Quadra-Fire Castile Insert Pellet 810-02901 (MBK) Owner's Manual

Castile pellet insert installation and operation

Hide thumbs

Also See for Castile Insert Pellet 810-02901 (MBK):

- Owner's manual installation and operation (52 pages)

Table of Contents

Advertisement

Quick Links

Owner's Manual

Installation and Operation

Models:

810-02901

(MBK)

810-03201

(PMH)

CASTINS-CSB

CASTINS-CWL

• Important operating and

maintenance instruc-

tions included.

Please read this entire manual

before installation and use of this

pellet fuel-burning room heater.

Failure to follow these instructions

could result in property damage,

bodily injury or even death.

•

Do not store or use gasoline or other flam-

mable vapors and liquids in the vicinity of this

or any other appliance.

• Do not overfire - If any external part starts

to glow, you are overfiring. Reduce feed rate.

Overfiring will void your warranty.

• Comply with all minimum clearances to com-

bustibles as specified. Failure to comply may

cause house fire.

CAUTION

Tested and approved for wood pellets and shelled

field corn fuel only. Burning of any other type of fuel

voids your warranty.

www.quadrafire.com

CASTILE PELLET INSERT

CAUTION

DO NOT DISCARD THIS MANUAL

Read, understand and

•

follow these instruc-

tions for safe installa-

tion and operation.

WARNING

Leave this manual

•

with party respon-

sible for use and

operation.

HOT! DO NOT TOUCH.

SEVERE BURNS MAY RESULT.

CLOTHING IGNITION MAY RESULT.

Glass and other surfaces are hot

during operation and cool down.

• Keep children away.

• CAREFULLY SUPERVISE children in same room as

appliance.

• Alert children and adults to hazards of high

temperatures.

• Do NOT operate with protective barriers open or

removed.

• Keep clothing, furniture, draperies and other

combustibles away.

Check building codes prior to installation.

• Installation MUST comply with local, regional, state

and national codes and regulations.

• Consult local building, fire officials or authorities

having jurisdiction about restrictions, installation

inspection, and permits.

250-7251F

R

Tested and

O-T L

Listed by

C

US

OMNI-Test Laboratories, Inc.

WARNING

CAUTION

September 1, 2008

Portland

Oregon USA

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Quadra-Fire Castile Insert Pellet 810-02901 (MBK)

-

Page 1: Installation And Operation

Owner’s Manual Installation and Operation Models: 810-02901 (MBK) 810-03201 (PMH) CASTINS-CSB CASTINS-CWL • Important operating and maintenance instruc- tions included. WARNING Please read this entire manual before installation and use of this pellet fuel-burning room heater. Failure to follow these instructions could result in property damage, bodily injury or even death. - Page 2 Castile Pellet Insert Hearth & Home Technologies welcomes you to our tradition of excellence! In choosing a Quadra-Fire appliance, you have our assurance of commitment to quality, durability, and performance. This commitment begins with our research of the market, including ‘Voice of the Customer’ contacts, ensuring we make products that will satisfy your needs.

-

Page 3: Table Of Contents

Section 1: Listing and Code Approvals A. Appliance Certifications ...4 B. Mobile Home Approved ...4 C. Glass Specifications ...4 D. Electrical Rating ...4 E. BTU & Efficiency Specifications ...4 Section 2: Getting Started A. Design, Installation & Location Considerations ...5 B. -

Page 4: Section 1: Listing And Code Approvals

Castile Pellet Insert Listing and Code Approvals A. Appliance Certification MODEL: Castile Pellet Insert LABORATORY: OMNI Test Laboratories, Inc REPORT NO. 061-S-42-2 TYPE: Solid Fuel Room Heater/Pellet Fuel Burning Type Insert STANDARD: ASTM E1509-95, ULC S628-93 and ULC/ORD-C1482-M1990 Room Heater Pellet Fuel Burning Type and (UM) 84-HUD, Mobile Home Approved Colorado: Approved 11-15-02... -

Page 5: Section 2: Getting Started

Getting Started A. Design, Installation & Location Considerations 1. Appliance Location Consideration must be given to safety, convenience, traffic flow, and the fact that the appliance will need a chimney and chimney connector. It is a good idea to plan your installation on paper, using exact measurements for clearances and floor protection, before actually beginning the installation. -

Page 6: Tools & Supplies Needed

Castile Pellet Insert C. Tools And Supplies Needed Tools and building supplies normally required for installation, unless installing into an existing masonry fireplace: Reciprocating Saw Safety Glasses Hammer Framing Square Phillips Screwdriver Electric Drill & Bits (1/4”) Tape Measure 1/4” Self-Tapping Screws Plumb Line Level May also need:... -

Page 7: Dimensions And Clearances

Dimensions and Clearances A. Appliance Dimensions 28-1/16" (713mm) 23-7/16" (595mm) 8" (203mm) 32-5/16" (821mm) Figure 7.1 - Top View Height Panel Size inch inch Small Cast 42-1/2 1078 Large Cast Small Econo NOTE: All views are shown with Panel & Cast Trim Set installed. September 1, 2008 11-1/16"... -

Page 8: Clearances To Combustibles As A Built-In, Ul And Ulc

Castile Pellet Insert B. Clearance To Combustibles, UL and ULC 0” (0mm) Clearance To Exposed Section And Face Trim Figure 8.1 Top of Hopper Side of Outside Skin Back of Hopper Vent Pipe to Combustible Front Panel Edge INSTALLED AS A BUILT-IN UNIT Shown Optional Outside Air 12 in (305mm) -

Page 9: Clearances To Combustibles, Masonry & Zero Clearance

C. Masonry and Zero Clearance Fireplaces MANTEL Figure 9.1 D. Floor Protection Floor protection hearth extension from door opening Floor protection to the side of door opening E. Minimum Opening for Masonry and Zero Clearance Fireplaces Figure 9.2 September 1, 2008 A Insert side to combustible side wall B Insert top to mantel... -

Page 10: Removing Metal Floor Of Factory-Built Firebox

Castile Pellet Insert F. Removing Metal Floor of Factory-Built Firebox • The firebrick (refractory), glass doors, screen rails, screen mesh and log grates can be removed from a factory-built firebox in order to gain minimum insert opening require- ments. • Any smoke shelves, shields and baffles may be removed from a factory-built firebox if attached with mechanical fas- teners. -

Page 11: A. Chimney & Exhaust Connections

Vent Information A. Chimney and Exhaust Connection Chimney & Connector: Use 3 or 4 inch (76-102mm) diameter type "L" or "PL" venting system. It can be vented vertically or horizontally. 2. Mobile Home: Approved for all Listed pellet vent. Use Listed double wall flue connector. -

Page 12: Equivalent Feet Of Pipe

Castile Pellet Insert C. Equivalent Feet of Pipe The table below can help you calculate the equivalent feet of pipe which is a method used to determine pellet vent size. Figure 12.1. Example of 3 Elbow-Rear Vent Termination Calculation 2 ft. 3 ft. -

Page 13: Section 5: Venting Systems

Venting Systems A. Direct Connect With Outside Air Outside Air through Rear Wall Figure 13.1 NOTE: • Illustrations reflect typical installations and are FOR DESIGN PURPOSES ONLY. • Illustrations/diagrams are not drawn to scale. • Actual installation may vary due to individual design preference. -

Page 14: Full Reline With Outside Air

Castile Pellet Insert C. Full Reline With Outside Air 12” (305mm) min. above NOTE; Use metal plate around exhaust vent pipe and seal all edges with non-flammable insulation such as fiberglass, mineral wool or ceramic. Do not use high temperature caulk- ing materials to seal any edge to prevent furture... -

Page 15: Section 6: Mobile Home

Mobile Home A. Mobile Home Installation You must use a Quadra-Fire Outside Air Kit for instal- lation in a mobile home. An outside air inlet must be provided for the combustion air and must remain clear of leaves, debris, ice and/or snow. -

Page 16: Section 7: Appliance Set-Up

Castile Pellet Insert Appliance Set-Up A. Reversible Top or Rear Flue Adapter Top Vent Installation 1. Release ammo can latches on each side. Figure 16.1. 2. Place the reversible adapter in the correct position for your installation. 3. Make sure BOTH latches are in position before securing them. -

Page 17: D. Zero Clearance Trim Support

C. Outside Air Kit Instructions Parts Included in Kit: 1 piece of 2 inch x 3 ft. flex hose, 2 hose clamps, 1 collar assembly, 1 termination cap assem- bly, 1 trim ring, fasteners. Tools Needed: Phillips head screwdriver; wire cutters; hole saw or jig saw. -

Page 18: Zero Clearance Trim Support

Castile Pellet Insert D. Zero Clearance Trim Support (Cont’d) Kit Includes: See Page 17 Tools Needed: Phillips head screwdriver 1. Remove contents from box and lay on protective surface to avoid scratching the paint. 2. Lay zero clearance front and sides face down. Bend the tab down toward the inside. -

Page 19: Panel Set & Cast Trim Set

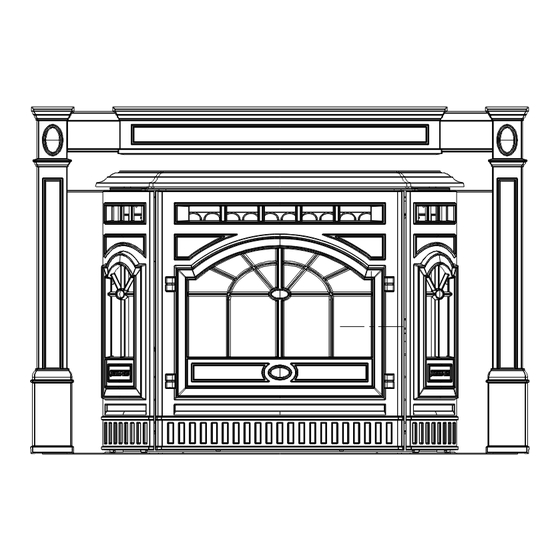

E. Panel Set And Cast Trim Set Included in Panel Kit: (2) side panels, left and right; (1) panel top; (1) fastener package. Included in Cast Trim Kit: (2) cast trim legs, left and right; (1) cast trim header; (2) cast trim footers, left and right; (1) fastener package. -

Page 20: Optional Log Set Placement Instructions

Castile Pellet Insert G. Optional Log Set Placement Instructions CAUTION Logs are FRAGILE. Use extreme care when handling or cleaning logs. Four Piece Log Set Installation 1. Open the hinged cast face and open the glass door assembly. Positioning the logs. Place the right rear log as shown. -

Page 21: Thermostat Installation

H. Thermostat Installation A 12 volt AC thermostat is required to operate this pellet appliance. You may use the included wall mount thermostat or purchase an optional programmable thermostat or remote control. The included thermostat is equipped with an adjustable heat anticipator. The current rating is .05 amps. -

Page 22: Section 8: Operating Instructions

Castile Pellet Insert Operating Instructions A. Fuel Size And Material 1. Wood Pellets Fuel pellets are made from sawdust or wood by-products. If the source material is hardwood, they can have a higher mineral content, creating more ash. Fuels containing bark will also have higher ash content. -

Page 23: Before Your First Fire

C. Before Your First Fire 1. First, make sure your appliance has been properly installed and that all safety requirements have been met. Pay particular attention to the fire protection, venting and thermostat installation instructions. 2. Double check that the ash pan and firebox are empty! 3. -

Page 24: Ignition Cycles

Castile Pellet Insert G. Iginition Cycles 1. During each ignition cycle, it is normal to see some smoke in the firebox. The smoke will stop once the fire starts. 2. The convection blower will automatically turn on after your appliance has reached the set temperature. This blower transfers heat from your appliance into the room, and will continue to run after the thermostat has stopped calling for heat until the appliance has cooled down. -

Page 25: Section 9: Troubleshooting

Troubleshooting Symptom Plug in appliance - No No current to outlet. response. .7 amp fuse defective. #3 snap disc tripped or defective. Control box defective. Call light on. No fire. Out of fuel. No fuel in firepot. #2 snap disc may be defective. Vacuum switch not closing, no vacuum. - Page 26 Castile Pellet Insert Symptom Slow or smoky start-up Dirty exhaust and/or venting system. (Cont’d) Feed system fails to Out of fuel. start. #2 snap disc may be defective. Vacuum switch not closing. No vacuum. Feed system jammed or blocked. Feed spring not turning with feed motor. Feed motor defective or not plugged in.

- Page 27 Symptom Convection blower fails to No call light. start. #1 snap disc defective. Blower not plugged in. Blower is defective. Control box is defective. Exhaust blower fails to Blower not plugged in. start or does not shut off. Blower is clogged with ash. Blower is defective.

-

Page 28: Maintaining & Servicing Appliance A. Proper Shutdown Procedures

Castile Pellet Insert Maintaining & Servicing Your Appliance A. Proper Shutdown Procedure CAUTION Shock and Smoke Hazard • Turn down thermostat, let appliance completely cool and exhaust blower must be off. Now you can unplug appliance before servicing. • Smoke spillage into room can occur if appliance is not cool before unplugging. - Page 29 2. Remove Cast Sides for Cleaning & Maintenance a. Loosen screw on top right corner directly under the cast top, but do not remove. Figure 28.1. b. With thumb, press upward on the frame to relieve the pressure on the cast side. Figure 28.2. c.

- Page 30 Castile Pellet Insert 5. Cleaning Ash Pan • Frequency: Weekly or every 5 bags of fuel • By: Homeowner Locate the ash pan underneath the firepot. Open the bottom ash door and slide the ash pan straight out. Empty into a non-combustible container and re-install ash pan.

- Page 31 10. Cleaning the Hopper • Frequency: Monthly or after burning 1 ton of fuel • By: Homeowner After burning approximately 1 ton of fuel you will need to clean the hopper to prevent sawdust build-up. A combination of sawdust and pellets on the auger reduces the amount of fuel supply to the firepot.

-

Page 32: High Ash Content Maintenance

Castile Pellet Insert 16. Door Gasket Inspection • Frequency: Monthly or after burning 1 ton of fuel • By: Homeowner To inspect the door rope (gasket), open the door and see that the door rope extends approximately 1/8 to 3/16 inch (3 to 9.5mm) from the door rope channel. -

Page 33: Igniter Replacement

E. Igniter Replacement Igniter Bracket Thumb Screw Figure 33.1 a. Shut down the appliance by turning down the thermostat and let the appliance completely cool down. After the appliance has cooled down, unplug it and remove the ash pan. b. The wire leads to the igniter are connected to the wire harness with 1/4 inch (6mm) male / female spade connectors. -

Page 34: Re-Installing Baffle & Brick Set

Castile Pellet Insert G. Baffle & Brick Set Removal 1. Follow proper shutdown procedures on Page 28. The top baffle has a hook on the bottom left side that rests on the top lip of the cast brick. There is a tab on the bottom right side that hooks into the side bracket. -

Page 35: Figure 35.4

Re-installing Baffle & Brick Set (Cont’d) Lift brick, pull forward at an angle and drop down into notches Figure 35.1 Figure 35.2 Figure 35.3 September 1, 2008 Hook on left side Figure 35.4 Figure 35.5 250-7251F Castile Pellet Insert Tab on right side Page 35... -

Page 36: Section 11: Reference Material

Castile Pellet Insert Reference Materials A. Component Function 1. Control Box a. The control box is located on lower right side of appliance, behind cast side on top of the junction box. b. There is a light located inside of the control box. The internal light will turn green when the appliance has reached a temperature of 200 and will turn red when it reaches 600... - Page 37 16. Snap Disc #1 (Convection Blower) 110°F Snap disc #1 is located behind the right cast side of the firebox above the red call light. There are 2 purple wires connected to it. This snap disc turns the convection blower on and off as needed.

-

Page 38: Component Locations

Castile Pellet Insert B. Component Locations Feed Motor Convection Blower Figure 38.1 - Blowers & Feed Motor Figure 38.3 Page 38 Exhaust Blower Figure 38.2 - Cleaning Rods & Heat Exchanger Tubes tp t S it Reset 250-7251F 10 Heat Exchanger Tubes o trol o Red all Lig t... -

Page 39: Exploded Views

C. Exploded Views Glass GLASS SIZE: 11-5/8” wide x 17-1/4” high Figure 38.1 - Door, Glass, & Handle Assembly Figure 38.2 - Firepot Assembly September 1, 2008 Item Screw 10-32 x 5/16 PH PHL MS ZC Screw 1/4-20 x 5/8 TH PHL Door Latch Assembly Glass Assembly Rope Retainer... - Page 40 Castile Pellet Insert Figure 40.1 Description 18 Face, Cast 19 Glass, Side Window 20 Side, Cast 21 Panel, Side, Right (not sellable) 22 Trim, Cast, Footer, Right 23 Trim, Cast, Leg, Right 24 Hopper Top Slide, Right 25 Door & Glass Assembly 26 Firepot Page 40 Description...

-

Page 41: Service Parts & Accessories

D. Service Parts and Accessories IMPORTANT: THIS IS DATED INFORMATION. The most current information is located on the Quadra-Fire web site at www.quadrafire.com. When ordering, supply serial and model numbers to ensure correct service parts. Item # Ash Pan Baffle Assembly Blower, Convection Blower, Exhaust with Gasket &... - Page 42 Castile Pellet Insert Item # Power Cord Side, Cast, Matte Black Side, Cast, Porcelain, (specifiy color) Side, Cast, Powder Coat, (specific color) Snap Disc #1, 110 degree Snap Disc #2, 250 degree, automatice reset Snap Disc #3, 250 degree, manual reset Thermocouple Cover Thermocouple, 14 inches Thermocouple Clamp...

-

Page 43: Service & Maintenance Log

Castile Pellet Insert E. Service And Maintenance Log Date of Service Performed By Description of Service Page 43 September 1, 2008 250-7251F... -

Page 44: E. Service & Maintenance Log

Castile Pellet Insert E. Service And Maintenance Log (Cont’d) Date of Service Performed By Description of Service Page 44 250-7251F September 1, 2008... -

Page 45: Homeowner's Notes

Castile Pellet Insert F. Homeowner’s Notes Page 45 September 1, 2008 250-7251F... -

Page 46: Warranty Policy

Castile Pellet Insert G. Warranty Policy Hearth & Home Technologies LIMITED WARRANTY Hearth & Home Technologies (“HHT”) and its respective brands extends the following warranty for HHT gas, wood, pellet and electric appliances purchased from an authorized HHT dealer and installed in the United States of America or Canada. - Page 47 Hearth & Home Technologies LIMITED WARRANTY (Cont’d) HHT’s obligation under this warranty does not extend to damages resulting from: (1) installation, operation or main- tenance of the appliance not in accordance with the installation instructions; operating instructions and the listing agent identification label furnished with the appliance;...

-

Page 48: Contact Information

Please contact your Quadra-Fire dealer with any questions or concerns. For the number of your nearest Quadra-Fire dealer please visit our web site at www.quadrafire.com SERIAL NUMBER: __________________ DATE PURCHASED: __________________ DATE INSTALLED: __________________ This product may be covered by one or more of the following patents: (United States) 4593510, 4686807, 4766876, 4793322, 4811534, 5000162, 5016609, 5076254, 5113843, 5191877, 5218953, 5263471, 5328356, 5341794, 5347983, 5429495, 5452708, 5542407, 5601073, 5613487, 5647340, 5688568, 5762062, 5775408, 5890485, 5931661, 5941237, 5947112, 5996575, 6006743, 6019099, 6048195, 6053165, 6145502, 6170481, 6237588, 6296474, 6374822, 6413079, 6439226, 6484712, 6543698, 6550687, 6601579,...

Need help?

Do you have a question about the Castile Insert Pellet 810-02901 (MBK) and is the answer not in the manual?

Questions and answers