Table of Contents

Advertisement

OPERATING AND

MAINTENANCE MANUAL

ISO 9001 : 2015

A brand of Tenco Inc.

Sales, Parts, and Service Center

2220 Michelin Street

Laval QC J7R 2Y5 Canada

Tel : +1 450.687.3280

Toll free (North America) : 1 800.631.9297

Fax : +1 450.781.8811

Info@rpmtechgroup.com | www.rpmtechgroup.com

Page 1

S00-OME-T4 rev 7

Advertisement

Table of Contents

Summary of Contents for Tenco RPM TECH RPM215

- Page 1 OPERATING AND MAINTENANCE MANUAL ISO 9001 : 2015 A brand of Tenco Inc. Sales, Parts, and Service Center 2220 Michelin Street Laval QC J7R 2Y5 Canada Tel : +1 450.687.3280 Toll free (North America) : 1 800.631.9297 Fax : +1 450.781.8811 Info@rpmtechgroup.com | www.rpmtechgroup.com...

-

Page 2: Table Of Contents

OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 FOREWORD ..................................4 SAFETY PRECAUTIONS ............................... 5 TECHNICAL SPECIFICATIONS .............................. 8 IDENTIFICATION PLATE ..............................10 SNOW BLOWER INSTALLATION ON THE LOADER ......................11 SECTION A - OPERATION, CONFIGURATION MENU AND OPERATING INSTRUCTIONS .......... - Page 3 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 .................................89 HEAR OLTS ..............................90 LOWER TORAGE SECTION C - TROUBLESHOOTING AND EMERGENCY PROCEDURES ................. 91 SECTION D - ENVIRONMENTAL POLICY ........................95 .............................96 ATERIAL ISPOSAL HART...

-

Page 4: Foreword

OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 Foreword This manual has been prepared to help you with the daily operation and maintenance of your new RPM TECH snow blower. Your snow blower has been designed and built to give maximum performance, economy and ease of operation under a wide variety of conditions. -

Page 5: Safety Precautions

OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 Safety Precautions IMPORTANT Read this manual carefully and familiarize yourself with all controls and instrumentation before operating the snow blower. Using equipment that you are not familiar with can cause accidents or injury. - Page 6 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 Read this manual carefully and familiarize yourself with all the controls before attempting to operate the snow blower. Working with unfamiliar equipment may lead to accidents or injury. Do not bypass the safety switches.

- Page 7 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 Always stop the engine before refueling. Extreme precautions should be taken regarding people’s safety during operation. Never perform work under snow blower without adequate support between the snow blower and the ground.

-

Page 8: Technical Specifications

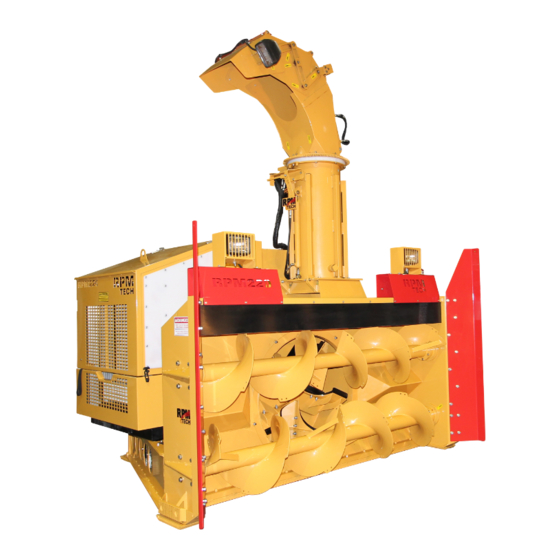

OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 Technical Specifications General description: All RPM Tech 2 stage dual auger loader-mounted snow blowers are powered by a diesel engine and are designed for industrial use. RPM detachable snow blowers are mounted on loaders and backhoes. Depending on the model, they can clear from 1300 to 3000 tons of snow per hour and cast snow up to 46 m (150 ft). - Page 9 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 Operating conditions: RPM snow blowers are designed to be functional in the most extreme conditions in winter. The table below shows temperature and humidity range in which the snow blowers are designed to operate. RPM220/ RPM48R/ RPM220/...

-

Page 10: Identification Plate

OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 Identification Plate The identification plate indicating the snow blower serial number is located on the right- hand side of the snow blower bucket. S00-OME-T4 rev 7 Page 10... -

Page 11: Snow Blower Installation On The Loader

OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 Snow Blower Installation on the Loader IMPORTANT 1- It is important to read the safety measures described in this manual to safely install the snow blower on your loader. - Page 12 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 2- Install the control instruments (joystick and screen) in the loader cabin. It is important to install these instruments in a safe and ergonomic manner for the operator. Then, connect the cabin harness to the loader arm harness(option).

-

Page 13: Section A - Operation, Configuration Menu And Operating Instructions

OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 1 Section A - Operation, Configuration Menu and Operating Instructions BEFORE The following pages describe the instruments and controls of your snow blower. using your new RPM Tech snow blower, you must read and understand this manual. - Page 14 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 2. FUEL GAUGE: Indicates, in percentage, the approximate amount of fuel left in the tank. The fuel level may fluctuate when the snow blower is in motion, when it stops or when starting the engine. To prevent condensation in the tank, it is a good habit to keep the tank full when storing the equipment.

- Page 15 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 10. ENGINE INTAKE AIR HIGH TEMPERATURE LIGHT: This indicator will light when the engine intake air temperature exceeds 150°F (66°C). If the light turns on during operation, the operator must stop the engine.

- Page 16 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 23. LIGHTS DISPLAY OPERATION: button 4, on the display, controls the snow blower lights. When the snow blower is equipped with only work lights, pressing button 4 one time will turn on the lights.

- Page 17 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 26. ACTIVE ENGINE CODES FUNCTION: When a problem occurs with the snow blower engine, the check engine light comes on. When this indicator is on, you may access the error codes menu by button "◄"...

- Page 18 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 27. DPF INHIBIT SWITCH: FOR ENGINES WITH 9.3L DISPLACEMENT AND MORE Button 1 controls the DPF inhibit switch. When press the regeneration will be inhibited. Cycling switched power or the DPF force switch will reset the inhibit command and turn the automatic regen strategy back on again.

-

Page 19: Black And White Operation Screen

OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 1.1.2 Black and White Operation Screen The operation screen, as shown in Figure A2, will turn on automatically when the snow blower is powered through the key switch. - Page 20 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 Figure A3: Second Operation Screen 1. TACHOMETER: This gauge shows the snow blower engine speed in revolutions per minute (rpm). The tachometer is used as guide to keep the engine running within the optimal range. To obtain the maximum tonnage from the engine, the rpm must be at maximum engine RPM.

- Page 21 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 5. VOLTMETER: Indicates the battery charging voltage. If the meter consistently indicates less than 13 volts or more than 15 volts during normal vehicle operation, have your vehicle’s electrical system checked.

- Page 22 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 10. DRUM LOCK ICON: By pressing the button 2 on the display, the drum commands will not respond. When the drum lock command is activated, the drum lock icon will be displayed on the screen. LOW ENGINE OIL PRESSURE, ENGINE HEATER LIGHT AND LOW VOLTAGE LIGHT:...

- Page 23 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 This light is in option and available on some equipment only. When the snow blower clutch is engaged in reverse, the clutch engagement light will turn on. This same light will blink while the clutch is engaging.

- Page 24 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 19. CLUTCH MENU: Button 4 controls the clutch menu. When pressed, the clutch menu will be displayed allowing the operator to select a clutch state. It’s good to note that button 4 only controls the menu, not the actual clutch state.

- Page 25 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 21. ACTIVE ENGINE CODES FUNCTION: When a problem occurs with the snow blower engine, the engine check light comes on. When this indicator is on, you may access the error codes menu by pressing the button "1"...

-

Page 26: Controls

OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 1.1.3 Controls 1. IGNITION SWITCH: This ignition switch controls the electrical system. Read the start engine procedure, described at page 60, before starting the snow blower. NOTE: The controller’s programming prevents the engine from starting if an emergency status is active. - Page 27 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 CONFIGURATION 1 Function 1: Chute rotation and deflector tilting Move the joystick to the left right to turn the chute in the desired direction. Pull the joystick towards you to raise the deflector and push it forward to lower the deflector.

- Page 28 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 CONFIGURATION 2 Function 1: Chute rotation and deflector tilting Move the joystick to the left right to turn the chute in the desired direction. Pull the joystick towards you to raise the deflector and push it forward to lower the deflector.

-

Page 29: Errors

OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 1.1.4 Errors The following table lists all the errors that are displayed by the screen. Error Engagement Condition Operation and Verification Oil pressure below 10 PSI Stop the engine as soon as possible. - Page 30 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 Error Engagement Condition Operation and Verification Check the loader cables and connectors between the joystick and the controller. Check tilt chute is locked, check adjustment on Chute unlocked magnetic pick-up.

-

Page 31: Configuration

OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 1.2 Configuration 1.2.1 Color Display “OK” button The Screen Configuration Menu, as illustrated in Figure A9, will display when the pressed and held when the key switch is turned “ON”. The “OK”... -

Page 32: Engine Errors

OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 1.2.1.2 Engine Errors Engines have the capability to record engine errors which can be displayed on request. The engine error page is used to display these errors. Press button 1 on the service menu to access the Engine Errors Menu. - Page 33 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 102 Engine Intake Manifold 0 Data valid but above normal operation range 1 Data valid but below normal operation range 100 Oil pressure 2 Data Erratic, Intermittent or Incorrect 110 Coolant temperature 3 Voltage Above Normal or Shorted to High Source...

-

Page 34: Button Configuration

OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 1.2.1.3 Button Configuration This page displays the functions of the currently installed joystick. It can be accessed by pressing button 2 from the Service menu page Press button 4 to exit this page. -

Page 35: Maintenance

OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 1.2.1.5 Maintenance Periodic maintenance may be recorded and reviewed on the service menu screen. The service light indicator will appear on the screen when a periodic maintenance is due. To reset indicator light, the next periodic maintenance must be recorded. - Page 36 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 5.2. New Log Entry: Press button 5 in the Maintenance Schedule menu to record new periodic maintenance service. At the opening of the page, a warning screen will appear. This message indicates that by pressing button 1, a new maintenance will be recorded in the logbook.

-

Page 37: Clock Configuration

OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 1.2.1.6 Clock Configuration The internal clock of the display is configurable. The clock configuration page is used for this purpose and is accessible from the Service menu by pressing the button buttons "◄"... -

Page 38: Service

OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 1.2.1.7 Service The configuration pages are password protected. Contact your RPM Tech dealer for your machine password. « ▲ » « ▼ » By using the buttons, the operator can increase or decrease... - Page 39 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 7.1. Joystick Menu: The joystick menu is used to configure the joystick type as well as its sensitivity. You access the Joystick Menu by pressing button 1 from the Service Menu.

- Page 40 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 7.1.2 Joystick Type / Options: This page lets you select and configure the joystick. Here is a brief description of the types of joysticks available and options: - 4-button joystick: Standard joystick provided with the unit.

- Page 41 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 7.2. Fan: The fan menu is used to select the type of fan installed on the unit and to configure the variable pitch fan. The menu is available from the service menu by pressing button Figure A26 : Fan Menu 7.2.1 Fan...

- Page 42 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 buttons "▲" B. Active Box: The active box is squared off. To change the active box, simply press "▼". When a box is selected, the user can edit the content by pressing the “OK”...

- Page 43 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 - Low beams: If lights are installed on the snow blower body, the operator may lower the intensity of the front lights and used them as low beams. A.

- Page 44 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 7.5. Alarms Configuration: Some alarms are configurable and optional. The alarms configuration page is used for this purpose. It is available from the service menu by pressing the button Below is a description of the alarms that are configurable or optional: - Maintenance: The periodic maintenance indicator can be enabled or disabled.

-

Page 45: Menu Tree

OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 1.2.1.8 Menu Tree LOGO « OK » Pressed Service Operation Menu Page Clock Engine Display Manuals Password Maintenance Configuration Errors Language Password Confirmed New Log Log Book Entry... -

Page 46: Black And White Display

OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 1.2.2 Black and White Display The Configuration Menu screen, as illustrated in Figure A33, will display when the button 4 is pressed and held when the key switch is turned “ON”. The button 4 must be held until the Configuration Menu screen appears on the display. -

Page 47: Engine Errors

OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 1.2.2.2 Engine Errors Electronic engines have the capability to record engine errors and they can be displayed on request. “MAIN The engine error page is used to display these errors. This page is accessible from the MENU”... -

Page 48: Button Configuration

OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 1.2.2.3 Button Configuration This page displays the functions of the currently installed joystick. This page is accessible from the “MAIN MENU” as shown in Figure A33. To get there you must select "MANUALS"... -

Page 49: Maintenance

OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 1.2.2.5 Maintenance Periodic maintenance may be recorded and reviewed on the service menu screen. The service light indicator will appear on the screen when a periodic maintenance is due. To reset indicator light, the next “MAIN MENU”... - Page 50 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 5.2. New Log Entry: Press button 4 in the Maintenance Schedule menu to record new periodic maintenance service. At the opening of the page, a warning screen will appear. This message indicates that by pressing button 4, a new maintenance will be recorded in the logbook.

-

Page 51: Clock Configuration

OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 1.2.2.6 Clock Configuration The internal clock of the display is configurable. The clock configuration page is used for this purpose. “MAIN MENU” This page is accessible from the as shown in Figure A33. -

Page 52: Service

OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 1.2.2.7 Service The configuration pages are protected by password. Contact your RPM Tech dealer for your machine password. By using the button 2, the operator can increase the displayed number. - Page 53 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 7.1. Joystick Menu: The joystick menu is used to configure the joystick type as well as its sensitivity. “SERVICE MENU” This page is accessible from the as shown in Figure A44.

- Page 54 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 7.1.2 Joystick Type / Options: This page lets you select and configure the joystick. Here is a brief description of the types of joysticks available and options: - 4-button joystick: Standard joystick provided with the unit.

- Page 55 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 7.2. Fan: The fan menu is used to select the type of fan installed on the unit and to configure the variable “SERVICE MENU” pitch fan.

- Page 56 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 To change the content of desired values, you must activate the box on which a change is desired and then press the button 3.

- Page 57 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 7.3. Light configuration: The functions relating to lights installed on the unit can be configured using the “SERVICE MENU” lights setup menu. This page is accessible from the as shown in Figure A44.

- Page 58 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 7.4 . Clutch Configuration: Clutch angles need to be reprogrammed when the angle sensor has been manipulated or moved, and/or periodically, to protect the clutch. Those limited angles are necessary for the hydraulic cylinder to ensure proper clutching.

- Page 59 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 shut down. Unlike the optional alarm, the shutdown will disengage the clutch on the snow blower and reduce the engine speed. - Optional hydraulic temperature: This alarm can be configured if the option of high hydraulic temperature is selected.

-

Page 60: Start-Up And Operating Instructions

OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 1.3 Start-up and Operating Instructions Operating Instructions for the Snow Blower attached to the Loader Loader operation with the snow blower attached: Refer to the loader operation manual for optimal travel conditions, stability and safety when using the loader with the snow blower attached. -

Page 61: Engine Warm Up

OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 1.3.3 Engine Warm Up Run the engine at idle speed for about five minutes, then, engage the clutch and run for another five minutes at idle to warm up the gearbox and the chain case. - Page 62 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 obstacles or object close to the snowbank. If you are in doubt, STOP and verify for yourself that it is safe to proceed. Do not disengage the clutch between loadings in order to reduce wear on the clutch plates.

-

Page 63: Stopping The Engine

OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 1.3.5 Stopping the Engine Allow engine to idle at 1000 rpm for approximately one minute with the clutch disengaged before shutting down. This will allow the turbocharger and exhaust manifold to cool and prevent possible distortion of components. -

Page 64: Clutch Control

OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 OUTDOOR STORAGE Whenever the blower is used at a temperature above freezing (0° Celsius, 32° Fahrenheit) in heavy wet snow, it is imperative to remove any accumulated snow and ice that is stuck in the blower workings prior to overnight outdoor storage (or any inactive period longer than 2 hours). -

Page 65: Clutch Configuration Procedure

OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 1.3.8 Clutch Configuration Procedure The clutch angles need to be reprogrammed when the angle sensor or clutch were manipulated. They will also need to be adjusted when the snow blower encounters major engagement errors. The configuration consists of programming the angle limits that the controller uses to prevent the clutch from slipping. -

Page 66: Welding

OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 1.3.9 Welding Here are the actions that must be taken before welding on your RPM Tech snow blower. 1. Turn off the key switch and disconnect the harness going inside the carrier cab. 2. -

Page 67: Transport And Handling

OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 1.4 Transport and Handling RPM snow blowers have anchor points for transportation and lifting with overhead travelling cranes. The following figures show the anchor points for each model of RPM snow blowers. Note: All RPM snow blowers have hooks near the screws to secure the snow blower during transport as shown in the photo below. - Page 68 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 Anchor point Anchor point for lifting with for lifting with an overhead an overhead travelling crane travelling crane Anchor points for lifting the RPM220 snow blower Anchor point Anchor point for transport...

-

Page 69: Section B - Lubrication And Maintenance

OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 2 Section B - Lubrication and Maintenance 2.1 Lubrication and Maintenance RPM215 This section gives full details of the service procedure necessary to maintain and preserve the peak efficiency of your snow blower, while the lubrication and maintenance chart on the following pages provides a quick reference to these requirements. -

Page 70: Lubrication And Maintenance Rpm217

OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 2.2 Lubrication and Maintenance RPM217 This section gives full details of the service procedure necessary to maintain and preserve the peak efficiency of your snow blower, while the lubrication and maintenance chart on the following pages provides a quick reference to these requirements. -

Page 71: Lubrication And Maintenance Rpm220

OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 2.3 Lubrication and Maintenance RPM220 / RPM36R This section gives full details of the service procedure necessary to maintain and preserve the peak efficiency of your snow blower, while the lubrication and maintenance chart on the following pages provides a quick reference to these requirements. - Page 72 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 2.4 Lubrication and Maintenance RPM40R This section gives full details of the service procedure necessary to maintain and preserve the peak efficiency of your snow blower, while the lubrication and maintenance chart on the following pages provides a quick reference to these requirements.

-

Page 73: Lubrication And Maintenance Rpm48R

OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 2.5 Lubrication and Maintenance RPM48R / RPM52R This section gives full details of the service procedure necessary to maintain and preserve the peak efficiency of your snow blower, while the lubrication and maintenance chart on the following pages provides a quick reference to these requirements. -

Page 74: Lubrication And Maintenance Hs300

OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 2.6 Lubrication and Maintenance HS300 This section gives full details of the service procedure necessary to maintain and preserve the peak efficiency of your snow blower, while the lubrication and maintenance chart on the following pages provides a quick reference to these requirements. -

Page 75: Maintenance Program Chart

OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 2.7 Maintenance Program Chart Service Maintenance Item interval BREAK-IN PERIOD 0.01 Clutch 0.02 Chute and drum chains 0.03 Radiator bolts tightening After first 30 hours 0.04 Grease fittings 0.05 Gearbox oil / planetary... - Page 76 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 Service Maintenance Item interval 5.04 Engine coolant system Intake duck, turbocharger, exhaust pipe, muffler 5.05 and rain cap Every 600 5.06 Engine coolant fluid hours or 5.07 Engine tune-up annually...

-

Page 77: Maintenance

OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 2.8 Maintenance Tools The blower does not require special equipment and accessories essential for the different adjustments to be made. Procedure for opening and closing the engine cowling Prior to servicing your snow blower, it is important to know the opening and closing procedure of the engine cowling. - Page 78 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 Carry out the following operations every 10 hours or daily 1.01 Engine Oil Level Allow the hot engine to cool a few minutes, and then check oil level with dipstick (1 Fig.

- Page 79 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 Every 10 hours or daily carry out the following operations (cont’d) 1.04 Air cleaner and Air Restrictor Indicator To check the condition of the air cleaner, you can check the air cleaner restriction indicator (1 Fig.

- Page 80 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 Every 25 hours carry out the following operations 2.01 Drum Rotation Lubricate the grease fittings all around the drum. (1 Fig. B6). 2.02 Fan Belt The tension of the belt is automatically adjusted by the belt idler.

- Page 81 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 Every 25 hours carry out the following operations (cont'd) 2.06 Hydraulic Oil Reservoir Check hydraulic oil level visually, making sure the level is 13mm (1/2 in.) from the top of the reservoir (1 Fig. B8).

- Page 82 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 Every 50 hours carry out the following operations 3.01 Fuel Filter / Water Separator (optional) Drain this filter to clean water. Replace this element every 300 hours of operation.

- Page 83 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 Every 200 hours carry out the following operations 4.01 Engine Oil and Filter Drain the engine oil, change the oil filter and refill with new oil. For further information, please consult the operation and maintenance manual from the engine manufacturer.

- Page 84 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 Every 200 hours carry out the following operations (cont’d) 4.03 Auger Bearings Lubricate each bearing with five (5) strokes of manual grease gun. 4.04 First and Second Drive Shaft The first drive shaft is located between the clutch and the chain case.

- Page 85 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 Every 200 hours carry out the following operations (cont’d) 4.05 Fuel Tank and Hoses Inspect the fuel tank and every hose for leaks or damages. Repair any leaks or replace damaged components.

- Page 86 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 Every 600 hours, or annually, carry out the following operations 5.01 Hydraulic Oil and Filter Change hydraulic oil and filter. Drain oil reservoir by removing oil drain plug and dipstick plug.

- Page 87 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 Every 600 hours, or annually, carry out the following operations (cont'd) 5.06 Engine Coolant Fluid Every 600 hours of operation, or annually, the engine cooling fluid needs to be changed. As each motor has different components and mounting, please refer to your engine’s operation and maintenance manual.

- Page 88 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 Every 600 hours, or annually, carry out the following operations (cont'd) 5.10 Clutch Angle Sensor To ensure that the angle sensor works properly, its mechanism must be adequately attached.

-

Page 89: Shear Bolts

OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 2.9 Shear Bolts For grade and dimension of shear bolts refer to your parts manual. Figure B26 Second drive shaft shear bolts Figure B25 Main drive shaft shear bolts Replacement Method for Shear Bolts If shear bolts break while operating, follow these instructions: 1. -

Page 90: Snow Blower Storage

OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 2.10 Snow Blower Storage When the snow blower is not in operation for an undefined period, it should be stored inside a dry building. -

Page 91: Section C - Troubleshooting And Emergency Procedures

OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 3 Section C - Troubleshooting and Emergency Procedures Accident or Equipment Failure In case of mechanical breakdown or accident, press the red emergency button located near the joystick. The engine of the snow blower will stop but the clutch will remain engaged. - Page 92 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 Clutch Disengages After Engagement. An Error is Activated During Clutch Operation When the clutch is engaged, the controller allows a 5 second delay to complete the engagement operation.

- Page 93 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 Clutch Engages, But Augers or Impeller Will not Turn 1. Check the safety shear bolts on both drive shafts and replace them if necessary. 2.

- Page 94 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 Manual Clutch If a problem occurs with the clutch end sensor, the clutch can be engaged manually. You need to turn off the angle sensor and use the clutch lever. When the sensor is off, the clutch command will activate an error when you use it.

-

Page 95: Section D - Environmental Policy

OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 4 Section D - Environmental Policy RPM Tech management has taken the green approach and takes the engagement of doing business in respect with the environment and principles of sustainable development. RPM Tech is a corporate citizen and therefore assumes its role as a leader in its industry by aiming for high quality standards in the making of its products and environment management. -

Page 96: Raw Material Disposal Chart

OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 4.1 Raw Material Disposal Chart Parts type Examples Disposal location Special instructions Chute Augers Recycler Make sure that all Metal parts that have not Skid Shoes Metal collector parts have no oil,... -

Page 97: Section E - Wireless System Operation

OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 5 Section E - Wireless System Operation The wireless control system has been designed to keep the same operation as if it would be controlled with a standard cable. -

Page 98: Section F - Annexes

OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 6 Section F - Annexes 6.1 Procedure to check and adjust clutch engagement force 1. Disconnect clutch cylinder by removing the locking pin (see 1, figure 2. - Page 99 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 Clutch Sensor Configuration Procedure for Color Display The clutch angles need to be reprogrammed when the clutch is manipulated. The configuration consists of programming the angle limits that the controller uses to prevent the clutch from slipping. 1.

- Page 100 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 Engaged Desired Value = Actual Value – 60 (when clutch is engaged) Click on save “button 1” once engaged value is imputed in the desired angle. Disengage the clutch and reprogram the disengaged portion.

- Page 101 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 Clutch sensor configuration procedure for black & white display (For units with a serial # greater than 2400RPM) The clutch angles need to be reprogrammed when the clutch is manipulated. The configuration consists of programming the angle limits that the controller uses to prevent the clutch from slipping.

- Page 102 OPERATING AND MAINTENANCE MANUAL FOR TIER 4 SNOW BLOWER MODELS: RPM215, RPM217, RPM220/36R, RPM40R, RPM48R/52R AND HS300 Engaged Desired Value = Actual Value – 60 (when clutch is engaged) Click on save “button 4” once engaged value is imputed in the desired angle. Disengage the clutch and reprogram the disengaged portion.

Need help?

Do you have a question about the RPM TECH RPM215 and is the answer not in the manual?

Questions and answers

how does one tension the #80 drive chain that drives the augers?