Summary of Contents for SEW-Eurodrive MOVIMOT CM3C DAC Series

- Page 1 *31546501_0225* Drive Technology \ Drive Automation \ System Integration \ Services Product Manual Drive Unit ® MOVIMOT performance DAC CM3C..DAC.. (AS-Interface) Edition 02/2025 31546501/EN...

- Page 2 SEW-EURODRIVE—Driving the world...

-

Page 3: Table Of Contents

Table of Contents Table of Contents General information ........................ 7 About this documentation .................... 7 Other applicable documentation .................. 7 Structure of the safety notes ................... 7 Decimal separator in numerical values ................ 9 Rights to claim under limited warranty ................ 9 Recycling, reprocessing, reuse.................. 9 Product names and trademarks.................. 9 Copyright notice ...................... 9 ®... - Page 4 Table of Contents 4.16 Technical data of the brake................... 81 ® 4.17 DynaStop torques ....................... 82 4.18 Torque characteristic curves.................. 83 4.19 Surface protection...................... 88 4.20 Screw fittings......................... 90 4.21 Guard bracket ....................... 92 4.22 Connection cables ...................... 93 4.23 Overhung loads...................... 95 4.24 Mounting positions ...................... 95 4.25 Dimension drawings of the drive unit ................ 96 4.26 Dimension drawings of connectors at the electronics cover ........ 101 4.27...

- Page 5 Table of Contents Electronics ........................ 179 Example nameplate and type designation of electronics.......... 183 Example nameplate and type designation of connection unit........ 185 7.10 Markings ........................ 187 7.11 FS logo description ..................... 188 Mechanical installation ...................... 189 Installation notes ...................... 189 Required tools and resources .................. 189 Installation tolerances for motor shaft ends .............. 189 Tolerances for torque ratings .................. 190 Installation requirements..................... 190 Setting up the drive unit .................... 191...

- Page 6 IT security guidelines for secure waste disposal............ 432 12.15 Waste disposal...................... 433 Inspection and maintenance .................... 434 13.1 Determining the operating hours................. 434 13.2 Inspection and maintenance intervals................. 435 13.3 Inspection and maintenance work ................ 436 Contacting SEW-EURODRIVE.................... 446 Index ............................ 447 ® Product Manual – MOVIMOT performance DAC...

-

Page 7: General Information

General information About this documentation General information About this documentation The documentation at hand is the original. This documentation is an integral part of the product. The documentation is intended for all employees who perform work on the product. Make sure this documentation is accessible and legible. Ensure that persons respon- sible for the systems and their operation as well as persons who work on the product independently have read through the documentation carefully and understood it. - Page 8 General information Structure of the safety notes 1.3.2 Structure of section-related safety notes Section-related safety notes do not apply to a specific action but to several actions pertaining to one subject. The hazard symbols used either indicate a general hazard or a specific hazard.

-

Page 9: Decimal Separator In Numerical Values

General information Decimal separator in numerical values Decimal separator in numerical values In this document, a period is used to indicate the decimal separator. Example: 30.5 kg Rights to claim under limited warranty Read the information in this documentation. This is essential for fault-free operation and fulfillment of any rights to claim under limited warranty. -

Page 10: Safety Notes For Movimot Performance

® Safety notes for MOVIMOT performance Preliminary information ® Safety notes for MOVIMOT performance Preliminary information The following general safety notes serve the purpose of preventing injury to persons and damage to property. They primarily apply to the use of products described in this documentation. -

Page 11: Target Group

If you need support with the configuration, contact SEW‑EURODRIVE Service. You can obtain information about the latest security-related problems via e-mail (cert@sew-eurodrive.com) or by visiting the Product Security Management website (http://go.sew/psm). You will find various contact options there for reporting security- related problems. -

Page 12: Designated Use

® Safety notes for MOVIMOT performance Designated use 2.4.2 IT security of the environment For drive and control components that are integrated in a network (e.g., fieldbus, WLAN or Ethernet network), settings can even be made from more remote locations. This brings with it the risk of a parameter change not visible externally resulting in un- expected, but not uncontrolled system behavior and this may impact negatively on op- erational safety and reliability, system availability or data security. -

Page 13: Functional Safety Technology

® Safety notes for MOVIMOT performance Functional safety technology 2.5.3 Restrictions of use The following applications are prohibited unless the device is explicitly designed for such use: • Use in potentially explosive areas. • Use in areas exposed to harmful oils, acids, gases, vapors, dust, and radiation. •... - Page 14 ® Safety notes for MOVIMOT performance Transportation/storage If the product is not immediately installed, it must be stored in a dry and dust-free loca- tion. The product can be stored for up to 9 months without requiring any special mea- sures before startup.

-

Page 15: Creating A Safe Working Environment

® Safety notes for MOVIMOT performance Creating a safe working environment Creating a safe working environment Before you work on the product, ensure a safe working environment. Observe the fol- lowing basic safety notes: 2.8.1 Performing work on the product safely Defective or damaged product Never install defective or damaged products. - Page 16 ® Safety notes for MOVIMOT performance Creating a safe working environment 2.8.2 Performing electrical work safely Observe the following information to perform electrical work safely: Electrical work may only be performed by an electrically skilled person or an electron- ically instructed person under the supervision of an electrically skilled person. The fact that the operation or display elements are no longer illuminated does not in- dicate that the product has been disconnected from the supply system and no longer carries any voltage.

-

Page 17: Installation/Assembly

® Safety notes for MOVIMOT performance Installation/assembly • Ensure that the unit is de-energized. • Observe the information signs and product safety labels on the product. Installation/assembly Ensure that the product is installed and cooled in accordance with the regulations in the documentation. -

Page 18: Magnetic Fields

® Safety notes for MOVIMOT performance Magnetic fields Depending on the degree of protection, products may have live, uninsulated, and sometimes moving or rotating parts as well as hot surfaces during operation. Never plug or unplug connectors while they are energized. Do not separate the connection to the product during operation. -

Page 19: Product Description

Product description System overview of MOVI-C® for decentralized installation Product description System overview of MOVI-C® decentraliz installation ® System overview of MOVI-C for decentralized installation Consistent – connected – complete ® The basis of the new product portfolio is the MOVI-C decentralized drive electronics. - Page 20 Product description System overview of MOVI-C® for decentralized installation Drive units without decentralized inverter ® MOVIGEAR classic MGF..-DSM-C 8 – 400 Nm continuous output torque motor 475 Nm maximum short-time torque motor ® ® Can be combined with all MOVI-C inverters (e.g. MOVIMOT flexible) Drive units with decentralized inverters ®...

- Page 21 Product description System overview of MOVI-C® for decentralized installation 3.1.2 Technical data ® MOVI-C decentralized inverter ® MOVI-C decentralized inverter (electronics cover) Description Decentralized inverter for mounting to: ® • MOVIGEAR performance ® • MOVIMOT advanced ® • MOVIMOT performance ®...

- Page 22 Product description System overview of MOVI-C® for decentralized installation ® MOVIGEAR classic ® MOVIGEAR classic (≙ IE5) Description Drive unit consisting of gear unit and synchronous motor (can be combined with electronics close to the motor or control cab- ® inet technology from the MOVI-C modular automation system).

- Page 23 Product description System overview of MOVI-C® for decentralized installation ® MOVIMOT advanced with DR2C..A motor ® MOVIMOT advanced with DR2C..A motor (≙ IE5) Description Drive unit consisting of gear unit, synchronous motor and de- centralized inverter • 0.69 kW – 6.80 kW Power rating •...

- Page 24 Product description System overview of MOVI-C® for decentralized installation ® MOVIMOT advanced with DRN.. motor ® MOVIMOT advanced with DRN.. Motor (≙ IE3) Description Drive unit consisting of gear unit, asynchronous motor and de- centralized inverter • With star connection: 0.37 kW – 7.5 kW Power rating •...

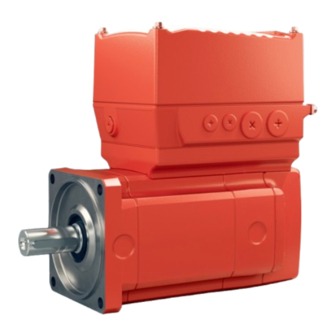

- Page 25 Product description System overview of MOVI-C® for decentralized installation ® MOVIMOT performance ® MOVIMOT performance (≙ IE5) Description Drive unit consisting of gear unit, synchronous motor and de- centralized inverter • Size 1: 0.75 – 1.88 kW Power rating • Size 2: 3.14 kW – 4.19 kW Overload capacity Up to 300% Drive data Torque range...

- Page 26 Product description System overview of MOVI-C® for decentralized installation ® MOVIMOT flexible ® MOVIMOT flexible (motors up to IE5) Description Decentralized inverter Output power of • Size 1 without cooling fins: 0.55 – 1.1 kW asynchronous • Size 1 with cooling fins: 1.5 kW – 2.2 kW motor •...

-

Page 27: Movimot ® Performance Drive Units At A Glance

Product description MOVIMOT® performance drive units at a glance MOVIMOT® performanc e drive units at a glance ® MOVIMOT performance drive units at a glance 3.2.1 Axially parallel gear units The following table shows an overview of the most important technical data of ®... - Page 28 Product description MOVIMOT® performance drive units at a glance 3.2.2 Right-angle gear units The following table shows an overview of the most important technical data of ® MOVIMOT performance drive units with right-angle gear units. Drive unit K..CM3C../D.. S..CM3C../D.. W..CM3C../D.. Technical data Output speed 13 –...

-

Page 29: Motor Assignment Of Movimot

Product description Motor assignment of MOVIMOT® performance Motor assignment of MOVIMOT® performanc ® Motor assignment of MOVIMOT performance following table shows available assignment variants ® MOVIMOT performance: Motor type Decentralized inverter (electronics cover) Size 1 Size 1 Size 2 without cooling fins with cooling fins with cooling fins 2.0 A... -

Page 30: Technical Data

Technical data General information Technical data General information 4.1.1 Power and torque ratings The power and torque ratings listed in this documentation refer to mounting position M1 and similar mounting positions in which the input stage is not completely sub- merged in oil. -

Page 31: General Technical Data Of Movimot Performance

Technical data General technical data of MOVIMOT® performance General technical data of MOVIMOT® performanc ® General technical data of MOVIMOT performance Interference immunity EN 61800-3, 2. environment (industrial environment) Interference emission EN 61800-3 category C3 No EMC category is specified for IT systems. Ambient temperature See chapter "Environmental conditions"... -

Page 32: Environmental Conditions

Technical data Environmental conditions Mass See chapter • "Motor, electronics cover, 2000 minˉ¹, size 1" (→ 2 36) • "Motor, electronics cover, 2000 minˉ¹, size 1" (→ 2 37) • "Motor, electronics cover size 2" (→ 2 40) 1) Depending on the configuration. Environmental conditions 4.3.1 Climatic conditions Extended storage Weatherproof IEC 60721-3-1 class 1K21, non-condensing, no condensation Deviating from the standard: Temperature -25 °C –... - Page 33 Technical data Environmental conditions Transport Weatherproof IEC 60721-3-2 class 2C2, no sea water Deviating from the standard: no corrosive gases, no salt mist Operation Stationary use, weatherproof ISO 9223 class C3 Deviating from the standard: no corrosive gases, no salt mist 4.3.5 Mechanically active substances Extended storage...

-

Page 34: Technical Data Movimot Performance

Technical data Technical data MOVIMOT® performance Technical data MOVIMOT® performanc ® Technical data MOVIMOT performance 4.4.1 Size 1 Input (speed class 1000 min ® MOVIMOT performance CM3C.. 80S/D.. 80S/D.. 80S/D.. Electronics cover (inverter) ..0020..0025..0032.. Nominal line voltage AC 3 × AC 380 –... - Page 35 Technical data Technical data MOVIMOT® performance Electronics cover (inverter) size 1 ® MOVIMOT performance CM3C.. 80S/D.. 80S/D.. 80S/D.. 80M/D.. 80M/D.. Electronics cover (inverter) ..0020..0025..0032..0040..0055.. Nominal output current 2.0 A 2.5 A 3.2 A 4.0 A 5.5 A N_inverter electronics cover = 4 kHz, V = 400 V line Apparent output power...

- Page 36 Technical data Technical data MOVIMOT® performance Motor, electronics cover size 1, speed class 1000 min ® MOVIMOT performance CM3C.. 80S/D.. 80S/D.. 80S/D.. Electronics cover (inverter) ..0020..0025..0032.. Nominal output current 2.0 A 2.5 A 3.2 A N_Inverter electronics cover Nominal power 0.74 kW 0.92 kW 1.05 kW Nominal torque...

- Page 37 Technical data Technical data MOVIMOT® performance Motor, electronics cover size 1, speed class 2000 min ® MOVIMOT performance CM3C.. 80S/D.. 80S/D.. 80S/D.. 80S/D.. 80M/D.. 80M/D.. Electronics cover (inverter) ..0020..0025..0032..0040..0040..0055.. Nominal output current 2.0 A 2.5 A 3.2 A 4.0 A 4.0 A 5.5 A...

- Page 38 Technical data Technical data MOVIMOT® performance 4.4.2 Size 2 Input (speed class 1000 min ® MOVIMOT performance CM3C.. 80S/D.. 80S/D.. 80S/D.. Electronics cover (inverter) ..0020..0025..0032.. Nominal line voltage AC 3 × AC 380 – 500 V line (according to EN 50160) Nominal line current AC 1.8 A 2.25 A 2.88 A...

- Page 39 Technical data Technical data MOVIMOT® performance Electronics cover size 2 ® MOVIMOT performance CM3C.. 100LM/D.. 100LM/D.. Electronics cover (inverter) ..0070..0095.. Nominal output current 7.0 A 9.5 A N_inverter electronics cover = 4 kHz, V = 400 V line Apparent output power 4.9 kVA 6.6 kVA Overload capacity <...

- Page 40 Technical data Technical data MOVIMOT® performance Motor, electronics cover size 2 ® MOVIMOT performance CM3C.. 100LM/D.. 100LM/D.. Electronics cover (inverter) ..0070..0095.. Nominal output current 7.0 A 9.5 A N_Inverter electronics cover Nominal power 3.14 kW 4.19 kW Nominal torque 15 Nm 20 Nm Maximum torque 44.6 Nm 58.1 Nm...

- Page 41 Technical data Technical data MOVIMOT® performance 4.4.3 Derating factors Derating depending on the ambient temperature The following figure shows the I reduction depending on the ambient temperature and the nominal mains voltage V line Ambient temperature in °C CM3C80S.., CM3C80M.. and CM3C100LM../D..0070.. with 400 V: 3 %/K CM3C../D..0070..

- Page 42 Technical data Technical data MOVIMOT® performance Derating depending on the installation altitude The following diagram shows the factor f (according to IEC 60034-1:2017, Table 12) by which the thermal motor torque has to be reduced depending on the installation altitude H. 3800 m 1000 m 2000 m 3000 m...

-

Page 43: Electronics Data

Technical data Electronics data Electronics data 4.5.1 DC 24 V supply Input for the independent backup voltage supply of the electronics DC 24 V input 24V_IN = DC 24 V -10%/+20% according to EN 61131-2 0V24_IN Project planning INFORMATION When the external backup voltage supply is used, the external backup voltage supply takes over the entire 24 V supply of the device. - Page 44 Technical data Electronics data Example The drive unit has the following consumer: • Basic requirement of electronics cover size 1 (-210 mA). ® • MOVILINK DDI encoder (-120 mA) • Keypad (-50 mA), • The STO is internally jumpered in the inverter (-20 mA). Without an external 24 ...

- Page 45 Technical data Electronics data 4.5.3 Digital inputs Digital inputs Number of inputs Input type PLC-compatible according to EN 61131‑2 (digital inputs type 3) DI01 – DI04: R ≈ 4.5 kΩ, sampling cycle ≤ 2 ms DI03/DI04: HTL encoder connection for counter function, maximum 120 kHz DI03: Master frequency input, maximum 120 kHz Signal level DC +11 to +30 V...

-

Page 46: Encoder

Technical data Encoder Encoder 4.6.1 Technical data of the motor encoder Encoder option Single-turn resolution Multi-turn resolution Interface connection: (position resolution per (max. counter value for motor revolution) complete motor revolutions) ® /EZ2Z 12 bits 4096 inc. – – MOVILINK DDI, coaxial Single-turn absolute encoder ®... - Page 47 Technical data Interfaces Slave profiles Station profiles AS-Interface Station type Number of Station Profile configuration Address range data bits profile Ext. Ext. configu- code ration code code Binary stations 4 DI/4 DO S-7.F 1 – 31 A/B station 4 DI/4 DO S-7.A.7 1A – 31A, and 1B – 31B 8 DI/8 DO S-7.A.A 1A –...

-

Page 48: Technical Data - Functional Safety

Technical data Technical data – functional safety Technical data – functional safety 4.8.1 STO safety sub-function The following table shows the technical data of the STO safety sub-function. The safe digital inputs F_STO_P1 and F_STO_P2 correspond to type 3 according to IEC 61131‑2. - Page 49 Technical data Technical data – functional safety 4.8.2 Characteristic safety values STO Characteristic values EN 61800-5-2 EN ISO 13849-1 Tested safety class/standard Safety Integrity Level SIL 3 Performance level e/category 3 basis Probability of dangerous fail- 2.5 × 10 ure per hour (PFH value) Service life 20 years, after which the component must be replaced with a new one. Proof test interval >...

-

Page 50: Tsm Memory Module

Technical data TSM memory module TSM memory module The TSM memory module is the only memory of the decentralized inverter. Therefore, all data and settings are saved on this memory module. The data and settings that were loaded onto the device at the time of delivery (delivery state or optional cus- tomer-specific parameterization /P "Parameters ex works") are also saved on the memory module. -

Page 51: Cbg

Technical data CBG.. keypads and accessories 4.10 CBG.. keypads and accessories 4.10.1 CBG11A keypad Description The keypad enables convenient startup, operation, parameterization, and diagnostics ® of inverters of the MOVI-C modular automation system due to the full-text display. The keypad has a mini USB interface with gateway function. A connection from the in- verter to a PC can be established using this interface for engineering with ®... - Page 52 Technical data CBG.. keypads and accessories Technical data CBG11A keypad Part number 28233646 Ambient temperature 0 – 60 °C Degree of protection IP40 according to EN 60529 Power consumption 0.6 W Dimensions in mm (W × H × D) 45 × 100 × 20 Display dimensions in mm (W × H) 28.5 ×...

- Page 53 Technical data CBG.. keypads and accessories 4.10.2 CBG21A keypad Description The keypad enables convenient startup, operation, parameterization, and diagnostics ® of inverters of the MOVI-C modular automation system due to the full-text display. The keypad has a mini USB interface with gateway function. A connection from the in- verter to a PC can be established using this interface for engineering with ®...

- Page 54 Technical data CBG.. keypads and accessories Technical data CBG21A keypad Part number 28238133 Ambient temperature -10 – 60 °C Degree of protection IP40 in accordance with EN 60529 Power consumption 1.4 W Dimensions in mm (W × H × D) 65 × 110 × 20 Display dimensions in mm (W ×...

- Page 55 Technical data CBG.. keypads and accessories 4.10.3 CBG22A local keypad Description The full-text display of the local keypad enables a convenient display of customer-spe- cific information texts of the higher-level controller. It also enables the operator to per- form diagnostics and manual operation. The local keypad has a mini USB interface with gateway function.

- Page 56 Technical data CBG.. keypads and accessories Technical data CBG22A local keypad Part number 28277554 Ambient temperature -10 – 60 °C Degree of protection IP40 in accordance with EN 60529 Power consumption 1.4 W Dimensions in mm (W × H × D) 65 × 110 × 20 Display dimensions in mm (W ×...

- Page 57 Technical data CBG.. keypads and accessories 4.10.4 Wall mounting CBM22A/K-20 Description The CBM22A/K-2.0 wall mounting is used to mount the CBG11A, CBG21A, or CBG22A keypads. With the integrated key switch, you can activate the functions in conjunction with the CBG22A local keypad (e.g. manual mode). For connecting to the X4142 engineering interface of the device, the CBM22A/K-2.0 wall mounting has a connection cable with an M12 connector (see the following fig- ure).

-

Page 58: Usm21A Interface Adapter

Technical data USM21A interface adapter 4.11 USM21A interface adapter An order using part number 28231449 includes the following parts: • USM21A interface adapter • USB connection cable for the USM21A – PC connection • Serial interface cable with 2 RJ10 connectors The USM21A interface adapter is used to connect the PC and the engineering inter- face of the device. -

Page 59: Brake Control

Technical data Brake control 4.12 Brake control 4.12.1 Functional description Brake control is only possible via the following options: Brake type (nominal voltage) Required option AC brakes 100 – 525 V Option /B The HV brake control is installed in the electronics cover. 4.12.2 HV brake control /B Description... - Page 60 Technical data Brake control Technical data HV brake control /B Voltage supply From the DC link of the device WARNING Danger due to electric voltage in brakes that are activated by the HV brake ® control /B. As long as MOVIMOT flexible is supplied with line voltage, the DC link potential is applied to the brake connections 13, 14, and 15.

- Page 61 Technical data Brake control HV brake control /B Control type functions Default Voltage control Brake control Supported SEW brakes Brakes from brake types SEW‑EURODRIVE and third- • BE.. party brakes in compatible • BZ.. voltage and current ranges • Energy-optimized operation •...

- Page 62 Technical data Brake control HV brake control /B Control type functions Default Voltage control Brake condi- Condition recording • Air gap measurement Not available tion monitor- functions • Brake lining reserve • Brake coil temperature • Relative thermal brake coil utiliza- tion Air gap measure- 100% brake lining reserve:...

-

Page 63: Braking Resistors

Technical data Braking resistors 4.13 Braking resistors 4.13.1 Overview The drive unit is equipped with a brake chopper. The following table shows the pos- sible uses in regenerative mode: Dissipation of regenerative energy Brake chopper Small amount Integrated braking resistor of regenerative energy Low –... - Page 64 Technical data Braking resistors 4.13.2 Integrated BW1/BW2 braking resistor The following diagram shows the current-carrying capacity of the BW1/BW2 braking resistor per braking operation: BW2 BW1 1200 1000 6000 [c/h] 1000 2000 3000 4000 5000 9007200742150795 Deceleration ramp 10 s Deceleration ramp 4 s Deceleration ramp 0.2 s Cycles/hour Calculation example...

- Page 65 Technical data Braking resistors 4.13.3 External braking resistor Operation with external braking resistor is necessary for applications with a large amount of regenerative energy. Description Operation with external braking resistor is necessary for applications with a large amount of regenerative energy. Assignment 4Q operation with external braking resistor is necessary for applications with a large amount of regenerative energy.

- Page 66 Technical data Braking resistors BW100-005/K-1.5, BW150-003/K-1.5, BW047-004/K-0.61 Braking resistance BW100-005/K1.5 BW150-003/K‑1.5 BW047-004/K‑0.61 Braking resistor part number 08282862 08282927 28179145 with open cable end Braking resistor part number 28176448 28176421 – with connector (for X2304) Peak braking power P Approval CE, cURus CE, cURus CE, cURus Current-carry-...

- Page 67 Technical data Braking resistors BW150-006.-T, BW100-009-T BW150-006-T BW100-009-T Braking resistor Braking resistor part number 17969565 17969573 Connection cable part number 28172558 28172558 (with connector for X2304) Peak braking power P Approval CE, cURus CE, cURus Current-carry- 100% cdf kW ing capacity 50% cdf kW 25% cdf kW 12% cdf kW...

- Page 68 Technical data Braking resistors BW068-006-T, BW068-012-T BW068-006-T BW068-012-T Braking resistor Braking resistor part number 17970008 17970016 Connection cable part number 28172558 28172558 (with connector for X2304) Peak braking power P 13.8 13.8 Approval CE, cURus CE, cURus Current-carry- 100% cdf kW ing capacity 50% cdf kW 25% cdf kW...

- Page 69 Technical data Braking resistors BW050-008-01, BW033-012-T Braking resistor BW050-008-01 BW033-012-01 Braking resistor part number 17962242 17962196 Connection cable part number 28172558 28172558 (with connector for X2304) Peak braking power P 18.8 28.3 Approval cURus cURus Current-carry- 100% cdf kW 0.48 0.72 ing capacity 50% cdf kW...

- Page 70 Technical data Braking resistors Connection cable The following cable is available for connecting the external braking resistors: Device Connection cable Length Braking resistor ® MOVIMOT advanced Part number: 13230409 30 m BW150-006-T ® MOVIMOT performance Type: LEONI LEC 001637 BW100-009-T 3Gx2.5 mm ®...

- Page 71 Technical data Braking resistors 4Q operation with integrated brake and external braking resistor The regenerative energy converted in the braking resistor and in the brake coil is add- ed to the total energy. 4.13.4 Technical data of BW100-005/K-1.5 and BW150-003/K-1.5 Power diagrams The following figure shows the rating diagrams of the braking resistors BW100-005/ K-1.5, BW150-003/K-1.5:...

- Page 72 Technical data Braking resistors Dimension drawing of BW100‑005/K-1.5 The following figure shows the dimensions of the external braking resistor BW100-005/K-1.5: 15.5 Ø8 1500 9007224553521035 Dimension drawing for the BS-005 protective grid The following figure shows the dimensions of the BS-005 protective grid: 25842294795 Type Main dimensions in mm...

- Page 73 Technical data Braking resistors 4.13.5 Technical data of BW150-006-T and BW100-009-T Power diagrams The following figure shows the rating diagrams of the braking resistors BW150-006-T and BW100-009-T: BW100-009-T BW150-006-T 25298798219 Power in KW Cyclic duration factor cdf in % ED Cyclic duration factor of the braking resistor, based on a cycle time of 120 s. Dimension drawing of BW150‑006-T The following figure shows the dimensions of the external braking resistor BW150‑006-T:...

- Page 74 Technical data Braking resistors Dimension drawing of BW100‑009-T The following figure shows the dimensions of the external braking resistor BW100-009-T: ø7x11 <435 25298815755 4.13.6 Technical data of BW068-006-T and BW068-012-T Power diagrams The following figure shows the power diagrams of the BW068-006-T and BW068-012- T braking resistors according to UL approval: 7 8 9 10 70 80...

- Page 75 Technical data Braking resistors Dimension drawing of BW068-006-T The following figure shows the dimensions of the external braking resistor BW068-006-T: ø7x11 <285 34606358411 Dimension drawing of BW068-012-T The following figure shows the dimensions of the external braking resistor BW068-012-T: ø7x11 <635 25298820747 ®...

- Page 76 Technical data Braking resistors 4.13.7 Technical data of BW050-008-01 and BW033-012-01 Continuous braking power The following table shows the continuous braking power of the BW050-008-01 and BW033-012-01 braking resistors: Braking resistor BW050-008-01 BW033-012-01 Continuous braking power according to IEC according to UL according to IEC according to UL 100% cdf...

-

Page 77: Mounting Kit For Braking Resistor Bw

Technical data Mounting kit for braking resistor BW...-.../..C 4.14 Mounting kit for braking resistor BW...-.../..C INFORMATION • The BW...-.../..C braking resistor must always be mounted and installed by the customer. • Observe the installation instructions "Braking resistor BW...-.../..C". The following figure shows the mounting kit for braking resistor BW...-.../..C without connector: 9007224553569547 ®... - Page 78 Technical data Mounting kit for braking resistor BW...-.../..C 4.14.1 Technical data Mounting kit BW100-001/ BW100-001/ BW100-002/ BW100-002/ K-0.14/M2C/IV K-0.14/M4C/IV K-0.14/M2C/IV K-0.14/M4C/IV Braking resistance Part number braking resistor 28306031 28306066 28306058 28306074 with connector for X2304 Braking resistor BW100-001/ BW100-001/ BW100-002/ BW100-002/ without connector K-0.15/M2C...

- Page 79 Technical data Mounting kit for braking resistor BW...-.../..C 4.14.2 Dimension drawing The following figure shows the dimension drawing of the mounting kit braking resistor without connector: 9007224554230283 BW100-001/K-../M2C 126.0 89.0 148.2 61.8 111.0 106.0 54.7 BW100-002/K-../M2C BW100-001/K-../M4C 158.0 94.0 149.0 61.8 144.0 142.0...

-

Page 80: Line Choke

Technical data Line choke 4.15 Line choke The line choke can be used as an option: • To support overvoltage protection • To smoothen the line current • For protection in the event of distorted line voltage • To limit the charging current, for example, when several inverters are connected together in parallel on the input end (nominal current of line choke = total of nom- inal input currents) 4.15.1... -

Page 81: Technical Data Of The Brake

Technical data Technical data of the brake 4.15.3 Dimension drawing The following figure shows dimensioned drawing of the line choke. 31249196171 Line choke Main dimensions in mm Mounting dimensions in Connection ND0070-503 ND0160-503 ND0300-503 ND0420-503 4.16 Technical data of the brake Observe the information in the "CM3C Synchronous Servomotors"... -

Page 82: Dynastop® Torques

Technical data DynaStop® torques DynaStop® torques ® 4.17 DynaStop torques 4.17.1 Notes INFORMATION ® For a functional description of DynaStop refer to chapter "Operation" > ® "DynaStop " (→ 2 330) 4.17.2 Operating range The following figure depicts the permissible/impermissible operating range of ®... -

Page 83: Torque Characteristic Curves

Technical data Torque characteristic curves 4.18 Torque characteristic curves ® 4.18.1 MOVIMOT performance CM3C80S..-0020 The following diagram shows the torque characteristic curves of the drive unit: 750 V 400 V 360 V ¹ 1000 2000 3000 4000 5000 ® Product Manual – MOVIMOT performance DAC... - Page 84 Technical data Torque characteristic curves CM3C80S..-0025 The following diagram shows the torque characteristic curves of the drive unit: 750 V 400 V 360 V 1000 2000 3000 4000 5000 ¹ CM3C80S..-0032 The following diagram shows the torque characteristic curves of the drive unit: 750 V 460 V 400 V...

- Page 85 Technical data Torque characteristic curves CM3C80S..-0040 The following diagram shows the torque characteristic curves of the drive unit: 750 V 500 V 460 V 400 V 360 V 1000 2000 3000 4000 5000 ¹ CM3C80M..-0040 The following diagram shows the torque characteristic curves of the drive unit: 750 V 460 V 400 V...

- Page 86 Technical data Torque characteristic curves CM3C80M..-0055 The following diagram shows the torque characteristic curves of the drive unit: 750 V 500 V 460 V 400 V 360 V 1000 2000 3000 4000 5000 ¹ CM3C100LM..-0070 The following diagram shows the torque characteristic curves of the drive unit: 500 V 460 V 360 V...

- Page 87 Technical data Torque characteristic curves CM3C100LM..-0095 The following diagram shows the torque characteristic curves of the drive unit: 500 V 460 V 400 V 360 V 1000 2000 3000 4000 5000 ¹ ® Product Manual – MOVIMOT performance DAC...

-

Page 88: Surface Protection

Technical data Surface protection 4.19 Surface protection 4.19.1 General information SEW‑EURODRIVE offers the following optional preventive measures for operating drive units under special environmental conditions. • OS surface protection Special preventive measures are additionally available as an option for output shafts. 4.19.2 Surface protection The drive unit is optionally available with the following variants of surface protection. - Page 89 Technical data Surface protection Surface protection OS2 to OS4 is not available for devices with a size 2 electronics cover. 4.19.3 Special protective measures Observe the information in the "CM3C" gearmotor catalog. ® Product Manual – MOVIMOT performance DAC...

-

Page 90: Screw Fittings

Technical data Screw fittings 4.20 Screw fittings 4.20.1 Cable glands / screw plugs / pressure compensation The following table shows the screw fittings and the screw plug that are optionally available from SEW‑EURODRIVE: Screw fitting type Image Con- Size Tightening Outer Tight- Part num-... - Page 91 Technical data Screw fittings 4.20.2 Screw plug connectors The following table shows the screw plugs for connectors optionally available from SEW‑EURODRIVE: Screw fitting type Image Contents Size Tightening Part torque number M23 plug 1 pieces M23 × 1.5 Tighten 19094558 for connector with male to the stop thread (stainless steel)

-

Page 92: Guard Bracket

Technical data Guard bracket 4.21 Guard bracket following table shows guard bracket optionally available from SEW‑EURODRIVE: Designation Image Content Tightening Part num- torques screws Guard bracket 1 Guard bracket 2.0 – 2.4 Nm 28202717 (stainless steel) 2 M5 × 12 screws 2 washers 2 lock washers 1 instruction manual For a dimension drawing of the guard brackets, see chapter "Dimension drawing of... -

Page 93: Connection Cables

Inner sheathing TPE-O, halogen-free Color Natural Filler Shield Braided copper wires, tinned min. optical coverage 85% Outer cable jacket TPU, halogen-free Color Green, similar to RAL2018 Label SEW-EURODRIVE 150665 Li9Y91YC11Y-HF .. Diameter 15.6 mm ® Product Manual – MOVIMOT performance DAC... - Page 94 Technical data Connection cables Technical data The following table shows the technical data of the signal cable: ® Properties Type: HELUKABEL Li9Y91YC11Y-HF SEW EURODRIVE 150665 UL properties UL758 (AWM) UL Style 20223 (sheath) UL Style 10493 (insulation) RoHS conformity Test voltage conductor/con- AC 1.5 kV 50 Hz/1 min.

-

Page 95: Overhung Loads

Technical data Overhung loads 4.23 Overhung loads ® 4.23.1 MOVIMOT performance Observe the information in the "CM3C" gearmotor catalog. 4.24 Mounting positions ® 4.24.1 Mounting positions for MOVIMOT performance with IEC flange stand-alone motors Position of electronics cover and cable entry ®... -

Page 96: Dimension Drawings Of The Drive Unit

Technical data Dimension drawings of the drive unit 4.25 Dimension drawings of the drive unit 4.25.1 Information regarding dimension drawings All dimensions in mm. Scope of delivery = Standard parts supplied by SEW‑EURODRIVE. = Standard parts not supplied by SEW‑EURODRIVE. Breather valves and cable glands The dimension drawings always show the screw plugs. - Page 97 Technical data Dimension drawings of the drive unit ® 4.25.2 Dimension drawings of MOVIMOT performance ® Gearmotor dimension sheets can be found in the catalog "CM3C.. MOVIMOT perfor- mance gearmotors". CM3C80 ® Product Manual – MOVIMOT performance DAC...

- Page 98 Technical data Dimension drawings of the drive unit CM3C80 ® Product Manual – MOVIMOT performance DAC...

- Page 99 Technical data Dimension drawings of the drive unit CM3C100 ® Product Manual – MOVIMOT performance DAC...

- Page 100 Technical data Dimension drawings of the drive unit CM3C100 ® Product Manual – MOVIMOT performance DAC...

-

Page 101: Dimension Drawings Of Connectors At The Electronics Cover

Technical data Dimension drawings of connectors at the electronics cover 4.26 Dimension drawings of connectors at the electronics cover 4.26.1 Dimension drawing of the connectors on electronics cover size 1 The following figure shows the additional dimensions of the connector. 9007229877301643 M12 connector design, male All dimensions in mm. - Page 102 Technical data Dimension drawings of connectors at the electronics cover The following figure shows the additional dimensions of the connector. 9007233591844363 M12 connector design, male All dimensions in mm. ® Product Manual – MOVIMOT performance DAC...

-

Page 103: Dimension Drawings Of Connectors In The Connection Box

Technical data Dimension drawings of connectors in the connection box 4.27 Dimension drawings of connectors in the connection box 4.27.1 Dimension drawing connection box size 1 connector The following figure shows an example of the additional dimensions of the optional connectors for a possible connector configuration. - Page 104 Technical data Dimension drawings of connectors in the connection box 4.27.2 Dimension drawing connection box size 1 connector including mating connector The following image shows the multiple dimensions/bending radii of the optional con- nector, including mating connector, together with prefabricated cables from SEW‑EURODRIVE.

- Page 105 Technical data Dimension drawings of connectors in the connection box 4.27.3 Dimension drawing connection box size 2 connector The following figure shows an example of the additional dimensions of the optional connectors for a possible connector configuration. For more information, refer to chapter "Electrical installation" > "Connector" > "Con- nector positions ...".

- Page 106 Technical data Dimension drawings of connectors in the connection box 4.27.4 Dimension drawing connection box size 2 connector including mating connector The following image shows the multiple dimensions/bending radii of the optional con- nector, including mating connector, together with prefabricated cables from SEW‑EURODRIVE.

-

Page 107: Dimension Drawing Of Guard Bracket

Technical data Dimension drawing of guard bracket 4.28 Dimension drawing of guard bracket The following figure shows the dimensions of the guard bracket. 135.5 35973190923 All dimensions in mm. ® Product Manual – MOVIMOT performance DAC... -

Page 108: Project Planning For The Drive Unit

Project planning for the drive unit Preliminary information Project planning for the drive unit Preliminary information INFORMATION Data may differ due to continuous product development. SEW-Workbench The SEW‑Workbench is the central configuration software for inverters from SEW‑EURODRIVE. All necessary configurations can be processed, from entering the application to gear unit, motor and inverter calculations. - Page 109 Project planning for the drive unit Data for drive selection/designation Data for drive selection/designation Gear unit ratio Ideal gear unit ratio Torques Peak torque of the motor Nominal motor torque Required application torque in the nth travel section Required application torque with considera- tion of the efficiency Effective (thermally equivalent S1) torque Maximum required application torque...

- Page 110 Project planning for the drive unit Data for drive selection/designation 5.3.1 Determining the motor data To select the proper drive, you first need the data (weight, speed, setting range, etc.) of the machine to be driven. This determines the torque and the rotational speed. Refer to the documentation "Drive Engineering –...

-

Page 111: Schematic Workflow For Project Planning

Project planning for the drive unit Schematic workflow for project planning Schematic workflow for project planning The following flow diagram illustrates the drive selection procedure for a positioning drive. The drive consists of a gearmotor that is supplied by an inverter. Required information about the machine to be driven •... -

Page 112: Control Mode

Project planning for the drive unit Control mode Control mode The characteristics of the motor connected to the inverter are influenced by the control modes used. 5.5.1 The CFC control mode is a current-controlled control mode. The CFC control mode al- lows the operation of asynchronous and synchronous motors with maximum torque dynamics. - Page 113 Project planning for the drive unit Control mode ® 5.5.2 ELSM ® The ELSM control mode enables operation of permanent-field synchronous motors without an encoder. Make sure that the inverter can deliver at least 150% I of the motor. Switching to a rotating motor is possible (flying start function). Continuous operation is only permitted above a transition speed of approx.

- Page 114 Project planning for the drive unit Control mode 5.5.3 Characteristics of the control modes Overview of the control modes PLUS ® ELSM Field-oriented, Voltage voltage-controlled, controlled Field-oriented, cur- Field-oriented, cur- Principle stator flux control- according to char- rent controller rent controller ler, torque control- acteristic curve Motor...

- Page 115 Project planning for the drive unit Control mode Characteristic values for setpoint resolution PLUS ® ELSM Torque – 32 bit (0.001% M NMot Rotational speed 32 bit (0.0001 min Position – 16 bit – (increment/revolution) Position – 32 bit – (increment absolute) Characteristic values for accuracy of torque and speed PLUS PLUS without encoder...

- Page 116 Project planning for the drive unit Control mode FCBs that can be activated for selected control mode PLUS ® Designation ELSM Output stage inhibit Default stop Manual mode Speed control Interpolated speed control Torque control – Interpolated torque control – Stop at application limits Emergency stop Motor parameter measurement...

-

Page 117: Fcb Concept

Project planning for the drive unit FCB concept FCB concept The FCB concept describes the modular firmware design of inverters from the ® MOVI-C modular automation system with which it is ensured that a wide range of drive functions can be selected or deselected quickly and easily using control words. All primary functions are selected as FCBs. - Page 118 Project planning for the drive unit FCB concept 5.6.1 Description of the FCBs FCB 01 Output stage inhibit Activating FCB 01 stops the connected motor via the motor brake. If no brake is in- stalled, the motor coasts to a stop. FCB 02 Default stop FCB ...

- Page 119 Project planning for the drive unit FCB concept FCB 07 Torque control The inverter can be operated as a torque-controlled axis. The user can specify profile values for deceleration and jerk as the basic conditions for torque control. The actual torque setpoint for the drive controller is generated in the controller cycle with the specified limit values by a profile generator integrated in the inverter.

- Page 120 Project planning for the drive unit FCB concept Modulo in negative direction with absolute position specification The position setpoint in user units is interpreted as the absolute position. It must be within the modulo range of the active drive: • Lower limit = "Modulo min."...

- Page 121 Project planning for the drive unit FCB concept FCB 12 Reference travel To perform positioning operations, a drive has to be referenced to a defined start or reference position within the permitted travel distance. From this reference position, positions such as the machine zero can be specified and approached. With each re- start of the inverter, referencing the position encoders is always necessary if position encoders do not have an absolute position detection.

- Page 122 Project planning for the drive unit FCB concept FCB 20 Jog mode FCB 20 is used for the setup mode when a higher-level controller is used. FCB 20 can only be activated in operating modes with encoder feedback. FCB 20 allows the user to move an axis in a positive and negative direction. Control is performed via control signals that are specified by means of control words, via digital inputs of a higher-level controller or via input terminals.

- Page 123 Project planning for the drive unit FCB concept FCB 25 Motor parameter measurement FCB 25 is used for determining the necessary parameters from the electric equivalent wiring diagram during startup. The nameplate data of the connected motor is required for motor parameter measure- ment.

- Page 124 Project planning for the drive unit FCB concept Profile value connection The following table shows which profile values are used by which FCBs. Parameter Maximum – – – – – – – – positive speed Maximum – – – – –...

-

Page 125: Recommendations For Motor And Inverter Selection

The values for M and n in the VFC , CFC, ELSM control modes can be found on the website sew-eurodrive.de. PLUS Typical dynamic limit characteristic of an asynchronous motor in the VFC /CFC control mode 9007238743734155 Maximum torque for the motor-inverter combination Rotational speed until the maximum torque M of the motor-inverter combination is available. - Page 126 Project planning for the drive unit Recommendations for motor and inverter selection Typical dynamic limit characteristic of a synchronous motor in CFC control mode 9007238743738251 Maximum torque for the motor-inverter combination Rotational speed until the maximum torque M of the motor-inverter combination is available. ®...

- Page 127 Project planning for the drive unit Recommendations for motor and inverter selection 5.7.3 Motor selection for synchronous motors The demands made on a servo drive include speed dynamics, stable speed, and posi- tioning accuracy. As a rule, the synchronous servomotors and the corresponding in- verters are designed for a high short-time overload.

-

Page 128: Motor/Inverter Characteristic Curves

Project planning for the drive unit Motor/inverter characteristic curves SEW‑EURODRIVE recommends using the following temperature sensors: • KTY84-130 (SEW‑EURODRIVEdesignation: KY) • Pt1000 (SEW‑EURODRIVE designation: PK) Motor/inverter characteristic curves The motor/inverter characteristic curves apply to the edition of these operating instruc- tions. - Page 129 Project planning for the drive unit Selecting an inverter 5.9.1 Overload capacity Load cycle with base load current – typical for the selection of asynchronous and servomotors The characteristic load cycle consists of a base load and an overload period. In the base load period, the output current must not exceed the specified value.

- Page 130 Project planning for the drive unit Selecting an inverter 5.9.2 Power reduction factors Due to the following operating and ambient conditions, a reduction of the output cur- rent may be necessary. Derating due to the rotary field frequency The specified nominal output current I of the inverter is the effective value.

- Page 131 Project planning for the drive unit Selecting an inverter Electronics cover size 2, ≤ 9.5 A f /Hz 48639185803 [1] Continuous output current I at the smallest possible PWM frequency cont [2] Temporally limited overload current 1) Configure the overload current in the SEW Workbench. Electronics cover size 2, = 12.5 A...

-

Page 132: Selecting The Braking Resistor

Project planning for the drive unit Selecting the braking resistor Derating due to the installation altitude Frequency inverters by SEW‑EURODRIVE are designed for overvoltage category III and for altitudes up to 2000 m according to EN 61800‑5-1. The air pressure and the air density decrease depending on the installation altitude. - Page 133 Project planning for the drive unit Selecting the braking resistor If the cyclic duration factor cdf is unknown, it can be calculated from the cycle duration and the braking time t using the following formula. x 100 % 9007219434171531 Cyclic duration factor Braking time Cycle duration INFORMATION...

- Page 134 Project planning for the drive unit Selecting the braking resistor Overload factor OF Flatpack resistors 10 % 100 % 18014419041960715 Cyclic duration factor in % Overload factor k Wire resistors, frame resistors 10 % 25 % 40 % 60 % 100 % 9007242996955915 Cyclic duration factor in %...

- Page 135 Project planning for the drive unit Selecting the braking resistor Grid resistors 100 % 10 % 18014401500012171 Cyclic duration factor in % Overload factor k 1.12 Peak braking power The maximum peak braking power that can be achieved is specified by the resistance value and the DC link voltage.

- Page 136 Project planning for the drive unit Selecting the braking resistor Current-carrying capacity of the brake chopper The resistance value of the braking resistor R must not be lower than the minimum permitted braking resistance R , see chapter "Technical data" (→ 2 30). This en- BRmin sures that the brake chopper is not damaged.

-

Page 137: Supply System Cables And Motor Cables

Project planning for the drive unit Supply system cables and motor cables 5.10.5 Supply cable for braking resistor Use only shielded or twisted cables. The cable cross section depends on the tripping current I The nominal voltage of the cable must be at least V /V = 450 V/750 V. -

Page 138: Emc-Compliant Installation According To En 61800-3

Project planning for the drive unit EMC-compliant installation according to EN 61800-3 5.12 EMC-compliant installation according to EN 61800-3 The inverters are designed for use as components for installation in machinery and systems. They comply with the EMC product standard EN 61800-3 "Adjustable-speed electrical drives". -

Page 139: Supply Voltage Selection

Project planning for the drive unit 24 V supply voltage selection 5.14 24 V supply voltage selection 5.14.1 Description The device has an internal 24 V voltage supply that can also be supported externally. If the device is supported by an external supply, the entire 24 V supply is provided by the external power supply unit. -

Page 140: Energy-Saving Functions

Project planning for the drive unit Energy-saving functions 5.15 Energy-saving functions 5.15.1 Standby mode The energy-saving function standby operation is designed for periods in which the operation is paused. If necessary, activate standby operation with a binary input or a bit of the control word. Switching from standby operation to operation takes only approx. - Page 141 Project planning for the drive unit MOVIMOT® performance Calculations for gear unit selection from project planning of the application Output end torques stat = ..≥ 0 Check individually for all n travel sections η η Consideration Consideration motoring operation: regenerative operation: η...

- Page 142 Project planning for the drive unit MOVIMOT® performance Calculations for motor selection from project planning Motor Motor Motor Select drive according Check to table drive/application ≤ M Motor ≤ n Motor = 2000 min Select multi-/single-turn Setting range less than 1:40? encoder >...

- Page 143 Project planning for the drive unit MOVIMOT® performance │ + ... + t │ u│M u│M + ... + t ≤ M brake 9.55 W = P brake Inspection of braking resistance based on braking energy and braking operations per hour MOVIMOT ®...

- Page 144 Project planning for the drive unit MOVIMOT® performance 5.16.2 Drive selection using the example of a roller conveyor Description of the application This chapter illustrates the drive unit selection using the example of a roller conveyor for transporting wooden pallets with the following specifications: Load weight 2500 kg Conveying speed...

- Page 145 Project planning for the drive unit MOVIMOT® performance Calculating the application The travel profile consists of the 3 travel sections acceleration, constant movement, and deceleration. t [min] 9007224477235339 The following table shows the calculations for the application that are required to de- termine the drive units: Calculations Static resistance to vehicle...

- Page 146 Project planning for the drive unit MOVIMOT® performance Calculations Torque in range M3 − × ÷ × η η 0 14 − × ÷ × = − 1000 0 7 .5 5 Nm ...

- Page 147 Project planning for the drive unit MOVIMOT® performance ® MOVIMOT performance CM3C.. 80S/D.. 80S/D.. 80S/D.. 80S/D.. 80M/D.. 80M/D.. Electronics cover (inverter) 0020 0025 0032 0040 0040 0055 Nominal torque 3.6 Nm 4.5 Nm 5.7 Nm 7.2 Nm 8 Nm 9 Nm Overload capacity of M 300% 300%...

- Page 148 Project planning for the drive unit MOVIMOT® performance ð Derating due to installation altitude 8. Checking the braking resistor ð Calculation of the regenerative power when decelerating: × × brake 9 55 × × 11 8 brake 9 55 ð The remainder of the check takes place in accordance with chapter "Regenera- tive current-carrying capacity of the integrated braking resistor" (→ 2 149).

- Page 149 Project planning for the drive unit MOVIMOT® performance 5.16.3 Regenerative load capacity of the integrated braking resistor The following diagram shows the current-carrying capacity of the BW1/BW2 braking resistor per braking operation: BW2 BW1 1200 1000 6000 [c/h] 1000 2000 3000 4000 5000 9007200742150795...

- Page 150 Project planning for the drive unit MOVIMOT® performance 5.16.4 Project planning notes – R.., F.., K.., S.., W.. gear units Efficiency of gear units General information The efficiency of the gear units is mainly determined by the gearing and bearing fric- tion as well as by churning losses.

- Page 151 Project planning for the drive unit MOVIMOT® performance Run-in phase The tooth flanks of new helical-worm and SPIROPLAN® gear units of the W..0 series are not yet completely smooth. This makes for a greater friction angle and less effi- ciency during the run-in phase than during later operation. This effect intensifies with increasing gear ratio.

- Page 152 Project planning for the drive unit MOVIMOT® performance Churning losses and thermal rating Churning losses may occur with the following conditions. They must be considered during the thermal check: • A mounting position in which the 1st gear unit stage fully immerses in the lubricant. ®...

-

Page 153: Dynastop - The Electrodynamic Retarding Function

Project planning for the drive unit DynaStop® – The electrodynamic retarding function DynaStop® – The electrodyna retarding function ® 5.17 DynaStop – The electrodynamic retarding function 5.17.1 Functional description INFORMATION ® For the functional description of DynaStop refer to chapter "Operation" > ®... -

Page 154: Ul-Compliant Installation

Project planning for the drive unit UL-compliant installation 5.18 UL-compliant installation INFORMATION Due to UL requirements, the following chapter is always printed in English and in some cases in French, regardless of the language of this documentation. Observe the following notes for UL-compliant installation: The devices are for use only in industrial machinery NFPA 79 applications. - Page 155 Project planning for the drive unit UL-compliant installation For maximum branch circuit protection see table below. SCCR: 65 kA /500 V when protected by Non-semiconductor fuses Inverse time circuit breakers (currents are maximum values) (currents are maximum values) 40 A max./600 V 40 A max./500 V min. 5.18.4 Motor Overload Protection The devices are provided with load and speed-sensitive overload protection and...

-

Page 156: Project Planning For Functional Safety

• PL e according to EN ISO 13849‑1 This was certified by TÜV Rheinland. A copy of the TÜV certificate can be requested from SEW-EURODRIVE. 6.3.2 Safe state For safety-related operation of the device, Safe Torque Off is defined as a safe state (see "Safety sub-function STO" (→ 2 156)). - Page 157 Project planning for functional safety Integrated safety technology 6.3.3 STO safety concept The device is supposed to be able to perform the safety sub-function "Safe Torque Off" according to EN 61800‑5‑2: • The device is characterized by the optional connection of an external safety con- troller/safety relay.

- Page 158 Project planning for functional safety Integrated safety technology 6.3.5 Safety sub-functions according to EN 61800-5-2 STO – Safe Torque Off When the STO safety sub-function is active, the power supply to the motor is interrupt- ed and the drive cannot generate any torque. The STO safety sub-function corre- sponds to a non-controlled stop according to EN 60204‑1, stop category 0.

- Page 159 Project planning for functional safety Integrated safety technology SS1-t – Safe Stop 1 with time control When the SS1-t safety sub-function is active, the motor is brought to a standstill elec- trically. The STO safety sub-function will be triggered after a specified, safety-related time.

- Page 160 Project planning for functional safety Integrated safety technology 6.3.6 Restrictions • It is to be noted that if the drive does not have a mechanical brake or if the brake is defective, the drive may coast to a halt (depending on the friction and mass mo- ment of inertia of the system).

-

Page 161: Safety Requirements

Project planning for functional safety Safety requirements Safety requirements 6.4.1 Introduction The requirement for safe operation is that the safety sub-functions of the device are properly integrated into an application-specific, higher-level safety sub-function. A sys- tem/machine-specific risk assessment must be carried out without fail by the system/ machine manufacturer and taken into account for the use of the drive system with the device. - Page 162 Project planning for functional safety Safety requirements • The values specified for the safety components must be strictly adhered to when designing the safety circuits. • The STO signals must not be used for feedback. • Only grounded voltage sources with protective electrical separation (PELV) in ac- cordance with EN ...

- Page 163 Project planning for functional safety Safety requirements • For high-frequency-suitable grounding, use special grounding straps whose con- nection points have a sufficiently large surface area. Do not use crimped eyelets. 55206489355 – Mount grounding straps over the entire surface on well-conducting surfaces. Contact points must be free of paints and other substances.

- Page 164 Project planning for functional safety Safety requirements • Connect the shield to the metal housing over a large area using a suitable cable bushing or shield terminals. Do not use pigtails for shield connection in terminal strips. The pigtail is an antenna that greatly weakens the shielding effect. •...

- Page 165 Project planning for functional safety Safety requirements 6.4.6 Requirements for the operation of the STO safety sub-function • Operation is only permitted within the limits specified on the data sheets. This ap- plies to an external safety controller, an external safety relay, as well as to the device and the approved safety options.

- Page 166 Project planning for functional safety Safety requirements 6.4.7 Requirements for the external safety controller A safety relay can be used as an alternative to a safety controller. The following re- quirements apply analogously: • The safety controller and all other safety-related subsystems must be approved for at least the safety class required in the overall system for the respective applica- tion-related safety sub-function.

- Page 167 Project planning for functional safety Safety requirements • Test pulses can take place in the switched on or switched off condition with con- nection type "Two-pole sourcing output". – The test pulses on both sourcing channels must be switched with a time delay. However, additional switch-off test pulses may occur simultaneously.

-

Page 168: Response Times

Project planning for functional safety Response times 6.4.8 Acceptance The system manufacturer must perform an overall evaluation in order to determine the safety of a machine or a system. The effectiveness of each risk minimization must be checked. It must also be checked if the required safety integrity (SIL and/or PL) is reached for each implemented safety function. -

Page 169: Device Structure

Device structure MOVIMOT® performance drive unit Device structure MOVIMOT® performanc e drive unit ® MOVIMOT performance drive unit ® 7.1.1 MOVIMOT performance DAC with electronics cover size 1 ® MOVIMOT performance drive units consist of the 2 core components of the servomo- tor and the decentralized inverter (see following figure). - Page 170 Device structure MOVIMOT® performance drive unit ® 7.1.2 MOVIMOT performance DAC with electronics cover size 2 ® MOVIMOT performance drive units consist of the 2 core components of the servomo- tor and the decentralized inverter (see following figure). The decentralized inverter is referred to as the electronics cover in the following.

-

Page 171: Cable Entry Position

Device structure Cable entry position Cable entry position The device is equipped with the following cable bushings: Electronics cover • Position X, 1, 2, 3 size 1 – X: 2 × M25 × 1.5 + 2 × M16 × 1.5 –... - Page 172 Device structure Cable entry position ® 7.2.2 Overview of MOVIMOT performance DBC, DAC with electronics cover size 2 The following figure shows the possible cable entries: 35572058123 The position of the cable bushings depends on the position of the decentralized in- verter.

-

Page 173: Nameplate Position

Device structure Nameplate position Nameplate position ® The following nameplate positions are possible for MOVIMOT performance: • X (standard position) • The position of the nameplate depends on the position of the decentralized inverter. ® 7.3.1 Overview of MOVIMOT performance DBC, DAC The following figure shows an example of the position of the nameplates on the device: eff% 88,3... -

Page 174: Example Nameplate And Type Designation Of The Drive Unit

Device structure Example nameplate and type designation of the drive unit Example nameplate and type designation of the drive unit ® 7.4.1 MOVIMOT performance DAC nameplate The following figure shows an example of a drive unit nameplate. The format of the type designation can be found in chapter "Type designation ...". - Page 175 Device structure Example nameplate and type designation of the drive unit ® 7.4.2 Type designation of MOVIMOT performance DAC The following table shows the type designation of the drive unit. Series, 1st gear unit KAF = Gear unit (+ design) Size, 1st gear unit Series, 2nd gear unit R = Primary gear unit...

- Page 176 Device structure Example nameplate and type designation of the drive unit AZ2Z Option IV = Connector at the connection box PK = Temperature sensor ® AZ2Z = Multi-turn encoder with MOVILINK DDI connection ® EZ2Z = Single-turn encoder with MOVILINK DDI connection PE = Pressure compensation fitting electronics BW1 = Integrated BW1 braking resistor...

-

Page 177: Example Of The Optional Nameplate "Electrical Regulations Ul/Ce

Device structure Example of the optional nameplate "Electrical regulations UL/CE" Example of the optional nameplate "Electrical regulations UL/CE" ® The optional type plate "UL/CE Electrical Regulation" for MOVIMOT performance drive units is in preparation. Examples for the optional nameplate "Connector positions" 7.6.1 Design with electronics cover size 1 The following figure shows an example of the optional nameplate "Connector posi-... - Page 178 Device structure Examples for the optional nameplate "Connector positions" 7.6.2 Design with electronics cover size 2 The following figure shows an example of the optional nameplate "Connector posi- tions": The nameplate shows the designations and positions of the connectors at the connec- tion box.

-

Page 179: Electronics

Device structure Electronics Electronics 7.7.1 Overview of electronics cover Devices with the following electronics covers are available depending on the nominal output current: Electronics cover Nominal out- Type designation Size Image put current 2.0 A DAC...-0020.. Size 1 without cooling fins 2.5 A DAC...-0025.. - Page 180 Device structure Electronics 7.7.2 Connection box and electronics cover (internal) size 1 The following figure shows the connection box and the bottom side of the electronics cover: 3 5 6 [17] [18] [17] [18] [17] [18] [17] [16] [15] [14] [13] [12] [11] [10]...

- Page 181 Device structure Electronics 7.7.3 Connection box and electronics cover (internal) size 2 The following figure shows the connection box and the bottom side of the electronics cover: [16] [15] [14] [13] [12] [11] [10] [17] [17] [17] 35573102987 Cable glands Connection box Line connection L1, L2, L3 Connector connection unit for electronics cover...

- Page 182 Device structure Electronics 7.7.4 Electronics cover (outer) size 1 The following figure gives an example of electronics cover designs: 29317784459 "LED displays" (→ 2 346) "Potentiometer f1 (underneath the screw plug)" (→ 2 299) "Potentiometer f2 (underneath the screw plug)" (→ 2 301) "Connector" (→ 2 283) 7.7.5 Electronics cover (outer) size 2 The following figure gives an example of electronics cover designs: 36725585163 "LED displays" (→ 2 346)

-

Page 183: Example Nameplate And Type Designation Of Electronics

Device structure Example nameplate and type designation of electronics Example nameplate and type designation of electronics 7.8.1 Inner nameplate of DAC.. electronics cover The following figure gives an example of a nameplate of the electronics cover. For the structure of the type designation, refer to chapter "Type designation of the electronics cover ...". - Page 184 Device structure Example nameplate and type designation of electronics 7.8.3 Type designation of DAC.. electronics cover The following table shows the type designation of the electronics cover: DAC Product family DAC = Electronics cover Direct AS-Interface Communication Communication type 1 = AS-Interface Connection configuration 0 = M12 connector on electronics cover (standard) Communication version...

-

Page 185: Example Nameplate And Type Designation Of Connection Unit

Device structure Example nameplate and type designation of connection unit ® MOVIKIT version ® 000 = No MOVIKIT module loaded ex-works Operating mode options B = Brake control C = Specific customer identification D = Device-specific parameterization of the delivery state P = Customer-specific parameterization 7.8.4 Example: Nameplate of a replaceable memory module The following figure shows an example of the nameplate for the replaceable memory... - Page 186 Device structure Example nameplate and type designation of connection unit 7.9.2 Type designation of connection unit The following table shows the type designation of the connection unit: Product family CU = Connection unit (motor with electronics cover) Hardware design ® ®...

-

Page 187: Markings

Device structure Markings 7.10 Markings The following table shows an example of the markings on the nameplate. The CE marking indicates compliance with the following European direc- tives: • Low Voltage Directive 2014/35/EU • EMC Directive 2014/30/EU • Machinery Directive 2006/42/EC •... -

Page 188: Fs Logo Description

Device structure FS logo description 7.11 FS logo description The FS logo on the nameplate is based on the combination of safety-related compo- nents that is installed. The following FS logo variants are possible: Device with STO connection via terminals or connectors ®... -

Page 189: Mechanical Installation

Mechanical installation Installation notes Mechanical installation Installation notes Perform the following steps before installation: WARNING! Electric shock caused by dangerous voltages in the connection box. Severe or fatal injuries. De-energize the device. Pay attention to the 5 safety rules in chapter “Carrying out electrical work safely”. -

Page 190: Tolerances For Torque Ratings

Mechanical installation Tolerances for torque ratings Tolerances for torque ratings Adhere to the specified tightening torques with a tolerance of +/- 10%. Installation requirements Check that the following conditions have been met: • The information on the drive unit's nameplate must match the voltage supply sys- tem. -

Page 191: Setting Up The Drive Unit

Mechanical installation Setting up the drive unit Setting up the drive unit 8.6.1 Notes Pay attention to the following information when installing the drive unit: • Perform the steps described in chapter "Installation notes" (→ 2 189) before in- stalling the drive unit: •... - Page 192 Mechanical installation Setting up the drive unit 8.6.3 Electronics cover Installing the electronics cover Install the electronics cover as follows: WARNING! Risk of burns due to hot surfaces. Severe injuries. Let the device cool sufficiently before touching it. 2. NOTICE! Loss of the guaranteed degree of protection. Possible damage to prop- erty.

- Page 193 Mechanical installation Setting up the drive unit Removing the electronics cover Remove the electronics cover as follows: WARNING! Risk of burns due to hot surfaces. Severe injuries. Let the device cool sufficiently before touching it. 2. Undo the screws of the electronics cover. 3.

- Page 194 Mechanical installation Setting up the drive unit 8.6.7 Pressure compensation on electronics (option /PE) Fitting the provided pressure compensation fitting (option/PE) For designs with an included pressure compensation fitting (option /PE), install the fit- ting depending on the mounting position used. The tightening torque is 4.0 Nm. Pressure compensation fitting installation positions The following table shows the installation location-dependent mounting positions of the pressure compensation fitting (option/PE):...

-

Page 195: Tightening Torques

Mechanical installation Tightening torques Tightening torques ® 8.7.1 Example of MOVIMOT performance The following figure shows an example of the installation of the threaded blanking plugs, cable glands and electronics cover. The number and position of threaded blank- ing plugs and cable bushings depend on the ordered variant. 38412007947 Tighten the screws in diametrically opposite sequence with a tightening torque of 6.0 Nm (for size 1) or 9.5 Nm (for size 2). - Page 196 Mechanical installation Tightening torques 8.7.2 Tightening torques for cable glands Tighten cable glands optionally included delivery SEW‑EURODRIVE with the following torques: Screw fitting type Image Con- Size Tightening Outer Tight- Part num- tent torque diame- ening ter of force Thread Cable cable clamp-...

-

Page 197: Electrical Installation

Electrical installation Installation planning taking EMC aspects into account Electrical installation Installation planning taking EMC aspects into account 9.1.1 Notes on arranging and routing installation components The correct operation of decentralized inverters depends on selecting the correct cables, providing correct grounding, and on a properly functioning equipotential bond- ing. - Page 198 Electrical installation Installation planning taking EMC aspects into account Example with electronics cover size 1 The following figure shows the connection of the equipotential bonding and the PE conductor: [1] The mechanical installation of a drive unit with hollow shaft does not create a conductive connection of drive unit and mounting plate (e.g.

- Page 199 Electrical installation Installation planning taking EMC aspects into account Example with electronics cover size 2 The following figure shows the connection of the equipotential bonding and the PE conductor: [1] The mechanical installation of a drive unit with hollow shaft does not create a conductive connection of drive unit and mounting plate (e.g.

-

Page 200: Equipotential Bonding At The Connection Box

Electrical installation Equipotential bonding at the connection box Equipotential bonding at the connection box The following cable gland with an M6 threaded bolt provides an additional option for HF-compatible equipotential bonding on a connection box: 9007203139701899 Tightening torque Part number Cable gland M6 nut for stud bolt... -

Page 201: Installation Instructions

Electrical installation Installation instructions Installation instructions 9.3.1 Permitted voltage systems Information on voltage supply sys- Information on permissibility tems TN and TT systems – voltage sys- Use is possible without restrictions. tems with directly grounded star point IT systems – voltage systems with Operation with an electronics cover of size 1 non-grounded star point in IT system design is permitted (...-513-..)! - Page 202 Electrical installation Installation instructions Mounting of insulating bushing (only with electronics cover size 2) The electronics covers of size 2 are compatible with IT systems only if you mount an insulating bushing. When ordering the electronics cover, SEW‑EURODRIVE supplies the insulating bushing as a single item in an accessory bag, provided it has been se- lected separately.

- Page 203 Electrical installation Installation instructions 9.3.2 Connecting supply system cables Observe the following information when connecting the supply system cables: • The nominal voltage and frequency of the device must correspond with the data of the supply system. • Dimension the cable cross section according to the input current I for rated line power, see product manual >...

- Page 204 Electrical installation Installation instructions 9.3.4 Activating line terminals X1 Adhere to the following sequence when actuating the line terminals X1: 25649924107 9.3.5 Activating terminals X3 for the braking resistor Adhere to the following sequence when actuating the X3 terminals for the braking re- sistor: 25650172171 9.3.6...

- Page 205 Electrical installation Installation instructions 9.3.7 Selecting the residual current device The inverter can cause a direct current in the PE conductor. Proceed as follows to select the residual current device: 1. If using a residual current device is not mandatory according to the standards, SEW‑EURODRIVE recommends not using a residual current device.

- Page 206 Electrical installation Installation instructions 9.3.9 Notes on PE connection PE connection to devices with a lifting eye The handle is only used to transport the unit. The handle is not required for operation. 1. Remove the lifting eye. Store the lifting eye for future service work. WARNING! Electric shock due to faulty PE connection.

- Page 207 Electrical installation Installation instructions PE connection to devices with hoop guard The optional guard bracket is used to protect the connectors on the electronics cover. Do not remove the guard bracket. 1. Connect the PE cable to the guard bracket according to the following figure. 2.0 –...

- Page 208 Electrical installation Installation instructions Leakage currents During normal operation, leakage currents ≥ 3.5 mA may occur. In order to fulfill EN 61800-5-1, observe the following information: • The ground connection (PE) must be installed in such a way that it meets the re- quirements for systems with high leakage currents.

- Page 209 Electrical installation Installation instructions 9.3.12 Installation above 1000 m amsl The devices can be used at altitudes above 1000 m above sea level up to 3800 m above sea level under the following marginal conditions. The maximum altitude is lim- ited due to the decreased dielectric strength at lower air density. •...

-

Page 210: Installation Topologies

Electrical installation Installation topologies Installation topologies 9.4.1 Installation topology (example: standard installation) following figure shows basic installation topology with ® MOVIMOT performance: Safety relay Supply system Optional AS-Interface Master AS-Interface Back-up AUX-PWR (24 V) fuse/line protection Control cabinet level Field level DAC.. -

Page 211: Movimot® Performance Dac Terminal Assignment

Electrical installation MOVIMOT® performance DAC terminal assignment MOVIMOT® performanc e DAC terminal assignment ® MOVIMOT performance DAC terminal assignment Attach units without a connector to the terminals as follows: WARNING! Electric shock caused by dangerous voltages in the connection box. - Page 212 Electrical installation MOVIMOT® performance DAC terminal assignment 9.5.2 Connection box size 2 ® The following figure shows the terminals of MOVIMOT performance DAC, size 2: 11 12 13 14 15 16 21 22 23 24 25 26 11 12 13 9.5.3 Assignment ®...

- Page 213 Electrical installation MOVIMOT® performance DAC terminal assignment Terminal Marking Function yellow F_STO_P1 Input STO+ control termi- yellow F_STO_P1 Input STO+ nals (to loop through) – 0V24_OUT 0V24 reference potential for DC 24 V output – 24V_OUT DC 24 V output – DI01 Digital input DI01 –...

- Page 214 Electrical installation MOVIMOT® performance DAC terminal assignment These jumpers are not present in the following designs: • Designs with connectors with STO function Additional information is available in the product manual > chapter "Project planning for functional safety" and chapter "Connection variants functional safety". ®...

-

Page 215: Electrical Installation - Functional Safety

Electrical installation Electrical installation – functional safety Electrical installation – functional safety 9.6.1 Installation instructions WARNING Only the types of connection described in this documentation may be used. Severe or fatal injuries. • Non-compliant connection variants specified in other documentation are not per- missible. - Page 216 Electrical installation Electrical installation – functional safety Requirements Use of safety relays The requirements of the manufacturers of safety relays (such as protecting the output contacts against welding) or of other safety components must be strictly observed. The basic requirements for cable routing apply as described in this documentation. For connecting the device to the safety relays, observe the installation requirements in accordance with chapter "Installation requirements" (→ 2 161).

- Page 217 Electrical installation Electrical installation – functional safety Switching off the STO signal for several drive units (STO group disconnection) The STO signal for several drive units can be provided by a single safety relay. The following requirements must be met: •...