Graco LD Series Instructions Manual

Hose reels

Hide thumbs

Also See for LD Series:

- Instructions manual (33 pages) ,

- Instructions (4 pages) ,

- Instructions manual (32 pages)

Table of Contents

Advertisement

Quick Links

Instructions

LD, SD and XD

Series Hose Reels

- For dispensing air, water, antifreeze, windshield washer solvent,

transmission fluid, oil and grease. Not for use in explosive atmospheres! -

A complete list of Models, including Maximum Working Pressure, begins on page 2

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

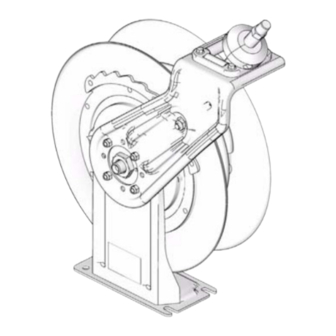

LD Series

(HR Models)

ti13159

SD Series

(HP Models)

ti13192

313431A

XD Series

(HS Models)

ti13193

Advertisement

Table of Contents

Summary of Contents for Graco LD Series

- Page 1 Not for use in explosive atmospheres! - A complete list of Models, including Maximum Working Pressure, begins on page 2 Important Safety Instructions Read all warnings and instructions in this manual. Save these instructions. LD Series SD Series XD Series (HR Models) (HP Models)

- Page 2 Model No. indicates the hose reel color. For example: A = white, B = metallic blue, C = red, D = black, E = Mercedes blue, or F = yellow. (Other color choices may be available from your Graco Distributor.) On the table below this last character is represented by the generic # symbol.

- Page 3 Model No. indicates the hose reel color. For example: A = white, B = metallic blue, F = yellow. (Other color choices may be available from your Graco Distributor.) On the table below this last character is represented by the generic # symbol.

- Page 4 Warnings Warnings The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclama- tion point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. Refer back to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where applicable.

- Page 5 Warnings WARNING MOVING PARTS HAZARD Moving parts can pinch or amputate fingers and other body parts. • Keep clear of moving parts. • Do not operate equipment with protective guards or covers removed. • Pressurized equipment can start without warning. Before checking, moving, or servicing equipment, follow the Pressure Relief Procedure in this manual.

-

Page 6: Typical Installation

Typical Installation Typical Installation A ground wire (G), bleed-type master air valve (E) and fluid drain valve (H) are required in your system installa- tion. These components help reduce the risk of serious injury, including electric shock and splashing in your eyes or on the skin. -

Page 7: Installation

. 1, using adapters if necessary. systems. However, it is not an actual system design. Contact your Graco distributor for assistance in design- • Fluid Drain Valve (H): install the drain valve point- ing a system to suit your needs. - Page 8 Installation Installation Mounting Options • A bank of all motor oil reels should be mounted about 5 ft (1.5m) from the center of the lift, toward the front of the lift rails (F . 5). All Mountings NOTE: Reels perform best when arm allows hose to pull straight off the spool as shown in F .

- Page 9 Installation Overhead Installations 3. To reposition roller support arm to any other position To reduce the risk of injury, when you are mounting a than the Ship Position (AA or EE): hose reel overhead, always use a lift truck. • HR &...

- Page 10 Installation d. Pump lubricant through line until all solvent is flushed out. 7. For enclosed channel installations, continue with instructions on page 18. For all other installations, continue Step 8. 8. Position hose stop so hose extends far enough for all operators to reach dispensing valve and tighten nuts to securely hold hose stop in place.

-

Page 11: Other Mounting Options

Installation Other Mounting Options Ceiling Mounting Without an I-Beam - Open Channel (All Models) (For HR and HP Model Reels Order Mounting Kit: 24A934, 24A935, 24A936, 24A937, 24A938 or 24A939. For HS Model Reels Order Mounting Kit: 24A219, 24A220, 24A221, 24A222.) HR and HP Models: Open Channel Mounting Kits HS Models: Mounting Kits 24A934... - Page 12 Installation Ceiling Mounting Directly to an I-Beam - HR & HP Models Only 1. Using the template (B), provided, drill holes in the I-Beam (C) (F . 7). 2. Bolt reel to I-Beam. 3. If you are installing permanent supply lines, drill 1.5 in.

- Page 13 Installation Ceiling Mounting to I-Beam without Drilling Holes - All models (Order Mounting Bracket Kit: 204741 for open or enclosed reels.) NOTE: For mounting 1-3 reels, two kits are required. For mounting 4-6 reels, three kits are required. 5. Continue installation following steps 5 - 10 of Over- head Installations instructions, beginning on page 9.

-

Page 14: Wall Mounting

Installation Wall Mounting (For HR and HP Model Reels Order Mounting Kit: 24A934, 24A935, 24A936, 24A937, 24A938 or 24A939. For HS Model Reels Order Mounting Kit: 24A219, 24A220, 24A221, 24A222.) HR and HP Models: Open Channel Mounting Kits HS Models: Mounting Kits 24A934 24A935 24A936... -

Page 15: Hose Installation

Installation Hose Installation Installing a Hose on a Bare Reel 1. Locate length of your hose in table below. Note how many times you must turn the spring to properly pre- set spring tension. Hose Length No. of Reel Turns 35 ft (10.7 m) 50 ft. - Page 16 Installation 10. Flush system. d. Pump lubricant through line until all solvent is flushed out. To avoid contaminating the fluid with line-scale, chips or other installation debris, before installing 11. Position hose stop so hose extends far enough for meter or dispense valve to end of hose, flush the all operators to reach dispensing valve.

- Page 17 Installation Increasing and Decreasing Spring Tension Dual Pedestal HS Model Hose Reels 5. Firmly grasp the breaker bar with both hands and turn it clockwise one turn at a time to increase (tighten) spring tension. 6. Replace and partially tighten one screw. You can now remove the breaker bar.

- Page 18 24A951 - 20 WRONG NUT,spring SCREW, 10 - 24 x 5/8” PANEL, end LABEL, Graco logo 1. Bolt reel base to mounting channel. 2. Slide hose reel into the reel base (302). Install the hold-down plate (303), washer (305) and capscrew CORRECT (304) as shown in F .

- Page 19 11. Clean and dry off surface of each end panel. Attach hole on the side panels (307 & 308) as shown in a Graco label (404) to the center of each end panel. . 15. Refer to the enlarged view shown in F 12.

- Page 20 Installation 310 / 401 . 15A . 15 313431A...

-

Page 21: Maintenance

Maintenance Maintenance Pressure Relief Procedure Replacing the Service Hose 1. Close the supply pump’s bleed-type master air valve 1. Relieve the pressure. (required for pneumatic systems). 2. If the hose reel is enclosed, remove enclosures as 2. Open the dispensing valve until pressure is fully necessary to access hose reel (F . - Page 22 Maintenance b. Separate two hose stop components (cc) to 9. Run the end of hose (B), through the hose guide (G) and then the hole (E) in reel (F . 18). remove from end of hose. 10. Attach the new hose (B) to the hose reel swivel (C) .

- Page 23 Parts LD Series Parts LD Series Part No. Description Part No. Description ◆ 109170 HOSE, coupled, 50 ft (all HRH55 mod- WASHER, 26 mm (all HRL and HRM els) models) ◆ 253850 HOSE, coupled, 50 ft (all HRL56 mod- WASHER, 23 mm(all HRH models)

- Page 24 Parts SD Series Parts SD Series Part No. Description Part No. Description ◆ 109158 HOSE, coupled, 50 ft (all HPH15 mod- WASHER, 30 mm ◆ els) RING, retaining 109170 HOSE, coupled, 50 ft (all HPH55 mod- XXXXXX KIT, spool (see page 28) ◆...

- Page 25 Parts SD Series ti13194 313431A...

- Page 26 Parts XD Series Parts XD Series Part No. Description Part No. Description 253853 HOSE, 50 ft (models HSL65A, XXXXXX KIT, spool (see page 28) ◆ HSL65B) ADJUSTER, power spring ◆ 253857 HOSE, 35 ft (models (HSM33A, WASHER, square center ◆ WASHER, 30 mm HSM33B) ◆...

- Page 27 Parts XD Series ti13196 313431A...

- Page 28 Kits Kits Spool Assembly Kits Line Size Length Part No. Model. Size Media (inches) (feet) Air/Water 15Y482 HRL56# Air/Water 15Y483 HRL65# 15Y484 HRM65# Grease 15Y485 HRH55# Air/Water HPL2D# 15Y486 HPL25# Air/Water HPL6D# 15Y487 HPL65# Air/Water 15Y488 HPL23# Air/Water 15Y489 HPL56# Air/Water 15Y490 HPL33#...

- Page 29 Kits Swivel Kits: I5Y479, I5Y480, Swivel Seal Kits: 24A952, 24953 I5Y481 (Instruction Manual: 406743) (Instruction Manual: 313432) 24A952 Used with Low and Medium Pressure Reels Low Pressure Reels: 15Y479 Description Description WASHER, flat SCREW M8 x 20 SCREW, M8 x 120 RING, retaining WASHER, 5/16”...

- Page 30 Kits Hose Inlet Kit: 224417, 218550, Hose Guide Kits 218549 Roller Bracket Repair: 218591 (Instruction Manual 406741) (Instruction Manual: 406743) Description 1/4” Inlet: 224417 BRACKET, hose guide Description PIN, roller HOSE, coupled, 24” ROLLER, hose FITTING, union, adapter, 90° NUT, lock SCREW BRACKET, roller 3/8”...

-

Page 31: Technical Data

Technical Data Technical Data Low Pressure Hose Reels and Hoses Fluid Pressure Air/Water, all hose diameters 300 psi (20.7 bar, 2.07 MPa) Inlet 1/2” NPSM Male Outlet 1/2”or 3/8” NPT Male Operating Temperature -20°F to 190°F (-28°C to 87°C) Wetted parts - Bare Hose Reel Only Zinc plated steel, anodized aluminum, Nitrile rubber Dimensions Page 32... - Page 32 Technical Data Dimensions HR Models Pressure Size E† G◆ 3.5 inches 7.8 inches 4.7 inches 9 inches 21.8 inches 7.0 inches 19.2 inches Medium (89 mm) (197 mm) (120 mm) (229 mm) (554 mm) (177 mm) (487 mm) High † Measurement taken from base to top of bolts. ◆...

- Page 33 Technical Data HP Models Pressure Size E† G◆ 3.5 inches 7.8 inches 4.7 inches 9 inches 19.5 inches 7.0 inches 17.1 inches Medium (89 mm) (197 mm) (120 mm) (229 mm) (498 mm) (177 mm) (435 mm) High 3.5 inches 7.8 inches 4.7 inches 9 inches...

- Page 34 Technical Data HS Models Pressure Size E† G◆ 6.5 inches 7.5 inches 7.7 inches 9 inches 18.5 inches 7.5 inches 18 inches Medium (165 mm) (191 mm) (196 mm) (229 mm) (473 mm) (196 mm) (460 mm) High 6.5 inches 7.5 inches 7.7 inches 9 inches...

- Page 35 Notes Notes 313431A...

-

Page 36: Graco Information

With the exception of any special, extended, or limited warranty published by Graco, Graco will, for a period as defined in the table below from the date of sale, repair or replace equipment covered by this warranty and determined by Graco to be defective.

Need help?

Do you have a question about the LD Series and is the answer not in the manual?

Questions and answers