Sandpiper s05 Service & Operating Manual

Metallic design level 1

Hide thumbs

Also See for s05:

- Service & operating manual (34 pages) ,

- Service & operating manual (29 pages) ,

- Service & operating manual (23 pages)

Table of Contents

Advertisement

Quick Links

SERVICE & OPERATING MANUAL

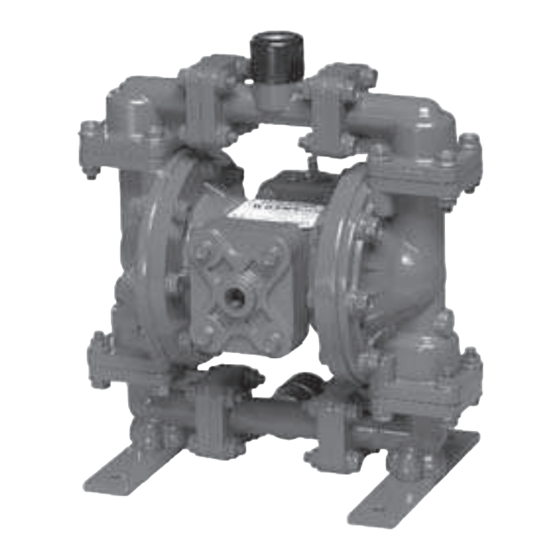

Model S05 Metallic Design Level 1

Table of Contents

Engineering Data and Temperature Limitations ........................................................1

Explanation of Pump Nomenclature .........................................................................2

Performance Curve...................................................................................................3

Dimensions (Aluminum Model) .................................................................................4

Metric Dimensions (Aluminum Model) ......................................................................5

Dimensions (Stainless Steel and Alloy C Models) ....................................................6

Metric Dimensions ( Stainless Steel and Alloy C Models) ........................................7

Principle of Pump Operation .....................................................................................8

Installation and Start-up ...........................................................................................8

Air Supply .................................................................................................................8

Air Valve Lubrication .................................................................................................8

Air Line Moisture .......................................................................................................8

Air Inlet and Priming .................................................................................................8

Between Uses ..........................................................................................................8

Installation Guide ......................................................................................................9

Troubleshooting .....................................................................................................10

Warranty .................................................................................................................10

Recycling ................................................................................................................11

Important Safety Information ..................................................................................11

Material Codes .......................................................................................................12

Composite Repair Parts Drawing ...........................................................................14

Available Service and Conversion Kits ...................................................................14

Composite Repair Parts List ...................................................................................15

Air Distribution Valve Assembly Drawing and Parts List .........................................16

Air Distribution Valve Servicing ...............................................................................17

Air Valve with Stroke Indicator Assembly Drawing and Part List ............................18

Air Distribution Valve with Stroke Indicator Option Servicing ..................................19

Solenoid Shifted Air Valve Drawing and Parts List .................................................20

WARREN RUPP, INC. • A Unit of IDEX Corporation • P.O. Box 1568, Mansfi eld, Ohio 44901-1568 USA • Telephone (419) 524-8388 • Fax (419) 522-7867 • www.warrenrupp.com

s05mdl1sm-REV0708

See page 2

for ATEX ratings.

CE

U.S. Patent #

5,996,627 & 6,241,487

Other U.S. Patents

Applied for

Solenoid Shifted Air Distribution Valve Option ........................................................21

Diaphragm Service Drawing, Non-Overlay .............................................................22

Diaphragm Service Drawing, with Overlay .............................................................22

Diaphragm Service Drawing ..................................................................................22

Diaphragm Servicing ..............................................................................................23

Overlay Diaphragm Servicing ................................................................................23

Pilot Valve Servicing, Assembly Drawing & Parts List ............................................24

Intermediate Assembly Drawing and Parts List ......................................................25

Intermediate Assembly and Actuator Plunger Servicing ........................................25

Check Valve Servicing ............................................................................................26

Check Valve Drawing ..............................................................................................26

Optional Muffl er Confi guration Drawing ..................................................................27

Dual Port Option Drawing (Aluminum Model) .........................................................28

Dual Porting Options (Aluminum Model) ................................................................29

Dual Porting Suction and Discharge (Aluminum Model) ........................................29

Single Porting Suction and Dual Porting Discharge (Aluminum Model) .................30

Dual Porting Suction and Single Porting Discharge (Aluminum Model) .................30

Single Port Suction and Discharge Repair Parts List (Aluminum Model) ...............30

Dual Port Suction and Discharge Repair Parts List (Aluminum Model) ..................30

Pumping Hazardous Liquids ...................................................................................31

Converting the Pump For Piping the Exhaust Air ...................................................31

Exhaust Conversion Drawing .................................................................................31

Converted Exhaust Illustration ................................................................................31

Pulse Output Kit Drawing .......................................................................................32

Pulse Output Kit Option ..........................................................................................32

Grounding the Pump ..............................................................................................33

CE Declaration of Conformity .................................................................................34

©Copyright 2008 Warren Rupp, Inc. All rights reserved.

Advertisement

Table of Contents

Summary of Contents for Sandpiper s05

-

Page 1: Table Of Contents

SERVICE & OPERATING MANUAL See page 2 for ATEX ratings. U.S. Patent # Model S05 Metallic Design Level 1 5,996,627 & 6,241,487 Other U.S. Patents Applied for Table of Contents Engineering Data and Temperature Limitations ............1 Solenoid Shifted Air Distribution Valve Option ............21 Explanation of Pump Nomenclature .................2... -

Page 3: Engineering Data And Temperature Limitations

Hot water or hot aqueous solutions (over 70°F) will attack FKM. (Fluorocarbon) 40°C 177°C 180°F -40°F Polyethylene 82°C -40°C SANDPIPER ® pumps are designed to be powered only by compressed air. For specifi c applications, always consult The Warren Rupp Chemical Resistance Chart s05mdl1sm-REV0708 Model S05 Metallic Page 1... -

Page 4: Explanation Of Pump Nomenclature

Explanation of Pump Nomenclature S05 Metallic · Design Level 1· Ball Valve Check Diaphragm/ Check Non-Wetted Shipping MODEL Pump Pump Valve Design Wetted Check Valve Valve Material Porting Pump Pump Weight Brand Size Type Level Material Materials Seat Options Options... -

Page 5: Performance Curve

Performance Curve, S05 Metallic, Design Level 1 MODEL S05 Metallic Performance Curve Performance based on the following: elastomer fitted pump, flooded suction, water at ambient conditions. The use of other materials and varying hydraulic conditions may result in deviations in excess of 5%. -

Page 6: Dimensions (Aluminum Model)

Dimensions: S05 Metallic (Aluminum Model) Dimensions in Inches Dimensional tolerance: ± " DIMENSION Integral Muffl er 4 5/16" 7 5/16" Pulse Output Kit 4 5/16" 7 5/16" Mesh Muffl er 6" 9" Sound Dampening Muffl er 6" 9" Metal Muffl er 5 5/8"... -

Page 7: Metric Dimensions (Aluminum Model)

Metric Dimensions: S05 Metallic (Aluminum Model) Dimensions in millimeters Dimensional tolerance: ±3mm DIMENSION Integral Muffl er 109mm 186mm Pulse Output Kit 109mm 186mm Mesh Muffl er 152mm 229mm Sound Dampening Muffl er 152mm 229mm Metal Muffl er 143 mm 219 mm... -

Page 8: Dimensions (Stainless Steel And Alloy C Models)

Dimensions: S05 Metallic (Stainless Steel & Alloy C Models) Dimensions in Inches Dimensional tolerance: ± " DIMENSION Integral Muffl er 4 5/16" 7 5/16" Pulse Output Kit 4 5/16" 7 5/16" Mesh Muffl er 6" 9" Sound Dampening Muffl er 6"... -

Page 9: Metric Dimensions ( Stainless Steel And Alloy C Models)

Metric Dimensions: S05 Metallic (Stainless Steel & Alloy C Models) Dimensions in millimeters Dimensional tolerance: ±3mm DIMENSION Integral Muffl er 109mm 186mm Pulse Output Kit 109mm 186mm Mesh Muffl er 152mm 229mm Sound Dampening Muffl er 152mm 229mm Metal Muffl er... -

Page 10: Principle Of Pump Operation

1/2" (13mm) in diameter between the problems. body, the pressure to the chambers pump and the piping to reduce strain s05mdl1sm-REV0708 Model S05 Metallic Page 8... -

Page 11: Installation Guide

For Metallic Pumps Available from Warren Rupp Air Inlet Line CAUTION The air exhaust should be piped to an area for safe disposition of the product being pumped, in the event of a diaphragm failure. s05mdl1sm-REV0708 Model S05 Metallic Page 9... -

Page 12: Troubleshooting

Refer to the Air Exhaust section of your obstruction. Check and clear all suction pump as calculated on the published pump SERVICE MANUAL. screens and strainers. PERFORMANCE CURVE. Pump is cavitating the fl uid by fast cycling. s05mdl1sm-REV0708 Model S05 Metallic Page 10... -

Page 14: Material Codes

Philthane (Tuftane) PTFE (Bronze and moly fi lled) Warren Rupp, SANDPIPER, Portapump, Oil Impregnated Carboxylated Nitrile Filled PTFE Tranquilizers and SludgeMaser are registered Die Cast Zinc Fluorinated Nitrile Blue Gylon tradenames of Warren Rupp, Inc. s05mdl1sm-REV0708 Model S05 Metallic Page 12... -

Page 16: Composite Repair Parts Drawing

PTFE and Santoprene Diaphragm, PTFE Check Balls, PTFE Seats. 476-199-654 WETTED END KIT Santoprene Diaphragm, PTFE Overlay Diaphragm, PTFE Check Balls, PTFE Seats. 476-199-659 WETTED END KIT One-PIece Bonded PTFE/Nitrile Diaphragm, PTFE Balls, PTFE Seats. *OVERLAY OPTION s05mdl1sm-REV0708 Model S05 Metallic Page 14... -

Page 17: Composite Repair Parts List

5/16 Lock Washer (Aluminum) 312-110-157 Elbow, Suction 900-004-115 5/16 Lock Washer (Stainless Steel) 312-111-157 Elbow, Discharge 900-004-330 5/16 Lock Washer (Stainless Steel) 360-099-360 Gasket, Spacer (used TPE Diaphragms only) Note: Atex Compliant 360-100-379 Gasket, Air Inlet s05mdl1sm-REV0708 Model S05 Metallic Page 15... -

Page 18: Air Distribution Valve Assembly Drawing And Parts List

Hex Flange Capscrew 1/4-20 x .75 NOTE: Pumps equipped with integral muffl ers are not ATEX compliant. NOTE: Pumps equipped with this valve assembly are ATEX compliant when a metal Note: Atex Compliant muffl er is used. s05mdl1sm-REV0708 Model S05 Metallic Page 16... -

Page 19: Air Distribution Valve Servicing

A) from the sleeve. Be careful not to pump is now ready for operation. scratch or damage the outer diameter of the spool. Wipe spool with a soft cloth and inspect for scratches or wear. s05mdl1sm-REV0708 Model S05 Metallic Page 17... -

Page 20: Air Valve With Stroke Indicator Assembly Drawing And Part List

(Includes all other items used on 031-166-000 above) For Pumps with alternate Mesh Muffl er or Piped Exhaust: 031-169-000 Air Valve Assembly (Includes all items used on 031-167-000 above minus 1-H, 1-I and 1-J) Note: Atex Compliant s05mdl1sm-REV0708 Model S05 Metallic Page 18... -

Page 21: Air Distribution Valve With Stroke Indicator Option Servicing

Wipe spool with a soft the opposite end. clean cloth and inspect for scratches or abrasive wear. s05mdl1sm-REV0708 Model S05 Metallic Page 19... -

Page 22: Solenoid Shifted Air Valve Drawing And Parts List

(usually 1500 A). A maximum permissible ripple of 20% is valid for all magnets of direct-current design. s05mdl1sm-REV0708 Model S05 Metallic Page 20... -

Page 23: Solenoid Shifted Air Distribution Valve Option

Compressed air provides the pumping power, while electrical signals control pump speed (pumping rate). OPERATION The Solenoid Shifted SANDPIPER has a solenoid operated, air distribution valve in place of the standard SANDPIPER’s pilot operated, air distribution valve. Where a pilot valve is normally utilized to cycle the pump’s air distribution valve,... -

Page 24: Diaphragm Service Drawing, Non-Overlay

Diaphragm Service Diaphragm Service Diaphragm Service for Drawing Drawing, with Overlay One-Piece Bonded Use With TPE Diaphragms Only (286-116-000 only) s05mdl1sm-REV0708 Model S05 Metallic Page 22... -

Page 25: Diaphragm Servicing

Fasten the outer chamber (item diaphragm plate has a through hole smaller tapped hole in the inner Install the second outer chamber. 14) to the pump, using the capscrews instead of a threaded hole. (item 10) washers. s05mdl1sm-REV0708 Model S05 Metallic Page 23... -

Page 26: Pilot Valve Servicing, Assembly Drawing & Parts List

Replace the o-rings and sleeve spool, not to shear any o-rings. Use air inlet gasket (item 20). The pilot valve if necessary. BP-LS-EP-2 multipurpose grease, or assembly (item 3) can now be removed equivalent. for inspection and service. s05mdl1sm-REV0708 Model S05 Metallic Page 24... -

Page 27: Intermediate Assembly Drawing And Parts List

It is the responsibility far as they will go. of the purchaser to retain this manual for reference. Failure to comply with the recommendations stated in this manual will damage the pump, and void factory warranty. s05mdl1sm-REV0708 Model S05 Metallic Page 25... -

Page 28: Check Valve Servicing

METALLIC SEATS Two o-rings (or conductive PTFE seals) (item 29) are required for metallic seats. s05mdl1sm-REV0708 Model S05 Metallic Page 26... -

Page 29: Optional Muffl Er Confi Guration Drawing

Air Valve Body. This muffl er is equipped with a metal element. OPTION 6 530-035-000 Metal Muffl er screws directly into the Air Body. Option 0 Option 6 Option 1 and 2 Note: ATEX compliant s05mdl1sm-REV0708 Model S05 Metallic Page 27... -

Page 30: Dual Port Option Drawing (Aluminum Model)

Dual Port Option Drawing (Aluminum Model Only) s05mdl1sm-REV0708 Model S05 Metallic Page 28... -

Page 31: Dual Porting Options (Aluminum Model)

(See arrows and optional positioning elbows can be rotated 90° increments in the Dual Porting Drawing.) (see arrows and optional positioning in the Dual Port Options Drawing.) NOTE: See Repair Parts Lists on next page. s05mdl1sm-REV0708 Model S05 Metallic Page 29... -

Page 32: Single Porting Suction And Dual Porting Discharge (Aluminum Model)

Nut, Hex 5/16-18 560-083-360 O-ring (Alum Manifold) 560-083-363 O-ring (Alum Manifold) 560-083-364 O-ring (Alum Manifold) 560-083-365 O-ring (Alum Manifold) 720-064-600 Seal (Alum Manifold) 900-004-115 Lock Washer 900-004-330 Lock Washer *Quantities change from Composite Repair Parts List. s05mdl1sm-REV0708 Model S05 Metallic Page 30... -

Page 33: Pumping Hazardous Liquids

On ATEX compliant units the pump valve body (item 1-A). comes equipped with a metal muffl er SUCTION Piping or hose may now be installed. LINE Illustration #3 s05mdl1sm-REV0708 Model S05 Metallic Page 31... -

Page 34: Pulse Output Kit Drawing

Valve Assembly or onto the air valve and senses each stroke of the main spool. Consult the factory for further information and availability. Pulse Output Kits 475-244-001 10-30 VDC 475-244-002 110/220 VAC 475-244-003 10-30VDC, 110VAC and 220 VAC s05mdl1sm-REV0708 Model S05 Metallic Page 32... -

Page 35: Grounding The Pump

WARNING Take action to prevent static sparking. Fire or explosion can result, especially when handling flammable liquids. The pump, piping, valves, containers or other miscellaneous equipment must be grounded. s05mdl1sm-REV0708 Model S05 Metallic Page 33... -

Page 36: Ce Declaration Of Conformity

Declaration of Conformity Warren Rupp, Inc., 800 North Main Street, Mans eld, Ohio, certi es that Air-Operated Double Diaphragm Pumps Series: HDB, HDF, M Non-Metallic, S Non-Metallic, M Metallic, S Metallic, Containment Duty, Gas, UL, High Pressure, W, Submersible and Tranquilizers comply with the European Community Directive 98/37/EC, Safety of Machinery.

Need help?

Do you have a question about the s05 and is the answer not in the manual?

Questions and answers