Summary of Contents for Mec Micro2032

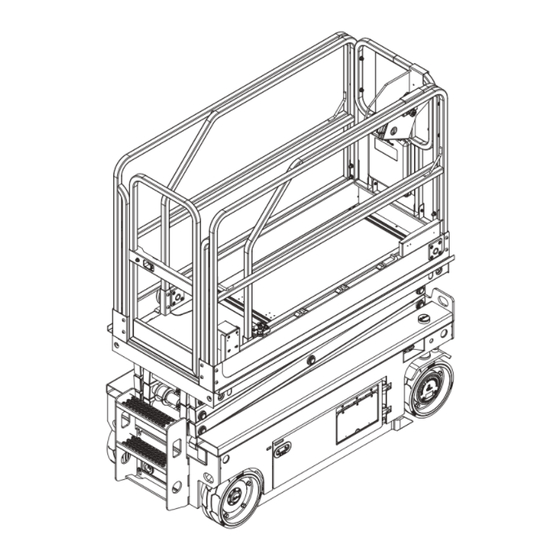

- Page 1 Service & Parts Manual Micro2032 ILLUSTRATION No. ART_6209 Meets requirements of ANSI A92.20-2020 and CSA B354.6-2019. Part # 96898 December 2024 Serial Number Range 19900025 - Up...

-

Page 2: Revision History

Revision History Date Reason for Update December 2024 New Release MEC Aerial Work Platforms 1401 S. Madera Avenue, Kerman, CA 93630 USA Toll Free: 1-877-632-5438 Phone: 1-559-842-1500 Fax: 1-559-842-1520 info@MECawp.com www.MECawp.com Page i Micro2032 - Service & Parts Manual - 96898... -

Page 3: Table Of Contents

� � � � � � � 46 Electrical Schematic � � � � � � � � � � � � � � � � � � � 47 Page ii Micro2032 - Service & Parts Manual - 96898... - Page 4 Section 18 - Decals . . 94 Decals � � � � � � � � � � � � � � � � � � � � � � � 94 Page iii Micro2032 - Service & Parts Manual - 96898...

-

Page 5: Chapter 1 - Service

All parts represented here are manufactured and supplied in accordance with MEC quality standards. We recommend that you use genuine MEC parts to ensure proper operation and reliable performance. To obtain maximum benefits from your MEC Aerial Work Platforms, always follow the proper operating and maintenance procedures. -

Page 6: Section 1 - Mec Operator Policy

Any procedures not found within this manual must be evaluated by the individual to assure oneself that they are “proper and safe.” Your MEC Aerial Work Platform has been designed, built, and tested to provide many years of safe, dependable service. Only trained, authorized personnel should be allowed to operate or service the machine. -

Page 7: Section 2 - Safety Symbols & General Safety Tips

December 2024 Safety Symbols & General Safety Tips Safety Symbols & General Safety Tips MEC manuals and decals use symbols, colors and signal words to help you recognize important safety, operation and maintenance information. ART_6091 RED and the word DANGER – Indicates an imminently hazardous DANGER situation which, if not avoided, will result in death or serious injury. -

Page 8: Section 3 - Torque Specifications

Torque values apply to fasteners as received from the supplier, dry or when lubricated with normal engine oil. If special graphite grease, molydisulphide grease, or other extreme pressure lubricants are used, these torque values do not apply. Page 4 Micro2032 - Service & Parts Manual - 96898... -

Page 9: Bolt Torque Specification - Metric Standard

Torque values apply to fasteners as received from the supplier, dry or when lubricated with normal engine oil. If special graphite grease, molydisulphide grease, or other extreme pressure lubricants are used, these torque values do not apply. Page 5 Micro2032 - Service & Parts Manual - 96898... -

Page 10: Hydraulic Components Torque Table

85 - 90 115 - 122 950 - 1050 107 - 119 130 - 140 176 - 190 130 - 140 176 - 190 1300 - 1368 147 - 155 Page 6 Micro2032 - Service & Parts Manual - 96898... -

Page 11: Section 4 - Specifications

*Working Height adds 6 feet (2 meters) to platform height. **Weight may increase with certain options. †Sheet material weight is part of the total platform capacity. This may limit capacity to one occupant. Page 7 Micro2032 - Service & Parts Manual - 96898... -

Page 12: Section 5 - Maintenance Lock

2. Rotate the Maintenance Lock away from the machine and let it hang down. 3. Lower the platform until the Maintenance Lock rests securely on the link. Keep clear of the Maintenance Lock when lowering the platform. Maintenance Lock ART_4995 Page 8 Micro2032 - Service & Parts Manual - 96898... -

Page 13: Section 6 - Machine Systems

IMMEDIATELY REPORT TO YOUR SUPERVISOR ANY DEFECT OR MALFUNCTION. ANY DEFECT SHALL BE REPAIRED PRIOR TO CONTINUED USE OF THE AERIAL WORK PLATFORM. INSPECTION AND MAINTENANCE SHOULD BE PERFORMED BY QUALIFIED PERSONNEL FAMILIAR WITH THE EQUIPMENT. Page 9 Micro2032 - Service & Parts Manual - 96898... -

Page 14: Section 7 - Machine Components

24) Pothole Guard 25) Hydraulic Pump Motor 26) Hydraulic Tank 27) Function Manifold 28) Hydraulic Filter 29) Batteries (2×) *Under the cover. Control Module Battery Module *Under the cover. ILLUSTRATION No. ART_6210 Page 10 Micro2032 - Service & Parts Manual - 96898... -

Page 15: Section 8 - Emergency Systems And Procedures

The Emergency Lowering System is used to lower the platform in case of power failure. To lower the platform, pull the Emergency Lowering Knob, located near the Base Control panel. ART_5884 Emergency Lowering Handle Page 11 Micro2032 - Service & Parts Manual - 96898... -

Page 16: Section 9 - Transport And Lifting Instructions

MEC machinery. Truck drivers are responsible for loading and securing machines, and should be properly trained and authorized to operate MEC machinery. ART_6091 WARNING Drivers are also responsible for selecting the correct and appropriate trailer according to government regulations and company policy. - Page 17 Raise the machine 6 inches (15 centimeters) and then tilt the forks back slightly to keep the machine secure. • Be sure the machine is level when lowering the forks. ART_5030 Page 13 Micro2032 - Service & Parts Manual - 96898...

- Page 18 Adjust the rigging to prevent damage to the machine Lifting Lifting and to keep the machine level. Points (2) Points (2) X Axis Y Axis Y Axis 26 inches 19.3 inches (66 centimeters) (49.1 centimeters) X Axis ART_5032 Page 14 Micro2032 - Service & Parts Manual - 96898...

-

Page 19: Daily Maintenance

3) Check the Batteries • New parts may be required to perform this procedure. Note: This check is not required for machines with lithium batteries, sealed batteries, or maintenance-free batteries. Page 15 Micro2032 - Service & Parts Manual - 96898... - Page 20 A malfunctioning machine must never be used. If malfunctions are discovered, the machine must be tagged and removed from Page 16 Micro2032 - Service & Parts Manual - 96898...

- Page 21 Inspect the Tires, Wheels and Castle Nut Torque (See page 17). • 2. Perform the following Annual Maintenance procedure: • Replace the Hydraulic Tank Return Filter Element (See page 17). Page 17 Micro2032 - Service & Parts Manual - 96898...

-

Page 22: Quarterly Maintenance

Note: For best results, use an extension of adequate size with a length no longer than 49 feet or 15 meters. The following must be measured and recorded once the battery has been fully charged, after a waiting time of at least 12 hours: • Total voltage Page 18 Micro2032 - Service & Parts Manual - 96898... - Page 23 12. Lower the platform to the stowed position and turn the machine off. 3) Inspect the Tires and Wheels (including castle nut torque) • Tools maybe be required to perform this procedure. Page 19 Micro2032 - Service & Parts Manual - 96898...

- Page 24 5. Check the machine functions from the platform controls. • Result: The machine functions should not operate. 6. Turn the key switch to the off position. • Result: No function should operate. Page 20 Micro2032 - Service & Parts Manual - 96898...

- Page 25 Tools maybe be required to perform this procedure. Proper drive functions are essential to safe machine operation. The drive function should respond quickly and smoothly to operator control. Drive performance should also be free of hesitation, jerking Page 21 Micro2032 - Service & Parts Manual - 96898...

- Page 26 2. Turn the key switch to platform control. Pull out the platform and ground red Emergency Stop button to the on position. 3. Lower the platform to the stowed position. Page 22 Micro2032 - Service & Parts Manual - 96898...

- Page 27 Tools maybe be required to perform this procedure. • New parts maybe be required to perform this procedure. Maintaining the module tray latch components in good condition is essential to good performance Page 23 Micro2032 - Service & Parts Manual - 96898...

- Page 28 18, the alarm does not sound and the machine will continue to lift the platform after the pothole guards are deployed. Adjust or replace the pothole limit switch. 4. Press the drive function select button. Attempt to steer or drive the machine. Page 24 Micro2032 - Service & Parts Manual - 96898...

- Page 29 6. Repeat this procedure beginning with step 2 for the left pothole guard. 7. Lower the platform to the stowed position, remove the block under the left pothole guard. 8. Turn off the machine. Page 25 Micro2032 - Service & Parts Manual - 96898...

-

Page 30: Semi-Annual Maintenance

• Result: The overload alarm at the platform controls sound, indicating a normal condition. • Result: The overload alarm at the platform controls does not sound. Calibrate the platform Page 26 Micro2032 - Service & Parts Manual - 96898... - Page 31 Extremely dirty conditions may require that the cap be inspected more often. 1. Remove and discard the hydraulic tank breather cap. 2. Install a new cap onto the tank. Page 27 Micro2032 - Service & Parts Manual - 96898...

-

Page 32: Annual Maintenance

1. Clean the area around the oil filter. Remove the filter with an oil filter wrench. 2. Apply a thin layer of oil to the new oil filter gasket. Page 28 Micro2032 - Service & Parts Manual - 96898... - Page 33 6. Activate and hold the platform up toggle switch. 7. Inspect the filter and related components to be sure that there are no leaks. 8. Clean up any oil that may have spilled. Page 29 Micro2032 - Service & Parts Manual - 96898...

-

Page 34: Biennial Maintenance

8. Clean up any oil that may have spilled. Properly discard the used oil. 9. Clean the inside of the hydraulic tank using a mild solvent. Allow the tank to dry completely. Page 30 Micro2032 - Service & Parts Manual - 96898... - Page 35 Component damage hazard. The pump can be damaged if operated ART_6091 without oil. Be careful not to empty the hydraulic tank while in the WARNING process of filling the hydraulic system. Do not allow the pump to cavitate. Page 31 Micro2032 - Service & Parts Manual - 96898...

-

Page 36: Lower Controls

Indoor or Outdoor. • Indoor • Select to allow unrestricted height when not exposed to wind. • Outdoor • Select to limit the maximum height when exposed to wind. Page 32 Micro2032 - Service & Parts Manual - 96898... -

Page 37: Ecu Setting And Calibrations

2. Pedal Switch Disable/Enable Voltage Output 2. Set Option 3. Press Sensor Mode Current Output 4. Pothole Guard Disable/Enable 5. Descent Delay Disable/Enable 6. Motion Alarm Disable/Enable 7. Load Sensing Disable/Enable Page 33 Micro2032 - Service & Parts Manual - 96898... - Page 38 1. English 2. Chinese 2. Language 3. Japanese 4. French 6.Other ECU: A5 SW-E700-DL-1_M 3. Revision HMI : A5 SW-E700-DL-1_O 4. Hour Meter Reset 5. Fault History Reset 6. PC Link Page 34 Micro2032 - Service & Parts Manual - 96898...

- Page 39 If at any time the automatic elevation must be stopped press the Emergency Stop Switch. Page 35 Micro2032 - Service & Parts Manual - 96898...

- Page 40 The emergency lowering cable must be used. 1. Select the “5. OL Descent High.” 2. Keep the machine in the stowed state. 3. Press the “Enter“ button to save the current valve. Page 36 Micro2032 - Service & Parts Manual - 96898...

- Page 41 This is set to 10% of max height. 1. Select the “8. Outdoor Limit Height.” 2. Lift the platform the maximum outdoor height. then lower 10%. 3. Press the “Enter“ button to save the current valve. Page 37 Micro2032 - Service & Parts Manual - 96898...

-

Page 42: Section 11 - Fault Codes

CAN bus of the machine is normal. Check whether the wiring of the motor MC Communication Fault Warning Only controller is normal, check the wiring from the controller to the drive motor. Page 38 Micro2032 - Service & Parts Manual - 96898... -

Page 43: Fault Codes

Replace the joystick handle. The joystick is not in the neutral position Joystick Not In Neutral Drive speed limit during power on. Check or replace joystick. Page 39 Micro2032 - Service & Parts Manual - 96898... - Page 44 Disregard if not Lithium Lithium battery management system fails, in BMS Fault Disable All Motion order to ensure safety, the control system will prohibit all actions. Disregard if not lithium. Page 40 Micro2032 - Service & Parts Manual - 96898...

- Page 45 X074 DRIVER SHORTED The coil of the contactor has B+ before it should. Possible motor controller failure. Contactor coil is broken. X075 CONTACTOR DRIVER Coil wiring error. Possible motor controller problem. Page 41 Micro2032 - Service & Parts Manual - 96898...

- Page 46 The motor encoder is broken. X176 HOME SENS.ERR XX Motor unable to turn. Possible motor controller problem. Check if the brake wiring is short circuit. X177 COIL SHOR. EB. Replace the motor controller. Page 42 Micro2032 - Service & Parts Manual - 96898...

- Page 47 Power on key switch again. X210 WRONG RAM MEM. After power on, the problem is still there, replace the motor controller. Excessive resistance to motor shaft rotation. X211 STALL ROTOR Motor mechanical problem. Page 43 Micro2032 - Service & Parts Manual - 96898...

- Page 48 Check the wiring to valve block. X242 OPEN COIL EV. Replace the motor controller. X243 THROTTLE PROG. X244 WARNING SLAVE Check the specific fault of the slave-controller. X245 IQMISMATCHED Replace motor controller. Page 44 Micro2032 - Service & Parts Manual - 96898...

- Page 49 Replace motor controller. Interference problem, check CAN resistance setting, interference level. X248 NO CAN MSG. For other software setting problems, you need to contact MEC Aerial Work Platforms. X249 CHECK UP NEEDED Change the “CHECK UP DONE” parameter to ON.

-

Page 50: Section 12 - Schematics

December 2024 Hydraulic Schematic Hydraulic Schematic Platform Loading (Option) Sensor Steer Cylinder Lift Cylinder Lower Valve 80bar 180bar Function Valve Pump Filter Filter Tank ILLUSTRATION No. Micro2032 Hydraulic Schematic ART_6364 Page 46 Micro2032 - Service & Parts Manual - 96898... -

Page 51: Electrical Schematic

Section 12 - Schematics December 2024 Electrical Schematic ILLUSTRATION No. Micro2032 Electrical Schematic ART_6365 Page 47 Micro2032 - Service & Parts Manual - 96898... - Page 52 December 2024 THIS PAGE HAS BEEN INTENTIONALLY LEFT BLANK Page 48 Micro2032 - Service & Parts Manual - 96898...

-

Page 53: Chapter 2 - Parts

This Parts sections consists of illustrated parts sections and is designed to provide you, the customer, with illustrations and the list of associated parts needed to properly maintain the MEC self-propelled aerial work platform. When used in conjunction with the Service section in this manual and the Operator’s Manual (provided separately), this manual will assist you in making necessary adjustments... -

Page 54: Section 13 - Chassis

Section 13 - Chassis December 2024 Steer Linkage and Wheels Assembly Steer Linkage and Wheels Assembly ILLUSTRATION No. Micro2032 Steer Linkage and Wheels Assembly ART_6347 Page 50 Micro2032 - Service & Parts Manual - 96898... - Page 55 Hose Clamp Support 50047 Nut NNYL M06-1.00 ZP 53207 Screw SHCS M06-1.00 × 30 ZP 45313 Hose Clamp 53124 Screw SHCS M06-1.00 × 20 ZP 45314 Hose Clamp 45315 Bolt Page 51 Micro2032 - Service & Parts Manual - 96898...

-

Page 56: Pothole Protection Assembly

Section 13 - Chassis December 2024 Pothole Protection Assembly ILLUSTRATION No. Micro2032 Pothole Protection Assembly ART_6348 Page 52 Micro2032 - Service & Parts Manual - 96898... - Page 57 Set Screw M05-0.80 × 10 Cone Point ZP 47092 Linkage Weldment 41047 41048 41214 Bearing 50003 WSHR M12 Standard Flat Washer ZP 49131 Pothole Link Plate 41045 Gas Shock 43573 Gas Shock Strut Page 53 Micro2032 - Service & Parts Manual - 96898...

-

Page 58: Battery Pack Module

Section 13 - Chassis December 2024 Battery Pack Module ILLUSTRATION No. Micro2032 Battery Pack Module ART_6349 Page 54 Micro2032 - Service & Parts Manual - 96898... - Page 59 WSHR M04 Spring Washer ZP 50284 WSHR M04 Standard Flat Washer ZP 41331 Contactor 53451 Screw THMS M05-0.80 × 8 ZP 46246 250A Fuse Assembly 46247 250A Fuse 46248 Fuse Block Page 55 Micro2032 - Service & Parts Manual - 96898...

-

Page 60: Power Unit Module

Section 13 - Chassis December 2024 Power Unit Module ILLUSTRATION No. Micro2032 Power Unit Module ART_6350 Page 56 Micro2032 - Service & Parts Manual - 96898... - Page 61 43576 Straight Fitting Function Manifold (Refer to page 86) 53257 Screw HHCS M08-1.25 × 20 Serrated Flange ZP 43574 Circlips 41037 Bearing 41814 Washer 41813 Hinge Pin REF - Reference Page 57 Micro2032 - Service & Parts Manual - 96898...

-

Page 62: Ground Control And Cover Assembly

Section 13 - Chassis December 2024 Ground Control and Cover Assembly ILLUSTRATION No. 1930SE Ground Control and Cover Assembly ART_5893 Page 58 Micro2032 - Service & Parts Manual - 96898... - Page 63 46257 Cover 46313 Ground Control Assembly (Refer to page 60) 53038 WSHR M05 Standard Flat Washer ZP 53043 WSHR M05 Spring Washer ZP 53067 Screw SHCS M05-0.80 × 40 ZP Page 59 Micro2032 - Service & Parts Manual - 96898...

-

Page 64: Ground Control Assembly

Section 13 - Chassis December 2024 Ground Control Assembly ILLUSTRATION No. Micro26 Ground Control Assembly ART_5870 Page 60 Micro2032 - Service & Parts Manual - 96898... - Page 65 Main Board 44693 Display 44795 Decal, Ground Control Panel 41418 Key Switch 91574 41157 Emergency Stop Switch 43632 Red Mushroom Head 43633 Base With 1 NO Contact 44694 EMS Switch Harness Page 61 Micro2032 - Service & Parts Manual - 96898...

-

Page 66: Hydraulic Tank Assembly

Section 13 - Chassis December 2024 Hydraulic Tank Assembly ILLUSTRATION No. Micro2032 Hydraulic Tank Assembly ART_6351 Page 62 Micro2032 - Service & Parts Manual - 96898... - Page 67 Part Number Description Qty. 41082 Breather 41412 Washer 41085 Fitting 41413 41166 Fitting 44002 Washer 41167 Fitting 49136 Tank 41087 Plug 41824 Filter 49137 Suction Pipe 44567 Washer 41826 Fitting Page 63 Micro2032 - Service & Parts Manual - 96898...

-

Page 68: Pump Motor Assembly

Section 13 - Chassis December 2024 Pump Motor Assembly ILLUSTRATION No. 1930SE Pump Motor Assembly ART_5896 Page 64 Micro2032 - Service & Parts Manual - 96898... - Page 69 Screw SHCS 3/8-24 × 1 1/4 ZP 53054 WSHR M10 Spring Washer ZP 50002 WSHR M10 Standard Flat Washer ZP 43205 Straight Fitting 41426 Pump 49138 Motor 46260 Straight Fitting Page 65 Micro2032 - Service & Parts Manual - 96898...

-

Page 70: Rear Wheel And Ladder

Section 13 - Chassis December 2024 Rear Wheel and Ladder ILLUSTRATION No. Micro2032 Rear Wheel and Ladder ART_6352 Page 66 Micro2032 - Service & Parts Manual - 96898... - Page 71 Screw HHCS M08-1.25 × 16 Serrated Flange ZP Charger Assembly (Refer to page 68) 53261 Nut NNYL M12-1.75 Flange ZP 43588 Seal 41029 Bearing 41024 Bearing 41304 Washer 53262 Castle Nut M22-1.50 ZP REF - Reference Page 67 Micro2032 - Service & Parts Manual - 96898...

-

Page 72: Charger Assembly

Section 13 - Chassis December 2024 Charger Assembly ILLUSTRATION No. 1930SE Charger Assembly ART_5898 Page 68 Micro2032 - Service & Parts Manual - 96898... - Page 73 Screw PHMS M06-1.00 × 20 ZP 50284 WSHR M04 Standard Flat Washer ZP 50285 Nut NNYL M04-0.70 ZP 46263 Battery Alarm 53432 Screw HHCS M06-1.00 × 25 Serrated Flange ZP Page 69 Micro2032 - Service & Parts Manual - 96898...

-

Page 74: Chassis Accessory Installation

Section 13 - Chassis December 2024 Chassis Accessory Installation ILLUSTRATION No. Micro2032 Chassis Accessory Installation ART_6353 Page 70 Micro2032 - Service & Parts Manual - 96898... - Page 75 49144 Sensor Cover 46270 Sheath 2 46271 Motor Controller 53266 Screw THMS M05-0.80 × 6 ZP 49145 Motor Controller Cover (To serial #20100299) 49146 Motor Controller Cover (From serial #20100300) Page 71 Micro2032 - Service & Parts Manual - 96898...

-

Page 76: Section 14 - Scissor

Section 14 - Scissor December 2024 Scissor Assembly Scissor Assembly ILLUSTRATION No. Micro2032 Scissor Assembly ART_6354 Page 72 Micro2032 - Service & Parts Manual - 96898... - Page 77 Lower Lift Cylinder Assembly (Refer to page 84) 53269 Screw CSCS M05-0.80 × 16 ZP 44884 Washer 2 Inner Arm 2 49157 41114 Block 49158 Right Single Link 44909 REF - Reference Page 73 Micro2032 - Service & Parts Manual - 96898...

-

Page 78: Section 15 - Platform

Section 15 - Platform December 2024 Main Platform Assembly Main Platform Assembly ILLUSTRATION No. Micro2032 Main Platform Assembly ART_6355 Page 74 Micro2032 - Service & Parts Manual - 96898... - Page 79 Material Rack 41134 Clip 53276 Screw PHMS M04-0.70 × 8 ZP 41059 Wire Clip 53278 Screw SHCS M04-0.70 × 20 ZP 41120 Bumper 53224 Screw THMS M05-0.80 × 12 ZP Page 75 Micro2032 - Service & Parts Manual - 96898...

-

Page 80: Platform Extension Assembly

Section 15 - Platform December 2024 Platform Extension Assembly 15 14 13 ILLUSTRATION No. Micro2032 Platform Extension Assembly ART_6356 Page 76 Micro2032 - Service & Parts Manual - 96898... - Page 81 Roller 41284 Slide Pad 53279 Screw CSCS M05-0.80 × 12 ZP 41270 Roller Bracket 53280 Screw CSCS M08-1.25 × 55 ZP 41120 Bumper 53224 Screw THMS M05-0.80 × 12 ZP Page 77 Micro2032 - Service & Parts Manual - 96898...

-

Page 82: Platform Locking Device Assembly

Section 15 - Platform December 2024 Platform Locking Device Assembly ILLUSTRATION No. Micro19-XD Platform Locking Device Assembly Art_5621 Page 78 Micro2032 - Service & Parts Manual - 96898... - Page 83 Nut NNYL M10-1.50 ZP 50002 WSHR M10 Standard Flat Washer ZP 41143 Foot Pedal 41144 Lock Pin Housing 41145 Spring 41146 Lock Pin 44767 Bracket 50020 Screw HHCS M10-1.50 × 50 ZP Page 79 Micro2032 - Service & Parts Manual - 96898...

-

Page 84: Platform Control Assembly

Section 15 - Platform December 2024 Platform Control Assembly ILLUSTRATION No. Micro2032 Platform Control Assembly ART_6357 Page 80 Micro2032 - Service & Parts Manual - 96898... - Page 85 Platform Control Box Mount Bracket (To serial #20100439) 49024 Platform Control Box Mount Bracket (From serial #20100440) 53264 Screw PHMS M06-1.00 × 20 ZP 53610 Screw CARB M08-1.25 × 50 ZP Page 81 Micro2032 - Service & Parts Manual - 96898...

-

Page 86: Platform Control Box Assembly

Section 15 - Platform December 2024 Platform Control Box Assembly ILLUSTRATION No. Micro26 Platform Control Box Assembly ART_5885 Page 82 Micro2032 - Service & Parts Manual - 96898... - Page 87 Female Insert 44774 44775 Female Contacts 43627 Cable Gland 41568 Alarm 44776 PCU Main board 46334 Platform Control Box Harness 44778 Housing Male Insert 44779 44780 Male Contacts 43627 Cable Gland Page 83 Micro2032 - Service & Parts Manual - 96898...

-

Page 88: Section 16 - Hydraulic System

Section 16 - Hydraulic System December 2024 Lower Lift Cylinder Assembly Lower Lift Cylinder Assembly ILLUSTRATION No. Micro2032 Lower Lift Cylinder Assembly ART_6358 Page 84 Micro2032 - Service & Parts Manual - 96898... - Page 89 53046 WSHR M06 Spring Washer ZP 53138 Screw SHCS M06-1.00 × 16 ZP 41164 Cable Connector 42821 Plug Orifice 43637 41413 41166 Fitting 43361 Washer 41167 Fitting 41630 Seal Kit Page 85 Micro2032 - Service & Parts Manual - 96898...

-

Page 90: Function Manifold

Section 16 - Hydraulic System December 2024 Function Manifold ILLUSTRATION No. 2632SE , 3346SE , 4046SE , 4555SE Function Manifold ART_5906 Page 86 Micro2032 - Service & Parts Manual - 96898... - Page 91 Straight Fitting 43076 Straight Fitting Orifice 43645 41537 Solenoid Valve Spool (SV1) 46294 Coil 42795 46295 Coil 41548 Solenoid Valve Spool (SV2) 46296 Flow Control Valve (FR1) 46297 Relief Valve (RV2) Page 87 Micro2032 - Service & Parts Manual - 96898...

-

Page 92: Hydraulic Hoses And Fittings

Section 16 - Hydraulic System December 2024 Hydraulic Hoses and Fittings Steer cylinder Function manifold Hose Assembly Adapter Union ILLUSTRATION No. Micro2032 Hydraulic Hoses and Fittings ART_6359 Page 88 Micro2032 - Service & Parts Manual - 96898... - Page 93 Hose Assembly, Main Pump Hose 43076 Straight Fitting 43582 Straight Fitting 43644 Straight Fitting 43576 Straight Fitting 43638 Straight Fitting 41085 Fitting 46260 Straight Fitting 43205 Straight Fitting 43206 Elbow 42480 Plug Page 89 Micro2032 - Service & Parts Manual - 96898...

-

Page 94: Section 17 - Electrical System

Limit Switch (Lift Down) Function Relay Manifold Controller Motor Fuse Assembly Motor Contactor Controller Charger Motor (Right) Power Switch Battery Motor (Left) Motor Controller ILLUSTRATION No. Micro2032 Electrical Harness ART_6366 Page 90 Micro2032 - Service & Parts Manual - 96898... - Page 95 Drive Motor Harness, Left (To serial #20100179) 49175 Drive Motor Harness, Left (From serial #20100180) 46347 Power Harness 49176 Power Harness 49177 Power Harness 49178 Power Harness 49179 Battery Harness Page 91 Micro2032 - Service & Parts Manual - 96898...

-

Page 96: Power To Platform

Section 17 - Electrical System December 2024 Power to Platform ILLUSTRATION No. 1930SE Power to Platform ART_5909 Page 92 Micro2032 - Service & Parts Manual - 96898... - Page 97 Section 17 - Electrical System December 2024 Item Part Number Description Qty. AC Plug (Refer to page 68) 49180 Wire Cable, Platform AC Power 42613 AC Socket REF - Reference Page 93 Micro2032 - Service & Parts Manual - 96898...

-

Page 98: Section 18 - Decals

Section 18 - Decals December 2024 Decals Decals BATTERY MODULE PLATFORM EXTENDED *On both sides Page 94 Micro2032 - Service & Parts Manual - 96898... - Page 99 Qty. - 1 91850 Qty. - 2 90732 Qty. - 1 43879 Qty. - 1 41646 Qty. - 1 96695 Qty. - 2 94866 Qty. - 2 94866 Qty. - 2 Page 95 Micro2032 - Service & Parts Manual - 96898...

- Page 100 December 2024 Notes Page 96 Micro2032 - Service & Parts Manual - 96898...

- Page 101 December 2024 Notes Page 97 Micro2032 - Service & Parts Manual - 96898...

- Page 102 MEC Parts Order Form Phone: 559-842-1523 Fax: 559-400-6723 Email: Parts@mecawp.com Please Fill Out Completely: Date: Ordered By: Account: Your Fax No.: Bill to: Ship to: Purchase Order Number Ship VIA ** All orders MUST have a Purchase Order Number **Fed Ex shipments require Fed Ex account number...

-

Page 103: Limited Owner Warranty

MEC Aerial Platform Sales Corp. and is found upon inspection by MEC Aerial Platform Sales Corp. to be defective in material and/or workmanship. MEC Aerial Platform Sales Corp. shall not be liable for any consequential, incidental or contingent damages whatsoever. - Page 104 MEC Aerial Work Platforms 1401 S. Madera Avenue, Kerman, CA 93630 USA Toll Free: 1-877-632-5438 Phone: 1-559-842-1500 Fax: 1-559-842-1520 info@MECawp.com www.MECawp.com...

Need help?

Do you have a question about the Micro2032 and is the answer not in the manual?

Questions and answers