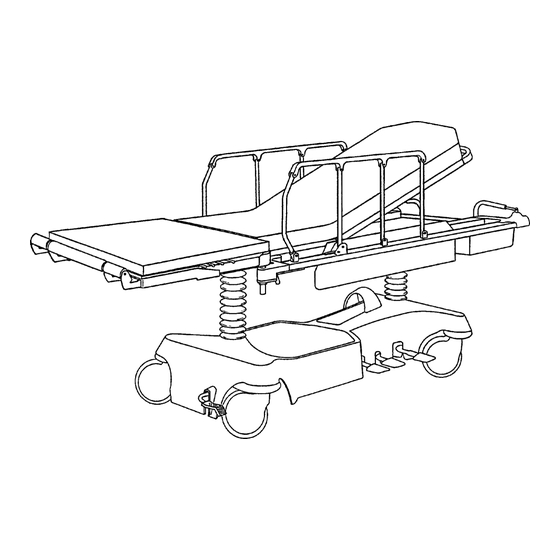

Stryker Medical Renaissance Series Maintenance Manual

Trauma bed

Hide thumbs

Also See for Renaissance Series:

- Maintenance manual (123 pages) ,

- Operation manual (19 pages) ,

- Maintenance manual (55 pages)

Summary of Contents for Stryker Medical Renaissance Series

- Page 1 IMPORTANT File in your maintenance records Renaissance Series 1060 OB/GYN Trauma Bed For stretchers with serial numbers of 9711034752 and above MAINTENANCE MANUAL For Parts or Technical Assistance 1–800–327–0770...

-

Page 2: Table Of Contents

Table of Contents Introduction Specifications ................Warning / Caution / Note Definition . - Page 3 Table of Contents Assembly Drawings and Parts Lists (Continued) Pneumatic Fowler Assembly ............Push Handle Assembly .

-

Page 4: Introduction

Introduction INTRODUCTION This manual is designed to assist you with the maintenance of the 1060 OB/GYN Trauma Bed. Read it thor- oughly before using the equipment or beginning any maintenance on it. SPECIFICATIONS Maximum Weight Capacity 400 pounds Overall Bed Length/Width 86.5”/31.75”... -

Page 5: Preventative Maintenance

Preventative Maintenance CHECKLIST (PERFORM A MINIMUM OF TWICE A YEAR) All fasteners secure (reference all assembly prints) Siderails move and latch properly (page 7) Engage brake pedal and push on the stretcher to ensure all casters lock securely (page 16) Steer function working properly All casters secure and swivel properly Body restraints working properly... -

Page 6: Cleaning

Cleaning Hand wash all surfaces of the stretcher with warm water and mild detergent. Dry thoroughly. DO NOT STEAM CLEAN, PRESSURE WASH, HOSE OFF OR ULTRASONICALLY CLEAN. Using these methods of cleaning is not recommended and may void this product’s warranty. Clean Velcro AFTER EACH USE. -

Page 7: Service Information

Service Information PNEUMATIC FOWLER ADJUSTMENT Required Tools: 3/32 Hex Allen Wrench 5/8 Open End Wrench 1/8 Hex Allen Wrench Channel Lock Pliers 3/16 Hex Allen Wrench Towel or Cloth 7/16 Open End Wrench Thread ”Locktite” Adjustment Procedure: 1. Refer to drawing 1060–1–30 (Pneumatic Fowler Assembly, page 52). 2. -

Page 8: Siderail Latch Adjustment

Service Information SIDERAIL LATCH ADJUSTMENT Required Tools: 1/8 Hex Allen Wrench WARNING The siderail latch adjustment is pre–set at the factory, and there should not normally be a need for readjust- ment. If adjustment must be done it is important to follow the procedure below. If it is not done properly, injury to the patient or user could occur. -

Page 9: Pedal Linkage Adjustment

Service Information PEDAL LINKAGE ADJUSTMENT – DUAL SIDE CONTROL BASE Required Tools: 3/32 Hex Allen Wrench 7/16 Open End Wrench 1/2 Open End Wrench (2) Wooden blocks (10 – 12 inches in length) Adjustment Procedure: 1. Pump the litter up to full height. 2. -

Page 10: Caster Cover Installation And Removal

Service Information CASTER COVER INSTALLATION AND REMOVAL Looking through the larger of the two side cut–outs, align cover with axle nut or bolt head, as shown. Double Prongs Push down on the opposite side of the cover until single prong engages with caster horn. Single Prong Top View (Cut–Away) Properly Attached... -

Page 11: Caster Maintenance

Service Information CASTER MAINTENANCE Required Tools: 5/8” Wrench 11/16” Wrench Maintenance Procedure: 1. Remove the plastic caster cover (see page 9). 2. Using the 5/8” wrench and the 11/16” wrench, remove the centerlock nut (item A) from the through bolt (item B) for the caster wheel. -

Page 12: Hydraulic System Troubleshooting

Service Information HYDRAULIC SYSTEM TROUBLESHOOTING Be sure the pedal linkage has been adjusted properly before beginning service on the jacks (see page 8). PROBLEM/SYMPTOM SOLUTION Jack will not raise to full height. Add hydraulic fluid (see p.12). Check for leaks. Jack will not hold in raised position. -

Page 13: Checking Hydraulic Fluid Level

Service Information CHECKING HYDRAULIC FLUID LEVEL Required Tools: 3/8 Open End Wrench 3/4 Open End Wrench Procedure: WARNING To avoid personal injury or damage to the stretcher, remove the litter and the base hood before beginning service on the jacks. 1. -

Page 14: Jack Descent Rate Adjustment

Service Information JACK DESCENT RATE ADJUSTMENT Required Tools: Screwdriver Bungee Cords (or equivalent) Adjustment Procedure: 1. Pump the litter up to full height. 2. Lift the base hood, separating the hood from the base frame. Using the bungee cords, support the base hood. -

Page 15: Hydraulic Check Valve Replacement

Service Information HYDRAULIC CHECK VALVE REPLACEMENT Required Tools: 3/8 Open End Wrench Stiff Wire (with bent, pointed end) Small Needle Nose Pliers 3/4 Open End Wrench Torque Wrench (with Ft. Lbs. adjust.) 7/32 Hex Allen Wrench 1/2 Inch Diameter Rod Replacement of Valve #1 WARNING To avoid personal injury or damage to the stretcher, remove the litter and the base hood before beginning... -

Page 16: Replacement Of Valve #2

Service Information HYDRAULIC CHECK VALVE REPLACEMENT (CONT’D) Replacement of Valve #2 WARNING To avoid personal injury or damage to the stretcher, remove the litter and the base hood before beginning service on the jacks. Lower the jack rod completely to relieve the pressure on the pump piston side of the jack. -

Page 17: Brake Adjustment

Service Information BRAKE ADJUSTMENT Required Tools: 3/32” Hex Allen Wrench Pry Bar Thread ”Locktite” BASE LUBRICATION Do not grease area shown. 1. Lubricate brake adjuster rod around area shown with MPG–2 grease or equivalent. - Page 18 Notes...

-

Page 19: Assembly Drawings And Parts Lists Base Assembly

1060–1–50 Base Assembly (with Wheels) - Page 20 1060–1–50 Base Assembly (with Wheels) Item Part No. Part Name Qty. 1210–1–120 Base Weldment Assembly (page 21) Brake Cam Ass’y, Hd. & Ft. 715–1–158 Caster Nut 715–1–61 Caster Brake Assembly (page 20) Brake Adjuster Assembly 715–201–201 Brake/Steer Pedal, Molded 14–2 Washer 26–13 Roll Pin...

-

Page 21: Brake Adjuster Assembly

715–1–150 Brake Adjuster Assembly Item Part No. Part Name Qty. 715–1–62 Threaded Stud Assembly 14–4 Nylon Washer 715–1–180 Bearing 28–8 Retaining Ring... -

Page 22: Brake Cam Assembly

715–1–213 Brake Cam Assembly Item Part No. Part Name Qty. 715–1–221 Brake Cam 16–59 Fiberlock Nut 8–21 Soc. Hd. Cap Screw 715–1–173 Brake Connecting Link... -

Page 23: Brake Pedal Assembly

716–1–263 Brake Pedal Assembly, Foot End Item Part No. Part Name Qty. 716–1–275 Brake Pedal 716–1–262 Brake Rod Ass’y, Ft. End NOTE Apply plastic adhesive to the mating surfaces of item A prior to assembly. -

Page 24: Caster Assembly

Caster and Caster Cover Replacement Kits Item Part No. Part Name Qty. 715–2–20 Caster Assembly 715–1–266 Caster Cover, Left 715–1–265 Caster Cover, Right P/N 715–259–400 – Kit to replace 4 standard caster assemblies with necessary hardware – no caster covers. P/N 715–269–400 –... -

Page 25: Fifth Wheel Base Assembly

Optional Fifth Wheel Base Assembly Item Part No. Part Name Qty. 3–20 Hex Hd. Cap Screw 16–16 Fiberlock Nut 16–49 Nylock Hex Nut 23–25 Hex Washer Hd. Screw 26–8 Roll Pin 81–219 Bearing (page 25) Fifth Wheel Assembly 715–1–136 Fifth Wheel Spring 715–1–149 715–1–157 Fifth Wheel Bearing... -

Page 26: Fifth Wheel Assembly

715–1–25 Fifth Wheel Assembly Item Part No. Part Name Qty. 715–1–339 Fifth Wheel Pivot Assembly 715–1–17 Fifth Wheel Bushing 16–11 Flexlock Nut 715–1–15 Spring 715–1–13 Fifth Wheel Bracket 16–12 Flexlock Nut 390–1–54 Wheel 3–31 Hex Head Cap Screw 3–82 Hex Head Cap Screw... -

Page 27: Base Assembly With Jacks

Side Control Base Assembly (with Jacks) Assembly part number 715–1–260... - Page 28 Side Control Base Assembly (with Jacks) Item Part No. Part Name Qty. 29–7 Dual Lock (Page 32) Jack Assembly 11–262 Flat Washer 3–62 Hex Hd. Cap Screw 11–3 Flat Washer 16–36 Nylock Hex Nut 715–1–192 Jack Support 3–85 Hex Hd. Cap Screw 715–1–193 Jack Support Clamp 13–38...

-

Page 29: Pump Pedal Assembly

Pedal Base Assembly, Pump Assembly part number 715–1–108 Item Part No. Part Name Qty. 715–1–83 Pedal Ass’y Weldm’t, Pump 715–1–126 Side Control Pedal Pad 81–44 Bearing, Bronze NOTE Apply plastic adhesive to the mating surfaces of item B prior to assembly. -

Page 30: Pedal Assembly, Left And Right

715–1–109 Pedal Base Assembly, Head End, Left Item Part No. Part Name Qty. 715–1–98 Release Ped. Wldmt., Hd. Lt. 721–40–25 Pedal NOTE Apply plastic adhesive to the mating surfaces of item B prior to assembly. - Page 31 715–1–110 Pedal Base Assembly, Head End, Right Item Part No. Part Name Qty. 715–1–97 Release Pedal Weldment 721–40–25 Pedal NOTE Apply plastic adhesive to the mating surfaces of item B prior to assembly.

-

Page 32: Base Hood Assembly

Base Hood Assembly Item Part No. Part Name Qty. 715–1–153 Hood Spacer 715–1–151 Foam Hood Mount 715–1–176 Oxygen Bottle Retainer 11–16 Washer 25–77 Pop Rivet... -

Page 33: 715-270-400 Jack Assembly

715–270–400 Jack Assembly Assembly part number 715–270–10 (reference only) Item Part No. Part Name Qty. Item Part No. Part Name Qty. 45–904 O–Ring 388–1–38 Plug 715–1–340 Cap Assembly 715–1–322 Reservoir 390–1–243 Gasket 390–1–244 Gasket 715–1–323 Actuator Cylinder 390–1–238 Gasket, Actuator 715–1–325 Actuator (Page 33) -

Page 34: Jack Base Assembly

Jack Base Assembly Assembly part number 715–370–5 (reference only) Item Part No. Part Name Qty. Item Part No. Part Name Qty. 14–50 Bearing Retainer 715–1–327 Cylinder Wear Ring 38–311 Compression Spring 715–1–328 Piston Wear Ring 45–6 O–Ring 715–1–329 Pump Seal 45–110 O–Ring 715–1–341... -

Page 35: Base Hood Labeling Assembly

Base Hood Labeling Assembly Item Part No. Part Name Qty. 1001–100–1 Hood Assembly 1060–1–7 Specification Label 741–1–145 Brake/Steer Label, Head 721–31–45 Brake/Steer Label, Foot 946–1–60 Stryker Logo Label 29–7 Dual Lock (not shown) 29–9 Dual Lock (not shown) 1010–1–50 Renaissance Series Logo Label... - Page 36 Stretcher Graphics Reference below for dept. label part numbers. Color Item A Control Label, Right Item B Control Label, Left Litter Bumper Strip 1001–700–111 1001–700–112 1010–700–15 PURPLE 1001–700–121 1001–700–122 1010–700–25 GREEN 1001–700–131 1001–700–132 1010–700–35 GRAY 1001–700–141 1001–700–142 1010–700–45 TEAL 1001–700–151 1001–700–152 1010–700–55 PINK...

-

Page 37: Base Assembly With Jacks

Side Control Base Assembly (with Jacks) - Page 38 Side Control Base Assembly (with Jacks) Item Part No. Part Name Qty. 3–47 Hex Head Cap Screw 3–62 Hex Hd. Cap Screw 3–85 Hex Hd. Cap Screw 4–146 Soc. Hd. Cap Screw 11–3 Washer 11–4 Flat Washer 11–262 Flat Washer 13–38 Ext.

-

Page 39: Release Pedal Assembly

Side Release Pedal Assembly Assembly part number 1210–1–150 Item Part No. Part Name Qty. 715–1–126 Side Control Pedal Pad 1210–1–152 Side Release Pedal Weldment 1... - Page 40 1060–1–210 Litter Assembly...

-

Page 41: Litter Assembly

1060–1–210 Litter Assembly HEAD END... - Page 42 1060–1–210 Litter Assembly...

- Page 43 1060–1–210 Litter Assembly Item Part No. Part Name Qty. Item Part No. Part Name Qty. 1060–1–245 Frame Weldment 16–3 Fiberlock Hex Nut 721–26–69 Upright Sleeve 15–21 Jam Nut 16–28 Nylock Hex Nut 1010–31–77 Gas Cylinder (page 53) Handle Ass’y 1010–31–31 Cylinder Mount 1010–26–80 Lock Pivot Ass’y, Rt.

-

Page 44: Arm Board Assembly, Left

1060–1–114 Arm Board Assembly, Left Shaft End (Ref.) Item Part No. Part Name Qty. 1060–1–77 Arm Board Ass’y, Left 16–28 Nylock Hex Nut 1010–32–98 Pivot 1060–1–74 Connecting Link Ass’y 1010–32–94 Pivot Arm Ass’y, Left 28–93 Retaining Ring 3–50 Hex Hd. Cap Screw 11–224 Nylon Flat Washer 14–21... -

Page 45: Arm Board Assembly, Right

1060–1–115 Arm Board Assembly, Right Shaft End (Ref.) Item Part No. Part Name Qty. 1060–1–76 Arm Board Ass’y, Right 16–28 Nylock Hex Nut 1010–32–98 Pivot 1060–1–74 Connecting Link Ass’y 1010–32–96 Pivot Arm Ass’y, Right 28–93 Retaining Ring 3–50 Hex Hd. Cap Screw 11–224 Nylon Flat Washer 14–21... -

Page 46: Board Support Assembly

1010–24–30 Board Support Assembly Item Part No. Part Name Qty. 1010–24–15 Support Block 1010–24–16 Support Arm 1010–24–14 Warning Label 38–263 Spring 8–17 Shoulder Bolt 1010–26–46 Ball Knob... -

Page 47: Foot Pan Assembly, Right

1060–1–97 Foot Pan Assembly, Right Item Part No. Part Name Qty. 1060–1–95 Foot Pan Weldment, Right (page 48) Foot Pan Latch Assembly 13–33 Internal Tooth Lock Washer 7–10 Truss Head Mach. Screw 1060–1–85 Foot Rest Cover, Right... -

Page 48: Foot Pan Assembly, Left

1060–1–98 Foot Pan Assembly, Left Item Part No. Part Name Qty. 1060–1–96 Foot Pan Weldment, Left (page 48) Foot Pan Latch Assembly 13–33 Internal Tooth Lock Washer 7–10 Truss Head Mach. Screw 1060–1–86 Foot Rest Cover, Left... -

Page 49: Foot Rest Assembly

1060–1–99 Foot Rest Assembly Item Part No. Part Name Qty. 1060–1–117 Pad, Foot Rest 1060–1–119 Bushing, Ft. Rest Lock 2 1060–1–118 Foot Rest 16–36 Nylock Nut 1060–1–132 Ft. Pan Handle Brkt. 1060–1–133 Foam Cover, Push Bar 1 1060–1–130 Tubing, Ft. Pan Handle 1 1–105 Flat Hd. -

Page 50: Leg Support Assembly

Leg Support Assembly Assembly part number 1060–1–165 (one) 960–62 (set of two) Item Part No. Part Name Qty. 1060–1–159 Leg Support Bar 24–44 T–Handle 1060–1–152 Disc 1060–1–153 1060–1–154 Split Ring 28–104 Retaining Ring 1060–1–155 Ball Post 1060–1–156 Leg Rest, ABS 1060–1–157 Mounting Plate 13–24... -

Page 51: Jack Support And Trend. Limiter Assembly

1060–1–20 Jack Support and Trend. Limiter Assembly Item Part No. Part Name Qty. 1060–1–8 Jack Support Ass’y, Right 1060–1–9 Jack Support Ass’y, Left 16–28 Nylock Nut 3–15 Hex Hd. Cap Screw (Page 51) Trend. Limiter Assembly 1010–32–85 Support Tube Assembly 46–1 Set Screw... -

Page 52: Trend. Limiter Assembly

1010–23–34 Trend. Limiter Assembly Item Part Name Part No. Qty. 1010–23–35 Limiter Plate Ass’y 4–8 Hex Soc. Machine Screw 15–4 Hex Nut 4–142 Hex Soc. Machine Screw 715–1–114 Limiter Pin Assembly 38–233 Extension Spring 16–16 Fiberlock Nut... -

Page 53: Pneumatic Fowler Assembly

1060–1–30 Pneumatic Fowler Assembly Item Part No. Part Name Qty. Item Part No. Part Name Qty. 1060–1–28 Fowler Weldment 21–104 Set Screw 1060–1–31 Handle Assembly 1060–1–32 Fowler Skin 1510–31–26 Housing 25–105 Pop Rivet 1510–31–28 Yoke 15–37 Jam Nut 946–35–25 Liner 1010–54–26 Handle Cover, Right 28–76... -

Page 54: Push Handle Assembly

Push Handle Assembly Assembly part number 1211–151–10 Item Part No. Part Name Qty. 26–10 Roll Pin 1010–254–24 Stop Link 1211–151–18 Sleeve Assembly... -

Page 55: Siderail Assembly, Right

1060–26–2 Siderail Assembly, Right FOOT END Item Part No. Part Name Qty. 1060–26–4 Top Rail 1010–26–83 Upright 1010–26–84 Upright, Bent 1010–26–82 Spacer 25–106 Semi–Tubular Rivet 1010–26–10 Round Hole Plug 1010–26–85 Upright, Latch 1010–26–12 Bent Spindle Stop... -

Page 56: Siderail Assembly, Left

1010–26–3 Siderail Assembly, Left Item Part No. Part Name Qty. 1060–26–4 Top Rail 1010–26–83 Upright 1010–26–84 Upright, Bent 1010–26–82 Spacer 25–106 Semi–Tubular Rivet 1010–26–10 Round Hole Plug 1010–26–85 Upright, Latch 1010–26–12 Bent Spindle Stop... -

Page 57: Foot End Mattress And Push Bar Assembly, 2

1060–25–2 Foot End Mattress & Push Bar Ass’y, 2” 1060–125–2 Foot End Mattress & Push Bar Ass’y, 3” Note: Mattress shown cut–away to show relationship of screws (D) to brackets (B) & (F) from inside, through fiberresin bottom panel of assembled mattress. Zipper in end panel allows entry under foam pad for installa- tion of screws (D). -

Page 58: Foot End Mattress And Push Bar Assembly, T-Shaped

1060–530–10 Foot End Mattress/Push Bar, T–Shaped Note: Mattress shown cut–away to show relationship of screws (D) to brackets (B) & (F) from inside, through fiberresin bottom panel of assembled mattress. Zipper in end panel allows entry under foam pad for installa- tion of screws (D). -

Page 59: Removable I.v. Pole Assembly

1060–625–25 Ft. End Mattress/Push Bar, Enhanced Comfort Note: Mattress shown cut–away to show relationship of screws (D) to brackets (B) & (F) from inside, through fiberresin bottom panel of assembled mattress. Zipper in end panel allows entry under foam pad for installa- tion of screws (D). -

Page 60: 2-Stage I.v. Pole Assembly

1211–110–10 2–Stage I.V. Pole Assembly Item Part No. Part Name Qty. 1001–59–32 Base Tube Assembly 1001–59–31 Extension Tube Assembly 1210–110–47 Lock Ring 1210–110–49 Lock Actuator 14–20 Nylon Flat Washer As Req’d 1010–59–16 I.V. Hook 52–17 Nylon Spacer 926–400–62 Stop Sleeve 1210–110–46 Back–Up Ring 8–31... -

Page 61: 2-Stage I.v. Pole Assembly

1010–59–10 Permanent I.V. Pole Assembly Item Part No. Part Name Qty. 1010–59–24 Base Tube Ass’y 1010–59–30 Exten. Tube Ass’y 1001–59–47 Lock Ring 1001–59–46 Lock Actuator 14–20 Nylon Flat Washer As Req’d 1010–59–16 I.V. Hook 52–17 Nylon Spacer 7–4 Truss Hd. Mach. Scr. -

Page 62: 2-Stage I.v. Pole Mounting Assembly

1010–81 2–Stage I.V. Mounting Assembly Item Part No. Part Name Qty. (Page 60) I.V. Pole Ass’y 1001–259–11 I V. Socket Ass’y 4–91 But. Hd. Cap Screw 16–20 Self–Locking Nut 1001–59–42 I.V. Plug... -

Page 63: Upright Oxygen Bottle Holder Assembly

1010–30 Upright Oxygen Bottle Holder Assembly Item Part No. Part Name Qty. 1010–30–11 Upright Bottle Holder 27–12 Cotter Pin 741–30–24 Nylon Stand–Off 1010–30–17 Label... -

Page 64: Procto Board Assembly

1060–50 Optional Procto Board Assembly Item Part No. Part Name Qty. 1060–50–9 Mounting Bracket Ass’y 4–148 Hex Soc. But. Hd. Cap Screw 16–36 Nylock Nut 1060–50–11 Arm Assembly 1060–50–10 Platform Assembly 7900–1–102 Velcro Pile 3–21 Hex Hd. Cap Screw 17–6 Acorn Nut 1060–50–20 Mattress Assembly... -

Page 65: C-Spine Cassette Holder Assembly

1060–70–1 C–Spine Cassette Holder Assembly Item Part No. Part Name Qty. (page 65) Support Pole Assembly 1060–70–25 I.V. Adaptor 1010–70–18 Specification Label (page 66) Storage Bracket Assembly 3–47 Hex Hd. Cap Screw 37–56 Washer 16–28 Nylock Nut 37–55 11–2 Washer 4–75 Soc. -

Page 66: C-Spine Support Pole Assembly

1010–70–10 C–Spine Support Pole Assembly View A–A Item Part No. Part Name Qty. 1010–70–33 Support Tube Cap 26–6 Roll Pin 1010–70–34 Support Arm Weldment 1010–70–42 Cassette Holder Weldment 1010–70–50 Adjustment Tube Weldment 1010–70–30 Base Tube Weldment 1010–70–45 Knob 25–55 Pop Rivet 1010–70–44 Pivot Pin 26–5... -

Page 67: Storage Bracket Assembly

921–70–19 Storage Bracket Assembly 4” (Ref.) 5.5” (Ref.) Item Part No. Part Name Qty. 921–70–20 Storage Bracket Weldment 1010–70–45 Knob 1010–70–23 Storage Label... -

Page 68: Warranty

Warranty Limited Warranty: Stryker Medical Division, a division of Stryker Corporation, warrants to the original purchaser that its products should be free from defects in material and workmanship for a period of one (1) year after date of delivery. Stryker’s obligation under this warranty is expressly limited to supplying replacement parts and labor for, or replacing, at its option, any product which is, in the sole discretion of Stryker, found to be defective. -

Page 69: Return Authorization

Warranty Return Authorization: Merchandise cannot be returned without approval from the Stryker Customer Service Department. An autho- rization number will be provided which must be printed on the returned merchandise. Stryker reserves the right to charge shipping and restocking fees on returned items. SPECIAL, MODIFIED, OR DISCONTINUED ITEMS NOT SUBJECT TO RETURN. - Page 70 6300 Sprinkle Road, Kalamazoo, MI 49001–9799 (800) 327–0770 DH 11/97 1060–1–142 REV J...

Need help?

Do you have a question about the Renaissance Series and is the answer not in the manual?

Questions and answers