Subscribe to Our Youtube Channel

Summary of Contents for ABB Terra HP Generation 3 CE

- Page 1 Installation manual Terra HP Generation 3 CE 175 kW Static DC system © Copyright 2022 ABB. All rights reserved...

- Page 2 Copyright All rights to copyrights, registered trademarks, and trademarks reside with their respective owners. ® Copyright ABB E-Mobility B.V.. All rights reserved. 9AKK107992A2254-EN | 005...

-

Page 3: Table Of Contents

Contents Contents About this document................8 Function of this document...................... 8 Target group..........................8 Revision history..........................8 Language.............................8 Illustrations..........................8 Units of measurement......................8 Typographical conventions..................... 8 How to use this document...................... 8 General symbols and signal words..................9 1.10 Special symbols for warnings and dangers............... 10 1.11 Colors of lines in schematic drawings.................10 1.12... - Page 4 Contents 3.5.3 DC output busbar in a static DC system............23 3.5.4 Charge post CP500 Generation 3, outside............23 3.5.5 Charge post CP500 Generation 3, inside............24 3.5.6 Overview of the cable glands of the charge post..........25 External residual-current device...................25 Options............................

- Page 5 Contents 6.3.2 Remove the cable gland plates................41 6.3.3 Install the charge post on the foundation............41 6.3.4 Install the cable gland plates................42 Electrical installation of the power cabinet........43 General procedure........................43 Connect the PE cables to the power cabinet..............43 Connect the AC input cable....................44 Connect the DC power cables, static 175 kW system............

- Page 6 Contents 11.4 Connect a wire that has a cable lug..................66 11.5 Connect a wire that has a ferrule..................66 Technical data..................67 12.1 EVSE type..........................67 12.2 Parts included in the delivery....................67 12.3 Required tools for installation....................68 12.4 Required parts for installation..................... 68 12.5 General specifications......................69 12.6...

- Page 7 Contents 12.19.8 Ethernet cable......................93 12.20 Electrical connection diagram....................95 9AKK107992A2254-EN | 005...

-

Page 8: About This Document

About this document About this document Function of this document The document is only applicable for this EVSE: Terra HP Generation 3, including the variants and options listed in section 12.1. The document gives the information that is necessary to install the EVSE. Target group The document is intended for qualified installation persons. -

Page 9: General Symbols And Signal Words

About this document 3. Do the steps in the procedures fully and in the correct sequence. 4. Keep the document in a safe location that you can easily access. This document is a part of the EVSE. General symbols and signal words Signal word Description Symbol... -

Page 10: Special Symbols For Warnings And Dangers

About this document Signal word Description Symbol Electrotechnical expertise is required, according to the local rules. Alternating current supply Note: It is possible that not all symbols or signal words are present in this document. 1.10 Special symbols for warnings and dangers Symbol Risk type General risk... -

Page 11: Related Documents

Manufacturer ABB E-Mobility B.V. Heertjeslaan 6 2629 JG Delft The Netherlands Contact data ABB E-Mobility B.V. in your country can give you support on the EVSE. You can find the contact data here: https://new.abb.com/ev-charging 1.14 Abbreviations Abbreviation Definition Alternating current... -

Page 12: Terminology

1.15 Terminology Term Definition Network operating center Facility of the manufacturer to do a remote check on of ABB EV Infrastructure the correct operation of the EVSE Cabinet Enclosure of the EVSE, including the components on the inside Cable slack... -

Page 13: Orientation Agreements

About this document 1.16 Orientation agreements Front side: face forward to the X-direction (positive is to the right) EVSE during normal use Y-direction (positive is rearward) Left side Z-direction (positive is upward) Right side Rear side 9AKK107992A2254-EN | 005... -

Page 14: Safety

Safety Safety Liability The manufacturer is not liable to the purchaser of the EVSE or to third parties for damages, losses, costs or expenses incurred by the purchaser or third parties if any target group mentioned in the related documents does not obey the rules below: •... -

Page 15: Personal Protective Equipment

Safety Personal protective equipment Symbol Description Protective clothing Safety gloves Safety shoes Safety glasses Safety instructions during transport Preliminary requirements • Installation engineer • • Make sure that the hoisting equipment or forklift truck can lift the EVSE safely. Take into account the mass and the center of gravity of the EVSE. •... -

Page 16: Safety Instructions For Earthing

Safety • Make sure that the load capacity of the grid is in accordance with the EVSE. • Earth the EVSE correctly. Refer to section 2.7. • Make sure that the wiring inside the EVSE is protected from damage and cannot get trapped when you open or close the cabinet. -

Page 17: Identifier Labels On The Evse (En 17186 Norm)

Safety Symbol Description Appliance class 1 Sign that means that you must read the manual before you install the EVSE Waste from electrical and electronic equipment Note: It is possible that not all symbols are present on the EVSE. Identifier labels on the EVSE (EN 17186 norm) The EVSE has identifier lables on the connectors. -

Page 18: Discard The Evse Or Parts Of The Evse

The manufacturer (ABB E-Mobility B.V.) and its affiliates are not liable for damages and/or losses related to such security breaches, any unauthorized access, interference, intrusion, leakage and/or theft of data or information. -

Page 19: Description

The properties of the electrical grid, the ambient conditions and the EV must comply with the technical data of the EVSE. Refer to chapter 12. • Only use the EVSE with accessories that are approved by the manufacturer (ABB E-Mobility B.V.) and that obey the local rules. •... -

Page 20: General Description Of The Evse

Description Note: The data in the illustration are only examples. Find the type plate on your EVSE to see the applicable data. • For the location of the type plate, refer to section 3.5. • For the EVSE type information, refer to section 12.1. General description of the EVSE The EVSE is an arrangement of these parts: •... -

Page 21: Overview And Functions

Description Lines Description AC input power connections DC power connections Control lines (general) Overview and functions 3.5.1 Power cabinet, outside Plinth cover Door Air outlet Air inlet (4x) Type plate Enclosure 9AKK107992A2254-EN | 005... -

Page 22: Power Cabinet, Inside

Description 3.5.2 Power cabinet, inside DC output busbars X-10 terminal block Cable inlets X-8 terminal block PE busbar CAN2FIBER device AC power connector Tilt sensor (option) Main switch Part Function DC output busbar To connect the DC output power cables Cable inlet A plate with openings for cables PE busbar... -

Page 23: Dc Output Busbar In A Static Dc System

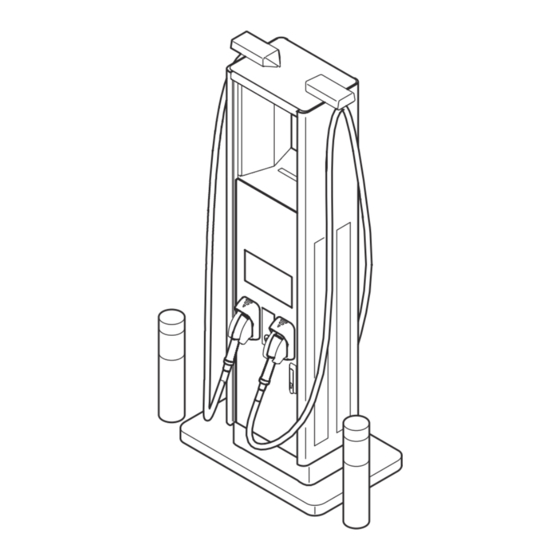

Description 3.5.3 DC output busbar in a static DC system Positive DC output busbar Negative DC output busbar 3.5.4 Charge post CP500 Generation 3, outside EV charge cable Cable retraction system RFID reader and the payment Enclosure terminal (option) Air inlet and outlet Connector holder Type plate Touchscreen... -

Page 24: Charge Post Cp500 Generation 3, Inside

Description 3.5.5 Charge post CP500 Generation 3, inside Cooling unit Q1 RCD DC power busbars X-10 terminal block Cable gland plates X-20 terminal block PE busbar CAN2FIBER device Part Function Cooling unit To decrease the temperature of the charge cables DC power busbars To connect the DC power cables Cable gland plates... -

Page 25: Overview Of The Cable Glands Of The Charge Post

Description 3.5.6 Overview of the cable glands of the charge post PE wire Ethernet cable AC auxiliary power cable DC+ in cable Optical CAN cable DC+ in cable Tilt sensor control cable (optional) DC- in cable Interlock and DC guard cable DC- in cable External residual-current device The manufacturer does not supply an external residual-current device. -

Page 26: Options

The tilt sensors require a 24 V power supply, daisy chain-connected from the power cabinets to the charge post. This power supply is not included in the scope of ABB E-Mobility B.V.. ABB E-Mobility B.V. recommends to use an uninterruptible power supply. -

Page 27: Pre-Installation

Pre-installation Pre-installation Pre-installation procedure (site planning) Preliminary requirements • All required permits to comply with the local rules, are granted. Procedure 1. Do a check on the configuration of the EVSE. Refer to the order. 2. Refer to the specifications to prepare and order these items: •... -

Page 28: Make Sure That The Floor Space For The Evse And The Airflow Around The Evse Is Correct

Pre-installation 7. Make sure that the site complies with the relevant usability standards, such as ADA and DIN 18040: a. Limit the curb heights. b. Take into account the limited reach of a wheelchair user. For usability standards specifications, refer to section 12.15.3. 8. -

Page 29: Prepare A Custom Foundation For The Power Cabinet

Pre-installation Procedure 1. Contact the manufacturer to order the foundation for your EVSE. Refer to section 1.13. 2. Dig the hole for the foundation. Caution: Make sure that the top surface of the foundation is above the ground level, to prevent intrusion of water. -

Page 30: Prepare A Prefab Concrete Foundation For The Charge Post

Pre-installation 4.4.4 Prepare a prefab concrete foundation for the charge post Preliminary requirements • Prefab concrete foundation. Refer to section 12.17.3. Procedure 1. Contact the manufacturer to order the foundation for your EVSE. Refer to section 1.13. 2. Dig the hole for the foundation. Caution: •... - Page 31 Pre-installation Procedure 1. Make the custom foundation. Caution: Make sure that the top surface of the foundation is above the ground level, to prevent intrusion of water. 2. Guide the cables into the holes (C1) to (C4) of the foundations. For the relation between the cables and the holes, refer to section 12.17.4.

-

Page 32: Inspection And Transport

Inspection and transport Inspection and transport Transport the EVSE to the site A transport company delivers the EVSE close to the site. The movement of the EVSE to its final location is your responsibility. • If you need to store the EVSE before installation, obey the ambient conditions for storage. -

Page 33: Transport The Evse On The Site

Inspection and transport Transport the EVSE on the site 5.5.1 General transport procedure Preliminary requirements • The cabinets are unpacked. Refer to section 5.4. Note: The charge post is delivered horizontally or vertically. Caution: Do not tilt the power cabinet to the horizontal position. In the horizontal position, the power cabinet breaks. -

Page 34: Move The Cabinet With A Forklift Truck

Inspection and transport Caution: • Do not drop the charge post. There is a risk of damage. Procedure 1. Install the swivel eye bolts or bolts with lifting loops (A). 2. Connect the hoisting equipment (B). 3. Carefully tilt the charge post (C) to the vertical position. -

Page 35: Hoist The Cabinet

Inspection and transport 5.5.4 Hoist the cabinet Preliminary requirements • The cabinet is unpacked. • Hoisting equipment, Refer to section 5.4. including cables (not chains), swivel eye bolts or bolts with lifting loops. Refer to section 12.3. Warning: Risk of pinching or crushing, the cabinet is heavy •... - Page 36 Inspection and transport Procedure 1. Remove the fasteners (A). 2. Discard the fasteners and the pallet. Refer to section 2.10. 9AKK107992A2254-EN | 005...

-

Page 37: Installation

Installation Installation General installation procedure Preliminary requirements • The AC input cable is • There is no voltage on available. the AC input cable during the complete installation • The foundations for the procedure. cabinet is prepared. • All cables are in the cable conduits and the full cable slack is applied. -

Page 38: Install The Cabinet On The Foundation

Installation 6.2.2 Install the cabinet on the foundation Preliminary requirements • Hoisting equipment or • Four fasteners M16 and forklift truck washers • Torque wrench Procedure 1. Carefully lower the cabinet on the foundation with a hoisting equipment or a forklift truck. Refer to section 5.5.1. -

Page 39: Guide The Cables To The Cabinet

Installation 6.2.4 Guide the cables to the cabinet Preliminary requirements • The cable inlets are open. Procedure 1. Guide the AC input cable, the AC auxiliary power cable, the interlock and DC guard and the CAN cables (A) through the opening (B). 2. -

Page 40: Mechanical Installation Of The Charge Post

Installation Procedure 1. Install the cover plate (B) on the foundation (A). 2. Install the fasteners (C). 3. Tighten the fasteners to the correct torque. For the specification, refer to section 12.14. Mechanical installation of the charge post 6.3.1 Install the charge post - general procedure Preliminary requirements •... -

Page 41: Remove The Cable Gland Plates

Installation 6.3.2 Remove the cable gland plates Preliminary requirements • The door is open. • Screwdriver, cross • The protection cover is • Set of open spanners removed. Procedure 1. Remove these parts: a. Fasteners (A) b. Cable gland plates (B) c. -

Page 42: Install The Cable Gland Plates

Installation 6.3.4 Install the cable gland plates Preliminary requirements • The door is open. • Screwdriver, cross • The protection cover is • Set of open spanners removed. Procedure 1. Install the nuts (A) of the cable glands over the cables. 2. -

Page 43: Electrical Installation Of The Power Cabinet

Electrical installation of the power cabinet Electrical installation of the power cabinet General procedure Note: For a detailed overview of all electrical connections, refer to section 12.20. Preliminary requirements • The DC cables are • installed in one of the cable conduits. -

Page 44: Connect The Ac Input Cable

Electrical installation of the power cabinet • Cable lugs. Refer to section 12.4. • Fasteners M12. Refer to section 12.4. Procedure 1. Cut the PE cables to make sure that the length is sufficient for connection to the PE busbar (A) with a loop. The loop is necessary to make sure that the PE cable is not the first cable that is disconnected when a collision... -

Page 45: Connect The Dc Power Cables, Static 175 Kw System

Electrical installation of the power cabinet Procedure 1. Prepare the cables: a. Cut the AC power cables to make sure that the length is sufficient for connection to the busbar bolts (A). b. Strip the insulation from the end of the cables (C), (D), and (E). Make sure that the stripped length is compatible with the cable lug. -

Page 46: Connect The Ac Auxiliary Power Cable In The Power Cabinet

Electrical installation of the power cabinet 5. Install the nuts and washers on the connector block bolts. 6. Tighten the nuts to the correct torque. For the specification, refer to section 12.14. Connect the AC auxiliary power cable in the power cabinet Preliminary requirements •... -

Page 47: Connect The Interlock And Dc Guard Cables To The Power Cabinet

Electrical installation of the power cabinet Connect the interlock and DC guard cables to the power cabinet Preliminary requirements • Interlock and DC guard • cable. Refer to section 12.19.5 • Wire loops Note: The illustration shows the terminal block X8 on the power cabinet and the connections treated in this section. -

Page 48: Connect The Optical Can Cables From The Charge Post To The Power Cabinet

Electrical installation of the power cabinet Connect the optical CAN cables from the charge post to the power cabinet Note: The Rx and Tx lines must be swapped between the charge the post and the power cabinet. Note: For a detailed overview of all electrical connections, refer to section 12.20. -

Page 49: Connect The Control Cable For The Tilt Sensors To The Power Cabinet (Option)

Electrical installation of the power cabinet Connect the control cable for the tilt sensors to the power cabinet (option) Preliminary requirements • Torque screwdriver, cross • Control cable for the tilt sensors. Refer to section • Wire cutter 12.19.7. • Wire stripper pliers •... -

Page 50: Electrical Installation Of The Charge Post

Electrical installation of the charge post Electrical installation of the charge post General procedure Note: For a detailed overview of all electrical connections, refer to section 12.20. Preliminary requirements • The DC power cables are • installed in one of the cable conduits. -

Page 51: Connect The Dc Power Input Cables

Electrical installation of the charge post Procedure 1. Prepare the wire: a. Cut the PE wire (A) to make sure that the length is sufficient for connection at the PE busbar (B) with a loop. The loop is necessary to make sure that the PE wire is not the first wire that is disconnected when a collision moves the charge post. -

Page 52: Connect The Ac Auxiliary Power Cable

Electrical installation of the charge post 5. Connect these cables: • DC+ cable (A) to the connector bolt (F1). • DC- cable (B) to the connector bolt (G1). 6. If you need to connect more DC cables, do steps 4 and 5 again for the other wires and connector bolts (F2) and (G2). -

Page 53: Connect The Interlock And Dc Guard Cable

Electrical installation of the charge post Connect the interlock and DC guard cable Note: For a detailed overview of all electrical connections, refer to section 12.20. Preliminary requirements • Torque screwdriver, cross • • Interlock and DC guard cable. Refer to section 12.19.5. -

Page 54: Connect The Optical Can Cable

Electrical installation of the charge post Note: The illustration shows the terminal block X20 of the charge post and the connections treated in this section. 1. Prepare ferrules for the wires that are mentioned below. Refer to section 11.2. 2. Connect these wires from the power cabinet: Wires from the power Connect to terminal Terminal name... -

Page 55: Connect The Ethernet Cable

Electrical installation of the charge post Procedure 1. Guide the optical CAN cables to the Power cabinet Charge post fibre-optics converter. 2. Remove the protection covers from the optical connectors. A100 3. Connect these wires: • Use the illustration as a reference. •... -

Page 56: Connect The Control Cable For The Tilt Sensors From The External Customer Interface To The Charge Post (Option)

Electrical installation of the charge post Procedure 1. Guide the cable (A) to the switch ethernet device (B). 2. Connect the RJ45 plug to the switch port X1 (C). Connect the control cable for the tilt sensors from the external customer interface to the charge post (option) Preliminary requirements •... -

Page 57: Prepare For Commissioning

Prepare for commissioning Prepare for commissioning Preliminary requirements • Installation engineer Danger: Hazardous voltage • Do not commission the EVSE. Only a service engineer of the manufacturer is qualified to commission the EVSE. Procedure 1. Tell the owner that the EVSE is ready for commissioning. 2. -

Page 58: Access To Parts

Access to parts Access to parts 10.1 Open the door of the power cabinet Preliminary requirements • Door key of the power cabinet Danger: Hazardous voltage • Make sure that only qualified personnel has access to the door key. Note: There is one unique door key for each power cabinet. Procedure 1. -

Page 59: Remove The Dc Busbar Cover

Access to parts Procedure 1. Remove these parts: • Fasteners (A) • Plinth covers (B) 10.3 Remove the DC busbar cover Preliminary requirements • Screwdriver, cross Procedure 1. Remove the fasteners (A). 2. Remove the cover (B). 10.4 Remove the AC covers Preliminary requirements •... -

Page 60: Close The Door Of The Power Cabinet

Access to parts Procedure 1. Remove these parts: • Fasteners (A) • Cover (B) • Cover (C) 10.5 Close the door of the power cabinet Preliminary requirements • Door key to the power cabinet. Danger: Hazardous voltage • Make sure that only qualified personnel has access to the door key. Note: There is one unique door key for each cabinet. -

Page 61: Open The Door Of The Charge Post

Access to parts 10.6 Open the door of the charge post Preliminary requirements • Door key of the charge post Danger: Hazardous voltage • Make sure that only qualified personnel has access to the door key. Note: • There is one unique door key for each charge post. •... -

Page 62: Remove The Protection Plate Of The Charge Post

Access to parts Procedure 1. Remove these parts: • Fasteners (A) • Plinth covers (B) 10.8 Remove the protection plate of the charge post Preliminary requirements • Screwdriver, cross Procedure 1. Remove these parts: • Fasteners (A) • Protection plate (B) 10.9 Close the door of the charge post Preliminary requirements... - Page 63 Access to parts Note: There is one unique door key for each charge post. Procedure 1. Close the door (A). 2. Turn the handle (B) counterclockwise. 3. Push the handle. 4. Turn the door key (C) clockwise to lock the door. 5.

-

Page 64: Generic Procedures

Generic procedures Generic procedures 11.1 Install a cable lug on a wire Preliminary requirements • Wire cutter • • Wire stripper pliers • Crimp plier • Cable lug Procedure 1. Make sure that the diameter of the cable lug is correct. The cable lug must be compatible with the wire. -

Page 65: Install Insulating Heatshrink Tubing On A Wire

Generic procedures Procedure 1. Make sure that the diameter of the ferrule is correct. The ferrule must be compatible with the wire. Obey the technical specifications set by the manufacturer. Refer to section 12.19. 2. Strip the insulation from the wire. The stripped length must be the same as the length of the cavity of the ferrule. -

Page 66: Connect A Wire That Has A Cable Lug

Generic procedures 11.4 Connect a wire that has a cable lug Preliminary requirements • Torque screwdriver, cross • Procedure 1. Loosen the bolt of the connection pin (A) on the busbar (B). 2. Install the eye of the cable lug (C) on the connection pin. -

Page 67: Technical Data

Technical data Technical data 12.1 EVSE type The EVSE type is a code, mentioned on the type plate. Refer to section 3.2. The code is made out of 3 parts: T U V Code part Description Value Meaning of the value Model Terra high power Part... -

Page 68: Required Tools For Installation

Technical data Parameter Specification Eye bolts to hoist the charge post M10, 45 mm (1 3/8 in) Caps to replace the eye bolts after trans- To fit in the holes for the eye bolts port of the charge post Note: It is possible that more parts are required in the delivery. Refer to the order. -

Page 69: General Specifications

Technical data Location Wire Size Maximum width Maximum length [mm] [in] [mm] [in] AC input power DC power Charge post DC power 12.5 General specifications Parameter Specification Compliance and safety Ingress protection rating IP54 9AKK107992A2254-EN | 005... -

Page 70: Electrical Installation Requirements (Europe)

Technical data Parameter Specification EMC rating for the charge post The charge post complies with these standards: • EN 61000-6-3 : 2007 + A1: 2001 Emis- sion standard for residential, com- mercial and light-industrial environ- ments (Class B) • EN 61000-6-2 : 2005 Immunity for in- dustrial environments •... -

Page 71: Dc Output Specifications

Technical data Parameter Specification Residual-current device In the range of 30 mA up to 300 mA The power cabinet has an integrated 300 mA RCD (Type A) for the power sec- tion. Power consumption of the power cabi- In standby status: ≤ 80 W Power consumption of the charge post In standby status: ≤... -

Page 72: Current Peaks During The Start Of A Charge Session (Dc Output)

Technical data 12.9 Current peaks during the start of a charge session (DC output) Parameter Specification Duration of the current peaks 25 µs Maximum current peak 60 A 12.10 Mass and center of gravity 12.10.1 Mass Parameter Specification [kg] [lbs] Mass of the power cabinet 1400 3086.5... -

Page 73: Center Of Gravity, Charge Post

Technical data 12.10.3 Center of gravity, charge post Center of gravity Parameter Specification [mm] [in] 13.9 1096 43.2 12.11 Tilt sensor specifications (option) Parameter Specification Tilt to disable the power from the low > 10° voltage source 12.12 Ambient conditions Parameter Specification Operation temperature... -

Page 74: Noise Level

Technical data Parameter Specification IK10 (screen: IK08) Altitude Maximum 2000 m (6562 ft) above the sea level 12.13 Noise level Noise level Specification [dB(A)] Charge post, 500 A continuous up to ≤ 60 at 1 m (39.4 in) 35 °C Maximum noise level of the charge post 68 at 1 m (39.4 in) Power cabinet... -

Page 75: Dimensions

Technical data 12.15 Dimensions 12.15.1 Power cabinet Parameter Specification [mm] [in] Width (X-dimension) 1170 46.1 Depth (Y-dimension) 30.3 Height (Z-dimension) 2030 30.3 Required cable slack for the AC input ca- 1000 39.4 ble (measured from the top of the foun- dation) Required cable slack for the PE cable 2000... -

Page 76: Height Of User Operable Elements

Technical data Parameter Specification [mm] [in] Required cable slack for the CAN cable 1200 47.2 (measured from the top of the founda- tion) Required cable slack for the tilt sensor 1200 47.2 control cable (measured from the top of the foundation), if applicable Parameter Specification [ft]... -

Page 77: Space Requirements

Technical data Parameter Specification [mm] [in] Top of the authentication clus- 37.6 Bottom of the touch screen dis- 1026 play Advised maximum height for 1118 user operable elements if the EVSE is placed on a curb. This requires HMI customization. Top of the touch screen display 1223 48.1... -

Page 78: Charge Post

Technical data Parameter Specification [mm] [in] 25.6 30.3 1050 41.3 25.6 12.16.2 Charge post Charge post Space required for cable Total required width for the charge replacement post Total required depth for the charge Space required for the air inlet and post to open the side panel Maximum sideway reach of the... -

Page 79: Charge Post: Exceptions For Bollards And Other Minor Fixed Obstacles

Technical data Parameter Specification [mm] [in] 13.6 15.7 30.6 19.3 13.6 12.16.3 Charge post: exceptions for bollards and other minor fixed obstacles Note: The bollards or minor fixed obstacles must have a maximum diameter of 150 mm (6 in), to permit service or maintenance operations. Charge post Required depth to open the side Total width to open the side panels... -

Page 80: Distance Requirements Between Power Cabinet And Charge Post

Technical data Parameter Specification [mm] [in] 1190 46.8 31.5 26.5 19.3 12.16.4 Distance requirements between power cabinet and charge post Parameter Specification [ft] Maximum distance between the power cabinet and the charge post 12.17 Foundation specifications 12.17.1 Power cabinet (prefab concrete) General specifications Parameter Specification... - Page 81 Technical data Dimensions, side view (Y12) Parameter Specification [mm] [in] 4.72 36.6 4.72 36.5 34.3 1170 46.1 11.8 22.4 11.8 23.0 23.0 (Y12) 1170 46.1 7.87 7.28 28.3 D1 (8x), diameter 6.30 D1 (4x), diameter 3.54 9AKK107992A2254-EN | 005...

- Page 82 Technical data Parameter Specification α1 93° α2 90° D1 hole 3° tapered D2 hole 3° tapered Dimensions, front view (X6) (Y4) Parameter Specification [mm] [in] 4.72 4.72 1000 39.4 1300 51.2 20.9 (X6) 30.3 15.7 24.6 10.8 30.5 20.7 (X12) 1300 51.2 27.6...

- Page 83 Technical data Parameter Specification [mm] [in] 0.79 R, all edges Parameter Specification α1 93° α2 90° Dimensions, top view Parameter Specification [mm] [in] 9.84 31.5 9.84 680 +/- 1 26.8 +/- 0.1 410 +/- 1 16.1 +/- 0.1 3.94 800 +/- 1 31.5 +/- 0.1 3.94 9AKK107992A2254-EN | 005...

-

Page 84: Power Cabinet (Custom)

Technical data Parameter Specification [mm] [in] 3.94 9.84 26.4 9.84 1050 +/- 1 41.3 +/- 0.1 3.94 670 +/- 1 26.4 +/- 0.1 3.94 3.94 Parameter Specification A (4x) T-Fixx M16 depth 80 (3.1) RVS B (4x) T-Fixx M10 depth 65 (2.6) RVS C (4x) T-Fixx M10 depth 65 (2.6) RVS 12.17.2... - Page 85 Technical data Parameter Specification A (4x) For M16 fasteners, depth 60 (2.4) Parameter Specification [mm] [in] 1170 46.1 1050 41.3 36.6 16.1 16.1 30.3 26.8 29.4 Cable conduit hole Maximum diameter [mm] [in] Function for cable conduit holes Cable conduit Cable conduit for these cables hole AC power...

-

Page 86: Charge Post (Prefab Concrete)

Technical data Cable conduit Cable conduit for these cables hole None None DC power: to the charge post 12.17.3 Charge post (prefab concrete) Foundation mass and loads Parameter Specification Mass 1030 kg (2271 lb) 15.06 kN (3386 klbf) 5.25 kN (1180 klbf) 8.36 kNm (74.1 klb-in) Dimensions, side views Parameter... - Page 87 Technical data Parameter Specification [mm] [in] 7.87 162.5 6.40 282.5 11.1 16.9 Parameter Specification α1 3° Dimensions, top view D1 D2 Parameter Specification [mm] [in] 5.71 4.72 10.4 1000 39.4 4.92 5.91 5.91 1400 55.1 17.3 D1, diameter 4.92 9AKK107992A2254-EN | 005...

-

Page 88: Charge Post (Custom)

Technical data Parameter Specification [mm] [in] D2, diameter 4.92 D3, diameter 2.36 Parameter Specification α1 3° Tube diameter for D1 125/119 mm (4.92/44.1 in) Tube diameter for D2 125/119 mm (4.92/44.1 in) Tube diameter for D3 60/56 mm (2.36/2.20 in) A (2x) DEMU anchor type 1988 type M16 depth 20 (8.66) -

Page 89: Overview Of The Cable Conduits

Technical data Parameter Specification [mm] [in] 22.8 20.7 14.6 Cable conduit hole Maximum diameter [mm] [in] Function for cable conduit holes Cable conduit Cable conduit for these cables hole AC auxiliary and PE CAN, interlock and DC guard DC power DC power 12.18 Overview of the cable conduits... - Page 90 Technical data Foundation of the power cabinet Foundation of the charge post Note: The arrows show the front side of the charge post and the power cabinet. Cable conduit Cables DC power AC auxiliary power Interlock DC guard AC power Cable conduit Maximum diameter [mm]...

-

Page 91: Cable Specifications

Technical data 12.19 Cable specifications 12.19.1 AC input cable for the power cabinet Parameter Specification Cores 3 wires + PE, according to IEC 60446 Cross section range 185 mm² to 240 mm² (365 kcmil to 474 kcmil) Conductor Bare copper, fine wired, bunch stranded, according to VDE 0295 Cl.5/IEC Cl.5 Diameter of the phase conductors Refer to the local rules. -

Page 92: Pe Cable

Technical data 12.19.3 PE cable Parameter Specification Cores 1 core, gn/ye Cross section range 35 mm² (69 kcmil) (2 AWG) Type Flexible, unshielded Diameter 13 - 21 mm Length Refer to the local rules. Conductor Fine strand copper wire according to VDE 0295 Cl. -

Page 93: Optical Can Cables Between The Power Cabinet And The Charge Post

Technical data Parameter Specification Insulation PVC or other material that is serviceable for outdoor use and UV-protected Test voltage 1.5 kV Strip length 11 mm (0.43 in) 12.19.6 Optical CAN cables between the power cabinet and the charge post Parameter Specification Number of cores 2 fibre cores for installation... - Page 94 Technical data Parameter Specification Insulation PVC that is serviceable for outdoor use, UV- protected, and oil resistant Characteristic impedance 120 Ω ± 10% Voltage rating 600 VAC Test voltage 1.5 kV Ambient temperature range -40ºC to 80ºC 9AKK107992A2254-EN | 005...

- Page 95 GND_CAN_OUT Internal USE Internal USE Internal USE Internal USE Internal USE Internal USE Proprietary & Confidential. All rights strictly reserved. Reproduction or issue to third parties in any form is not permitted without written authority from ABB. 9AKK107992A2254-EN | 005...

Need help?

Do you have a question about the Terra HP Generation 3 CE and is the answer not in the manual?

Questions and answers