Subscribe to Our Youtube Channel

Summary of Contents for Afag LF9

- Page 1 Linear feeder LF9 / LF11 Translation of operating and installation instructions Copyright by Afag GmbH...

- Page 2 This operation instruction applies to: Type Order number 230 V / 50 Hz 15105783 Linear feeder 115 V / 60 Hz 15068632 Linear feeder LF11 230 V / 50 Hz 11005757 Version of Documentation: BA_LF9-11_R05.1_EN.docx Release: R05.1 Date: 12/02/2020 Page 2 12/02/2020 R05.1...

-

Page 3: Table Of Contents

Table of contents Safety instructions ....................4 Explanation of symbols and notes ......................4 Basic safety information ........................... 5 Intended use ............................. 5 Notes for Pacemakers and Defibrillators ....................5 Description of the LF linear feeder ................ 6 General ..............................6 Functional description .......................... -

Page 4: Safety Instructions

1 Safety instructions 1.1 Explanation of symbols and notes Symbols: Assembly and commissioning must be carried out by qualified person- nel only and according to these operating instructions. Please observe the meaning of the following symbols and notes. They are grouped into risk levels and classified according to ISO 3864-2. -

Page 5: Basic Safety Information

1.4 Notes for Pacemakers and Defibrillators Afag vibration conveyors are tested in accordance with regulation 15 of the German Statuto- ry Accident Insurance Association [Deutsche Gesetzliche Unfallversicherung, DGUV] (previ- ously BGV B11 of German Accident Prevention Regulations). The permissible values of ex- posure area 2 are not exceeded, therefore no measures are required pursuant to Section 4 (2) of the DGUV regulation 15. -

Page 6: Description Of The Lf Linear Feeder

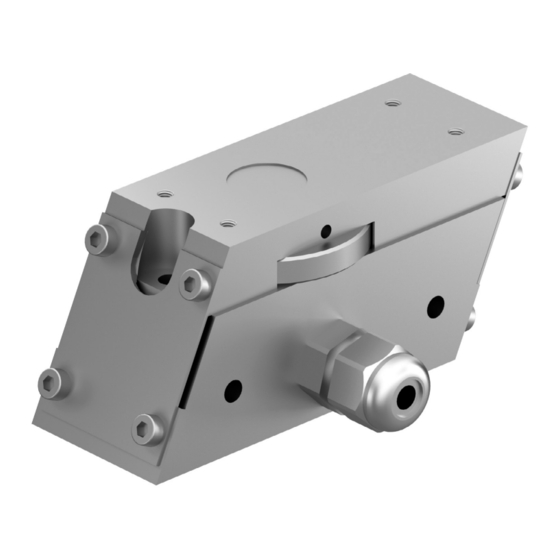

2.1 General The LF, together with a transport rail, is designed for feeding bulk materials. The LF must only be used in combination with the corresponding Afag controller. This combination guarantees optimum transport behaviour. The LF must be fixed onto a sufficiently solid support, in order to avoid the conduction of vibrations to other parts 2.2 Functional description... - Page 7 The magnet, connected to the support, creates a force which attracts reps. releases the oscillating plate dependent on the oscillation frequency of the power supply. The pulsating movement of the oscillation plate causes the material to jump from the rail at each oscillation and is conveyed as a result of the angle of inclination of the leaf springs.

-

Page 8: Technical Data

2.3 Technical data Figure 2 Dimensions LF Conveying direction Figure 3 Dimensions LF Page 8 12/02/2020 R05.1... - Page 9 Table 1: Technical data Description Units LF11 [mm] [mm] [mm] 106,15 [mm] Dimensions [mm] [mm] [mm] [mm] [mm] 13,2 [mm] [mm] Operating voltage [VAC] 230 / 115 Mains frequency [Hz] 50 / 60 Degree of protection [IP] Vibration frequency (full wave) [1/min] 6000 6000 / 7200...

-

Page 10: Assembly Instructions

3.2 Installing the unit The LF is firmly screwed to the foundation using the boreholes on the bottom. 2 screws in case of the LF9 are affixed from below. The use of mounting plates allows the optional mounting from above. -

Page 11: Mounting Of The Linear Track

A steel plate should be used which is at least 20mm thick and more than 120mm wide. Suitable substructures are to be provided for the height adjustment. Suitable afag stand- ard parts are available for complete station extensions in combination with afag helical conveyors. -

Page 12: Power Supply

3.4 Power supply WARNING ▪ Any work on the electrical supply may only be performed by trained, authorised, qualified personnel. ▪ The power supply must be protected by an FI switch (pro- vided by the customer). ▪ The helical conveyor may only be operated with the power supply specified on the name plate. -

Page 13: Operating Instructions

4 Operating instructions 4.1 Correlations between the transport speed and the LF spring package (See Figure 6) Basically the LF and the transport rail are adjusted in the standard configuration. This means that all oscillating elements are set optimally. The following factors however influence the combination LF / transport rail: The parts to be conveyed (size, weight, shape, material and quality) The feed rate The support... -

Page 14: Setting The Distance Between The Rail And The Support Surface

4.2 Setting the distance between the rail and the support surface This setting is only necessary when: All spring packages have been exchanged or re-assembled The LF has been dismantled WARNING Unplug the power cable, before proceeding with further actions! 1. -

Page 15: Torques

4.4 Torques Tightening torques M in Nm for shank screws with metric ISO control threads and head supports according to DIN 912 or DIN 931: Tightening torques M in Nm Screw Strength class 8.8 Strength class 10.9 Strength class 12.9 14,0 16,5 (M7) -

Page 16: Maintenance Instructions

Unplug the power cable, before proceeding with further actions! Interruptions caused by defective components must be repaired by replacing the defec- tive component, only. NOTE Defective components must only be replaced by Afag original spare parts. Page 16 12/02/2020 R05.1... - Page 17 Linear feeder does not run after switching it on Cause of fault: Fault repair Plug not connected Connect plug Connecting cable between bowl feeder Connect plug and controller not plugged in Regulator on controller set to „0“ Turn regulator to position Defective fuse in control unit Replace fuse Bowl feeder lacks performance after operating for a certain length of time...

-

Page 18: Replacing Springs Or Spring Packages

5.2 Replacing springs or spring packages (See Figure 7) This procedure is only necessary when: The oscillating behaviour of the LF has changed A spring is broken WARNING Unplug the power cable, before proceeding with further actions! NOTE Spring packages must contain the same leaf spring type! The relevant spring cross section can be taken from chapter 2.3. - Page 19 Figure 7 R05.1 12/02/2020 Page 19...

-

Page 20: Replacing The Magnetic Coil

5.3 Replacing the magnetic coil (see Figure 8) This procedure is only necessary when: The magnetic coil is defective WARNING Unplug the power cable, before proceeding with further actions! 1. Loosen the screws (1) on the oscillation plate (2) and remove the entire unit 2. - Page 21 Figure 8 R05.1 12/02/2020 Page 21...

-

Page 22: Setting The Air Gap Between Magnetic Coil And Anchor Bolt

1. Turn the anchor bolt , therefore: (see Figure 9,Figure 10) LF9: Loosen socket screw (2.5 mm). Turn the anchor screw (3) with your hand into the corresponding direction. 2. The air-gap between magnetic coil (4) and anchor screw (3) is to be adjusted by... -

Page 23: Spare And Wearing Parts

Figure 9 Figure 10 Figure 11 5.5 Spare and wearing parts Table 2: Wear parts Type Pos. Designation Order number LF 9 Leaf spring 0,7mm 15184920 LF 11 Leaf spring 0,5mm 11006743 R05.1 12/02/2020 Page 23... -

Page 24: Accessories

For a detailed description of the control devices, please refer to the AFAG general catalogue. Non-OEM control devices can also be used for as long as they meet the technical requirements. -

Page 25: Address For Orders

6.3 Address for orders Germany: Switzerland: Afag GmbH Afag Automation AG Wernher-von-Braun-Straße 1 Zuführtechnik D – 92224 Amberg Fiechtenstrasse32 CH – 4950 Huttwil Tel.: ++49 (0) 96 21 / 65 0 27-0 Fax: ++49 (0) 96 21 / 65 0 27-490 Tel.: ++41 (0) 62 / 959 86 86...

Need help?

Do you have a question about the LF9 and is the answer not in the manual?

Questions and answers