Summary of Contents for SMC Networks MHT2

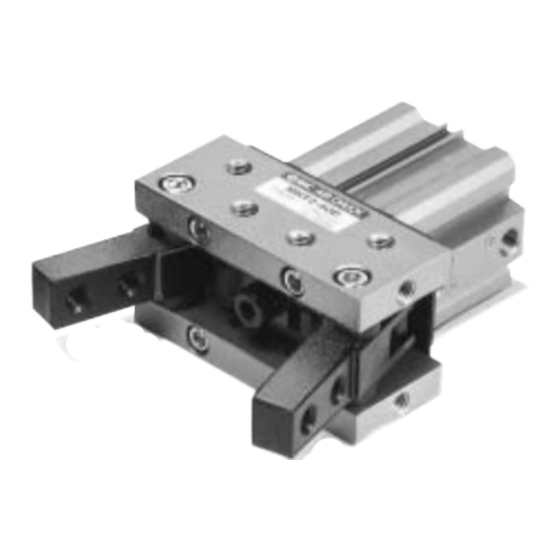

- Page 1 Angular Style Air Gripper Toggle Type MHT2 Series MRHQ Misc. 12-9-1...

-

Page 2: How To Order

Angular Style Air Gripper Toggle Type MHT2 Series Size: 32, 40, 50, 63 How to Order Ideal for gripping MHT2 F9BW S heavy workpiece. The toggle mechanism Toggle type Number of auto holds workpiece even Auto switch air gripper switches when pressure drops. - Page 3 Angular Style Air Gripper MHT2 Series Toggle Type Effective Gripping Force • Workpiece gripping point should be within the MHT2-32D L = 100 mm range indicated in the graph. Pressure 0.6 MPa 0.4 MPa 0.2 MPa Opening/Closing angle (Both sides)

- Page 4 MHT2 Series Dimensions 8-M6 x 1 mounting thread MHT2-32D Thread depth 10 (Both sides) 4-M6 x 1 thread depth 10 Mounting thread Finger closing port Rc 1/8 Finger opening port Rc 1/8 4-M6 x 1 thread depth 15 Mounting thread 4-M6 x 1 bottom hole dia.

- Page 5 Angular Style Air Gripper MHT2 Series Toggle Type Dimensions MHT2-50D 8-M10 x 1.5 mounting thread Thread depth 12 (Both sides) 4-M8 x 1.25 thread depth 14 Mounting thread Finger closing port Rc 1/4 Finger opening port Rc 1/4 4-M10 x 5 bottom hole dia. 8.6 4-M10 x 1.5 thread depth 12...

-

Page 6: Replacement Parts

MHT2 Series Construction Component Parts Description Material Note Side plate Aluminum alloy Hard anodized Finger Carbon steel Black zinc chromated Lever Carbon steel Black zinc chromated Joint Carbon steel Black zinc chromated Shaft Stainless steel Joint pin Stainless steel Cylinder plate... - Page 7 Angular Style Air Gripper MHT2 Series Toggle Type Auto Switch Hysteresis Mounting of Auto Switch Rail mounting type Hysteresis Switch operating position (ON) Switch reset position (OFF) Hysteresis (Max.) angle Model MHT2-32D MHT2-40D MHT2-50D MHT2-63D MRHQ Direct mounting type Misc.

- Page 8 MHZ2/MHZJ2/MHK2/MHKL2/MHC2/MHT2 Series Auto Switch Installation Example and Mounting Position Various auto switch applications are possible through different combinations of auto switch quantities and detecting positions. 1) Detection when Gripping Exterior of Workpiece 1. Confirmation of fingers in 2. Confirmation of workpiece held 3.

- Page 9 Auto Switch Various auto switch applications are possible through different combinations of auto switch quantities and detecting positions. 2) Detection when Gripping Interior of Workpiece 1. Confirmation of fingers in reset 2. Confirmation of workpiece held 3. Confirmation of workpiece released Detection example position Position of...

-

Page 10: Safety Instructions

Safety Instructions These safety instructions are intended to prevent a hazardous situation and/or equipment damage. These instructions indicate the level of potential hazard by labels of "Caution", "Warning" or "Danger". To ensure safety, be sure to observe ISO 4414 Note 1) JIS B 8370 Note 2) and other safety practices. - Page 11 Common Precautions Be sure to read before handling. For detailed precautions on every series, refer to main text. 4. Use clean air Selection If the compressed air supply is contaminated with chemicals, Warning cynthetic materials, corrosive gas, etc., it may lead to break down or malfunction.

- Page 12 Quality Assurance Information (ISO 9001, ISO 14001) Reliable quality of products in the global market To enable our customers throughout SMC’s quality control system the world to use our products with even greater confidence, SMC has Make customers our first priority, offering Create new them reliable and obtained certification for international...

- Page 13 SMC Product Conforming to Inter SMC products complying with EN/ISO, CSA/UL standards are supporting CE Mark The CE mark indicates that machines and components meet essential requirements of all the EC Directives applied. It has been obligatory to apply CE marks indicating conformity with EC Directives when machines and components are exported to the member Nations of the EU.

-

Page 14: National Standards

SMC Product Conforming to International Standards national Standards you to comply with EC directives and CSA/UL standards. Mark of compliance Mark of compliance for CSA/UL for CSA í CSA Standards & UL Standards UL and CSA standards have been applied in North America (U.S.A. and Canada) symbolizing safety of electric products, and are defined to mainly prevent danger from electric shock or fire, resulting from trouble with electric products. - Page 15 SMC’s Global Service Network America Europe U.K. SMC Pneumatics (U.K.) Ltd. U.S.A. SMC Corporation of America Vincent Avenue, Crownhill, Milton Keynes, MK8 0AN, Backinghamshire, U.K. 3011 North Franklin Road Indianapolis, IN 46226, U.S.A. TEL: 01908-563888 FAX: 01908-561185 TEL: 317-899-4440 FAX: 317-899-3102 GERMANY SMC Pneumatik GmbH CANADA...

- Page 16 SMC’s Global Service Network Europe Oceania/Asia AUSTRALIA SMC Pneumatics (Australia) Pty.Ltd. FINLAND SMC Pneumatics Finland OY 14-18 Hudson Avenue Castle Hill NSW 2154, Australia PL72, Tiistinniityntie 4, SF-02231 ESP00, Finland TEL: 09-8595-80 FAX: 09-8595-8595 TEL: 02-9354-8222 FAX: 02-9894-5719 NORWAY SMC Pneumatics Norway A/S NEW ZEALAND SMC Pneumatics (New Zealand) Ltd.

Need help?

Do you have a question about the MHT2 and is the answer not in the manual?

Questions and answers