Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for PR electronics 4114

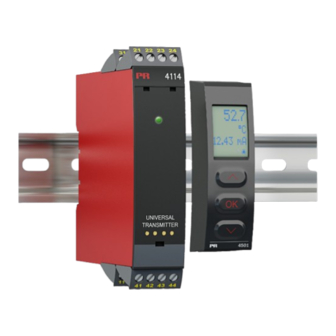

- Page 1 PERFORMANCE MADE SMARTER Product manual 4114 Universal transmitter T E M P E R AT U R E I . S . I N T E R FA C E S CO M M U N I C AT I O N I N T E R FA C E S...

- Page 2 6 Product Pillars to meet your every need Individually outstanding, unrivalled in combination With our innovative, patented technologies, we make signal conditioning smarter and simpler. Our portfolio is composed of six product areas, where we offer a wide range of analog and digital devices covering over a thousand applications in industrial and factory automation.

-

Page 3: Table Of Contents

Universal transmitter 4114 Table of contents Warning .................... -

Page 4: Warning

HAZARD- Troubleshooting the device. VOLTAGE Repair of the device and replacement of circuit breakers must be done by PR electronics A/S only. CAUTION Warning Do not open the front plate of the device as this will cause damage to the connector for the display / programming front PR 45xx. -

Page 5: Symbol Identification

Should there be any doubt as to the correct handling of the device, please contact your local distributor or, alternatively, PR electronics A/S www.prelectronics.com Mounting and connection of the device should comply with national legislation for mounting of electric materials, i.e. wire cross section, protective fuse, and location. - Page 6 Normal operation Operators are only allowed to adjust and operate devices that are safely fixed in panels, etc., thus avoiding the danger of personal injury and damage. This means there is no electrical shock hazard, and the device is easily accessible. Cleaning When disconnected, the device may be cleaned with a cloth moistened with distilled water.

-

Page 7: How To Demount System 4000

When front LED lights red / display shows AO.ER PR 4114 is designed as a SIL 2 device with a high safety level. Therefore, a continuous measurement of the outgoing current is carried out on a 4...20 mA and 20...4 mA output signal. If the current output signal is different from the internal calculated output value or the current output is 0 (due to e.g. -

Page 8: Application

When 4114 is used in combination with the 45xx display / programming units, all operational parameters can be modified to suit any application. As the 4114 is designed with electronic hardware switches, it is not necessary to open the device for setting of DIP-switches. -

Page 9: Applications

Applications Input signals: Volt - Potentio- meter Current RTD and lin.R Connect., wires Order separately: 5910 CJC connector. See the connection drawing on page 16. Output signals: 10 V 10 V Analog, 0/4...20 mA and voltage Supply: 21.6...253 VAC 19.2...300 VDC 4114V105-UK... -

Page 10: Pr 45Xx Display / Programming Front

Application • Communications interface for modification of operational parameters in 4114. • Can be moved from one 4114 device to another and download the configuration of the first unit to subsequent units. • Fixed display for readout of process data and status. -

Page 11: Order

Order 4114 = Universal transmitter Accessories 4501 = Display / programming front 4511 = Modbus communication enabler 4512 = Bluetooth communication enabler 5910 = CJC connector Electrical specifications Environmental conditions Operating temperature ....... . -20°C to +60°C Storage temperature . - Page 12 Accuracy, the greater of general and basic values: General values Input type Absolute accuracy Temperature coefficient ≤ ±0.1% of span ≤ ±0.01% of span / °C Basic values Type Basic accuracy Temperature coefficient ≤ ±4 µA ≤ ±0.4 µA / °C ≤...

- Page 13 TC input Min. Max. Type Standard value value 0°C +1820°C IEC 60584-1 -100°C +1000°C IEC 60584-1 -100°C +1200°C IEC 60584-1 -180°C +1372°C IEC 60584-1 DIN 43710 -200°C +900°C -180°C +1300°C IEC 60584-1 -50°C +1760°C IEC 60584-1 -50°C +1760°C IEC 60584-1 -200°C +400°C IEC 60584-1...

-

Page 14: Visualisation In The 45Xx Of Sensor Error Detection And Input Signal Outside Range

Visualisation in the 45xx of sensor error detection and input signal outside range Sensor error check: Device Configuration Sensor error detection: OUT.ERR=NONE. 4114 Else: Outside range readout (IN.LO, IN.HI): If the valid range of the A/D converter or the polynomial is exceeded Input Range Readout Limit IN.LO... -

Page 15: Sensor Error Detection Limits

Error in FLASH 1) No load on the current output Check measurement of analog output current AO.ER (only S4...20 / S20...4 mA) Communications test 45xx / 4114 NO.CO Connection error Check that input signal matches input IN.ER 1) Error levels on input... -

Page 16: Connections

Connections Supply Inputs: TC, internal RTD, 2-wire RTD, 3- / 4-wire Resistance, 2-wire CJC sensor 41 42 41 42 41 42 Resistance, 3- / 4-wire Potentiometer 2-wire transmitter Current 41 42 41 42 41 42 41 42 Voltage *TC, CJC connector * Order separately: 41 42 41 42... -

Page 17: Block Diagram

0.2 mA 21.6...253 VAC or wires 19.2...300 VDC V loop Supply A / D D / A 10 V 500 Ω 50 Ω Green 20 Ω EEPROM I + V Out. Out. Out. 50.0 l / min VALVE 5 4114 4114V105-UK... -

Page 18: Configuration / Operating The Function Keys

In general When configuring the 4114, you will be guided through all parameters and you can choose the settings which fit the application. For each menu there is a scrolling help text which is automatically shown in line 3 on the display. - Page 19 Language (LANG): In the menu ”LANG” you can choose between 7 different language versions of help texts that will appear in the menu. You can choose between UK, DE, FR, IT, ES, SE and DK. Auto diagnosis The device performs an advanced auto diagnosis of the internal circuits. The following possible errors can by displayed in the front unit 45xx.

-

Page 20: Routing Diagram

Routing diagram Power up If no key is activated for 1 minute, the display will return to the default state 1.0 without saving configuration changes. 1 Increase value / choose next parameter 2 Decrease value / choose previous parameter 3 Save the chosen value and proceed to the next menu Hold 3 Back to previous menu / return to menu 1.0 without saving. - Page 21 S20-4 20-4 20-0 S4-20 23mA 4-20 999.9 999.9 VOLT 0/3.5mA 0-20 -199.9 -199.9 CURR -200 -200 NONE 100.0 CURR 4-20 23mA 150.0 DISP.LO DISP.HI ANA.OUT O.RANGE OUT.ERR OUT.LO OUT.HI Txt 13 Txt 14 Txt 36 Txt 37 Txt 38 Txt 41 Txt 42 10-2 10-0...

-

Page 22: Routing Diagram, Advanced Settings (Adv.set)

Routing diagram, advanced settings (ADV.SET) DISP 2.0 In the submenu simulation (SIM) you must press 3 PASS SAVE to return to the default state 1.0. LANG LOAD SAVE SETUP MEMORY Txt 43 Txt 44 A.OUT DISP A.OUT SETUP CONTRA LIGHT VALVE 5 LINE 3 Txt 43... -

Page 23: Help Text Overview

Select Pt100 as sensor type Enter display setup Perform memory operations Select Pt200 as sensor type [44] Load saved configuration into 4114 Select Pt250 as sensor type Save 4116 configuration in 45xx Select Pt300 as sensor type [45] Select Pt400 as sensor type... -

Page 24: Document History

Document history The following list provides notes concerning revisions of this document. Rev. ID Date Notes 2011 EU-RO marine approval added. 4114V105-UK... - Page 25 We are near you, all over the world Our trusted red boxes are supported wherever you are All our devices are backed by expert service and a 5-year business with a global reach. This means that we are warranty. With each product you purchase, you receive always nearby and know your local markets well.

- Page 26 Benefit today from PERFORMANCE MADE SMARTER PR electronics is the leading technology company specialized in making industrial process control safer, more reliable and more efficient. Since 1974, we have been dedicated to perfecting our core competence of innovating high precision technology with low power consumption.

Need help?

Do you have a question about the 4114 and is the answer not in the manual?

Questions and answers