Summary of Contents for PS Automation PSF-Q EX Series

- Page 1 PSF-Q-M-EX 2014/34/EU (IECEX) Operating Instructions Version 28/05/2024 Art.No.: 8035801 ©2024 PS Automation GmbH...

-

Page 2: Table Of Contents

Content 1. Product description ............................... 2 2. Applicable standards ..............................3 3. Key figures ..................................4 3.1 Type key .................................. 5 4. Symbols used and safety ............................... 5 5. Intended use ................................. 6 5.1 Special conditions ..............................7 6. Storage ..................................7 7. -

Page 3: Applicable Standards

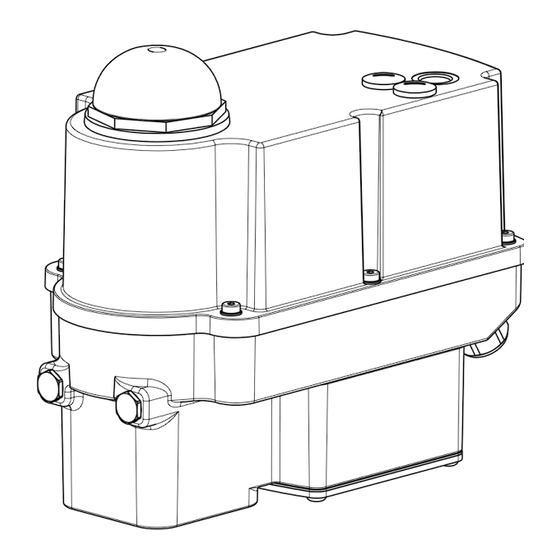

Conduit entries are available in the lower section of the housing for inserting the electrical cables. The construction, as well as the interaction of the individual components and the housing regarding their suitability for use in hazardous areas, are tested by PS Automation GmbH and confirmed by the identification with the type label. -

Page 4: Key Figures

3. Key figures Certificate number IECEx TPS 22.0019X Ex marking Ex db eb IIC T6 Gb Ex db eb IIC T4 Gb or rather Ex tb IIIC T80 °C Db Ex tb IIIC T100 °C Db Enclosure size approx. 135 x 245 x 202 mm (BxLxH) (Ex e/Ex t housing) Actuating power Depending on variant... -

Page 5: Type Key

Type key 22 W / 50 Nm / 25 s / PSF-Q-M50-EX/ Example CW / CCW / 24 VAC / 50-60 Hz PSF-Q-M80-EX 28 W 80 Nm 30 s Actuator type (output valve shaft clockwise) / (output valve shaft counterclockwise) Voltage supply Frequency Max. -

Page 6: Intended Use

Notice of hazards The following hazard symbols are used in these instructions: Attention! There are general hazards that can lead to property and/or personal injury. Caution! Life threatening electrical voltages may be present! Danger! This symbol warns of an imminent danger to the health of persons. Failure to follow these notices may result in injury. -

Page 7: Special Conditions

• Mounting and adjustment of the actuator as well as its maintenance are not considered as intended use. Enhanced safety precautions must be implemented in such situations! • Assembly/disassembly, operating and maintenance work may only be carried out by suitable skilled personnel familiar with the work. - Page 8 Installation • The conductor must be connected carefully at the terminal points so that the individual wires are not damaged. The maximum connection data on the type plate and the applicable documents must be taken into consideration. • The device must be integrated into a suitable earthing or equipotential bonding system before commissioning, a connection part (4 mm²) is available for this purpose on the underside of the actuator.

-

Page 9: Manual Override And Setting Of The Dip Switches

8. Manual override and setting of the DIP switches 8.1 Setting the actuators during commissioning (cover open) When commissioning the actuators, the cover must be opened. The cover may only be opened in non-hazardous areas and only in a dry environment (see chapter 11 for instructions). To actuate the actuator during setting work (valve assembly and end position setting), an electrical manual override by means of a push button is available (for operation, see chapter 14.3). -

Page 10: Setting The Actuators During Operation (Cover Closed)

8.2 Setting the actuators during operation (cover closed) To actuate the actuator during setting work in potentially explosive atmospheres (end position setting), an electrical manual override by means of a push button is provided in the cover (for conditions see chapter 14.3). To reach the manual override, the screw plugs must be opened. -

Page 11: Valve Mounting

9. Valve mounting The PSF-Q-M-EX actuators are designed with a mechanical interface according to ISO 5211 for valve mounting. The gear contains an exchangeable drive bush to connect the actuator to the valve shaft. • Check if the actuator flange suits the valve flange. •... -

Page 12: Opening And Closing The Cover

11. Opening and closing the cover The cover may only be opened in non-hazardous areas and only in a dry environment. Take appropriate ESD handling precautions before opening the housing: • Earth the actuator. • Touch earthed housing parts before opening the cover. Hexagon socket Opening: screw... -

Page 13: Electric Supply

13. Electric supply 13.1 Safety instructions During the connection of the mains voltage, this must be disconnected and secured against unintended reactivation. The actuator cover must be opened for the electrical connection (see chapter 11). The mains connection cables must be designed for the nominal current of the actuator. Yellow-green coloured wiring shall be used only for connecting the protective earth connections. -

Page 14: Connection Diagram

13.2 Connection diagram Figure 9 shows the electrical connection for standard drives. The wiring diagram in the actuator is binding for the connection. For the connection of optional accessories, please refer to the respective operating instructions. Figure 10: Connection for potential Figure 9: Electrical connection equalisation PE earth connection has to be connected to gear casing at... -

Page 15: Signalisation And Functions

14. Signalisation and functions 14.1 DIP switches Function Function Signal Set Value Position feedback Voltage Current Function Control via set value Control via binary inputs Output valve shaft counterclockwise (CCW) with increasing set value Output valve shaft clockwise (CW) with increasing set value Close with torque / Open with torque... -

Page 16: Handwheel

14.2 Handwheel • Push the handwheel towards the gear casing: the motor is deactivated. • Hold down and turn the handwheel: CW: Valve shaft clockwise (CW). CCW: Valve shaft counterclockwise (CCW). • Release the handwheel: the handwheel is out of function, the motor is reactivated after 5 seconds. Figure 11: Handwheel... -

Page 17: Operator Push Buttons

14.3 Operator push buttons Function Action Push button B1 Push button B2 LED sequence Both LEDs are flashing Activate > Push 3 seconds > Push 3 seconds alternately Output valve shaft Push Green LED is flashing clockwise (CW) Manual Output valve shaft Push Red LED is flashing Operation... -

Page 18: Status Display

14.4 Status display Green LED Red LED Actuator not commissioned Is flashing quickly Normal operation / Actuator running Normal operation / Actuator stationary Manual mode active Is flashing alternately Is flashing alternately Manual mode: output valve shaft Is flashing counterclockwise (CCW) Manual mode: output valve shaft Is flashing clockwise (CW) -

Page 19: Manual Commissioning (See Also Chapter 14.3)

14.6 Manual commissioning (see also chapter 14.3) • Ensure secure connection between valve and actuator. • To activate the individual commissioning push button B1 for minimum 7 seconds. • For manual operation use push buttons B1 and B2 until the required open valve position is reached. •... -

Page 20: Operation

15. Operation The operator of an electrical system in a potentially explosive environment must keep the equipment in proper condition, operate it properly, monitor it and carry out maintenance and repair work. See also IEC/EN 60079- 17/IEC/EN 60079-19. During operation, all internal parameters, such as the required motor torque and the current position, as well as the operating states of the actuator are continuously monitored. -

Page 21: Valve Curve

15.2 Valve curve Switch position S2-10 can be used to select the relationship between the set value and the actuator position. Two curves are available. With the linear valve curve, the actuator position in % corresponds to the set value in %. The "Quick Opening Curve"... -

Page 22: Maintenance

17. Maintenance The actuators are maintenance-free if used under the operating conditions as designated in the data sheet. The gearboxes are lubricated for life and do not require further lubrication. Caution! During maintenance and repair the actuator must not be operated electrically. Personnel carrying out work and maintenance and servicing must be skilled and familiar with the work. -

Page 23: Decommissioning And Disposal

18. Decommissioning and disposal • Disconnect the mains supply and ensure that it is secured against an accidental switching-on. • Open the cover. • Remove external electrical connections. • Take off the actuator from the valve. Disposal For its disposal, the product should be treated as waste containing electrical and electronic equipment and should not be disposed of as household waste. - Page 24 Our representatives: Italy India PS Automazione S.r.l. PS Automation India Pvt. Ltd. Via Pennella, 94 Srv. No. 25/1, Narhe Industrial Area, I-38057 Pergine Valsugana (TN) A.P. Narhegaon, Tal. Haveli, Dist. Tel.: <+39> 04 61-53 43 67 IND-411041 Pune Fax: <+39> 04 61-50 48 62 Tel.: <+ 91>...

Need help?

Do you have a question about the PSF-Q EX Series and is the answer not in the manual?

Questions and answers