Table of Contents

Advertisement

Assembly and operating instructions

Translation of the Original Assembly Instructions EN

ES20-050

Order no.: 50425969

◼

ES20-100

Order no.: 50425970

◼

ES20-200

Order no.: 50425971

◼

ES20-300

Order no.: 50425972

◼

ES30-050-SL

Order no.: 50425973

◼

ES30-100-SL

Order no.: 50425974

◼

Assembly Instructions EN

Electric slide

ES-20

◼

◼

ES-20 I ES-30

25.05.2023

I

ES-30

ES30-100

◼

ES30-200-SL

◼

ES30-200

◼

ES30-300

◼

ES30-400

◼

ES30-500

◼

◼

V1.7

Order no.: 50425975

Order no.: 50425976

Order no.: 50425977

Order no.: 50425978

Order no.: 50425979

Order no.: 50425980

1–69

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Afag ES-20

- Page 1 Order no.: 50425978 ◼ ◼ ES30-050-SL Order no.: 50425973 ES30-400 Order no.: 50425979 ◼ ◼ ES30-100-SL Order no.: 50425974 ES30-500 Order no.: 50425980 ◼ ◼ ◼ ◼ ◼ Assembly Instructions EN ES-20 I ES-30 25.05.2023 V1.7 1–69...

- Page 2 Your Afag team © Subject to modifications The electric slides have been designed by Afag Automation AG according to the state of the art. Due to the constant technical development and improvement of our products, we reserve the right to make technical changes at any time.

-

Page 3: Table Of Contents

3.2.3 Preferred combinations ES30 .............. 22 3.2.4 Module loads ES30 ................23 3.2.5 Motor overview ES30 ................23 Transport, packaging and storage ..............24 Safety instructions for transport ..............24 ◼ ◼ ◼ Assembly Instructions EN ES-20 I ES-30 25.05.2023 V1.7 3–69... - Page 4 Fault causes and remedy ................63 Maintenance and repair ..................64 General notes ..................... 64 Safety instructions for maintenance and repair .......... 64 Maintenance activities and maintenance intervals ........65 4 – 69 ◼ ◼ ◼ Assembly instructions EN ES-20 I ES-30 25.05.2023 V1.7...

- Page 5 Spare parts and repair work ............... 66 Decommissioning and disposal ................. 67 10.1 Safety instructions for decommissioning and disposal ....... 67 10.2 Decommissioning ..................67 10.3 Disposal ...................... 67 Declaration of incorporation ................68 ◼ ◼ ◼ Assembly Instructions EN ES-20 I ES-30 25.05.2023 V1.7 5–69...

-

Page 6: General

This note contains important additional information as well as useful tips for safe, efficient and trouble-free operation of the electric slide. 6 – 69 ◼ ◼ ◼ Assembly instructions EN ES-20 I ES-30 25.05.2023 V1.7... -

Page 7: Additional Symbols

In these assembly instructions the following symbols are used to highlight instructions, results, references, etc. Symbol Description Instructions (steps ...) Results of actions References to sections ◼ Enumerations not ordered ◼ ◼ ◼ Assembly Instructions EN ES-20 I ES-30 25.05.2023 V1.7 7–69... -

Page 8: Applicable Documents

This does also apply to defective accessories and wear parts. Normal wear and tear are excluded from the warranty). The warranty covers the replacement or repair of defective Afag parts. Further claims are excluded. The warranty shall expire in the following cases: ▪... -

Page 9: Safety Instructions

Any use other than or beyond the intended use described above is considered a misuse/improper use of the electric slides. Especially the following use is considered a misuse: ▪ Use in potentially explosive atmospheres ◼ ◼ ◼ Assembly Instructions EN ES-20 I ES-30 25.05.2023 V1.7 9–69... -

Page 10: Obligations Of The Operator And The Personnel

▪ the operating company shall be solely responsible for such damage, and ▪ AFAG does not accept any liability for damages caused by improper use. 2.4 Obligations of the operator and the personnel 2.4.1... -

Page 11: Obligations Of The Personnel

Authorized persons who due to their specialized professional training, expertise and experience are capable of identifying risks and preventing possible hazards arising from the use of the machine. ◼ ◼ ◼ Assembly Instructions EN ES-20 I ES-30 25.05.2023 V1.7 11–69... -

Page 12: Personal Protective Equipment (Ppe)

2.7 Changes & modifications No changes may be made to the electric slides which have not been described in these assembly instructions or approved in writing by Afag Automation AG. AFAG Automation AG accepts no liability for unauthorised changes or improper assembly, installation, commissioning, maintenance or repair work. -

Page 13: General Hazards / Residual Risks

▪ Only qualified personnel may work with or on the electric slides. ▪ Read the assembly instructions carefully before carrying out any work on or with the electric slides. ◼ ◼ ◼ Assembly Instructions EN ES-20 I ES-30 25.05.2023 V1.7 13–69... -

Page 14: Danger Due To Electricity

Limbs can be crushed by moving components! ▪ Work on and with the electric slides may only be carried out by qualified personnel. ▪ Never reach into the system during normal operation! 14 – 69 ◼ ◼ ◼ Assembly instructions EN ES-20 I ES-30 25.05.2023 V1.7... -

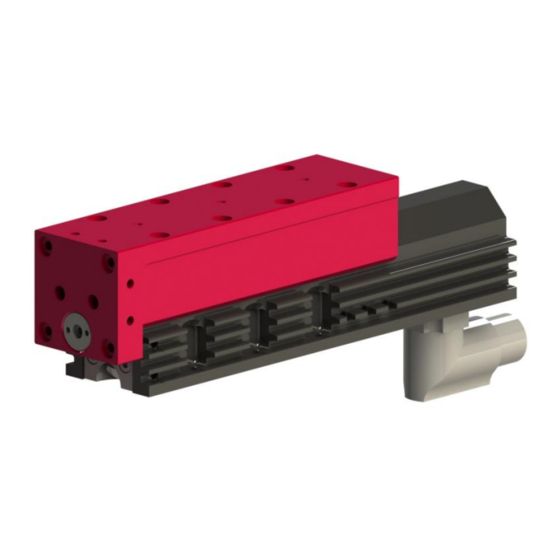

Page 15: Technical Data

Technical data Technical data 3.1 Electric slide ES20 3.1.1 Dimension drawing ES20 Fig. 1 Dimensional drawing of electric slide ES20 ◼ ◼ ◼ Assembly Instructions EN ES-20 I ES-30 25.05.2023 V1.7 15–69... -

Page 16: Technical Data Es20

Technical data 3.1.2 Technical data ES20 16 – 69 ◼ ◼ ◼ Assembly instructions EN ES-20 I ES-30 25.05.2023 V1.7... -

Page 17: Preferred Combinations Es20

Technical data 3.1.3 Preferred combinations ES20 ◼ ◼ ◼ Assembly Instructions EN ES-20 I ES-30 25.05.2023 V1.7 17–69... -

Page 18: Module Loads Es20

3.1.5 Motor overview ES20 Stator Rotor Wiper Module Stator Rotor Wiper Order no. Order no. Order no. Wiper seal PAW01-12 50429988 ES20-050 PS01-23x80F-HP-R 50429980 PL01-12x170/130-HP 50429981 18 – 69 ◼ ◼ ◼ Assembly instructions EN ES-20 I ES-30 25.05.2023 V1.7... - Page 19 Technical data Wiper seal PAW01-12 50429988 ES20-100 PS01-23x160H-HP-R 50430155 PL01-12x270/230-HP 50430156 Wiper seal PAW01-12 50429988 ES20-200 PS01-23x160H-HP-R 50430155 PL01-12x350/310-HP 50430297 Wiper seal PAW01-12 50429988 ES20-300 PS01-23x160H-HP-R 50430155 PL01-12x480/440-HP 50430300 ◼ ◼ ◼ Assembly Instructions EN ES-20 I ES-30 25.05.2023 V1.7 19–69...

-

Page 20: Electric Slide Es30

Technical data 3.2 Electric slide ES30 3.2.1 Dimensional drawing ES30 Fig. 2 Dimensional drawing of electric slide ES30 20 – 69 ◼ ◼ ◼ Assembly instructions EN ES-20 I ES-30 25.05.2023 V1.7... -

Page 21: Technical Data Es30

Technical data 3.2.2 Technical data ES30 ◼ ◼ ◼ Assembly Instructions EN ES-20 I ES-30 25.05.2023 V1.7 21–69... -

Page 22: Preferred Combinations Es30

Technical data 3.2.3 Preferred combinations ES30 22 – 69 ◼ ◼ ◼ Assembly instructions EN ES-20 I ES-30 25.05.2023 V1.7... -

Page 23: Module Loads Es30

50431219 Wiper seal PAW01-20 50431223 ES30-300 PS01-37x120F-HP-C 50431216 PL01-20x500/440-HP 50431220 Wiper seal PAW01-20 50431223 ES30-400 PS01-37x120F-HP-C 50431216 PL01-20x600/540-HP 50431221 Wiper seal PAW01-20 50431223 ES30-500 PS01-37x120F-HP-C 50431216 PL01-20x700/640-HP 50431222 ◼ ◼ ◼ Assembly Instructions EN ES-20 I ES-30 25.05.2023 V1.7 23–69... -

Page 24: Transport, Packaging And Storage

Scope of delivery electric slide ES20 and ES30 Unt. ES20 ES30 Module ES20 Module ES30 Centering sleeves ø 7x3 Centering bushing ø 9x4 Mounting screws M4x14 Mounting screws M6x20 Mounting/operating instructions Mounting/operating instructions 24 – 69 ◼ ◼ ◼ Assembly instructions EN ES-20 I ES-30 25.05.2023 V1.7... -

Page 25: Transport

▪ Relative air humidity: < 90%, non condensing 4.4 Packaging The electric slides are transported in the transport packaging of AFAG Automation AG. If no AFAG packaging used, the electric slides must be packed so that they are protected against shock and dust. NOTICE... -

Page 26: Structure And Description

100 mm 50425974 ES30-100 100 mm 50425975 ES30-200-SL 200 mm 50425976 ES30-200 200 mm 50425977 ES30-300 300 mm 50425978 ES30-400 400 mm 50425979 ES30-500 500 mm 50425980 26 – 69 ◼ ◼ ◼ Assembly instructions EN ES-20 I ES-30 25.05.2023 V1.7... -

Page 27: Accessories

The thread on the stator and the end of the rotor with four flats are facing downwards. In the normal installation position, dimension SP=35 adjusted by clamping the MagSpring stator with fully retracted slide. This measure (SP=35) is the same for all MagSprings. ◼ ◼ ◼ Assembly Instructions EN ES-20 I ES-30 25.05.2023 V1.7 27–69... - Page 28 The MagSpring for the front attachment is supplied as a set and consists the following components: MagSpring Stator and rotor Compensating element Bracket Adapter Hexagon nut Mounting parts 28 – 69 ◼ ◼ ◼ Assembly instructions EN ES-20 I ES-30 25.05.2023 V1.7...

- Page 29 Structure and description Overview MagSpring ES20 ◼ ◼ ◼ Assembly Instructions EN ES-20 I ES-30 25.05.2023 V1.7 29–69...

- Page 30 Structure and description Technical data MagSpring ES20 11N-22N 30 – 69 ◼ ◼ ◼ Assembly instructions EN ES-20 I ES-30 25.05.2023 V1.7...

- Page 31 Structure and description ◼ ◼ ◼ Assembly Instructions EN ES-20 I ES-30 25.05.2023 V1.7 31–69...

- Page 32 Structure and description Technical data MagSpring ES20 40N-60N 32 – 69 ◼ ◼ ◼ Assembly instructions EN ES-20 I ES-30 25.05.2023 V1.7...

- Page 33 Structure and description ◼ ◼ ◼ Assembly Instructions EN ES-20 I ES-30 25.05.2023 V1.7 33–69...

- Page 34 Structure and description Overview MagSpring ES30 34 – 69 ◼ ◼ ◼ Assembly instructions EN ES-20 I ES-30 25.05.2023 V1.7...

- Page 35 Structure and description Technical data MagSpring ES30 11N-22N ◼ ◼ ◼ Assembly Instructions EN ES-20 I ES-30 25.05.2023 V1.7 35–69...

- Page 36 Structure and description 36 – 69 ◼ ◼ ◼ Assembly instructions EN ES-20 I ES-30 25.05.2023 V1.7...

- Page 37 Structure and description Technical data MagSpring ES30 40N-60N ◼ ◼ ◼ Assembly Instructions EN ES-20 I ES-30 25.05.2023 V1.7 37–69...

- Page 38 Structure and description 38 – 69 ◼ ◼ ◼ Assembly instructions EN ES-20 I ES-30 25.05.2023 V1.7...

-

Page 39: Compensation Spring

Description Top clamp Cylinder pin Tension spring Spring cover Holder spring cover Clamp at the bottom Mounting parts Spring compensation ES20-50-SL Orden number 50427546 Net weight 0.079 kg ◼ ◼ ◼ Assembly Instructions EN ES-20 I ES-30 25.05.2023 V1.7 39–69... -

Page 40: External Position Measuring System For Es20 And Es30

Advantages: ▪ Referencing not necessary ▪ High repeatability and absolute accuracy ▪ Dynamic and quiet driving ▪ Minimize control noise External position measuring system ES20 40 – 69 ◼ ◼ ◼ Assembly instructions EN ES-20 I ES-30 25.05.2023 V1.7... - Page 41 The sensor is installed parallel to the belt using a feeler gauge. The value can be found in the table below. Sensor Distance min. Distance max. Recommended distance type [mm] [mm] [mm] 1MSA501 distance Fig. 9 External position measuring system (example illustration) ◼ ◼ ◼ Assembly Instructions EN ES-20 I ES-30 25.05.2023 V1.7 41–69...

-

Page 42: Servo Controller

Structure and description 5.3.4 Servo controller Fig. 10 Overview of servo controllers 42 – 69 ◼ ◼ ◼ Assembly instructions EN ES-20 I ES-30 25.05.2023 V1.7... - Page 43 Structure and description Technical data servo controllers Controller C11xx ◼ ◼ ◼ Assembly Instructions EN ES-20 I ES-30 25.05.2023 V1.7 43–69...

- Page 44 Structure and description Controller C12xx 44 – 69 ◼ ◼ ◼ Assembly instructions EN ES-20 I ES-30 25.05.2023 V1.7...

- Page 45 Structure and description Controller E12xx ◼ ◼ ◼ Assembly Instructions EN ES-20 I ES-30 25.05.2023 V1.7 45–69...

-

Page 46: Controllers, Cables, Plugs

Structure and description 5.3.5 Controllers, cables, plugs The C11xx and C12xx controllers are supplied with a plug set. 46 – 69 ◼ ◼ ◼ Assembly instructions EN ES-20 I ES-30 25.05.2023 V1.7... - Page 47 Structure and description ◼ ◼ ◼ Assembly Instructions EN ES-20 I ES-30 25.05.2023 V1.7 47–69...

- Page 48 Structure and description Cable types Motor cable M16-0-1-1 Motor cable extension to M16-0-0-1/2 Motor cable M17-0-1-1 48 – 69 ◼ ◼ ◼ Assembly instructions EN ES-20 I ES-30 25.05.2023 V1.7...

- Page 49 Structure and description Motor cable extension to M17-0-0-1/-2 Motor cable-M20-0-2-1 Motor cable-M22-0-2-1 ◼ ◼ ◼ Assembly Instructions EN ES-20 I ES-30 25.05.2023 V1.7 49–69...

-

Page 50: Transformers And Power Supplies

Structure and description 5.3.6 Transformers and power supplies Power supply S01-72/500, 1 phase 50 – 69 ◼ ◼ ◼ Assembly instructions EN ES-20 I ES-30 25.05.2023 V1.7... - Page 51 Structure and description Power supply S01-72/1000, 3 phases ◼ ◼ ◼ Assembly Instructions EN ES-20 I ES-30 25.05.2023 V1.7 51–69...

-

Page 52: Program For Supports - Es-Modules

Structure and description 5.3.7 Program for supports - ES-Modules 52 – 69 ◼ ◼ ◼ Assembly instructions EN ES-20 I ES-30 25.05.2023 V1.7... -

Page 53: Installation, Assembly & Setting

▪ Take appropriate measures to ensure safe operation! liability assumed damages caused improper installation/assembling work carried out by the operator. chap. 2 „Safety instructions“ in this Also observe the safety instructions in manual. ◼ ◼ ◼ Assembly Instructions EN ES-20 I ES-30 25.05.2023 V1.7 53–69... -

Page 54: Assembly & Attachment

Hole pitch 48x48 mm Fig. 12 Mounting holes on the base element For mounting use the centering sleeves ( chapter 6.2.2) included in the scope of delivery. 54 – 69 ◼ ◼ ◼ Assembly instructions EN ES-20 I ES-30 25.05.2023 V1.7... -

Page 55: Centering Bushing

Hole grid 48 x 48 mm 48 x 48 mm Bore hole and fastening thread Ø 6.3 mm Centr. sleeves (H7) 11004942 Ø 9 mm Ø 9 mm ◼ ◼ ◼ Assembly Instructions EN ES-20 I ES-30 25.05.2023 V1.7 55–69... -

Page 56: Tightening Torques

Mounting of the module (base element): Ø 4.1 with centring Ø 7 H7 hole pitch 30 x 30 mm Fig. 14 Electric slide ES 20 (mounting basic element) 56 – 69 ◼ ◼ ◼ Assembly instructions EN ES-20 I ES-30 25.05.2023 V1.7... -

Page 57: Mounting Es30 (Slide)

Electric slide ES 30 (mounting basic element) NOTICE Magnetic tape with information! The magnetic tape of the external measuring system contains information. ▪ Keep sufficient distance from other magnetic sources. ◼ ◼ ◼ Assembly Instructions EN ES-20 I ES-30 25.05.2023 V1.7 57–69... -

Page 58: Rotatability Of C Motor Connector (Es30)

Fig. 17 Setting the C-motor connector (ES30 modules) Our service technicians will be happy to answer any further questions you may have about setting the C-motor plugs. 58 – 69 ◼ ◼ ◼ Assembly instructions EN ES-20 I ES-30 25.05.2023 V1.7... -

Page 59: Programming Of The Electric Slides

▪ Replace the defective position sensor or limit switch cable immediately. 6.3.2 Programming The programming differs depending on the control system used. Observe the respective manuals of the control system manufacturer! ◼ ◼ ◼ Assembly Instructions EN ES-20 I ES-30 25.05.2023 V1.7 59–69... -

Page 60: Commissioning

▪ Only connect or disconnect the cables when the control unit is switched off. ▪ Observe the operating instructions of the controller used! Observe the safety instructions in chapter 2 "Safety instructions" of these mounting instructions! 60 – 69 ◼ ◼ ◼ Assembly instructions EN ES-20 I ES-30 25.05.2023 V1.7... -

Page 61: Preparatory Activities For Commissioning

3. Connect the cable to the electric slide and the system control. 4. Perform test run: Start with slow movements Then continue under normal operating conditions Commissioning is completed. ◼ ◼ ◼ Assembly Instructions EN ES-20 I ES-30 25.05.2023 V1.7 61–69... -

Page 62: Setting Up & Retrofitting

▪ Ensure that the movement of the electric slide is not restricted by mounted attachments. ▪ Take appropriate measures to ensure safe operation! 62 – 69 ◼ ◼ ◼ Assembly instructions EN ES-20 I ES-30 25.05.2023 V1.7... -

Page 63: Fault Elimination

▪ Reduce payload Slide does not move ▪ Slide blocked by foreign matter ▪ Remove foreign matter ▪ Module defect ▪ Send module to Afag for overhaul ▪ Check connections and connect ▪ Module incorrectly connected module correctly ▪ Incorrect control ▪... -

Page 64: Maintenance And Repair

▪ Before starting any activities, switch off the media supply and make sure it cannot be switched on again unintentionally! chapter 2 „Safety instructions“ in Also observe the safety instructions in this manual. 64 – 69 ◼ ◼ ◼ Assembly instructions EN ES-20 I ES-30 25.05.2023 V1.7... -

Page 65: Maintenance Activities And Maintenance Intervals

▪ If the electric slides are to be operated in an environment with abrasive dusts or corrosive or aggressive vapours, gases or liquids, the approval of Afag Automation AG must be obtained in advance. 9.3.1 Overview of the maintenance points Fig. -

Page 66: Further Maintenance

AFAG for repair within the warranty period. After expiry of the warranty period, the customer may replace or repair defective modules or wear parts himself or send them to the AFAG repair service. Please note that AFAG does not provide any warranty for modules that have... -

Page 67: Decommissioning And Disposal

▪ Electronic parts, electrical scrap, auxiliary and operating materials must be disposed of by approved specialist companies. ▪ Information on proper disposal can be obtained from the responsible local authorities. ◼ ◼ ◼ Assembly Instructions EN ES-20 I ES-30 25.05.2023 V1.7 67–69... -

Page 68: Declaration Of Incorporation

The relevant technical documentation was created according to Annex VII, Part B of the above-mentioned Directive. Authorised representative for compiling the technical documentation: Niklaus Röthlisberger, Product Manager, Afag Automation AG, CH-6144 Zell Zell, 31.05.2023 Adrian Fuchser Klaus Bott... - Page 69 Afag Automation Americas Afag Automation APAC Schaeff Machinery & Services LLC. Afag Automation Technology (Shanghai) Co., Ltd. 883 Seven Oaks Blvd, Suite 800 Room 102, 1/F, Bldg. 56, City Of Elite Smyrna, TN 37167 No.1000, Jinhai Road, Pudong New District...

Need help?

Do you have a question about the ES-20 and is the answer not in the manual?

Questions and answers