Table of Contents

Advertisement

Table of Contents

Engineering Data and Performance Curve............................................................ 1

Explanation of Pump Nomenclature ...................................................................... 2

Recycling ............................................................................................................... 2

Temperature Limitations and Dimensions ............................................................. 3

Principle of Operation ............................................................................................ 4

Installation and Start-Up ........................................................................................ 4

Air Supply .............................................................................................................. 4

Air Inlet & Priming .................................................................................................. 4

Installation Guide ................................................................................................... 5

Air Exhaust ............................................................................................................ 7

Between Uses ....................................................................................................... 7

Flap Valve Servicing .............................................................................................. 7

Diaphragm Servicing ............................................................................................. 7

Reassembly ........................................................................................................... 7

Pilot Valve .............................................................................................................. 8

Pilot Valve Actuator ................................................................................................ 8

Service Instructions: Troubleshooting ................................................................... 8

Warranty, Recommended Accessories .................................................................. 8

Grounding The Pump ............................................................................................ 9

Material Codes .................................................................................................... 10

Composite Repair Parts List ........................................................................... 11-12

Composite Repair Drawing.................................................................................. 13

CE Declaration of Conformity - Machinery .......................................................... 14

CE Declaration fo Conformity - ATEX .................................................................. 15

Explanation of ATEX Certification ........................................................................ 15

Warren Rupp, Inc. • A Unit of IDEX Corporation • 800 N. Main St., Mansfield, Ohio 44902 USA

hdf2dl6sm-rev0316

See pages 17 for

II 2GD T5

ATEX ratings

: Externally Serviceable Air Distribution System ................................ 6

®

Telephone (419) 524-8388 • Fax (419) 522-7867 • warrenrupp.com

SERVICE & OPERATING MANUAL

Original Instructions

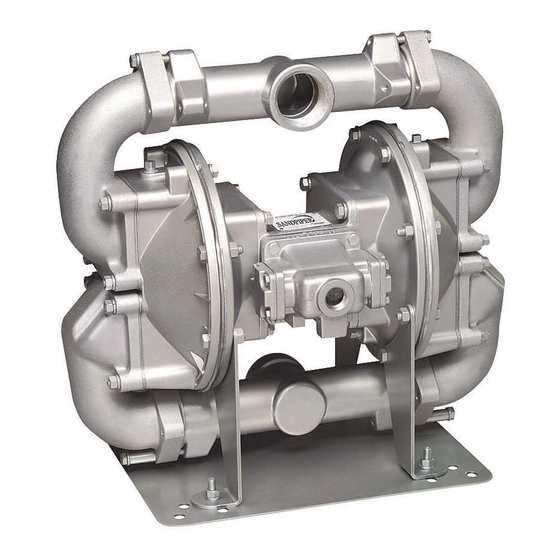

Model HDF2

Type 6

©Copyright 2016 Warren Rupp, Inc. All rights reserved.

Advertisement

Table of Contents

Summary of Contents for Sandpiper HDF2

-

Page 1: Table Of Contents

SERVICE & OPERATING MANUAL Original Instructions Model HDF2 Type 6 See pages 17 for II 2GD T5 ATEX ratings Table of Contents Engineering Data and Performance Curve............1 Explanation of Pump Nomenclature ..............2 Recycling ....................... 2 Temperature Limitations and Dimensions ............. 3 Principle of Operation .................... -

Page 2: Safety Information

Safety Information IMPORTANT WARNING When used for toxic or aggressive fluids, the pump should Read the safety warnings and instructions in this manual always be flushed clean prior to disassembly. before pump installation and start-up. Failure to comply with the recommendations stated in this manual could damage the pump and void factory warranty. -

Page 3: Engineering Data And Performance Curve

125 psi or 289 ft. of water (0 to 530 liters per minute) design (8.8 Kg/cm or 88 meters) MODEL HDF2 Performance Curve AIR CONSUMPTION SCFM (M /hr) Performance based on the following: elastomer fitted pump, flooded suction, water at ambient conditions. The use of other materials and varying hydraulic 10(17) 20(34) conditions may result in deviations in excess of 5%. -

Page 4: Explanation Of Pump Nomenclature

Explanation of Pump Nomenclature, HDF2 MATERIALS OF CONSTRUCTION To order a pump or replacement parts, first enter the Model Number HDF2, followed by the Type Designation listed below in the far left column. Outer Inner Flap Type Manifold Outer Inner... -

Page 5: Temperature Limitations And Dimensions

Maximum and Minimum Temperatures are the limits for which Materials and Dimensions: HDF2 these materials can be operated. Temperatures coupled with pressure affect the longevity of diaphragm pump components. Maximum life should not be expected at the extreme limits of the temperature ranges. -

Page 6: Principle Of Operation

For the most efficient use of compressed air and the longest diaphragm life, throttle the air inlet to the lowest cycling rate that does not reduce flow. hdf2dl6sm-rev0316 Model HDF2 Page 4... -

Page 7: Installation Guide

Bottom Discharge Flap Valve Unit CAUTION The air exhaust should be piped to an area for safe Available from disposition of the product Distributor being pumped, in the event of a diaphragm failure. Available from Warren Rupp hdf2dl6sm-rev0316 Model HDF2 Page 5... -

Page 8: Esads+Plus ® : Externally Serviceable Air Distribution System

A NOTE ABOUT AIR VALVE LUBRICATION The SANDPIPER pump’s pilot valve and main air valve assemblies are designed to operate WITHOUT lubrication. This is the preferred mode of operation. There may be instances of personal preference, or poor quality air supplies when lubrication of the com- pressed air supply is required. -

Page 9: Air Exhaust

This is important for dry prime. However, after priming action has started, valves will function due to differential pressure without concern or trouble. hdf2dl6sm-rev0316 Model HDF2 Page 7... -

Page 10: Pilot Valve

• Warren Rupp Speed Control: For manual or programmable process control. Manual adjustment or 4-20mA reception. For more detailed information on these accessories, contact your local Warren Rupp Factory-Authorized Distributor, or Warren Rupp corporate headquarters. hdf2dl6sm-rev0316 Model HDF2 Page 8... -

Page 11: Grounding The Pump

To reduce the risk of static electrical sparking, this pump must be grounded. Check the local electrical code for detailed grounding instruction and the type of equipment required, or in the absence of local codes, an industry or nationally recognized code having juristiction over specific installations. hdf2dl6sm-rev0316 Model HDF2 Page 9... -

Page 12: Material Codes

Silver Plated Steel Glass Filled Polypropylene; Color: BLACK Nickel Plated Unfilled Polypropylene; Color: NATURAL PortaPump, Tranquilizer and SludgeMaster are Filled Nylon Polyvinyl Chloride registered tradenames of Warren Rupp, Inc. Food Grade Santoprene; Color: NATURAL Black Vinyl hdf2dl6sm-rev0316 Model HDF2 Page 10... -

Page 13: Composite Repair Parts List

286.007.363 DIAPHRAGM 286.007.364 DIAPHRAGM 286.007.365 DIAPHRAGM 286.007.366 DIAPHRAGM 312.012.010 ELBOW SUCTION 312.012.110 ELBOW SUCTION 312.012.156 ELBOW SUCTION 334.014.010 FLANGE, SUCTION (DUAL PORTED ONLY) 334.014.110 FLANGE, SUCTION (DUAL PORTED ONLY) 334.014.156 FLANGE, SUCTION (DUAL PORTED ONLY) hdf2dl6sm-rev0316 Model HDF2 Page 11... - Page 14 STUD, 1/4-20 900.005.330 WASHER, LOCK, 3/8 900.006.330 WASHER, LOCK - 7/16 (ALUMINUM) 900.006.330 WASHER, LOCK - 7/16 902.003.000 WASHER, SEALING 560.046.360 O-RING (STAINLESS STEEL UNITS ONLY) Parts underlined are only available for sale in kits hdf2dl6sm-rev0316 Model HDF2 Page 12...

-

Page 15: Composite Repair Drawing

©2010 Warren Rupp, Inc. All rights reserved. ® SANDPIPER is a registered tradename of Warren Rupp, Inc. Printed in U.S.A. hdf2dl6sm-rev0316 Model HDF2 Page 13... -

Page 16: Ce Declaration Of Conformity - Machinery

Warren Rupp that bears a Warren Rupp brand shall fail under normal use and service due to a defect in material or workmanship within five years from the date of shipment from Warren Rupp’s factory. Warren Rupp brands include Warren Rupp ,SANDPIPER , MARATHON , PortaPump , SludgeMaster™... -

Page 17: Ce Declaration Fo Conformity - Atex

EC / EU Declaration of Conformity The objective of the declaration described is in conformity with the relevant Union harmonisation legislation: Directive 94/9/EC (until April 19, 2016) and Directive 2014/34/EU (from April 20, 2016). Manufacturer: Applicable Standard: Warren Rupp, Inc. EN13463-1: 2001 A Unit of IDEX Corportion EN13463-5: 2003...

Need help?

Do you have a question about the HDF2 and is the answer not in the manual?

Questions and answers