Summary of Contents for McCrometer FPI Mag Plus 5000

- Page 1 FPI M Electromagnetic Flow Meter Installation, Operation and Maintenance Manual For use with FPI Mag Plus model 5000 30126-04 Rev. 1.0 26AUG2024...

-

Page 2: Table Of Contents

Contents SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 Safety Symbols . -

Page 3: Safety

Safety Warnings When installing, operating, and maintaining McCrometer equipment where hazards may be present, you must protect yourself by wearing Personal Protective Equipment (PPE) and be trained to enter confined spaces. Examples of confined spaces are manholes, pumping stations, pipelines, pits, septic tanks, sewage digesters, vaults, degreasers, storage tanks, boilers, and furnaces. -

Page 4: Description Of Flow Meter

FPI M DESCRIPTION OF FLOW METER 1 .0 DESCRIPTION OF FLOW METER The FPI Mag® Plus flow meter provides accurate flow measurement for full-pipe clean water applications. The electromagnetic sensor automatically senses and corrects for shifting velocity in the pipe by constantly obtaining an area weighted mean velocity. -

Page 5: Verify Serial Numbers

FPI M UNPACKING AND VERIFYING COMPONENTS 2 .1 Verify Serial Numbers The FPI Mag Plus flow meter is comprised of two primary components: the sensor and the transmitter. The transmitter and sensor are supplied as a custom calibrated matched system. Verify the system serial numbers on both the transmitter and sensor match. -

Page 6: Tools Required For Installation

FPI M SENSOR PROBE INSTALLATION 2 .3 Tools Required for Installation Tools provided: Tools recommended for installation: 2 - 9/16" or 3/4" reversible ratchet wrenches. (Size is dependent 1 - pipe wrench 1 - 7/16" wrench on the size of the retaining rods capable of a 4"... -

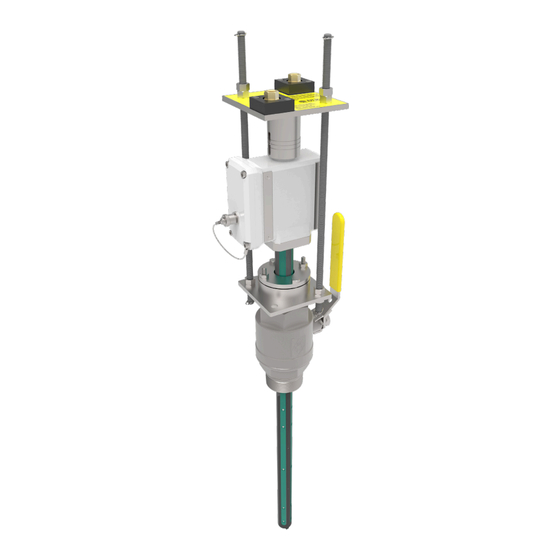

Page 7: Step 1: Review Names Of Sensor Components

FPI M SENSOR PROBE INSTALLATION STEP 1: Review names of sensor components This manual refers to the part names of the sensor. It is important to be familiar with the parts and their names as shown below in Figure 5 when following the installation instructions. For a full list of replaceable parts with part numbers, see Section 8.0. -

Page 8: Recommendations

The upstream and downstream straight-pipe recommendations are conservative, based on research completed in the McCrometer NIST traceable calibration facility. In many cases, the installation distances suggested below can be shortened depending on flow conditions and piping layout. - Page 9 Note: The table above is not inclusive of each possible installation scenario for the McCrometer FPI Mag Plus. For installations not included in the table, the McCrometer Applications Team is available to review cases and make a determination as to the viability of the installation.

-

Page 10: Step 4: Verify Sufficient Installation Clearance From Obstructions

FPI M SENSOR PROBE INSTALLATION VALVE VALVE VALVE VALVE 1D DOWN- 1D DOWN- 20D UPSTREAM 20D UPSTREAM STREAM STREAM FLOW FLOW FLOW FLOW Figure 7 . FPI Mag Plus Installation Orientation With A Gate Valve Or Elbow Rotational axis of a butterfly valve Butterfly Valve Install the FPI Mag Plus perpendicular to... -

Page 11: Step 5: Installing The Ball Valve

FPI M SENSOR PROBE INSTALLATION STEP 5: Installing the ball valve WARNING! Pressurized pipes should only be hot tapped, cut, or drilled by qualified personnel using high quality saddles, valves and stainless steel nipples. If possible, depressurize the pipe before attempting any installation. The sensor comes standard with a 2"... -

Page 12: Step 6: Ensure Sensor Will Be Installed Perpendicular To The Pipe

FPI M SENSOR PROBE INSTALLATION STEP 6: Ensure sensor will be installed perpendicular to the pipe The FPI should be installed perpendicular to the pipe as shown in Figure 12 for a vertical installation. The allowable tolerance for installation is ± 0.5°. A perpendicular installation is determined by the coupling that is mounted on the pipe. Prior to installing the FPI a level ruler should be used to check the coupling and ensure that it sits level. -

Page 13: Step 8: Connect The Sensor Onto Ball Valve

FPI M SENSOR PROBE INSTALLATION STEP 8: Connect the sensor onto ball valve The sensor assembly uses a compression seal, which keeps the sensor watertight when the pipe is under pressure. Care must be taken when installing the sensor to avoid leaks. Follow the steps below to install the sensor onto the pipe valve: Put a generous amount of the pipe sealant or Teflon tape on the compression seal threads. -

Page 14: Step 10: Insert The Sensor Probe Through The Ball Valve Into The Pipe

(Figure 18) NOTE 3: Using the sensor insertion tool McCrometer recommends using a sensor insertion tool (see Figure 19) to rotate the captive nuts. This will ensure the top plate compresses evenly and will help avoid any damage to the sensor. - Page 15 FPI M SENSOR PROBE INSTALLATION Follow the steps below to insert the sensor probe into the pipe . If you disassembled and reassembled the compression seal, hand tighten the compression seal bolts and nuts. DO NOT FULLY TIGHTEN THE COMPRESSION SEAL BOLTS AND NUTS. If you did not disassemble the compression seal, proceed to step 2.

-

Page 16: Step 11: Apply Appropriate Compression Load To The Sensor

FPI M SENSOR PROBE INSTALLATION STEP 11: Apply appropriate compression load to the sensor A compression load is required to be applied at the top of the sensor forcing the bottom of the sensor to seat firmly against the far wall of the pipe. The amount of load is indicated by the three lines etched into the top plate and the location of the set screw relative to the lines. -

Page 17: Step 12: Install The Retaining Rods

FPI M SENSOR PROBE INSTALLATION STEP 12: Install the retaining rods After the sensor has been inserted and the load adjusted, remove the insertion rods and install the shorter retaining rods. This will make the sensor assembly more compact. (Figure 25) If the short retaining rods are not used, run a 3/8"... -

Page 18: Step 13: Attach The Ground Wire

FPI M SENSOR REMOVAL STEP 13: Attach the ground wire The FPI meter is electrically continuous to a conductive (non PVC) pipe through the retaining rods. Additional grounding may be required to a dedicated earth ground via ring terminal and 10 AWG wire (not provided). -

Page 19: Electronics Installation

FPI M ELECTRONICS INSTALLATION Repeat the process for the second long retaining rod. Once both of the long retaining rods are securely in place, completely remove the short retaining rods. Loosen the compression seal bolts until the seal just begins to leak. This will relieve the pressure on the compression seal allowing the sensor to be removed. -

Page 20: Specifications

FPI Mag Plus 5000 Flow Meter Specifications All speci cations apply to both FPI Mag Plus 3000 and FPI Mag Plus 5000 models except where noted. The full pipe averaging ow meter comes complete with Mounting Hardware, AC Converter with Dual 4-20mA output, 25 Feet of Dual Submersible Cables with quick connects at sensor, Stainless Steel Body, 316 Stainless Steel Electrodes, NSF Approved Fusion Bonded Epoxy Coating, 2”... - Page 21 * Certi ed by IAPMO R&T to NSF/ANSI 61 for material safety and NSF/ANSI 372 for low lead content. Note regarding cable length: McCrometer recommends minimizing cable length. Electromagnetic ow meters may have unfavorable signal strength to noise ratio in electrically noisy environments. Longer lengths of cable increase the likelihood of interference.

-

Page 22: Speci Cation Sheet

Speci cation Sheet FPI M FPI M SPECIFICATIONS FPI Mag Plus Flow Meter Flow Meter Pipe Sizes and Flow Ranges with ProComm Max Transmitter Imperial Units Standard Flow Ranges Minimum Velocity Pipe ID Range Program Pipe Size Clearance (GPM Standard) Range Defaults (Nominal) - Page 23 FPI M SPECIFICATIONS SPECIFICATIONS 10.0 SPECIFICATIONS PROCOMM MAX TRANSMITTER SPECIFICATIONS Physical Speci cations Electronic Housing Diecast aluminum, powder coated enclosure w/ tamper resistant seal Remote Mount: Height: 7.3” (18.5 cm) Width: 8.5” (21.6 cm) Transmitter Depth: 4.3” (10.9 cm) Dimensions Meter Mount: Height: 6.9”...

- Page 24 FPI M SPECIFICATIONS DIMENSIONS Remote Mount Transmitter Dimensions Height 7.4" (18.9 cm) Width 8.5" (21.6 cm) Depth 4.4" (11.2 cm) 4.4" 7.0" 2.25" C TO C 7.4" 7.5" C TO C 8.5" 140º 10.3" 8.7" Page 24 30126-48 Rev. 1.0 | 23AUG2024 Page 22 30126-04 Rev.

-

Page 25: Replacement Parts

FPI M REPLACEMENT PARTS 8 .0 REPLACEMENT PARTS Diagram Part Description Number Number Protective Cap FPI-002RP Captive Nut 42226 Captive Nut Bearing Retainer 42225 Captive Nut Bearing 92121 Top Plate for use with 3/8" retaining rods MIM043 Top Plate for use with 1/2" retaining rods MIM053 Set screw (2 ea.) 920001001... -

Page 26: Returning A Unit For Repair

Prior to calling for a return authorization number, determine the model number, serial number (located inside the front panel of the transmitter), and reason for return. • Contact McCrometer Customer Service Department and ask for a Return Authorization (RA) number. • Telephone: 1-800-220-2279 •... -

Page 27: Warranty

AGENTS PURSUANT TO ANY QUOTATION. Copyright © 2024 McCrometer, Inc. All printed material should not be changed or altered without permission of McCrometer. Any published pricing, technical data, and instructions are subject to change without notice. Contact your McCrometer representative for current pricing, technical data, and instructions.

Need help?

Do you have a question about the FPI Mag Plus 5000 and is the answer not in the manual?

Questions and answers