Light: The Gyra Light is similar to the Mars Light, but is slower in motion. 12.3.1. Switching on Outputs and Different Options • Coupler function: You can use this function to control Krois® or Each function output can / must be unlocked prior to using it. Fur- ROCO® couplers, also in connection with automatic pushing/re- thermore, each output offers the choice of a lighting effect or can moving. - Page 45 Function outputs Rule 17 Reverse: Like Rule 17 Forward, but the brightness will be For each physical output, the three controlling CVs are defined increased to a 100% when the locomotive drives as follows: backwards. Function Mode Brightness Automat. Special Dimmer: Causes the output to be dimmed to around output...

- Page 46 Fig. 21: Function Mapping - Factory default values for LokSound V4.0 Physical function outputs Logic functions 1 FS(f) Stand forward 2 266 1 8 16 32 64 128 2 268 1 8 16 32 2 269 FS(r) Stand backward 2 282 1 8 16 32 64 128 2 284 1 8 16 32 2 285...

- Page 47 Logic functions 2 Sound functions 1 Sound functions 2 Sound functions 3 1 2 4 8 32 64 128 2 270 2 4 8 16 32 64 128 2 271 1 2 4 8 16 32 64 128 2 272 1 2 4 8 16 32 64 128 1 2 4 8 32 64 128 2 286 2 4 8 16 32 64 128 2 287 1 2 4 8 16 32 64 128 2 288 1 2 4 8 16 32 64 128...

-

Page 48: Grade Crossing Holding Time

LokSound V4.0 set to 5. 2. We find out that for LED compensation mode, we should set LokSound micro V4.0 the Special function CV to 128. 3. We want to have a brightness level of 25. 4. Using the table on the left side, we find that the Mode Select CV for AUX4 is 299. -

Page 49: Automatic Coupler Function (Removing/Pushing)

The LokSound V4.0 decoder is able to do the automatic decou- LokSound V4.0 pling. When you push the function button the loco drives back- LokSound micro V4.0 wards against the train and then removes from it again. This pro- cedure can be influenced via three CVs. -

Page 50: Adjusting The Sound Effects

Adjusting the Sound Effects 13. Adjusting the Sound Effects third lighting circuit that switches the left lower headlight of the The LokSound V4.0 allows you to adjust the sound in a way that „A“- headlight configuration whenever the lights are turned on. suit your preferences for your locomotives. - Page 51 Adjusting the Sound Effects Steam sound table Diesel sound table Function Sound slot Range Default Function Sound slot Range Default Sound on/off 0 – 128 Sound on/off 0 – 128 Sound on/off 0 – 128 Sound on/off 0 – 128 Whistle (playable) 0 –...

-

Page 52: Prime Mover Startup Delay

Adjusting the Sound Effects Electric sound table Special sound table Function Sound slot Range Default Function Sound slot Range Default Sound on/off 0 – 128 Random sounds 0 – 128 Sound on/off 0 – 128 Brake sound 0 – 128 Camshaft contactors (for Signal horn #1 (playable) 3 0 –... -

Page 53: Manual Notching (Diesel Only)

Adjusting the Sound Effects 13.3. Manual notching (Diesel locomotives only) 13.4. Synchronising the steam chuff (Steam locomotives only) Usually, the LokSound V4.0 decoder automatically selects the die- To synchronise the steam chuff with the wheel revolutions, you sel speed notch appropriate for the desired speed. However, in may use an external cam as described in chapter 6.9. -

Page 54: Minimum Distance Of Steam Chuffs

Adjusting the Sound Effects decrease the value of CV 58. This procedure will oaken the 13.6. Adjusting the braking sound threshold gear factor of the LokSound V4.0 decoder. The LokSound decoder is able to play a wheel-synchron brake sound. To play a brake sound, Damit das Bremsgeräusch ab- 13.4.1. -

Page 55: Decoder Reset

Prior to use RailCom® must be unlocked by setting bit 3 in CV 29. CV 28 offers further options. Ex works, RailCom® is active in ESU LokSound V4.0 decoders. -

Page 56: Railcom® Plus

You can carry out the update yourself for free without having to never ever have to change the locomotive address of a new loco- remove the decoder from the locomotive. All you need is the ESU motive by hand! Just put the locomotive on the tracks and it will LokProgrammer. -

Page 57: Wire Harnesses With 8-Pin Or 6-Pin Socket

(please provide your fax-no. or email address) or 18.4. Mounting Adapter 21MTC go to www.esu.eu/en/forum and we will reply within a few days. If you wish to convert a locomotive with a LokSound decoder with the 21MTC interface, the adapter plate 51967 comes in handy:... -

Page 58: Technical Data

20. Technical Data LokSound LokSound V4.0 micro V4.0 Operation Voltage 5 – 40V 5 – 21V DCC operation using 14/28/128 Fahrstufen, 2-digit and 4-digit addresses; automatic recognition of operational mode Digital Motorola®, with 14/28 speed steps, Ok 255 Ok 255 address range for Motorola®-mode M4-operation with automatic recognition Selectrix®... -

Page 59: List Of All Supported Cvs

Version number Internal software version of decoder Manufacturer‘s ID Manufacturers‘s ID ESU - Writing value 8 in this CV triggers a reset to factory default values Analogue mode F1-F8 Status of functions F1 to F8 in analogue mode (see chapter 12.4) - Page 60 List of all supported CVs Name Description Range Value Brake mode Allowed brake modes Function Value ABC braking, voltage higher on the right hand side ABC braking, voltage higher on the left hand side ZIMO® HLU brakes active Brake on DC, if polarity against driving direction Brake on DC, wenn Polarität gleich wie Fahrtrichtung RailCom®...

- Page 61 List of all supported CVs Name Description Range Value Extended Configuration #1 Additional important settings for LokSound Decoders 0 - 255 Description Value Enable Load control (Back-EMF) Disable Load control (Back-EMF) DC Motor PWM frequency 20kHz motor pulse frequency 40 kHz motor pulse frequency Märklin®...

- Page 62 List of all supported CVs Name Description Range Value Load control parameter «K» for „K“-component of the internal PI-controller for the low speed steps. 0 - 255 slow driving Defines the effect of load control. The higher the value, the stronger the effect of Back EMF control.

- Page 63 Enable serial protocol for C-Sinus Adaptive regulation frequency Constant regulation frequency Starting voltage Analog DC 0-255 Maximum speed Analog DC 0-255 Starting voltage AC (not for LokSound micro V4.0) 0-255 Maximum speed Analog AC (not for LokSound micro V4.0) 0-255...

- Page 64 List of all supported CVs Name Description Range Value Manual Notching «Offset» The value determines the number of speed steps to which the motor 0 - 255 revolution will be increased («notch up»). See chapter Grade Crossing Hold Time Grade Crossing holding time. See chapter 12.3.3 Automatic decoupling Speed of the loco while decoupling;...

-

Page 65: How To Programm Long Addresses

(no content for the present) -

Page 66: Appendix

Appendix 22. Appendix 22.1.2. Read out addess If you wish to read out a loco address please read the values of CV 17 and CV 18 one after another and proceed then in reverse order: 22.1. Programming Long Addresses Let’s assume you have read: As described in chapter 9.2. -

Page 67: Warranty Card

Due to liability reasons any inspections or repairs can only be carried out on products that are not installed in a locomotive or carriage. Any locomotive sent to ESU for inspection will be returned without even touching it. There is no extension of the warranty period due to any repairs or replacements carried out by ESU. - Page 68 (use extra page if needed) Art.No.: Purchase Date: Address: Operation Mode: AC Analogue AC Digital DC Analog DC Digital (DCC) Digital system: ESU ECoS Märklin® 6012 ROCO® Digital LGB® Digital LGB® MZS Intellibox® Lenz® Digital Others: 3. Error description Headlight output front...

Need help?

Do you have a question about the LokSound micro V4.0 and is the answer not in the manual?

Questions and answers