Table of Contents

Advertisement

Quick Links

Operating & Installation Instructions

Translation of the Original Assembly Instructions EN

Linear feeder LF9

Linear feeder LF9

Linear feeder LF11

Operating & Installation Instructions

Linear Feeder

LF9 / LF11

(230 V/50 Hz)

Order no.: 15105783

(115 V/60 Hz)

Order no.: 15068632

(230 V/50 Hz)

Order no.: 11005757

LF9 / LF11

Date 24.08.2023

Version 6.0

1–36

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Afag LF9

- Page 1 Operating & Installation Instructions Linear Feeder LF9 / LF11 Translation of the Original Assembly Instructions EN Linear feeder LF9 (230 V/50 Hz) Order no.: 15105783 Linear feeder LF9 (115 V/60 Hz) Order no.: 15068632 Linear feeder LF11 (230 V/50 Hz) Order no.: 11005757...

- Page 2 Your Afag team © Subject to modifications The linear feeders have been designed by Afag Automation AG according to the state of the art. Due to the constant technical development and improvement of our products, we reserve the right to make technical changes at any time.

-

Page 3: Table Of Contents

2.8.2 Danger due to electricity ..............12 2.8.3 Hazards due to strong alternating magnetic fields ....... 12 2.8.4 Mechanical hazards ................12 Technical data ...................... 13 Dimensional drawing LF9 / LF11 ..............13 Technical data LF9/LF11 ................14 Accessories ....................15 3.3.1 Mounting parts ..................15 3.3.2 Controller .................... - Page 4 9.2.6 Spare and wear parts, repairs .............. 32 Decommissioning and disposal ................. 33 10.1 Safety instructions ..................33 10.2 Decommissioning ..................33 10.3 Disposal ...................... 33 4 – 36 Operating & Installation Instructions LF9 / LF11 Date 24.08.2023 Version 6.0 ...

-

Page 5: General

NOTICE This safety note points out a potentially dangerous situation which, if not avoided, can cause substantial damage to property and the environment. Operating & Installation Instructions LF9 / LF11 Date 24.08.2023 Version 6.0 5–36 ... -

Page 6: Additional Symbols

In these assembly instructions the following symbols are used to highlight instructions, results, references, etc.. Symbol Description Instructions (steps ...) Results of actions References to sections Enumerations not ordered 6 – 36 Operating & Installation Instructions LF9 / LF11 Date 24.08.2023 Version 6.0 ... -

Page 7: Warranty

This does also apply to defective accessories and wear parts. Normal wear and tear are excluded from the warranty. The warranty covers the replacement or repair of defective Afag parts. Further claims are excluded. The warranty shall expire in the following cases: ... -

Page 8: Safety Instructions

The LF together with the conveyor rail are designed for conveying bulk material. The linear feeder can only be operated in combination with the associated Afag control unit. The following uses of the LF are considered as improper use : ... -

Page 9: Foreseeable Misuse

observe and communicate universally applicable laws and regulations regarding accident prevention and environmental protection, provide the necessary personal protective equipment (e.g., protective gloves) and instruct the personnel to wear it. Operating & Installation Instructions LF9 / LF11 Date 24.08.2023 Version 6.0 9–36 ... -

Page 10: Obligations Of The Personnel

Authorized persons who due to their specialized professional training, expertise and experience can identify risks and preventing possible hazards arising from the use of the machine. 10 – 36 Operating & Installation Instructions LF9 / LF11 Date 24.08.2023 Version 6.0 ... -

Page 11: Personal Protective Equipment (Ppe)

Changes and modifications No changes may be made to the linear feeders which have not been described in these operating instructions or approved in writing Afag Automation AG. Afag Automation AG accepts no liability for unauthorised changes or improper assembly, installation, commissioning, maintenance or repair work. -

Page 12: Danger Due To Electricity

Work on and with the LF may only be carried out by qualified personnel. Never reach into the system during normal operation! 12 – 36 Operating & Installation Instructions LF9 / LF11 Date 24.08.2023 Version 6.0 ... -

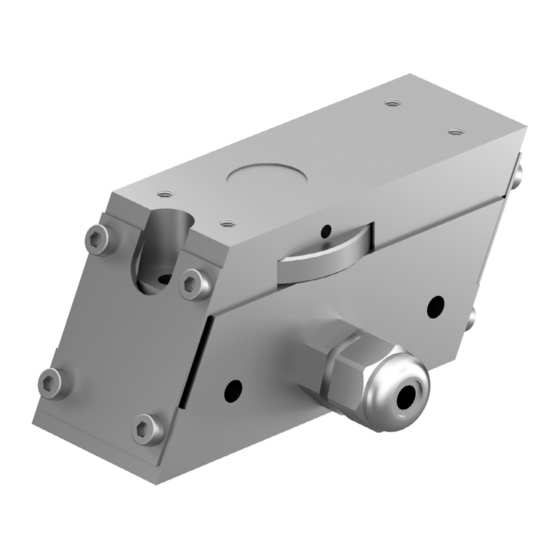

Page 13: Technical Data

Technical data Technical data Dimensional drawing LF9 / LF11 Fig. 1 Dimensional drawing LF Operating & Installation Instructions LF9 / LF11 Date 24.08.2023 Version 6.0 13–36 ... -

Page 14: 3.2 Technical Data Lf9/Lf11

Technical data 3.2 Technical data LF9/LF11 14 – 36 Operating & Installation Instructions LF9 / LF11 Date 24.08.2023 Version 6.0 ... -

Page 15: Accessories

230V/50Hz - 50391819 MSG802 Sensor feed 115V/60Hz For more information on the controller, see chap. 6.3 and the controller manufacturer's instructions. Operating & Installation Instructions LF9 / LF11 Date 24.08.2023 Version 6.0 15–36 ... -

Page 16: Transport, Packaging And Storage

The corresponding documentation is supplied with each linear feeder (e.g., operating and installation instructions, etc.). Fig. 2 Scope of delivery LF [Unt] Designation Linear feeder LF9 / LF11 Operating and installation instructions 16 – 36 Operating & Installation Instructions LF9 / LF11 Date 24.08.2023 Version 6.0... -

Page 17: Transport

Relative air humidity: < 90%, non condensing Packaging The linear feeder is transported in the Afag Automation AG transport packaging. If no Afag packaging is used, the linear feeder must be packed in such a way that it is protected against shocks and dust. NOTICE... -

Page 18: Design And Description

With heavy or large workpieces however, it is necessary to use an oscillating frequency of 50 Hz. A half wave of the mains supply is thereby blocked. 18 – 36 Operating & Installation Instructions LF9 / LF11 Date 24.08.2023 Version 6.0 ... -

Page 19: Installation, Assembly & Setting

Observe the safety instructions in chap. 2 "Safety instructions" of this Installation instructions as well as the instructions in chap. 6.3. Operating & Installation Instructions LF9 / LF11 Date 24.08.2023 Version 6.0 19–36 ... -

Page 20: Assembly

Fastening the module The LF is firmly bolted to the foundation by means of the holes drilled in the floor. For the LF9, two screws are inserted from below. With the help of mounting plates ( chap. 3.3.1), optional mounting from above is possible. -

Page 21: Assembly Of The Conveyor Rail

20mm thick and has a width of more than 120mm. The height adjustment must be made by means of appropriate substructures. Suitable Afag standard parts are available for complete station set-ups in conjunction with Afag bowl feeders. -

Page 22: Important Notes

Fig. 5 CEE appliance plug A detailed description of the control units can be found in the instructions of the controller manufacturer in the AFAG in the AFAG Catalogue (www.afag.com). 22 – 36 Operating & Installation Instructions LF9 / LF11 Date 24.08.2023... -

Page 23: Settings

6. Use the controller to adjust the conveying speed. 7. Depending on the material to be conveyed, additional springs must be installed or removed. The process is finished. Operating & Installation Instructions LF9 / LF11 Date 24.08.2023 Version 6.0 23–36 ... -

Page 24: Adjustlinear Rail

3. Tighten the screws (1) of the spring assemblies again. 4. Check air gap between solenoid coil and anchor screw and readjust if necessary. The process is completed. 24 – 36 Operating & Installation Instructions LF9 / LF11 Date 24.08.2023 Version 6.0 ... -

Page 25: Operation

Risk of property damage if different controllers are used! Operation with another control unit will result in the destruction of the piezo element. Only operate the linear feeder with the Afag Piezo control unit PSG-1! Operating & Installation Instructions LF9 / LF11 Date 24.08.2023... -

Page 26: Fault Elimination

Fault causes and remedy Faults caused by defective components may only be remedied by replacing these defective components! Only Afag original wear and spare parts may be used! Fault Possible cause Remedy: Plug not connected to mains ... -

Page 27: Maintenance And Repair

Observe the operating instructions of the controller used! Also observe the safety instructions in chap. 2 „Safety instructions“ in this manual. Operating & Installation Instructions LF9 / LF11 Date 24.08.2023 Version 6.0 27–36 ... -

Page 28: Maintenance Activities And Maintenance Intervals

Maintenance activities and maintenance intervals The maintenance intervals must be strictly observed. The intervals refer to a normal operating environment. 9.2.1 Overview of the maintenance points Fig. 7 Maintenance linear feeder LF9 (exemplary) System Interval Maintenance point Maintenance work Remarks... -

Page 29: Replaceleaf Springs

To replace the leaf springs, proceed as follows: Fig. 8 Replacing leaf springs LF9 (exemplary representation) 1. Loosen the screws (1) on the vibrating rail (2) and on the base (3) and remove them together with the support (4). -

Page 30: Replace Solenoid Coil

To replace the solenoid coil, proceed as follows: Fig. 9 Replacing solenoid coil LF9 (exemplary representation) 1. Loosen the screws (1) of the vibrating rail (2) and remove the whole unit. 2. Remove the plug from the controller and dismount it. -

Page 31: Adjust Air Gap

Procedure for setting the air gap: Fig. 10 Adjusting the air gap LF9 (exemplary representation) 1. Before adjusting the air gap, the anchor screw (3) must be adjusted as follows: 2. Loosen the Allen screw (1) (2.5 mm). -

Page 32: Further Maintenance

AFAG for warranty repair within the warranty period. After expiry of the warranty period, the customer may replace or repair defective modules or wear parts himself or send them to the Afag repair service. Please note that Afag does not assume any warranty for modules that have... -

Page 33: 10 Decommissioning And Disposal

Electronic parts, electrical scrap, auxiliary and operating materials must be disposed of by approved specialist companies. Information on proper disposal can be obtained from the responsible local authorities. Operating & Installation Instructions LF9 / LF11 Date 24.08.2023 Version 6.0 33–36 ... - Page 34 34 – 36 Operating & Installation Instructions LF9 / LF11 Date 24.08.2023 Version 6.0 ...

- Page 35 Operating & Installation Instructions LF9 / LF11 Date 24.08.2023 Version 6.0 35–36 ...

- Page 36 36 – 36 Operating & Installation Instructions LF9 / LF11 Date 24.08.2023 Version 6.0 ...

Need help?

Do you have a question about the LF9 and is the answer not in the manual?

Questions and answers