Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Knauer Liquid Handler 2.1

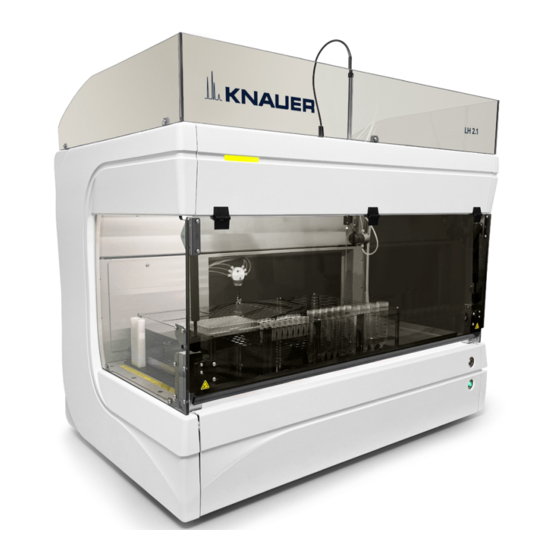

- Page 1 Liquid Handler 2.1 Instructions Document no. V6761...

- Page 2 Support in Germany, Austria and Switzerland: Telefon: +49 30 809727-111 (workdays 9-17h CET) Fax: +49 30 8015010 E-mail: support@knauer.net Contact your local KNAUER partner for support: www.knauer.net/en/Support/Distributors-worldwide Publisher: KNAUER Wissenschaftliche Geräte GmbH Hegauer Weg 38 14163 Berlin Telefon: +49 30 809727-0...

-

Page 3: Table Of Contents

Table of contents 1. General ................1 About these instructions . - Page 4 Table of contents 5. Installation and start up of the Liquid Handler ........13 Functional parts of the Liquid Handler .

- Page 5 Table of contents 14. Disposal ................35 14.1 AVV marking .

- Page 6 Table of contents Liquid Handler LH 2.1 Instructions, V6761...

-

Page 7: General

You can download these and other instructions from the KNAUER web- site: www.knauer.net/library Signal words Possible dangers related to the device are distinguished in personal and material damages. -

Page 8: Legal Information

However, check the packaging for transport damage. In case you notice any damage, inform the Technical Support and the shipping company within three workdays. 1.4.3 Warranty Conditions Please inform yourself about our terms and conditions on the KNAUER website: https://www.knauer.net/terms. 1.4.4 Declaration of conformity... -

Page 9: Basic Safety Instructions

Refrain from the use of the device for the following purposes or conditions: Medical purposes. The device is not approved as a medical product. ƒ Operating outdoors. Otherwise, the manufacturer KNAUER does not ƒ guarantee the functionality and safety of the device. User qualification... -

Page 10: Operator Responsibility

Basic safety instructions Operator responsibility The operator is any person who operates the device himself or leaves it to a third party for use and who bears the legal product responsibility for the protection of the user or third parties during operation. The obligations of the operator are listed below: Know and follow the applicable work safety regulations. -

Page 11: Working With Solvents

Specific environments 2.7.1 Explosive environment Never use the system in potentially explosive atmospheres without appropriate protective equipment. For further information, contact the Technical Support of KNAUER. Liquid Handler LH 2.1 Instructions, V6761... -

Page 12: Cooling Room

Devices which are shipped without the completed document “Service request form and decontamination report” will not be repaired. If you would like to return a device to KNAUER, make sure to enclose the com- pleted document: www.knauer.net/servicerequest. Liquid Handler LH 2.1 Instructions, V6761... -

Page 13: Product Information

3. Product information Scope of delivery Note: The inlet capillary for the fractionation valve is not included in the scope of delivery. The flat bottom fittings needed for the 1/8“ and 1/16“ capillaries are part of the accessory kit. The following articles are included in the scope of delivery: Device Liquid Handler LH 2.1 incl. -

Page 14: Rear View

Product information 3.2.2 Rear view On the rear side of the Liquid Handler LH 2.1 you can find the power plug, a LAN connection as well as the serial number of the device. Service interface Note that the LAN connection is only used during maintenance work. The control interface establishes the connection between PC and LH 2.1 via RS-232. -

Page 15: Symbols And Signs

Product information Symbols and Signs The following symbols and signs can be found on the device: Symbol Meaning Danger of electric shock. In the event of non-ob- servance, it will result in death, serious injuries, or damage or destruction of the device. Danger of electrostatic-discharge. -

Page 16: Installation And Start-Up In General

4. Installation and start-up in general Before you specify the location, read the technical data (see chapter “15. Technical data” on page 36). There are listed all device-specific information about electricity, ambient conditions and humidity. Note: Only if the requirements for ambient conditions of the operating environment are met, the intended use can be ensured. -

Page 17: Ambient Temperature

Installation and start-up in general There are no sources of high frequency close to the device. ƒ The device is ventilated adequately (see chapter “4.2.1 Location” on ƒ page 10). The device is not exposed to temperature fluctuations (see chapter ƒ... - Page 18 Country-specific plugs: Before switching on the device, check wheth- ƒ er the supplied plug is approved for your country. An overview of the device-specific and country-specific plug types by KNAUER can be found: www.knauer.net/plugs Power strips: If several devices are connected to one power strip, al- ƒ...

-

Page 19: Installation And Start Up Of The Liquid Handler

5. Installation and start up of the Liquid Handler Functional parts of the Liquid Handler The following figures summarizes the functional parts of the Liquid Handler LH 2.1. Legend Dispenser syringe Selection valve for wash solutions Status LED Device door with lock Fractionation valve Injection needle Confirmation button to... -

Page 20: Loosen Transport Locking Device

Installation and start up of the Liquid Handler Legend Injection valve with sample loop Drainage tray Wash station Racks with vessels Outlet fraction collec- tion Control interface Storage compartment Fig. 4: Functional parts of the Liquid Handler LH 2.1 Loosen transport locking device Tool Allen screwdriver, size 3 mm ƒ... -

Page 21: Connecting The Device To The Control Interface

Installation and start up of the Liquid Handler Connecting the device to the control interface On the rear of the control interface you will find the connectors for the single components of the LH 2.1. Connection Figure 1. The RS-232 cable that is connected from the inside to the rear of the LH 2.1 has to... -

Page 22: Connecting Selection Valve To Wash Solution

Installation and start up of the Liquid Handler Legend Wash station Drain tubing Drainage tray Fig. 8: Wash station with drain tubing Connecting selection valve to wash solution The ports of the selection valve are connected to the wash solutions via capillaries. -

Page 23: Connecting The Fractionation Valve

Installation and start up of the Liquid Handler 4. Connect the needle tubing Port 1 of the selction valve of the LH2.1 (tube 457 cm, 180“) of the in- jection needle (“tip”) with port tip of the LH 2.1 sample loop of the injection valve. -

Page 24: Switching On And Status Display

6. Switching on and status display Switching on The devices have to be switched on in the following order: 1. LH 2.1 Device 2. VU 4.1 with injection valve 3. Control interface Initialization After the device has been switched on a five-stage initialization process starts. - Page 25 Switching on and status display Color Status Green Device is ready for operation. Flashes green Device initialization Yellow Front cover is open. Flashes yellow Injection running. Device error/Communication error Flashes red User requested unlocking of the front cover. Note: When the error message KOMMANDO-TIMEOUT occurs, an acoustic signal will sound once for 200 ms.

-

Page 26: Configuring The Liquid Handler Lh 2.1

7. Configuring the Liquid Handler LH 2.1 HTTP configuration surface You can use the HTTP configuration surface to configure the network. Enter the IP address of the LH 2.1 (192.168.1.126) in your web browser. From there you can go to the service menu. You can use the HTTP con- figuration surface simultaneously to the control of the LH 2.1 by Purity- Chrom®... - Page 27 Configuring the Liquid Handler LH 2.1 Fig. 14: Service menu Menu Meaning Injector Settings for autosampler: LOOP VOLUME - Volume of the sample loop of the VU 4.1 injection ƒ valve (µl) SYRINGE VOLUME - Volume of the syringe (µl) ƒ...

- Page 28 Configuring the Liquid Handler LH 2.1 Menu Meaning Needle washing Wash volume, wash speed and the position of the hole in the front of the wash station for needle washing (“needle wash position”) as X-, Y-, and Z-coordinates in mm (see chapter “8.3 Tip washing” on page 28).

-

Page 29: Configuration Tool

Configuring the Liquid Handler LH 2.1 Configuration Tool You can not use the LH 2.1 configuration surface simultaneously to the control of the LH 2.1 by a different software. The application /.exe has to be run as a administrator once (see Fig. 15). If you are not doing this, a runtime error will be displayed in the COMMUNICATION LOGS . -

Page 30: Connecting Configuration Tool With The Device

Configuring the Liquid Handler LH 2.1 7.3.1 Connecting Configuration Tool with the device FILE – In order to connect the LH 2.1 to the Configuration Tool you have to choose the corresponding Winsock Port or the serial interface. READ/ WRITE – With the buttons you can read the settings of the LH 2.1 or send the shown parameter to the device. -

Page 31: Controlling The Position Manually

Configuring the Liquid Handler LH 2.1 7.3.4 Controlling the position manually Use the TEACHING WINDOW to position the LH 2.1 step by step or enter the X-coordinate, Y-coordinate and Z-coordinate in order to move it at the desired position. You can choose from step lengths of 50 mm, 10 mm, 1 mm, and 0.1 mm. -

Page 32: Mode Of Operation Liquid Handler Lh 2.1

8. Mode of operation Liquid Handler LH 2.1 Stabing injuries Inside Liquid Handler and behind the front cover is a needle that trans- ports samples automatically. Unthoughtfulness can cause injuries. Only use the device with closed front cover. Stop the operation before opening the front cover. Sample loop Pump Bu er tubing... -

Page 33: Sample Aspiration During Sandwich Injection

Mode of operation Liquid Handler LH 2.1 5. The dispenser syringe aspirates the programmed dead volume DEAD VOLUME . After the aspiration the injection needle (“tip”) stays inside the vessel for the programmed retention time SYRINGE DELAY . AIR – The injection needle (“tip”) leaves the vessel, and air is aspi rated. -

Page 34: Tip Washing

Mode of operation Liquid Handler LH 2.1 Tip washing The hole in the front of the WASH STATION is used for washing the injection needle (“tip”) ( NEEDLE WASHING ). The hole in the middle of the wash station is used to dispose of excess solution from the dispenser syringe and is connected with the waste tube directly. -

Page 35: General Notes

(port 2) with which excess solution can be disposed of. Sample vessel racks of the Liquid Handler 2.1 can be organized sym- ƒ metrically (see chap. “7. Configuring the Liquid Handler LH 2.1” on page 20). -

Page 36: Functionality Tests

10.1 Installation Qualification (IQ) The customer may request the Installation Qualification, which is free of charge. In case of a request, the technical support of KNAUER or a pro- vider authorized by KNAUER performs this functionality test during the installation. -

Page 37: Troubleshooting

11. Troubleshooting First measures for troubleshooting: Check all cables and fittings. ƒ Check whether air has gotten into the supply lines. ƒ Check the device for leaks. ƒ Further measures: Compare the current problem with the list of possible problems (see ƒ... -

Page 38: Possible Problems And Rectifications

Troubleshooting 11.2 Possible problems and rectifications Problem Solution Control interface can not If the control interface is turned on and off connect with the valve while the VU 4.1 is turned on, connecting drive VU 4.1. problems can occur. In this case, turn off all devices and then turn them on in the following order: 1. -

Page 39: Maintenance And Care

Switch off the device. Pull the power plug. 12.1 Maintenance contract The device may only be opened by the Technical Service of KNAUER or any company authorized by KNAUER. This maintenance work is covered by a separate maintenance contract. 12.2 Cleaning and caring for the device Device defect Intruding liquids can cause damage to the device. -

Page 40: Transport And Storage

Carry the device with at least two persons. 13.3 Transporting the device Documents: If you want to return your device to KNAUER for repairs, ƒ enclose the completed document... -

Page 41: Disposal

160214. 14.2 WEEE registration number KNAUER as a company is registered by the WEEE number DE 34642789 in the German "Elektroaltgeräteregister" (EAR). The number belongs to category 8 and 9, which, among others, comprises laboratory equipment. -

Page 42: Technical Data

ƒ supported Sample loop 10 ml loop per default, further loops available Sample rack Capacity 5 KNAUER sample racks Type Not part of the scope of delivery, ƒ selectable Sample racks for microtiter plates ƒ 2 ml, 15 ml and 50 ml vessels available ƒ... -

Page 43: Communication And Software

Technical data Adjustable parameters Loop volume (volume of sample loop) ƒ Syringe volume (volume of syringe) ƒ Syringe speed (aspiration speed) ƒ Syringe delay (delay of the dispenser ƒ syringe) Sandwich injection ƒ Injection volumes ƒ Wash volumes ƒ Wash speed ƒ... -

Page 44: General

Technical data 15.4 General Device Dimensions (W × H × D) 96 cm x 104 cm x 70 cm Weight Approx. 82 kg For indoor use only Work space (W × D) 70 cm x 30 cm Power supply 100 - 240 V, 10 - 5 A, 50 / 60 Hz Air humidity 30 - 80 %, non-condensing Operating altitude... -

Page 45: Repeat Orders

Use the included packing list for repeat orders of spare parts. If there are any questions concerning repeat orders, contact the Technical Support. Further Information Further information on spare parts and accessories can be found online: www.knauer.net. 16.1 Device Name Order no. -

Page 46: Chemical Compatibility Wetted Materials

The following list contains information about the chemical compatibility of all wetted materials which are used in devices made by KNAUER. The data bases on a literature research on the manufacturer specifications of the materials. The wetted materials of this device are listed in the chapter "Technical data". - Page 47 Chemical compatibility wetted materials Since PET belongs chemically to esters, it is not compatible with inorgan- ic acids, hot water and alkalis. Maximum operating Temperature: up to 120 °C. Polyimide (Vespel®): This material is wear-resistant and permanent resilient thermically (up to 200 °C) as well as mechanically.

-

Page 48: Metals

Chemical compatibility wetted materials Polychlortrifluorethylene (PCTFE, Kel-F®): The semi-crystalline thermoplastic material is free of plasticizer and dimensionally stable, even in a wide temperature range (−240 °C to+205 °C). It is moderately resistant against ether, halogenated solvents and toluene. Halogenated solvents over +60 °C and chlorine gas should not be used. - Page 49 Chemical compatibility wetted materials Ceramic Ceramic is resistant against corrosion and wear and is fully biocompati- ble. An incompatibility against acids, alkalis and solvents commonly used in HPLC is not known. Aluminum oxide (Al Due to their high resistance to wear and corrosion, alumina ceramic is used as a coating for mechanically stressed surfaces.

- Page 50 Annex: Installation Qualification (IQ)

- Page 51 Installation Qualification (IQ) for a Device Generated Reviewed Approved Function Name Date Signature 0. Customer approval Prior to installation at the customer site, the customer has reviewed the OQ document and agrees with the design and scope. Company name: Name Function Reviewed &...

- Page 52 KNAUER Wissenschaftliche Geräte GmbH. Scope The customer can request the Installation Qualification. In case of a request, the technical support of KNAUER or a provider authorized by KNAUER performs this functionality test during the installation. The IQ is a standardized docu-...

- Page 53 Installation Qualification (IQ) for a Device Customer and manufacturer data Customer Manufacturer KNAUER Wissenschaftliche Geräte GmbH Company Customer number Contact person/agent Address Hegauer Weg 38 Postal code/City 14163 Berlin +49 30 80 97 27 111 Phone support@knauer.net E-mail Installation Qualification Tests...

- Page 54 Installation Qualification (IQ) for a Device Ensure that the instal- The installation site matches the specifications in the user lation site is suitable instructions. according to the user instructions. Connect the device to The device starts (operating the power supply and noise).

- Page 55 Installation Qualification (IQ) for a Device List of changes to the document Revision no. Description of change Additional information Date/signature VIQ-Installation-Qualification-Device, Version 3.1, Revision: Date: Signature: Page 5/7...

- Page 56 Installation Qualification (IQ) for a Device 10. Certificate and approval A KNAUER employee or an person authorized by KNAUER has checked the device and performed all tests described in the IQ. The IQ form has to be signed by an authorized person. The scope of the IQ meets the customer‘s requirements.

- Page 57 Installation Qualification (IQ) for a Device Annex: List of supporting documents Test no. Description VIQ-Installation-Qualification-Device, Version 3.1, Revision: Date: Signature: Page 7/7...

- Page 58 Latest KNAUER instructions online: www.knauer.net/library KNAUER Phone: +49 30 809727-0 Wissenschaftliche Geräte GmbH Fax: +49 30 8015010 Hegauer Weg 38 E-mail: info@knauer.net 14163 Berlin Internet: www.knauer.net © KNAUER 2023...

Need help?

Do you have a question about the Liquid Handler 2.1 and is the answer not in the manual?

Questions and answers