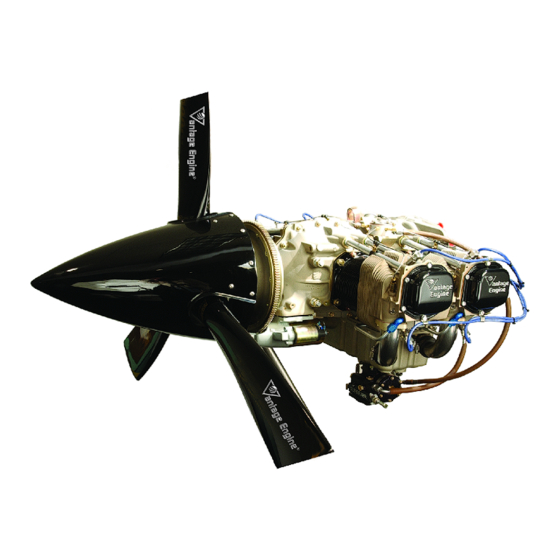

Superior Vantage Engine O-360 SERIES Maintenance Manual

Hide thumbs

Also See for Vantage Engine O-360 SERIES:

- Installation & operation manual (114 pages) ,

- Overhaul manual (182 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Superior Vantage Engine O-360 SERIES

- Page 1 O-360 & IO-360 SERIES ENGINES MAINTENANCE MANUAL 621 South Royal Lane, Suite 100 / Coppell, TX 75019 / 800-277-5168 www.superiorairparts.com Manual P/N SVMM01, Revision B, February 2007 02-00-00 © February 2007 Superior Air Parts Inc. Description and Operation...

-

Page 2: General Information

Maintenance Manual O-360 and IO-360 Series Engines THIS PAGE INTENTIONALLY LEFT BLANK © February 2007 Superior Air Parts Inc. General Information... -

Page 3: Revision History

05-00-00, p1 3/6/06 annual” to & del mag cap removal from 100 hr insp 05-20-00, p3 72-00-10 All Add Celsius Temperature conversions to Fahrenheit 72-00-12 All 02/28/07 temperatures 72030-00 All 72-50-00 All © February 2007 Superior Air Parts Inc. General Information... - Page 4 Maintenance Manual O-360 and IO-360 Series Engines THIS PAGE INTENTIONALLY LEFT BLANK © February 2007 Superior Air Parts Inc. General Information...

-

Page 5: Safety Advisory

SOLVENT IS TOXIC. USE IN WELL-VENTILATED AREA. PREVENT EYE AND SKIN CONTACT AND DO NOT BREATHE VAPORS. IN CASE OF EYE CONTACT, FLUSH WITH WATER. IN CASE OF SKIN CONTACT, WASH WITH SOAP AND WATER. © February 2007 Superior Air Parts Inc. General Information... - Page 6 THROTTLE POSITION “CLOSED”. • MIXTURE CONTROL POSITION “IDLE-CUT OFF”. • SET BRAKES AND BLOCK AIRCRAFT WHEELS. ENSURE THAT AIRCRAFT • TIE DOWNS ARE INSTALLED AND VERIFY THAT THE CABIN DOOR LATCH IS OPEN. © February 2007 Superior Air Parts Inc. General Information...

-

Page 7: Table Of Contents

General 20 00 25 Hour Inspection 50 Hour Inspection 100 Hour or Annual Inspection 500 Hour Inspection 1000 Hour Inspection Recommended TBO Recommended Accessory Replacement 50 00 Unscheduled Inspection and Maintenance © February 2007 Superior Air Parts Inc. General Information... - Page 8 Oil System Components Degreasing Decarbonizing Corrosion Removal Parts Preservation and Corrosion Prevention Engine Assembly General Engine Installation General Preparing Engine for Service Installation of Engine Torques, Fits, and Clearances General Service Limits viii © February 2007 Superior Air Parts Inc. General Information...

- Page 9 Propeller Governor System 30 00 Cylinder Section General Cylinder Replacement Cylinder Break-in Procedures 50 00 Lubrication Section General Oil Pressure Adjustment Oil Filter Adapter and Vernatherm Valve Oil Sump Suction Screen © February 2007 Superior Air Parts Inc. General Information...

- Page 10 Idle Speed and Mixture Adjustment Primer Nozzle Cleaning 74 00 00 Ignition Section General Magneto Replacement Ignition Harness Replacement Appendix 1 Unison Industries L-1363B, 4300/6300 Series Magneto Maintenance and Overhaul Manual © February 2007 Superior Air Parts Inc. General Information...

-

Page 11: List Of Figures

Oil System Schematic 72-50-00.2 Oil Filter and Adapter Assembly 72-50-00.3 Oil Sump Assembly 72-50-00.4 Oil Pressure Relief Valve 73-00-00.1 Engine Fuel Pump Assembly 74-00-00.1 Magneto Components 74-00-00.2 Timing Diagram 74-00-00.3 Ignition Wiring Diagram © February 2007 Superior Air Parts Inc. General Information... - Page 12 Maintenance Manual O-360 and IO-360 Series Engines THIS PAGE INTENTIONALLY LEFT BLANK © February 2007 Superior Air Parts Inc. General Information...

-

Page 13: List Of Tables

Equipment and Materials List 72-00-11.1 Dimensional Limits 72-00-11.2 Backlash and End Clearance Limits 72-00-11.3 Torque Limits 72-00-11.4 Valve Spring Dimensional Limits 72-00-11.5 Crush Type Gasket Tightening Angles 72-00-12.1 Preservation and Storage Materials xiii © February 2007 Superior Air Parts Inc. General Information... - Page 14 Oil Sump Capacity 72-00-15.3 Minimum Octane Fuels 72-00-15.4 Consumables 72-00-15.4 Hoses 72-10-00.1 Alternator Belt Tension Requirements 72-30-00.1 Equipment and Material List 72-50-00.1 Oil Pressure Springs 73-00-00.1 List of Materials 74-00-00.1 List of Equipment © February 2007 Superior Air Parts Inc. General Information...

-

Page 15: Introduction

Maintenance Manual O-360 and IO-360 Series Engines INTRODUCTION About This Manual Superior Air Parts has made clear and accurate Information contained this Engine information available for those who maintain, Maintenance Manual fulfills content own and repair the Vantage O-360 and IO-360 requirements of FAR 33.4 Appendix A33.3(a) - Page 16 Maintenance Manual O-360 and IO-360 Series Engines THIS PAGE INTENTIONALLY LEFT BLANK 01-00-00 © March 2006 Superior Air Parts Inc. Introduction...

-

Page 17: Description And Operation

The model number designation is defined in a way that the digits of the model number can easily identify the basic configuration of the engine as described in Figure 02-00-00.1. 02-00-00 © March 2006 Superior Air Parts Inc. Description and Operation... -

Page 18: Engine Model Number Designation

Conical Mount, Front Propeller Governor 3rd Digit Accessory Package Ignition System Fuel System Unison Magnetos Precision Fuel System 4th Digit Power Rating: Piston Compression Ratio 8.5:1 Figure 02-00-00.1 • Engine Model Number Designation 02-00-00 © March 2006 Superior Air Parts Inc. Description and Operation... -

Page 19: Specifications

Direction of Accessory Ratio Rotation Starter 16.556:1 Counter- Alternator 3.250:1 Clockwise Tachometer 0.500:1 Clockwise Magneto 1.000:1 Clockwise Counter- Vacuum Pump 1.300:1 Propeller Governor 0.866:1 Clockwise Fuel Pump 0.500:1 Plunger Operated 02-00-00 © March 2006 Superior Air Parts Inc. Description and Operation... - Page 20 Aero Accessories IO-360 4371 4371 M4001 RSA-5-AD1 AF15473 * See Table 72-00-15.4 for approved consumables (spark plugs, oil filters, belts, hoses) and Table 02-09-00.6 below for approved secondary engine accessories. 02-00-00 © March 2006 Superior Air Parts Inc. Description and Operation...

-

Page 21: Features And Operating Mechanisms

Constant speed models have a plug installed at and valve rockers. the rear of the front main bearing cavity. 02-00-00 © March 2006 Superior Air Parts Inc. Description and Operation... - Page 22 Fuel Systems choked and honed to allow optimal operating conditions for the rings and pistons at operating Carbureted - Superior Air Parts O-360 engines temperatures. are equipped with a float type carburetor The MA-4-5 carburetors are of the single barrel float...

- Page 23 SPARK PLUG PRIMING SYSTEM CHT PROBE LOCATION (TYPICAL EACH HEAD) ALTERNATOR & BELT (IF PROVIDED WITH ENGINE) STARTER THROTTLE LEVER FUEL LINE CARBURETOR Figure 02-00-00.2 • O-360 Engine Front View 02-00-00 © March 2006 Superior Air Parts Inc. Description and Operation...

- Page 24 OIL FILTER ASSEMBLY HARNESS MAGNETO FUEL PUMP PRIMING SPARK PLUG FUEL SYSTEM LINE STARTER MIXTURE LEVER INDUCTION OIL SUMP SYSTEM ASSEMBLY CARBURETOR Figure 02-00-00.3 • O-360 Engine Left Side View 02-00-00 © March 2006 Superior Air Parts Inc. Description and Operation...

- Page 25 Maintenance Manual O-360 and IO-360 Series Engines INTER-CYLINDER BAFFLE SPARK PLUG MAGNETO MAGNETO OIL FILTER Figure 02-00-00.4 • O-360 Engine Top View 02-00-00 © March 2006 Superior Air Parts Inc. Description and Operation...

- Page 26 FUEL PUMP OIL DRAIN PLUG COMMON PRIMER LINE SOURCE FUEL PUMP INLET FUEL LINE OIL SUCTION SCREEN FUEL MIXTURE THROTTLE LEVER LEVER Figure 02-00-00.5 • O-360 Engine Rear View 02-00-00 © March 2006 Superior Air Parts Inc. Description and Operation...

- Page 27 SPARK PLUG SPARK PLUG FUEL INJECTOR CHT PROBE LOCATION (TYPICAL EACH HEAD) ALTERNATOR & BELT STARTER (IF PROVIDED WITH ENGINE) FUEL INJECTION SERVO Figure 02-00-00.6 • IO-360 Engine Front View 02-00-00 © March 2006 Superior Air Parts Inc. Description and Operation...

- Page 28 HOUSING STARTER SUPPORT OIL FILTER ASSEMBLY WIRING HARNESS MAGNETO FUEL PUMP STARTER FUEL LINE SPARK PLUG OIL SUMP FUEL INJECTION SERVO Figure 02-00-00.7 • IO-360 Engine Left Side View 02-00-00 © March 2006 Superior Air Parts Inc. Description and Operation...

- Page 29 Maintenance Manual O-360 and IO-360 Series Engines FUEL INJECTION MANIFOLD FUEL INJECTIOR Figure 02-00-00.8 • IO-360 Engine Top View 02-00-00 © March 2006 Superior Air Parts Inc. Description and Operation...

- Page 30 VENT LINE CONNECTION FUEL PUMP INLET DIAPHRAGM FUEL OIL DRAIN PLUG PUMP OIL SUCTION SCREEN OIL DRAIN PLUG THROTTLE CONTROL LEVER MIXTURE CONTROL LEVER Figure 02-00-00.9 • IO-360 Engine Rear View 02-00-00 © March 2006 Superior Air Parts Inc. Description and Operation...

-

Page 31: Airworthiness Limitations Section

Refer to 500 Hour Inspection Program for details of this inspection. See the included Unison Industries L-1363B 4300/6300 Series Magneto Maintenance and Overhaul Manual, in Appendix 1, for additional information. FAA APPROVED 04-00-00 © March 2006 Superior Air Parts Inc. Airworthiness Limitation Section... - Page 32 Maintenance Manual O-360 and IO-360 Series Engines THIS PAGE INTENTIONALLY LEFT BLANK 04-00-00 © March 2006 Superior Air Parts Inc. Airworthiness Limitation Section...

-

Page 33: Scheduled Inspection And Maintenance

They apply to the engine only. Refer airframe manufacturer's instructions additional information regarding airframe inspections. Refer to the propeller manufacturer’s instructions for additional information regarding propeller inspections. 05-00-00 © March 2006 Superior Air Parts Inc. Scheduled Inspection and Maintenance... - Page 34 Maintenance Manual O-360 and IO-360 Series Engines THIS PAGE INTENTIONALLY LEFT BLANK 05-00-00 © March 2006 Superior Air Parts Inc. Scheduled Inspection and Maintenance...

-

Page 35: Hour Inspection

MAY CAUSE INJURY TO SKIN AND EYES. RUBBER APRON, AND CHEMICAL-SAFETY PUT ON RUBBER GLOVES AND GOGGLES. SHOES. MAKE SURE THAT YOU HAVE SUFFICIENT AIRFLOW KEEP SOLVENT FUMES BELOW THE MSDS LIMIT. 05-20-00 © March 2006 Superior Air Parts Inc. Scheduled Inspection and Maintenance... - Page 36 Check cowling and baffles for secure attachment or damage. Any damaged or missing part of the cooling system must be repaired or replaced before the aircraft resumes operation. 05-20-00 © March 2006 Superior Air Parts Inc. Scheduled Inspection and Maintenance...

-

Page 37: 100 Hour Or Annual Inspection

Never install a spark plug that has been attached to the condenser stud. dropped. Dispose of dropped spark plug Torque P-lead nut to 13-15 inch- and install new spark plug. pounds. 05-20-00 © March 2006 Superior Air Parts Inc. Scheduled Inspection and Maintenance... - Page 38 Typically leakage will occur rotated too far, back up at least one- either past the valve seat or rings. half revolution and start over again principle differential pressure 05-20-00 © March 2006 Superior Air Parts Inc. Scheduled Inspection and Maintenance...

- Page 39 If cylinder pressure readings still indicate must be accomplished before the aircraft a defective cylinder, remove and inspect resumes operation. suspect cylinder Vantage Engine Overhaul Manual, or replace the cylinder, see section 72-30-01. 05-20-00 © March 2006 Superior Air Parts Inc. Scheduled Inspection and Maintenance...

-

Page 40: 500 Hour Inspection

Replace brush assembly if brushes extend less than .25” from edge of brush holder case. Recommended TBO The Vantage Engine has a recommended TBO of 1000 hours. 05-20-00 © March 2006 Superior Air Parts Inc. Scheduled Inspection and Maintenance... -

Page 41: Unscheduled Inspection And Maintenance

05-50-00 © March 2006 Superior Air Parts Inc. Unscheduled Inspection and Maintenance... - Page 42 Failure to do so may result in catastrophic engine failure. Further operation of an engine immersed in water without inspection is the responsibility of the authority returning the engine to service. 05-50-00 © March 2006 Superior Air Parts Inc. Unscheduled Inspection and Maintenance...

-

Page 43: Engine Section

Testing and Fault Isolation • Cleaning • Engine Removal • Engine Installation • Torques, Fits, and Clearances • Preservation and Storage • Servicing • Front Section • Cylinder Section • Lubrication Section 72-00-00 © March 2006 Superior Air Parts Inc. Engine Section... - Page 44 Maintenance Manual O-360 and IO-360 Series Engines THIS PAGE INTENTIONALLY LEFT BLANK 72-00-00 © March 2006 Superior Air Parts Inc. Engine Section...

-

Page 45: Testing And Fault Isolation

NOTE: The Fault Isolation sequence is in order OTHER PROTECTIVE GEAR. IN CASE OF of approximate ease of checking, not EYE CONTACT, FLUSH WITH WATER FOR necessarily in order of probability. MINUTES SEEK MEDICAL 72-00-01 © March 2006 Superior Air Parts Inc. Testing and Fault Isolation... -

Page 46: Engine Will Not Start

Examine air scoop and remove restrictions. Improper fuel; detonation, high CHT Drain and refill tank with proper fuel. Faulty ignition; rough running engine Tighten all connections. Check system with tester. Check ignition timing. 72-00-01 © March 2006 Superior Air Parts Inc. Testing and Fault Isolation... -

Page 47: Rough Engine Operation

High oil temperature See Table 72-00-01.9, “High Oil Temperature”. Defective pressure gage. Replace defective gage. Stoppage in oil pump intake passage Check line for obstruction. Clean suction strainer. 72-00-01 © March 2006 Superior Air Parts Inc. Testing and Fault Isolation... -

Page 48: High Oil Temperature

Insure that oil filler cap is tight and that o-ring is or in engine compartment in good condition. Insure that breather hose exit is cut and located to avoid creating a vacuum in the breather hose. 72-00-01 © March 2006 Superior Air Parts Inc. Testing and Fault Isolation... -

Page 49: Engine Removal

Preservation and Storage • Remove all clamps attaching engine wire section of this manual for procedures and bundles to engine components and route materials. bundles clear of the engine. 72-00-05 © March 2006 Superior Air Parts Inc. Engine Removal... - Page 50 Maintenance Manual O-360 and IO-360 Series Engines THIS PAGE INTENTIONALLY LEFT BLANK 72-00-05 © March 2006 Superior Air Parts Inc. Engine Removal...

-

Page 51: Engine Disassembly

Refer to section 72-50 for lubrication system component removal and replacement. Refer to Chapter 74 for ignition system removal and replacement. 72-00-06 © March 2006 Superior Air Parts Inc. Engine Disassembly... - Page 52 Maintenance Manual O-360 and IO-360 Series Engines THIS PAGE INTENTIONALLY LEFT BLANK 72-00-06 © March 2006 Superior Air Parts Inc. Engine Disassembly...

-

Page 53: Cleaning

ABRASIVES WITH GRIT BLASTING EQUIPMENT. Spark Plugs and Electrical Components • Spark plugs should be removed from the engine and placed into a rack designating their original locations in the engine. 72-00-07 © March 2006 Superior Air Parts Inc. Cleaning... -

Page 54: Oil System Components

AND SPRAY ALL PARTS WITH LUBRICATING YOUR EYES. THIS WILL HELP PREVENT IMMEDIATELY AFTER CLEANING INJURIES TO PERSONNEL OR DAMAGE TO ORDER TO PREVENT CORROSION. THE EQUIPMENT. IF YOU GET AN EYE INJURY, SEEK MEDICAL ATTENTION. 72-00-07 © March 2006 Superior Air Parts Inc. Cleaning... -

Page 55: Corrosion Removal

Inspect the engine and its components to be sure they are clean and dry. 72-00-07 © March 2006 Superior Air Parts Inc. Cleaning... - Page 56 Maintenance Manual O-360 and IO-360 Series Engines THIS PAGE INTENTIONALLY LEFT BLANK 72-00-07 © March 2006 Superior Air Parts Inc. Cleaning...

-

Page 57: Engine Assembly

Refer to section 72-30 for cylinder assembly and prior to engine run. removal and replacement. Refer to section 72-50 for lubrication system component removal and replacement. 72-00-09 © March 2006 Superior Air Parts Inc. Engine Assembly... - Page 58 Maintenance Manual O-360 and IO-360 Series Engines THIS PAGE INTENTIONALLY LEFT BLANK 72-00-09 © March 2006 Superior Air Parts Inc. Engine Assembly...

-

Page 59: Engine Installation

Engines that have been subjected to a cold WARNING: DO NOT INSTALL THE IGNITION environment for long periods of time should HARNESS "B" NUTS ON THE SPARK PLUGS be placed into at least a 70°F (21°C) 72-00-10 © February 2007 Superior Air Parts Inc. Engine Installation... - Page 60 Maintenance Manual O-360 and IO-360 Series Engines UNTIL THE INSTALLATION IS COMPLETED. FAILURE TO COMPLY COULD RESULT IN BODILY INJURY WHEN THE PROPELLER IS ROTATED DURING INSTALLATION. 72-00-10 © February 2007 Superior Air Parts Inc. Engine Installation...

-

Page 61: Torques, Fits, And Clearances

"tight", i.e., an interference fit. example is the fit of the valve guide in the cylinder head. Where no "T” exists, the fit is a clearance dimension. 72-00-11 © March 2006 Superior Air Parts Inc. Torques, Fits, and Clearances... -

Page 62: Dimensional Limits

Table 72-00-12.2 • Backlash and End Clearance Limits Minimum Maximum Description of Limit (in.) (in.) Propeller Governor Gear (End Clear) 0.002 0.024 Vacuum Pump Gear (End Clear) 0.010 0.057 72-00-11 © March 2006 Superior Air Parts Inc. Torques, Fits, and Clearances... -

Page 63: Torque Limits

Fuel and Prop Governor Elbow Locknuts Spin-on Oil Filter 192-216 Fuel Pump Socket Head Bolts (3/8-16) 225-250 Vernatherm Valve Injector and Primer Nozzle Nut and Capscrews (10-24, 10-32) Primer and Injector Tubing Nuts 72-00-11 © March 2006 Superior Air Parts Inc. Torques, Fits, and Clearances... -

Page 64: Crush Type Gasket Tightening Angles

135º NOTE: Install Crush Gasket with seam toward aluminum case. Tighten thread until cap or valve body contacts gasket. Turn additional angle shown above. Lock wire in place. 72-00-11 © March 2006 Superior Air Parts Inc. Torques, Fits, and Clearances... -

Page 65: Preservation And Storage

Preservative Oil Mil-C-16173 Grade 2, or equivalent Commercially Available Dehydrator plugs, AN4062-1 or MS27215-2 Commercially Available Covers, as required Commercially Available Moisture Resistant Caps Commercially Available Moisture Resistant Tape Commercially Available 72-00-12 © February 2007 Superior Air Parts Inc. Preservation and Storage... -

Page 66: Temporary Storage

IAW plugs. Protect the ignition lead ends with “Indefinite Storage” procedures. AN-4060 protectors or equivalent. Using a 72-00-12 © February 2007 Superior Air Parts Inc. Preservation and Storage... -

Page 67: Indefinite Storage

Remove cylinder dehydrators and plugs Correct any discrepancies prior to returning from upper and lower spark plug holes. aircraft to service. • Change oil and filter after 25 hours of operation. 72-00-12 © February 2007 Superior Air Parts Inc. Preservation and Storage... - Page 68 Maintenance Manual O-360 and IO-360 Series Engines THIS PAGE INTENTIONALLY LEFT BLANK 72-00-12 © February 2007 Superior Air Parts Inc. Preservation and Storage...

-

Page 69: 13 Repair Procedures

Refer to instructions in the Inspection and Check section of this Refer to section 72-30 for cylinder assembly manual. removal and replacement. 72-00-13 © March 2006 Superior Air Parts Inc. Repair Procedures... - Page 70 Maintenance Manual O-360 and IO-360 Series Engines THIS PAGE INTENTIONALLY LEFT BLANK 72-00-13 © March 2006 Superior Air Parts Inc. Repair Procedures...

-

Page 71: Servicing

General Fuels This section specifies the fuels, lubricants, and consumables required to operate the Vantage Superior Vantage Engines are certified for use series engines. For aircraft servicing, refer to with the following fuels. Minimum octane fuels the aircraft manufacturer's manual. -

Page 72: Consumables

Fuel Inj. Servo Aeroquip AE3663163G0161 Fuel Injection Superior SV1001-4CR-334 Servo to Fuel Stratoflex 124J001-4CR-0334 Manifold Aeroquip AE3663161E0334 Propeller Governor Rear Governor Superior SV1001-6CR-400 Adapter to Front Stratoflex 124J001-6CR-0400 of Crankcase Aeroquip AE3663161G0400 72-00-15 © March 2006 Superior Air Parts Inc. Front Section... -

Page 73: Starter

No other maintenance is required. checking starter for proper operation. Starter Replacement The starters used on the Superior Vantage Engines are for 12 or 24 volt electrical systems, as required by the airframe, and have a drive gear appropriate for a 149 tooth ring gear. -

Page 74: Starter Installation

Maintenance Manual O-360 and IO-360 Series Engines Figure 72-10-00.1 • Starter Installation 72-10-00 © March 2006 Superior Air Parts Inc. Front Section... -

Page 75: Alternator

Adjust alternator location 72-10-01.1 below. appropriately, torque adjustment bolt appropriately, and check for required belt tension. Readjust, as necessary, to meet tension required. Figure 72-10-00.2 • Alternator Installation 72-10-00 © March 2006 Superior Air Parts Inc. Front Section... - Page 76 WARNING: DO NOT INSTALL THE IGNITION HARNESS "B" NUTS ON THE SPARK PLUGS UNTIL THE INSTALLATION IS COMPLETED. FAILURE TO COMPLY COULD RESULT IN BODILY INJURY WHEN THE PROPELLER IS ROTATED DURING INSTALLATION. 72-10-00 © March 2006 Superior Air Parts Inc. Front Section...

- Page 77 Maintenance Manual O-360 and IO-360 Series Engines Figure 72-10-01.2 • Alternator and Mounting Hardware Detail 72-10-00 © March 2006 Superior Air Parts Inc. Front Section...

-

Page 78: Propeller Governor System

Start aircraft, check for proper operation of bearing cavity and require no maintenance. propeller governor. Shut down aircraft and check for oil leaks and correct as necessary. 72-10-00 © March 2006 Superior Air Parts Inc. Front Section... - Page 79 Maintenance Manual O-360 and IO-360 Series Engines Figure 05-00-00.4 • Propeller Governor Oil Hose 72-10-00 © March 2006 Superior Air Parts Inc. Front Section...

- Page 80 Maintenance Manual O-360 and IO-360 Series Engines THIS PAGE INTENTIONALLY LEFT BLANK 72-10-00 © March 2006 Superior Air Parts Inc. Front Section...

-

Page 81: 00 Cylinder Section

• Remove the cylinder base nuts. Then, by pulling it directly away from the crankcase, remove the cylinder. Do not allow the piston 72-30-00 © February 2007 Superior Air Parts Inc. Cylinder Section... - Page 82 Refer to Figure 72- cylinder is replaced. Tighten the 1/2-inch 30-00.1. nuts to 300 inch-pounds torque, using the 72-30-00 © February 2007 Superior Air Parts Inc. Cylinder Section...

-

Page 83: Assembled Cylinders

Maintenance Manual O-360 and IO-360 Series Engines Figure 72-30-00.1 • Assembled Cylinders 72-30-00 © February 2007 Superior Air Parts Inc. Cylinder Section... - Page 84 Maintenance Manual O-360 and IO-360 Series Engines Figure 72-30-00.2 • Piston Pin and Piston Assembly 72-30-00 © February 2007 Superior Air Parts Inc. Cylinder Section...

- Page 85 Maintenance Manual O-360 and IO-360 Series Engines Figure 72-30-00.3 • Piston Ring Compressor 72-30-00 © February 2007 Superior Air Parts Inc. Cylinder Section...

- Page 86 Maintenance Manual O-360 and IO-360 Series Engines Figure 72-30-00.4 • Cylinder Base Nut Tightening Sequence 72-30-00 © February 2007 Superior Air Parts Inc. Cylinder Section...

-

Page 87: Installation Of Pushrods

Maintenance Manual O-360 and IO-360 Series Engines Figure 72-30-00.5 • Installation of Pushrods 72-30-00 © February 2007 Superior Air Parts Inc. Cylinder Section... - Page 88 Maintenance Manual O-360 and IO-360 Series Engines Figure 72-30-00.6 • Rocker Arm and Pushrod Assembly 72-30-00 © February 2007 Superior Air Parts Inc. Cylinder Section...

-

Page 89: Intercylinder Baffle Assembly

Maintenance Manual O-360 and IO-360 Series Engines Figure 72-30-00.7 • Intercylinder Baffle Assembly 72-30-00 © February 2007 Superior Air Parts Inc. Cylinder Section... -

Page 90: Cylinder Break-In Procedures

P-leads and remove top spark plugs from all four cylinders. 2. Using starter switch, engage starter to rotate engine for 30 seconds or until 20 psi oil pressure is indicated. 72-30-00 © February 2007 Superior Air Parts Inc. Cylinder Section... - Page 91 • • Fill with ashless dispersant oil of the Monitor RPM, oil pressure, oil temperature appropriate grade for the expected normal and cylinder temperature. operating conditions ambient temperature. 72-30-00 © February 2007 Superior Air Parts Inc. Cylinder Section...

- Page 92 Maintenance Manual O-360 and IO-360 Series Engines THIS PAGE INTENTIONALLY LEFT BLANK 72-30-00 © February 2007 Superior Air Parts Inc. Cylinder Section...

-

Page 93: 00 Lubrication Section

If valve is not working properly, replace with new lower higher pressure spring SL53E19600 valve assembly, which includes a appropriate. new crush gasket. Torque to 300 in-lb and safety wire to adapter. 72-50-00 © February 2007 Superior Air Parts Inc. Lubrication Section... -

Page 94: Oil Sump Suction Screen

Install safety wire, securing plug to sump. Remove oil sump finger screen by cutting the safety wire securing it to the sump and removing screen plug. Inspect screen for debris. 72-50-00 © February 2007 Superior Air Parts Inc. Lubrication Section... -

Page 95: Oil System Schematic

Maintenance Manual O-360 and IO-360 Series Engines Figure 72-50-00.1 • Oil System Schematic 72-50-00 © February 2007 Superior Air Parts Inc. Lubrication Section... - Page 96 Maintenance Manual O-360 and IO-360 Series Engines Figure 72-50-00.2 • Oil Filter and Adapter Assembly 72-50-00 © February 2007 Superior Air Parts Inc. Lubrication Section...

-

Page 97: Oil Sump Assembly

Maintenance Manual O-360 and IO-360 Series Engines Figure 72-50-00.3 • Oil Sump Assembly 72-50-00 © February 2007 Superior Air Parts Inc. Lubrication Section... - Page 98 Maintenance Manual O-360 and IO-360 Series Engines Figure 72-50-00.4 • Oil Pressure Relief Valve 72-50-00 © February 2007 Superior Air Parts Inc. Lubrication Section...

-

Page 99: Engine Fuel System

FROM SPARKS, FLAME SURFACES. PUT ON SPLASH GOGGLES, SOLVENT-RESISTANT GLOVES AND OTHER PROTECTIVE GEAR. IN CASE OF EYE CONTACT, FLUSH WITH WATER FOR 15 MINUTES AND SEEK MEDICAL ATTENTION. 73-00-00 © March 2006 Superior Air Parts Inc. Engine Fuel System... -

Page 100: Engine Fuel Pump Assembly

Maintenance Manual O-360 and IO-360 Series Engines Figure 73-00-00.1 • Engine Fuel Pump Assembly 73-00-00 © March 2006 Superior Air Parts Inc. Engine Fuel System... -

Page 101: Fuel Pump Replacement

DAMAGE TO EQUIPMENT. IF YOU GET AN • Install fuel pump socket head bolts, torque EYE INJURY, GET MEDICAL ATTENTION. to 225-250 in-lb. Safety wire the two drilled socket head screws to each other. 73-00-00 © March 2006 Superior Air Parts Inc. Engine Fuel System... - Page 102 Maintenance Manual O-360 and IO-360 Series Engines THIS PAGE INTENTIONALLY LEFT BLANK 73-00-00 © March 2006 Superior Air Parts Inc. Engine Fuel System...

-

Page 103: 00 Fuel Injection System

NOT removed from the nozzle assembly. If removal is necessary, both must be thoroughly cleaned prior to reassembly. shield must have a tight fit on the body. 73-10-00 © March 2006 Superior Air Parts Inc. Fuel Injection System... - Page 104 Maintenance Manual O-360 and IO-360 Series Engines THIS PAGE INTENTIONALLY LEFT BLANK 73-10-00 © March 2006 Superior Air Parts Inc. Fuel Injection System...

-

Page 105: Carburetion System

50 RPM. Every time the idle is adjusted, the engine should be run up to 2000 RPM to clear the engine before proceeding with the RPM check. 73-20-00 © March 2006 Superior Air Parts Inc. Carburetion System... - Page 106 Maintenance Manual O-360 and IO-360 Series Engines THIS PAGE INTENTIONALLY LEFT BLANK 73-20-00 © March 2006 Superior Air Parts Inc. Carburetion System...

-

Page 107: Ignition Section

The ring gear is marked at 20° and 25° BTDC. Refer to engine specifications in the model specific Installation and Operation Manual (SVIOM01) or engine dataplate for the 74-00-00 © March 2006 Superior Air Parts Inc. Ignition Section... -

Page 108: Ignition Harness Replacement

96 in-lb torque. • Continue to tighten both nuts in alternating steps to 200 in-lb torque. • Remove the timing light from the magneto condenser stud. • Re-install harness cap to magnetos. 74-00-00 © March 2006 Superior Air Parts Inc. Ignition Section... -

Page 109: Magneto Components

Maintenance Manual O-360 and IO-360 Series Engines Figure 74-10-01.1 • Magneto Components 74-00-00 © March 2006 Superior Air Parts Inc. Ignition Section... -

Page 110: Timing Diagram

Maintenance Manual O-360 and IO-360 Series Engines Figure 74-10-01.2 • Timing Diagram 74-00-00 © March 2006 Superior Air Parts Inc. Ignition Section... - Page 111 Maintenance Manual O-360 and IO-360 Series Engines Figure 74-20-00.10 • Ignition Wiring Diagram 74-00-00 © March 2006 Superior Air Parts Inc. Ignition Section...

- Page 112 Maintenance Manual O-360 and IO-360 Series Engines THIS PAGE INTENTIONALLY LEFT BLANK 74-00-00 © March 2006 Superior Air Parts Inc. Ignition Section...

-

Page 113: Appendix

Maintenance Manual O-360 and IO-360 Series Engines Appendix 1 Unison Industries L-1363B 4300/6300 Series Magneto Maintenance and Overhaul Manual Appendix 1 © March 2006 Superior Air Parts Inc. - Page 114 Maintenance Manual O-360 and IO-360 Series Engines THIS PAGE INTENTIONALLY LEFT BLANK Appendix 1 © March 2006 Superior Air Parts Inc.