Table of Contents

Advertisement

SERVICE & OPERATING MANUAL

Original Instructions

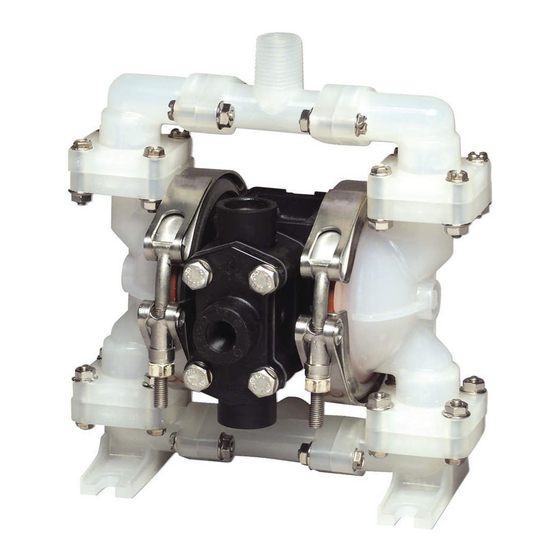

Model PB¼

Type 3

Air-Operated

Double Diaphragm Pump

Table of Contents

Engineering Data and Temperature Limitations ....................1

Performance Curve ...............................................................1

Explanation of Pump Nomenclature ......................................2

Dimensions ............................................................................3

Metric Dimensions .................................................................4

Principle of Pump Operation..................................................5

Check Valve Servicing ...........................................................5

Diaphragm Servicing .............................................................5

Troubleshooting .....................................................................6

Warranty ................................................................................6

Recycling ...............................................................................6

Important Safety Information .................................................6

Material Codes ......................................................................7

Installation Guide ...................................................................7

Composite Repair Parts Drawing ..........................................8

Available Service and Conversion Kits ..................................8

Composite Repair Parts List ..................................................9

Grounding the Pump .............................................................9

Solenoid Shifted Option Drawing.........................................10

Solenoid Shifted Air Valve Parts List ...................................10

Solenoid Shifted Options ..................................................... 11

Solenoid Connector Drawing ............................................... 11

CE Declaration of Conformity - Machinery ..........................12

CE Declaration of Conformity - ATEX ..................................13

Explanatiion of ATEX Markings ...........................................14

Warren Rupp, Inc., • A Unit of IDEX Corporation • 800 N. Main St., P.O. Box 1568, Mansfield, Ohio 44901-44902 USA

pb025nmdl3sm-rev0913

See pages 2, 13 and 14

See page 2

for ATEX ratings.

for ATEX ratings.

Telephone (419) 524-8388 • Fax (419) 522-7867 • www.warrenrupp.com

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Sandpiper Model PB 1/4

-

Page 1: Table Of Contents

SERVICE & OPERATING MANUAL Original Instructions Model PB¼ Type 3 See pages 2, 13 and 14 See page 2 for ATEX ratings. for ATEX ratings. Air-Operated Double Diaphragm Pump Table of Contents Engineering Data and Temperature Limitations ....1 Performance Curve ...............1 Explanation of Pump Nomenclature ........2 Dimensions ................3 Metric Dimensions ..............4... -

Page 3: Engineering Data And Temperature Limitations

The use of other materials and varying hydraulic conditions may result in deviations in excess of 5%. AIR CONSUMPTION SCFM (M 3 /hr) 1(1.7) 2(3.4) 3(5.1) 4(6.8) 5(8.5) 6(10.2) U.S. Gallons per minute Liters per minute (SANDPIPER pumps are designed to be powered only by compressed air) CAPACITY ® pb025nmdl3sm-rev0913 Page 1... -

Page 4: Explanation Of Pump Nomenclature

Explanation of Pump Nomenclature MATERIALS OF CONSTRUCTION To order a pump or replacement parts, first enter the Model Number PB1/4, followed by the Type Designation listed below in the far left column. Shipping Outer Inner Outer Intermediate Diaphragm Valve Ball Valve Diaphragm Options PB¼... -

Page 5: Dimensions

Dimensions: PB¼ Non-Metallic Dimension Standard 7" 3 1/8" 5 1/2" Pulse Output Kit 7" 3 1/8" 5 1/2" pb025nmdl3sm-rev0913 Page 3... -

Page 6: Metric Dimensions

Metric Dimensions: PB¼ Non-Metallic Dimension Standard Pulse Output Kit pb025nmdl3sm-rev0913 Page 4... -

Page 7: Principle Of Pump Operation

PRINCIPLE OF PUMP OPERATION phragm stroke when a actuator plunger is AIR VALVE LUBRICATION BETWEEN USES This ball type check valve pump is contacted by the diaphragm plate. This The air distribution valve and the When the pump is used for materials powered by compressed air and is a actuator plunger then pushes the end pilot valve are designed to operate... -

Page 8: Troubleshooting

TROUBLESHOOTING What to Check: Undersized suction What to Check: Pumped fluid in air What to Check: Blocked discharge Possible Symptoms: line. exhaust muffler. line. • Pump will not cycle. Corrective Action: Meet or exceed Corrective Action: Disassemble C o r r e c t i v e A c t i o n : C h e c k f o r •... -

Page 9: Material Codes

Aluminium, Black PTFE Coated Nylon General Electric Co. PVDF Coated Nylon Injection Molded Zinc Plated Steel Rupplon, SANDPIPER, PortaPump, Tranquilizer and Polyethylene Chrome Plated Steel SludgeMaster are registered tradenames of Glass Filled Polypropylene Aluminium, Electroless Nickel Plated Warren Rupp, Inc. -

Page 10: Composite Repair Parts Drawing

pb025nmdl3sm-rev0913 Page 8... -

Page 11: Composite Repair Parts List

Composite Repair Parts List ITEM PART NO. DESCRIPTION ITEM PART NO. DESCRIPTION 095-077-551 Body, Main Air Valve 612-146-520 Plate, Outer Diaphragm 095-077-503 Body, Main Air Valve 612-146-502 Plate, Outer Diaphragm 031-106-000 Sleeve & Spool Set 612-146-552 Plate, Outer Diaphragm 560-101-360 O-Rings 200-057-115 Clamp, V-Band... -

Page 12: Solenoid Shifted Option Drawing

Solenoid Shifted Option Drawing ASSEMBLY INSTRUCTIONS: Must Be Performed Prior To Start-Up. The tee (item SOLENOID SHIFTED AIR VALVE PARTS LIST 51), nipple (item 50), fitting (item 53) and tubing (item 52) have been pre-assembled at (Includes all items used on Composite Repair Parts List except as shown) the factory. -

Page 13: Solenoid Shifted Options

By alternately applying and removing power to the solenoid, the pump cycles much like a standard SANDPIPER pump, with one exception. This option provides a way to precisely control and monitor pump speed. -

Page 14: Ce Declaration Of Conformity - Machinery

Declaration of Conformity Manufacturer: Warren Rupp, Inc. , 800 N. Main Street, P.O. Box 1568, ® Mansfield, Ohio, 44901-1568 USA certifies that Air-Operated Double Diaphragm Pump Series: HDB, HDF, M Non-Metallic, S Non-Metallic, M Metallic, S Metallic, T Series, G Series, RS Series U Series, EH and SH High Pressure, W Series, SMA and SPA Submersibles, and Tranquilizer Surge Suppressors comply with the European Community Directive 2006/42/EC on Machinery, according to Annex VIII. -

Page 15: Ce Declaration Of Conformity - Atex

EC Declaration of Conformity In accordance with ATEX Directive 94/9/EC, Equipment intended for use in potentially explosive environments. Manufacturer: Applicable Standard: Warren Rupp, Inc. EN13463-1: 2001, ® EN13463-5: 2003 A Unit of IDEX Corportion 800 North Main Street P.O. Box 1568 Mansfield, OH 44901-1568 USA EN 60079-25: 2004 For pumps equipped with Pulse Output ATEX Option... -

Page 16: Explanatiion Of Atex Markings

EC Declaration of Conformity ATEX Summary of Markings Non-Conductive Type Marking Listed In Fluids Pump types, S1F, S15, S20, II 2 G Ex ia c IIC T5 KEMA 09ATEX0071 X KEMA 09ATEX0071 X and S30 provided with the II 3/2 G Ex ia c IIC T5 CE 0344 KEMA 09ATEX0071 X pulse output option...

Need help?

Do you have a question about the Model PB 1/4 and is the answer not in the manual?

Questions and answers

What must be the maintenance schecules to predict or prevent the failures?