Table of Contents

Advertisement

SERVICE & OPERATING MANUAL

Original Instructions

Certified Quality

ISO 9001 Certified

ISO 14001 Certified

Warren Rupp, Inc.

A Unit of IDEX Corporation

800 N. Main St.,

Mansfield, Ohio 44902 USA

Telephone 419.524.8388

Fax 419.522.7867

SANDPIPERPUMP.COM

© Copyright 2017 Warren Rupp, Inc.

All rights reserved

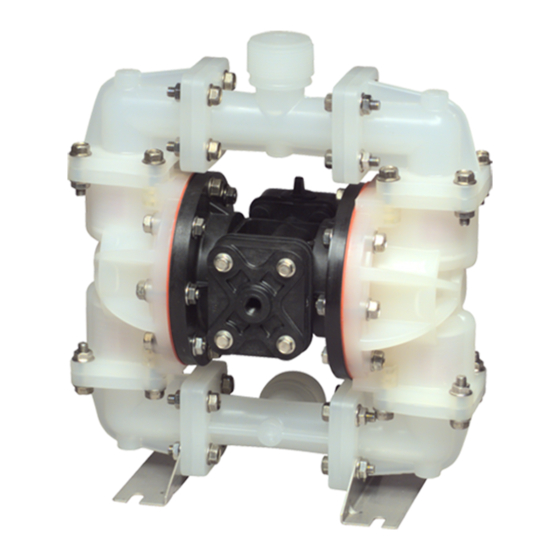

Model S07

Non-Metallic

Design Level 1

.

s a n d p i p e r p u m p

c o m

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Sandpiper S07

- Page 1 SERVICE & OPERATING MANUAL Original Instructions Certified Quality Model S07 Non-Metallic Design Level 1 ISO 9001 Certified ISO 14001 Certified Warren Rupp, Inc. A Unit of IDEX Corporation 800 N. Main St., Mansfield, Ohio 44902 USA Telephone 419.524.8388 Fax 419.522.7867 SANDPIPERPUMP.COM...

-

Page 2: Safety Information

Safety Information IMPORTANT WARNING When used for toxic or aggressive fluids, the pump should Read the safety warnings and instructions in this manual always be flushed clean prior to disassembly. before pump installation and start-up. Failure to comply with the recommendations stated in this manual could damage the pump and void factory warranty. -

Page 3: Table Of Contents

Table of Contents SECTION 1: PUMP SPECIFICATIONS ....1 • Explanation of Nomenclature • Performance • Materials • Dimensional Drawings SECTION 2: INSTALLATION & OPERATION ..5 • Principle of Pump Operation • Recommended Installation Guide • Troubleshooting Guide SECTION 3: EXPLODED VIEW ......8 •... -

Page 4: Explanation Of Nomenclature

E1, E3, E2. Solenoid Kit w/24VAC/12VDC Coil Polypropylene E5, E7, E8 or E9, are certified and approved by the above agencies. They are NOT ATEX compliant. Your Serial #: _____________________________________ (fill in from pump nameplate) sandpiperpump • Model S07 Non-Metallic s07nmdl1sm-rev0817... -

Page 5: Performance

Performance S07 NON-METALLIC MODEL S07 Ball Valve Non-Metallic Performance Curve Performance based on the following: elastomer fitted pump, flooded suction, water at ambient conditions. SUCTION/DISCHARGE PORT SIZE The use of other materials and varying hydraulic conditions may result in deviations in excess of 5%. - Page 6 S07 Non-Metallic Performance Curve, Trihedral Model MODEL S07 Trihedral Valve Performance Curve Performance based on the following: elastomer fitted pump, flooded suction, water at ambient conditions. The use of other materials and varying hydraulic conditions may result in deviations in excess of 5%.

-

Page 7: Dimensional Drawings

About Centerlines Ports are Available In: ¾" BSPT (Tapered) (Internal) 1½" BSPT (Tapered) (External) Dimension 4 1/16" 7 1/16" Standard Pump 4 1/16" 7 1/16" Pulse Output Kit Mesh Muffler 5 3/4" 9 15/16" sandpiperpump • Model S07 Non-Metallic s07nmdl1sm-rev0817... - Page 8 About Centerlines *Both Suction and Discharge Ports are Available In: ¾" BSPT (Tapered) (Internal) 1½" BSPT (Tapered) (External) R5/32" 4 Places Dimension 103mm 179mm Standard Pump 224mm Pulse Output Kit 103mm 146mm 222mm Mesh Muffler sandpiperpump Model S07 Non-Metallic • s07nmdl1sm-rev0817...

-

Page 9: Principle Of Pump Operation

MUFFLER source is at a higher level than the pump (flooded suction condition), pipe the exhaust higher than the product source to prevent siphoning spills. 1" DIAMETER AIR EXHAUST PIPING LIQUID LEVEL SUCTION LINE sandpiperpump • Model S07 Non-Metallic s07nmdl1sm-rev0817... -

Page 10: Recommended Installation Guide

To start the pump, slightly open the air shut-off valve. After the pump primes, the air valve can be opened to increase air flow as desired. If opening the valve increases cycling rate, but does not increase the rate of flow, cavitation has occurred. The valve should be closed slightly to obtain the most efficient air flow to pump flow ratio. sandpiperpump Model S07 Non-Metallic • s07nmdl1sm-rev0817... -

Page 11: Troubleshooting Guide

Inspect check valves and seats for wear and proper setting. Replace if necessary. Entrained air or vapor lock in chamber(s). Purge chambers through tapped chamber vent plugs. For additional troubleshooting tips contact After Sales Support at service.warrenrupp@idexcorp.com or 419-524-8388 sandpiperpump • Model S07 Non-Metallic s07nmdl1sm-rev0817... -

Page 12: Composite Repair Parts Drawing

PTFE/Santoprene Bond Diaphragm, PTFE Check Balls and PTFE Seals. 476-166-654 WETTED END KIT Santoprene Diaphragms, TFE Overlay Diaphragm, TFE Check Balls and TFE Seals. **Note: Pumps equipped with these components are not ATEX compliant. sandpiperpump Model S07 Non-Metallic • s07nmdl1sm-rev0817... -

Page 13: Composite Repair Parts List

675-042-115 Ring, Retaining 685-056-120 Rod, Diaphragm 720-012-360 Seal, Diaphragm Rod 720-046-600 Seal, Manifold 720-051-600 Seal, Check Valve Retainer 722-081-520 Seat, Check Valve 722-081-542 Seat, Check Valve 722-081-552 Seat, Check Valve NOT SHOWN: 535-069-000 Nameplate sandpiperpump • Model S07 Non-Metallic s07nmdl1sm-rev0817... -

Page 14: Material Codes

Check Balls/EPDM Seats out parts and pumps whenever possible, Color coded: YELLOW 661..EPDM/Santoprene ® after any hazardous pumped fluids are 666..FDA Nitrile Diaphragm, thoroughly flushed. PTFE Overlay, Balls, and Seals 668..PTFE, FDA Santoprene /PTFE ® sandpiperpump Model S07 Non-Metallic • s07nmdl1sm-rev0817... -

Page 15: Air Distribution Valve Assembly

Failure to comply with the recommendations stated in this manual will Note: Pumps equipped with this valve assembly are not damage the pump, and void factory warranty. ATEX compliant. ATEX Compliant sandpiperpump • Model S07 Non-Metallic s07nmdl1sm-rev0817... - Page 16 Push the spool in of the spool. Wipe spool with a soft until the pin touches the end cap on the clean cloth and inspect for scratches opposite end. or abrasive wear. sandpiperpump Model S07 Non-Metallic • s07nmdl1sm-rev0817...

-

Page 17: Air Valve With Stroke Indicator Assembly

(Includes all other items used on 031-166-000 above) For Pumps with alternate Mesh or Sound Dampening Mufflers or Piped Exhaust: 031-169-000 Air Valve Assembly (Includes all items used on 031-167-000 above minus 1-H, 1-I and 1-J) ATEX Compliant sandpiperpump • Model S07 Non-Metallic s07nmdl1sm-rev0817... -

Page 18: Pilot Valve Assembly

(item 3-A). Wipe capscrews. Connect the air supply to the pump. clean and inspect sleeve and o-rings for dirt, The pump is now ready for operation. cuts or wear. Replace the o-rings and sleeve if necessary. sandpiperpump Model S07 Non-Metallic • s07nmdl1sm-rev0817... -

Page 19: Intermediate Assembly

*Note: It is recommended that new retaining rings be installed. Next remove the two plunger bushings (items 7). Inspect the bushings for wear or scratches. Replace the bushings as necessary. Inspect the two o-rings (24) for cuts and/or wear. sandpiperpump • Model S07 Non-Metallic s07nmdl1sm-rev0817... - Page 20 Diaphragm Service Drawing, Diaphragm Service Drawing with Overlay (Use With TPE Diaphragms Only) Diaphragm Service Drawing with One-Piece Bonded sandpiperpump Model S07 Non-Metallic • s07nmdl1sm-rev0817...

- Page 21 Santoprene (13.56 Newton meters). Allow exterior of the standard TPE diaphragm void factory warranty. a minimum of 15 minutes to elapse after (item 14). sandpiperpump • Model S07 Non-Metallic s07nmdl1sm-rev0817...

- Page 22 219-009-005 Solenoid Coil,110VAC 50Hz like a standard SANDPIPER pump, with one exception. This option 219-009-006 Solenoid Coil, 230VAC 50Hz provides a way to precisely control and monitor pump speed.

-

Page 23: Declaration Of Conformity

Warren Rupp brand shall fail under normal use and service due to a defect in material or workmanship within five years from the date of shipment from Warren Rupp’s factory. Warren Rupp brands include Warren Rupp ,SANDPIPER ® ® SANDPIPER Signature Series , MARATHON , Porta-Pump , SludgeMaster™ and Tranquilizer ®...

Need help?

Do you have a question about the S07 and is the answer not in the manual?

Questions and answers