Table of Contents

Advertisement

Quick Links

SERVICE & OPERATING MANUAL

Original Instructions

Certified Quality

7

ISO 9001 Certified

ISO 14001 Certified

1935/2004/EC

Warren Rupp, Inc.

A Unit of IDEX Corporation

800 N. Main St.,

Mansfield, Ohio 44902 USA

Telephone 419.524.8388

Fax 419.522.7867

SANDPIPERPUMP.COM

© Copyright 2017 Warren Rupp, Inc.

All rights reserved

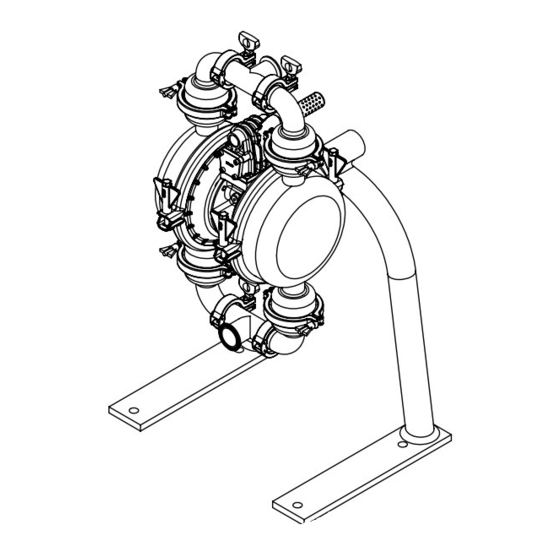

Model F15C

Metallic Sanitary Processing Pump

Constructed with FDA Compliant Materials

Design Level 1

s a n d p i p e r p u m p. c o m

Advertisement

Table of Contents

Summary of Contents for Sandpiper F15C

- Page 1 SERVICE & OPERATING MANUAL Original Instructions Certified Quality Model F15C Metallic Sanitary Processing Pump Constructed with FDA Compliant Materials Design Level 1 ISO 9001 Certified ISO 14001 Certified 1935/2004/EC Warren Rupp, Inc. A Unit of IDEX Corporation 800 N. Main St., Mansfield, Ohio 44902 USA Telephone 419.524.8388...

- Page 2 ATEX Pumps - Conditions For Safe Use 1. Ambient temperature range is as specifi ed in tables 1 & 2 on the next page 2. ATEX compliant pumps are suitable for use in explosive atmospheres when the equipment is properly grounded in accordance with local electrical codes 3. Conductive Polypropylene, conductive Acetal or conductive PVDF pumps are not to be installed in applications where the pumps may be subjected to oil, greases and hydraulic liquids. 4. When operating pumps equipped with non-conductive diaphragms that exceed the maximum permissible projected area, as defi ned in EN ISO 80079-36 : 2016 section 6.7.5 table 8, the following protection methods must be applied - Equipment is always used to transfer electrically conductive fl uids or - Explosive environment is prevented from entering the internal portions of the pump, i.e. dry running. sandpiperpump • Model F15C Metallic f15mdl1sm-rev0219...

- Page 3 Range [°C] Class Temperature [°C] -20°C to +80°C T100°C -20°C to +108°C T135°C -20°C to +60°C -20°C to + 160°C T200°C -20°C to +177°C (225°C) T2 Table 2. Category M2 ATEX Rated Pumps for Mining Ambient Temperature Process Temperature Range [°C] Range [°C] -20°C to +60°C -20°C to +150°C Note: The ambient temperature range and the process temperature range should not exceed the operating temperature range of the applied plastic parts as listed in the manuals of the pumps. sandpiperpump Model F15C Metallic • f15mdl1sm-rev0219...

-

Page 4: Table Of Contents

• Service & Repair Kits • Composite Repair Parts List • Material Codes SECTION 7: WARRANTY & CERTIFICATES ..14 • Warranty • CE Declaration of Conformity - Machinery • CE Declaration of Conformity - EC Regulation 1935/2004/EC sandpiperpump • Model F15C Metallic f15mdl1sm-rev0219... -

Page 5: Explanation Of Nomenclature

Design Level C Sanitary Design Level Muffler Options Wetted Material S Stainless Steel Metal Muffler Pump Options Diaphragm/Check Valve Materials D FDA Santoprene / FDA Santoprene None H FDA Hytrel / PTFE K PTFE with FDA Hytrel Backer / PTFE Z PTFE One-Piece Fusion Diaphragm / PTFE Your Serial #: _____________________________________ (fill in from pump nameplate) *Complies with Code of Federal Regulations (CFR) Title 21 Part 177 sandpiperpump Model F15C Metallic • f15mdl1sm-rev0219... -

Page 6: Performance

Capacity in Liters Per Minute NOTE: Performance based on the following: PTFE fitted pump, flooded suction, water at ambient conditions. The use of other materials and varying hydraulic conditions may result in deviations in excess of 5%. sandpiperpump • Model F15C Metallic f15mdl1sm-rev0219... -

Page 7: Materials

In addition, the ambient temperature range and the process temperature range do not exceed the operating temperature range of the applied non-metallic parts as listed in the manuals of the pumps . For specific applications, always consult the Chemical Resistance Chart. Note: This document is a high level guide. Please be aware that not all model and or material combinations are possible for all sizes. Please consult factory or your distributor for specific details. sandpiperpump Model F15C Metallic • f15mdl1sm-rev0219... -

Page 8: Dimensional Drawings

The dimensions on this drawing are for reference only. A certified drawing can be requested if physical dimensions are needed. 13.95 1-1/2” 15.72 DISCHARGE SANITARY CLAMP FLANGE 2.50 2.00 1/2" NPT 3/4" NPT AIR INLET AIR EXHAUST 31.56 25.72 26.07 29.82 9.78 1-1/2” SUCTION SANITARY CLAMP FLANGE 15.57 10.00 14.00 3.00 18.57 sandpiperpump • Model F15C Metallic f15mdl1sm-rev0219... -

Page 9: Principle Of Pump Operation

(flooded suction MUFFLER condition), pipe the exhaust higher than the product source to prevent siphoning spills . 1" DIAMETER AIR EXHAUST PIPING LIQUID LEVEL SUCTION sandpiperpump Model F15C Metallic • LINE f15mdl1sm-rev0219... -

Page 10: Recommended Installation Guide

To start the pump, slightly open the air shut-off valve. After the pump primes, the air valve can be opened to increase air flow as desired. If opening the valve increases cycling rate, but does not increase the rate of flow, cavitation has occurred. The valve should be closed slightly to obtain the most efficient air flow to pump flow ratio. sandpiperpump • Model F15C Metallic f15mdl1sm-rev0219... -

Page 11: Troubleshooting Guide

Inspect check valves and seats for wear and proper setting . Replace if necessary . Entrained air or vapor lock in chamber(s) . Purge chambers through tapped chamber vent plugs . For additional troubleshooting tips contact After Sales Support at service.warrenrupp@idexcorp.com or 419-524-8388 sandpiperpump Model F15C Metallic • f15mdl1sm-rev0219... - Page 12 Pump Inspection and Cleaning The Elima-Matic sanitary pump can be cleaned using several techniques. However, it is important to follow guidelines set by the IAMFES, the USPHS, and the DIC and/or internal rules for inspection, cleaning and sanitization. Remove the valve balls and ball cages from the pump and clean components separate from the pump. If the pump is to be steam cleaned, disconnect the suction line from the pump. Connect the steam line to the pump inlet. Maintain the flow of steam through the pump for at least five minutes after the temperature at the outlet has reached 200°F (94°C). Hot water may also be used. Pump water that is maintained at minimum of 170°F (77°C) through the pump for at least five minutes. Please note that the maximum cleaning temperature of the pump is 220° (104°C). Chemical cleaning may also be used in sanitizing the pump. Be sure to consult your distributor or the manufacturer to verify that the elastomer(s) used in the pump are compatible with the chemicals being used in the cleaning process. sandpiperpump • Model F15C Metallic f15mdl1sm-rev0219...

- Page 13 SEE NOTE 4 METALLIC SEAT OPTION Torque Setting: 200 in-lbs. (22 N-m) Torque Setting: 350 in-lbs. (39 N-m) Service & Repair Kits 476.382.659 Wet End Kit 1-Piece PTFE Diaphragms, PTFE Check Balls, PTFE Tri-Clamp Gaskets sandpiperpump Model F15C Metallic • f15mdl1sm-rev0219...

- Page 14 Ball Cage 670 .V004 .110 Manifold Tee P29-168 Stand Attachment SP31-651 Pump Stand P29-650CP Locking Pin P29-652 Large Clamp SP31-110A Large Clamp Bolt SP31-110B Large Clamp Wing Nut FG39C Small Tri-Clamp V273A Large Tri-Clamp V274A sandpiperpump • Model F15C Metallic f15mdl1sm-rev0219...

- Page 15 Warren Rupp brand shall fail under normal use and service due to a defect in material or workmanship within five years from the date of shipment from Warren Rupp’s factory. Warren Rupp brands include Warren Rupp ,SANDPIPER ® ® SANDPIPER Signature Series , MARATHON , Porta-Pump , SludgeMaster™ and Tranquilizer ®...

- Page 16 Declaration of Conformity Manufacturer: Warren Rupp, Inc., 800 N. Main Street, Mansfield, Ohio, 44902 USA certifies that SANDPIPER Air-Operated Double Diaphragm Food Processing Pump Models ® and Tranquilizer Surge Suppressor Models comply with the European Community Regulations: ® (EC) No 1935/2004 for Food Contact Materials...

- Page 17 ATEX EU Declaration of Conformity Manufacturer: Warren Rupp, Inc. A Unit of IDEX Corporation 800 North Main Street Mansfield, OH 44902 USA Warren Rupp, Inc. declares that Air Operated Double Diaphragm Pumps (AODD) and Surge Suppressors listed below comply with the requirements of Directive 2014/34/EU and all applicable standards. Applicable Standards •...

Need help?

Do you have a question about the F15C and is the answer not in the manual?

Questions and answers