PS Automation PSF402.2 Operating Instructions Manual

Hide thumbs

Also See for PSF402.2:

- Short operating instructions (12 pages) ,

- Operating instructions manual (16 pages) ,

- Operating instructions manual (16 pages)

Summary of Contents for PS Automation PSF402.2

- Page 1 Operating Instructions PSF402.2 Version 2017/05/30 ©2017 PS Automation GmbH Subject to changes! ...

-

Page 2: Table Of Contents

Contents Type key .................................... 2 1. Symbols and safety ............................... 3 2. Usage as per specification ............................. 4 3. Storage .................................. 4 4. Operating conditions and installation position ...................... 4 5. Function .................................. 5 6. Manual operation ................................. 5 7. Valve mounting ................................ 6 7.1 Valve mounting spring extend (SE) ......................... 6 7.2 Valve mounting spring retract (SR) ......................... 6 8. Removing / closing the cover ............................ 7 9. Electric supply ................................ 7 9.1 Safety instructions .............................. 7 9.2 Wiring diagram ................................ 8 10. Signalisation / functions .............................. 8 10.1 DIP switch ................................ 8 10.2 Operating direction ............................... 9 10.3 Operator push button ............................ 9 10.4 Status display .............................. 10 10.5 Automatic commissioning ........................... 10 10.6 Manual commissioning ............................ 11 10.7 Manual operation ............................... 11 ... -

Page 3: Symbols And Safety

1. Symbols and safety General dangers of non‐compliance with safety regulations PSF actuators are built at state‐of the art technology and are safe to operate. Despite of this, the actuators may be hazardous if operated by personnel that has not been sufficiently trained or minimum instructed, and if the actuators are handled improperly, or not used as per specification. This may cause danger to life and limb of the user or a third party, damage the actuator and other property belonging to the owner, reduce safety and function of the actuator. To prevent such problems, please ensure that these operating instructions and this chapter in particular have been read and understood by all personnel involved in the installation, commissioning, operation, maintenance and repair of the actuators. Basic safety notes The actuators may only be operated by skilled and authorized operating personnel. Make sure to follow all security advices mentioned in this manual, any national rules for accident prevention, as well as the owner´s instructions for work, operation and safety. The isolating procedures specified in these operating instructions must be followed for all work pertaining to the installation, commissioning, operation, change of operating conditions and modes, maintenance, inspection, repair and installation of accessories. Areas that can be under voltage have to be isolated before working on them. Ensure that the actuators are always operated in faultless condition. Any damage or faults, and changes in the operational characteristics that may affect safety, must be reported at once. Danger signs The following danger signs are used in this operating manual: Caution! There is a general risk of damage related to health and/or properties. Danger! Electrical voltages are present that may lead to death. Life threatening risks may occur due to electrical voltages! ... -

Page 4: Usage As Per Specification

2. Usage as per specification PSF actuators are exclusively designed to be used as electric valve actuators. They are meant to be mounted on valves in order to run their motors. Any other use is considered to be non‐compliant and the manufacturer cannot be held liable for any damage resulting from it. The actuators can only be used within the limits laid out in the data sheets, catalogues and other documents. Otherwise, the manufacturer cannot be held liable for any resulting damage. Usage as per specification includes the observance of the operating, service and maintenance conditions laid down by the manufacturer. Not to be regarded as usage as per specification are mounting and adjusting the actuator as well as servicing. Special precautions have to be taken while doing this! The actuators may only be used, serviced and repaired by personnel that is familiar with them and informed about potential hazards. The specific regulations for the prevention of accidents have to be observed. Damages caused by unauthorized modifications carried out on the actuators are excluded from the manufacturer's liability. Supply voltage may only be switched on after the proper closure of the main cover or terminal box. 3. Storage For appropriate storage, the following instructions have to be met: Only store the actuators in ventilated, dry rooms. Store the actuators on shelves, wooden boards, etc., to protect them from soil moisture. Cover the actuators with plastic foil to protect them from dust and dirt. Protect the actuators against mechanical damage. 4. Operating conditions and installation position Standard actuators may be operated at ambient temperatures according to the technical data sheet. Operating modes correspond to IEC 60034‐1, 8: S2 for short cycle and S4 for modulating operation. ... -

Page 5: Function

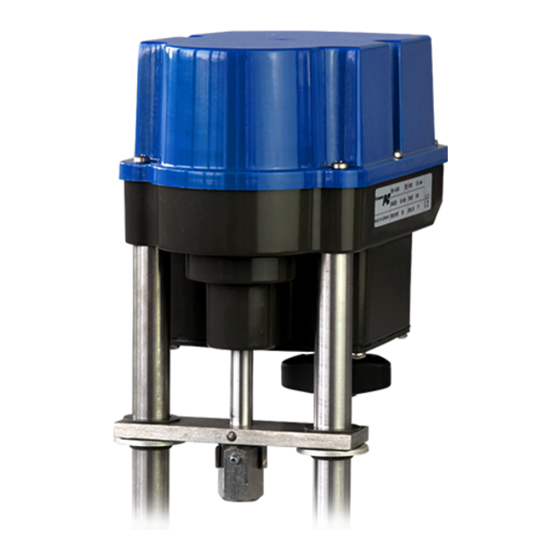

Installation position Outdoor usage: When using the actuators in environments with high temperature fluctuations or high humidity, we recommend using a heating resistor. Figure 2: Installation positions 5. Function The PSF actuators are designed as electric valve actuators with failsafe function. The actuator is mounted onto the valve via pillars. Depending on the type of valve used, mounting pillars or a special valve mounting bracket is required. Based on a brushless DC motor (BLDC) the generated torque is transmitted via a multi‐stage spur gear onto a spindle nut. The spindle nut transmits the input torque into an axial thrust force via a spindle. The linear stroke is transmitted to the valve spindle by a coupling piece. The stroke is measured and controlled by a linear 12 Bit Hall sensor. In case of mains power loss, the stroke movement is in OPEN or CLOSE direction by spring force. Electrical wiring is done to a terminal block under the actuator cover. 6. Manual operation Two push buttons are installed to drive the actuator in case of installation work such as mounting onto a valve, or setting the limit switches positions (see 10.7). ... -

Page 6: Valve Mounting

7. Valve mounting pillar spring clamp with coupling pin coupling locking nut valve stem 1 mm bracket pillar nut Figure 4: Valve mounting 7.1 Valve mounting spring extend (SE) Initial position: Valve stem is retracted 1. Put actuator onto the bracket. 2. Remove the coupling pin and screw the coupling 13 mm on the valve stem. There must be a 1 mm gap between the pillars and the bracket. 3. Insert the coupling pin again and fix the locking nut. 4. Connect the actuator to electric supply (see 9.). 5. -

Page 7: Removing / Closing The Cover

8. Removing / closing the cover Open the cover only in a dry environment. Attention! Observe precautions for handling. Ground the actuator. Before opening the cover, touch grounded housing parts. Open: Loosen the screws by using a screwdriver and unscrew them entirely out of the gear casing. The screws are protected against loss. Open the cover only in a dry environment. Close: Put the cover on the gear casing and press down slightly. Tighten the screws gently and then crosswise. ... -

Page 8: Wiring Diagram

9.2 Wiring diagram Figure 6 indicates the electrical connections for standard actuators. The wiring diagram inside the actuator is binding for the specific actuator wiring. For any optional accessories, see the separate wiring diagram in the corresponding installation instructions. Figure 6: Wiring diagram PE earth connection has to be connected to gear casing at ! 10. Signalisation / functions 10.1 DIP switch S1 1 2 3 4 5 6 7 8 Function Signal set value ... -

Page 9: Operating Direction

7 S2 Function 1 2 3 4 5 6 Off On Split‐range low: 0‐5 V / 0‐10 mA Off On Split‐range low: 2‐6 V / 4‐12 mA Off Cut‐off by force if valve stem is in extended position On ... -

Page 10: Status Display

Function Action push button B1 Push button B2 LED sequence Start Push 7 seconds Both LEDs are on Green LED is flashing 7x (if commissioning is finished), Automatic Commissioning finished green LED is flashing commissioning quickly (if commissioning failed) Exit Push 1 x Red or green LED is on Both LEDs are flashing Activate Push 7 seconds alternately Manual Rectract valve stem Push Green LED is flashing commissioning Extend valve stem Push ... -

Page 11: Manual Commissioning

Push button B1 to return to normal operation. After successful commissioning, check the found or adjusted stroke by comparing the set value and the valve position. In case of unsuccessful commissioning the green LED is flashing quickly. Please check valve mounting. For commissioning a stroke of at least 1 mm in direction “close with force” is required before the actuator has reached its mechanical stop. Furthermore, the actuator must be able to perform a stroke of at least 5 mm. 10.6 Manual commissioning Ensure secure connection between valve and actuator. To activate the individual commissioning push button B1 for minimum 7 seconds. For manual operation use push buttons B1 and B2 until the required open valve position is reached. Start commissioning of both positions and store them by simultaneously pushing the buttons B1 and B2 for minimum 3 seconds. After successful commissioning, the green LED is flashing 7 times. Push button B1 to return to normal operation. After successful commissioning, check the found or adjusted stroke by comparing the set value and the valve position. In case of unsuccessful commissioning the green LED is flashing quickly. Please check valve mounting. For commissioning, a stroke of at least 1 mm in direction “close with force” is required before the actuator has reached its mechanical stop. Furthermore, the actuator must be able to perform a stroke of at least 5 mm. 10.7 Manual operation Push button B1 and B2 simultaneously for minimum 3 seconds to change to manual operation mode. Push button B1 to retract valve stem. Push button B2 to extend valve stem. Push button B1 and B2 simultaneously for minimum 3 seconds to exit from manual operation mode. ... -

Page 12: Split Range

11.1 Split Range The setting “set value/splitrange” at S2‐3/4/9 splits the set value into an upper and a lower range. Due to this function multiple actuators can be controlled by only one set value signal. Set value Actuator 1 Actuator 2 ... -

Page 13: Commissioning

12. Commissioning Open the cover (see chapter 8.), put the actuator on the valve (see chapter 7.), connect the electric supply (see chapter 9.). Perform automatic (see chapter 10.5) or manual (see chapter 10.6). Close the cover. 13. Maintenance The actuators are maintenance‐free if used under the operating conditions as designated in the data sheet. The gearboxes are lubricated for life and do not require further lubrication. Caution ! During maintenance and repair the actuator must not be operated electrically. 13.1 Cleaning The actuators should be cleaned dryly. Do not use abrasive cleaning agents or cleaning products containing solvents as the labelling of the safety stickers and the type plate might become illegible. Do not operate the actuator during the cleaning process. 13.2 Maintenance The actuators have a pre‐tensioned spring inside, the gearbox housing must not be opened. Defective actuators should be returned to our plant in Bad Duerkheim, Germany, or to our representatives, to be checked for damages and their possible causes. 13.3 Spare parts Damaged actuators should be returned to our plant in Bad Dürkheim, Germany, or to our representatives, to be checked for damages and their possible causes. 14. Decommissioning and disposal Disconnect the mains supply and ensure that it is secured against an accidental switching‐on. ... -

Page 14: Appendix

15. Appendix 15.1 Accessoires Various options are available in order to adapt the actuators to the various service conditions. For technical data, please refer to the respective data sheets. 2 potential‐free position switches, mechanical, with silver‐plated changeover Position signal 2WE contacts switches, mechanical 24 V to 230 V AC/DC @ 0.1 A – 5 A Position signal 2 potential‐free position switches, mechanical, with gold‐plated changeover 2WE switches gold, contacts gold mechanical 5 V to 30 V AC/DC @ 1 mA – 100 mA; contact resistance 30 mOhm 2 position signal relays with changeover contacts, calibrated automatically to valve stroke Position signal relays 24 V to 230 V AC/DC @ 0.1 A – 1 A Switching point adjustable 0‐100 % of the stroke using potentiometers Heating resistor HR Heating resistor to prevent condensation Wide range power supply For 100 ‐ 240 VAC 1~ supply voltage Increased enclosure IP Increase of enclosure to IP67 14 ... -

Page 15: Declaration Of Incorporation Of Part Completed Machinery And Declaration Of Conformity In Compliance With The Directives On Emc And Low Voltage

15.2 Declaration of incorporation of part completed machinery and declaration of conformity in compliance with the directives on EMC and low voltage ... - Page 16 Great Britain Hong Kong IMTEX Controls Ltd. MaxAuto Company Ltd. Unit 5A, Valley Industries, Room 2008, 20/F., CCT Telecom Building Hadlow Road 11 Wo Shing Street GB‐Tonbridge, Kent TN11 0AH Fotan, Shatin, Hong Kong Tel.: <+44> (0) 17 32‐85 03 60 Tel.: <+852> 26 87‐50 00 Fax: <+44> (0) 17 32‐85 21 33 Fax: <+852> 81 01‐37 43 eMail: sales@imtex‐controls.com eMail: info@maxonic.com.hk www.imtex‐controls.com www.maxonicauto.com Italy China PS Automazione S.r.l. Shenzhen Maxonic Automation Via Pennella, 94 Control Co., Ltd. I‐38057 Pergine Valsugana (TN) Maxonic Automation Control Mansion Tel.: <+39> 04 61‐53 43 67 ...

Need help?

Do you have a question about the PSF402.2 and is the answer not in the manual?

Questions and answers

In case of loss of electrical energy, what is the valve position? close,open last posiion

The valve position of the PS Automation PSF402.2 in case of loss of electrical energy is not specified in the provided context.

This answer is automatically generated