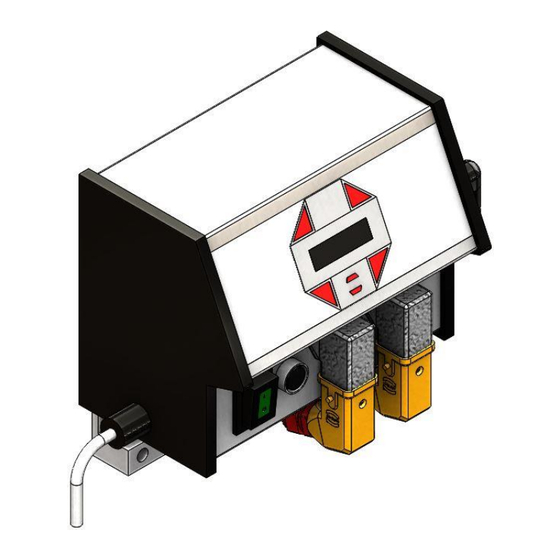

RNA ESK 2001 Operating Instructions Manual

Controllers for vibratory drive systems

Hide thumbs

Also See for ESK 2001:

- Operating instructions manual (20 pages) ,

- Operating instructions manual (17 pages) ,

- Operating instructions manual (24 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for RNA ESK 2001

- Page 1 Operating Instructions Controllers Vibratory Drive Systems ESK 2001...

-

Page 2: Table Of Contents

Table of Contents About this document ......................4 Safety information ........................4 2.1. Design of safety directives ....................4 2.2. Fundamental safety directives .................... 4 2.3. Personnel ..........................4 2.4. Intended use ........................5 2.5. Residual hazards ........................ 5 2.5.1. Device .......................... - Page 3 Declaration of Conformity According to the Low-Voltage Directive 2014/35/EU and Electromagnetic Compatibility Directive 2014/30/EU We hereby declare that the product meets the following requirements: Low-Voltage Directive 2014/35/EC Electromagnetic Compatibility Directive 2014/30/EU The following harmonized standards have been applied: DIN EN 60204 T1, EN 61439-1 See separate Declaration of Conformity provided on delivery Remarks: The controllers have been manufactured in accordance with the Low Voltage Directive 2014/35/EU and are...

-

Page 4: About This Document

1. About this document Attention Read this document carefully and observe the safety directives before commencing any work. Document description: This document provides assistance in choosing your product. You will also find information on mechanical and electrical installation, operation, product extensions and accessories. Non-observance may cause trouble with the product or the environment, reduce the product lifetime or lead to other damage. -

Page 5: Intended Use

Use of the product in living areas may lead to EMC disturbance. The user is responsible for taking interference suppression measures. • They are optimised for operation of RNA bowl feeders and linear feeders. Observe the limits indi- cated in the technical specification. Attention! •... -

Page 6: Degree Of Protection - Protection Of Persons And Equipment

2.5.3. Degree of protection - Protection of persons and equipment • All specifications relate to installed condition ready for operation. • All slots not used must be closed by protection caps or dummy plugs in order not to reduce the pro- tection against accidental contact. -

Page 7: Technical Data

IP 54 Degree of protection: Less than 2mA Leakage current max. 30W Power loss 3.4. Accessories Designation RNA article code XS1, XS2 Load connector, 5-pin 31002323 (100Hz drives) XS1, XS2 Load connector, 5-pin 31002322 (50Hz drives) Male connector, 5-pole, straight 35051144... -

Page 8: Modes Of Operation

Vibratory drive systems by RNA do not require the operator to take care of selecting the right operating mode. The operating mode is determined by a code in the RNA vibrating drive connector. A wire jumper from pin 3 to 4 in the connector switches the controller to mode 2: 100 or 120 Hz. In the absence of this wire jumper the controller operates in mode 1: 50 or 60 Hz. -

Page 9: Sensor Inputs And Sensor Linkages

4.3. Sensor inputs and sensor linkages Two sensor inputs are integrated into the controller. They enable you to implement accumulation checks, level checks, cycle monitoring and other monitoring tasks. The following basic assignments are made: Sensor input 1 acts on channel 1, unless otherwise programmed in menu C006. Sensor input 2 acts on channel 2. -

Page 10: Status Outputs And Relays

4.5. Status outputs and relays The status outputs are used for remote diagnostics of the controller status or of the links of several controllers with one another. They are designed as freely available NPN-doped transistor circuits and they are floating. With the status output READY the transistor circuit is switched through whenever the controller is connected to power supply and switched on by its power switch closed. -

Page 11: Starting-Up The Controller

The controller display (membrane keypad) On / Off Pressing this button switches off all connected devices. The display shows "OFF". The controller remains ready for operation. Cursor up and cursor down Use these buttons to scroll through the controller menu or set the parameters. Enter Press this button to acknowledge the parameters entered with the cursor. -

Page 12: Description Of Individual Codes For Controller Programming

CODE Calling-up the software version Definition: 411. 57. 10. 23.11.99 Device type: KANAL l KANAL 2 Date 59 = ESK 2001 CODE Version No. 58 = ESG 2001 Device type 57 = ESK 2000 Internal No. 56 = ESG 2000... -

Page 13: Application-Specific Changes To Default Settings

Save and return to Return main menu (*) For RNA feeders with 200 V magnets = 90 % (1) Only for channel 2: After removal of the enabling signal channel 2 switches off with a delay (5 minutes). Rhein-Nadel Automation GmbH... -

Page 14: Code C003 Seal Setpoint

5.5.2. Code C003 Seal setpoint Objective: Sealing-in the setpoints in the main menu. A direct change of the values is no longer possible. You can only make changes now through codes C001 and C002. Select code Set code Code C003 KANAL l KANAL 2 CODE... - Page 15 Logic with blowing-off I = active the exit tracks 0 = not active AND logic without blowing I = active off the exit tracks 0 = not active (Version No. 10 and higher) OR logic I = active 0 = not active Min/Max logic I = active 0 = not active...

- Page 16 AND logic of the two sensor inputs without blowing-off the exit track. Bowl feeder (channel 1) stops when both sensors are operated. Orienting air can be switched off with delay (4 sec.) via relay K2. OR logic of the two sensor inputs. Bowl feeder (channel 1) stops when one of the two sensors is operated.

-

Page 17: Code C008 Cycle Monitoring

5.5.5. Code C008 cycle monitoring Objective: Monitoring of sensors 1 (accumulation check) and/or 2. When activating the cycle monitoring function, the "AND, SOL" links in code C006 must not be acti- vated!!! Select code Set code KANAL l KANAL 2 CODE Code C008 Sensor input 1 is moni-... -

Page 18: Code C009 Show Status

5.5.6. Code C009 Show status Objective: Checking of the set vibrating frequency and of the sensor inputs. Select code Set code Code C009 KANAL l KANAL 2 CODE External enabling signal I = active 0 = not active Channel 1 Channel 1 vibrating fre- I = 50 Hz quency... -

Page 19: Code C100 Setting The Feed Rate By External Voltage Input

5.5.8. Code C100 Setting the feed rate by external voltage input. Objective: Setpoint change by external voltage Select code Set code Code C100 External voltage applica- I = active tion to channel 1 0 = not active External voltage applica- I = active tion to channel 2 0 = not active... -

Page 20: Code C210 Retrieving Parameters

5.5.10. Code C210 Retrieving parameters Objective: Resetting to default values or retrieving stored application-specific settings Select code Set code Code C210 Factory setting Application-specific rameters Save and return to Return main menu FAC Select and acknowledge FAC to apply the factory default settings US.PA.: Select and acknowledge US.PA to retrieve the application-specific set of parameters previously saved under C143. -

Page 21: Dimensioned Drawing

7. Dimensioned drawing Rhein-Nadel Automation GmbH VT-BA-ESK2001_EN_2023.docxVT-BA-ESK2001_EN_2023.docx... -

Page 22: Connection Diagram

8. Connection diagram Rhein-Nadel Automation GmbH VT-BA-ESK2001_EN_2023.docxVT-BA-ESK2001_EN_2023.docx... - Page 23 Headquarters Rhein-Nadel Automation GmbH Reichsweg 19-23 D-52068 Aachen Phone: +49 (0)241-5109-0 E-mail: vertrieb@RNA.de www.RNA.de Further manufacturing sites Further RNA group companies: of the RNA Group Lüdenscheid site PSA Zuführtechnik GmbH Rhein-Nadel Automation GmbH Steinäckerstraße 7 Nottebohmstraße 57 D-74549 Wolpertshausen D-58511 Lüdenscheid...

Need help?

Do you have a question about the ESK 2001 and is the answer not in the manual?

Questions and answers