Graco LD Series Instructions Manual

Enclosed hose reels

Hide thumbs

Also See for LD Series:

- Instructions manual (36 pages) ,

- Instructions (4 pages) ,

- Instructions manual (32 pages)

Table of Contents

Advertisement

Quick Links

Instructions

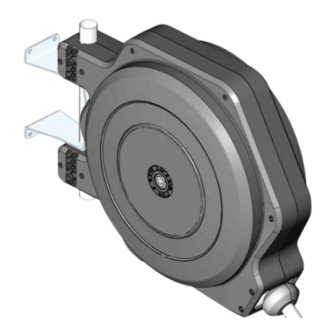

LD Series Enclosed

Hose Reels

For dispensing air, water, antifreeze, windshield washer solvent, transmission fluid, oil and

grease. Not recommended for outdoor use.

Not approved for use in European explosive atmosphere locations.

Part Numbers and Models: Pages 4-6

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

Community Design Registration Number: 0012097

12-0001

Registration Number: ZL201030154438.8

Taiwan Patent Number: D140640

US Patent: D637.067

Korea Patent: 30608479

Patents Pending

313938J

EN

ti13505

Advertisement

Table of Contents

Summary of Contents for Graco LD Series

- Page 1 Instructions LD Series Enclosed Hose Reels 313938J For dispensing air, water, antifreeze, windshield washer solvent, transmission fluid, oil and grease. Not recommended for outdoor use. Not approved for use in European explosive atmosphere locations. Part Numbers and Models: Pages 4-6...

- Page 2 Warnings Warnings The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclama- tion point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. Refer back to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where applicable.

- Page 3 Warnings WARNING MOVING PARTS HAZARD Moving parts can pinch or amputate fingers and other body parts. • Keep clear of moving parts. • Do not operate equipment with protective guards or covers removed. • Pressurized equipment can start without warning. Before checking, moving, or servicing equipment, follow the Pressure Relief Procedure in this manual.

- Page 4 Models Models *The last character of each Model No. indicates the hose reel color. For example: D = black. On the table below this last character is represented by the generic # symbol. For example, to show the complete model number for a black HEL13# model hose reel, the # symbol in the table is replaced with “D”.

- Page 5 Models LD Enclosed Hose Reel Packages Model Numbers Each hose reel package includes a replacement hose reel, mounting bracket and inlet kit. Application, hose size and maximum pressure rating details for each replacement hose reel are provided on the Replacement Hose Reels table on page 4.

- Page 6 Models Hose Reel with Swivel Bracket and Inlet Kit: Includes Swivel Bracket Kit 24C772 Replacement Model No. Inlet Kit★ Hose Reel 24F771 24H655 24C443 24F772 24H656 24C443 24F773 24H657 24C444 24F774 24H658 24C444 24F775 24H659 24C444 24F776 24H660 24C444 24F777 24H661 24C537 24F778...

-

Page 7: Typical Installation Layout

Installation Installation A ground wire (G), bleed-type master air valve (E) and fluid drain valve (H) are required in your system installa- tion. These components help reduce the risk of serious injury, including electric shock and splashing in your eyes or on the skin. -

Page 8: Wall Mounting

Installation Wall Mounting To reduce the risk of injury, be sure the mounting sur- face is strong enough to support the reels, weight of the lubricants and stress caused by hard pulls on the service hoses. See Technical Data, page 21 for weights of hose reel assemblies. - Page 9 Installation CLICK Align ti13510 ti13511 313938J...

-

Page 10: Overhead Mounting

Installation Overhead Mounting To reduce the risk of injury, be sure the mounting sur- face is strong enough to support the reels, weight of the lubricants and stress caused by hard pulls on the service hoses. See Technical Data, page 21 for weights of hose reel assemblies. - Page 11 Installation CLICK Align ti13511 313938J...

- Page 12 Installation Flushing Before installing meter or dispense valve to end of hose, flush supply line with a compatible solvent such as Stoddard solvent or mineral spirits. Place end of hose in waste container. Blow out entire lubricant supply line with air Flush equipment with a compatible solvent until fluid Pump dispensing lubricant through line until all sol- runs clear.

- Page 13 Repositioning Hose Stopper (optional) Repositioning Hose Stopper (optional) ti13525 313938J...

- Page 14 Installing Meter Installing Meter 313938J...

-

Page 15: Adjusting Spring Tension

Adjusting Spring Tension Adjusting Spring Tension IMPACT HAZARD The spring is always under great tension and could be propelled or uncoil with enough force to cause serious injury. • The hose reel spring is not a serviceable part. Do not attempt to replace or service the spring. •... - Page 16 Adjusting Spring Tension ti13515 Turn ti13516 313938J...

- Page 17 Decreasing Spring Tension Decreasing Spring Tension Push in on ratchet. Grasp handle firmly with both hands; then turn ratchet counter-clockwise 1/4 turn ONLY. Repeat this procedure of pushing in and turning ratchet counter-clockwise, ONLY 1/4 turn at a time, until spring tension has been completely released. See Table 1, page 15 for the recommended number of 1/4 turns needed to completely release the spring tension.

-

Page 18: Operation

Operation Operation 313938J... -

Page 19: Repair And Maintenance

Repair and Maintenance Repair and Maintenance Pressure Relief Procedure ti13524 ti13523 313938J... - Page 20 Disassembly ti13512 ti13514 ti13513-2...

- Page 21 Parts Parts 1◆ 1f/1g 1‡ 1★ TI14425 313938J...

- Page 22 Parts Part No. Description Part No. Description 24J302 HOSE, 12 mm id x 10 m BRACKET, swivel, included in all HEL, 24J303 HOSE,6 mm id x 10 m 1‡ 15Y706 HEM and HEH models and models 24F735 - 24F752 KIT, swivel, air, A/W (24F789, 24F790, 24F791, 24F792, 24F793, 24F794, BRACKET, fixed, included in models 24C531...

- Page 23 Parts Inlet Kits Replacement Hose Kit (17) Swivel Kit (19) Stop (27) Reel To determine the correct Mounting Bracket and/or Inlet 24F789, HEL13# 262214 24C531 178029 Kit to order for your hose reel model, see tables on pages 4, 5, and 6. 24F790, HEL15# 262216 24C531...

-

Page 24: Technical Data

Technical Data Technical Data In the following table, Technical Data is provided for the HEL, HEM, HEH, 24M275 and 24M276 hose reel models and for the replacement hose reels. Refer to the Package Model Numbers table on page 5 to verify which replacement hose model is included in your hose reel package. -

Page 25: Mounting Pattern

Technical Data Mounting Pattern Dimensions 6 mm (1/4 in.) bolts 50 mm (1.97 in.) 470 mm (18.5 in.) 171 mm (6.73 in.) 650 mm (25.6 in.) 180 mm (7.1 in.) 313938J... -

Page 26: Graco Standard Warranty

With the exception of any special, extended, or limited warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be defective.

Need help?

Do you have a question about the LD Series and is the answer not in the manual?

Questions and answers