Summary of Contents for PS Automation PSF Series

- Page 1 Operating Instructions Version 2023/09/28 Art.No.: 8035613 ©2023 PS Automation GmbH Subject to changes...

-

Page 2: Table Of Contents

Contents Type key .................................... 2 1. Symbols and safety ............................... 3 2. Usage as per specification ............................. 4 3. Storage ..................................4 4. Operating conditions and installation position ......................4 5. Function ..................................5 6. Manual operation ................................. 5 7. Valve mounting ................................6 7.1 Valve mounting spring extend (SE) ......................... -

Page 3: Symbols And Safety

1. Symbols and safety General dangers of non-compliance with safety regulations PSF actuators are built at state-of the art technology and are safe to operate. Despite of this, the actuators may be hazardous if operated by personnel that has not been sufficiently trained or minimum instructed, and if the actuators are handled improperly, or not used as per specification. -

Page 4: Usage As Per Specification

2. Usage as per specification PSF actuators are exclusively designed to be used as electric valve actuators. They are meant to be mounted on valves in order to run their motors. Any other use is considered to be non-compliant and the manufacturer cannot be held liable for any damage resulting from it. -

Page 5: Function

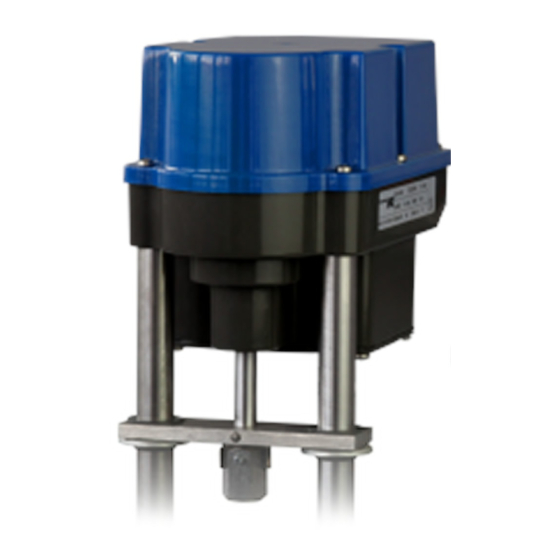

Installation position Outdoor usage: When using the actuators in environments with high temperature fluctuations or high humidity, we recommend using a heating resistor. Figure 2: Installation positions 5. Function The PSF actuators are designed as electric valve actuators with failsafe function. The actuator is mounted onto the valve via pillars. -

Page 6: Valve Mounting

7. Valve mounting pillar spring clamp with coupling pin coupling locking nut valve stem 1 mm bracket pillar nut Figure 4: Valve mounting 7.1 Valve mounting spring extend (SE) Initial position: Valve stem is retracted 1. Put actuator onto the bracket. 2. -

Page 7: Removing / Closing The Cover

8. Removing / closing the cover Open the cover only in a dry environment. Attention! Observe precautions for handling. Ground the actuator. Before opening the cover, touch grounded housing parts. Open: Loosen the screws by using a screwdriver and unscrew them entirely out of the gear casing. -

Page 8: Wiring Diagram

9.2 Wiring diagram Figure 6 indicates the electrical connections for standard actuators. The wiring diagram inside the actuator is binding for the specific actuator wiring. For any optional accessories, see the separate wiring diagram in the corresponding installation instructions. *optional Figure 6: Wiring diagram PE earth connection has to be connected to gear casing at Ensure that all connecting cables are stripped to the correct length so that they are protected... -

Page 9: Signalisation / Functions

10. Signalisation / functions 10.1 DIP switch Function Signal set value position feedback Voltage Current Function Control via analogue set value Control via binary inputs Extend valve stem with increasing set value Retract valve stem with increasing set value Close with force / Open with force Close with force / Open with 20 mm stroke Close with force / Open with 30 mm stroke Close with force / Open with 40 mm stroke... -

Page 10: Operating Direction

10.2 Operating direction SE = Spring Extend: Extend actuator stem / retract valve stem SR = Spring Retract: Retract actuator stem / extend valve stem Figure 7: Operating direction 10.3 Operator push button Function Action push button B1 push button B2 LED sequence >... -

Page 11: Status Display

Exit Push 1 x Red or green LED is on 10.4 Status display Green LED Red LED Actuator not commissioned is flashing quickly Normal operation / actuator running Normal operation / actuator stationary Manual mode active is flashing alternately is flashing alternately Manual mode: Extend valve stem is flashing Manual mode: Retract valve stem... -

Page 12: Manual Operation

After successful commissioning, check the found or adjusted stroke by comparing the set value and the valve position. In case of unsuccessful commissioning the green LED is flashing quickly. Please check valve mounting. For commissioning, a stroke of at least 1 mm in direction “close with force” is required before the actuator has reached its mechanical stop. -

Page 13: Maintenance

13.2 Maintenance The actuators have a pre-tensioned spring inside, the gearbox housing must not be opened. Defective actuators should be returned to our plant in Bad Duerkheim, Germany, or to our representatives, to be checked for damages and their possible causes. 13.3 Spare parts Damaged actuators should be returned to our plant in Bad Dürkheim, Germany, or to our representatives, to be checked for damages and their possible causes. -

Page 14: Ec Declaration Of Conformity

15.2 EC Declaration of Conformity... -

Page 15: Ca Declaration Of Conformity

15.3 CA Declaration of Conformity... - Page 16 Our representatives: Italy India PS Automazione S.r.l. PS Automation India Pvt. Ltd. Via Pennella, 94 Srv. No. 25/1, Narhe Industrial Area, I-38057 Pergine Valsugana (TN) A.P. Narhegaon, Tal. Haveli, Dist. Tel.: <+39> 04 61-53 43 67 IND-411041 Pune Fax: <+39> 04 61-50 48 62 Tel.: <+ 91>...

Need help?

Do you have a question about the PSF Series and is the answer not in the manual?

Questions and answers