WAGO 750-806 Manuals

Manuals and User Guides for WAGO 750-806. We have 2 WAGO 750-806 manuals available for free PDF download: Manual, Technical Description

WAGO 750-806 Manual (214 pages)

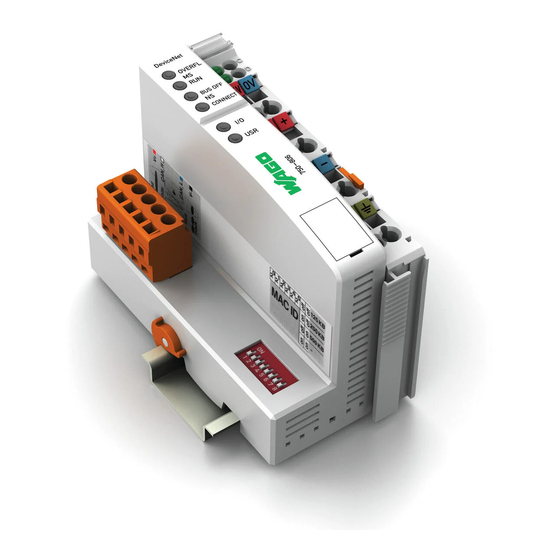

Fieldbus Controller DeviceNetTM

16-bit CPU

Brand: WAGO

|

Category: Controller

|

Size: 5 MB

Table of Contents

-

-

-

-

View40

-

Connectors42

-

DIP Switch48

-

Device Data50

-

System Data50

-

Power Supply51

-

Accessories51

-

Approvals53

-

-

Mounting

56-

Spacing59

-

-

Run-Up68

-

PFC Cycle68

-

Memory Space72

-

Addressing76

-

-

-

System Events104

-

Dynamic Assembly111

-

Heartbeat112

-

Bit-Strobe113

-

Diagnostics

114-

LED Signaling114

-

Usr Led123

-

-

-

Devicenet TM125

-

Transfer Media126

-

Cabling127

-

Topology128

-

I/O Messages132

-

-

TM Devices132

-

-

Data Exchange133

-

Process Image133

-

EDS Files135

-

Object Model135

-

-

I/O Modules

168-

Overview168

-

System Modules193

-

-

-

106032 X)203

-

List of Figures

207-

List of Tables209

-

Advertisement

WAGO 750-806 Technical Description (152 pages)

Modular I/O System DeviceNet

Brand: WAGO

|

Category: I/O Systems

|

Size: 2 MB

Table of Contents

-

-

-

-

Description39

-

Hardware40

-

LED Display56

-

-

-

Description62

-

Hardware63

-

LED Display99

-

Blink Code101

-

-

Technical Data103

-

4 O Modules

105 -

7 Glossary

150 -

9 Index

152

Advertisement