Subscribe to Our Youtube Channel

Summary of Contents for APS ELM205-V10

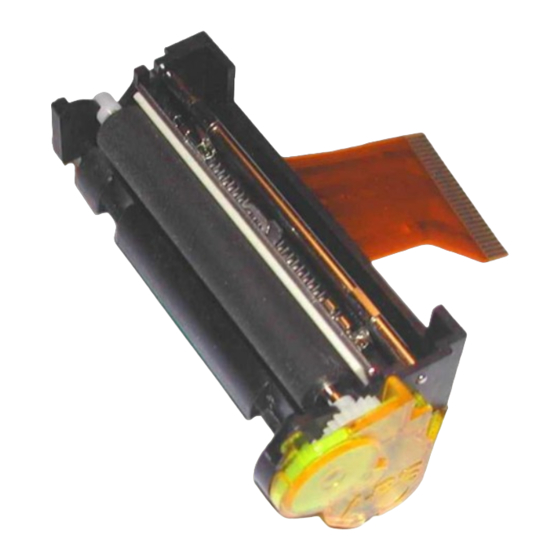

- Page 1 Advanced Printing Systems Front page ELM205-V10 Technical Manual ELM205-V10 - Technical Manual - Rev. F Page 1...

- Page 2 08-Nov-11 Page 5 Updated Operating Temperature Range to - 20/+60 °C 15-Nov-12 Added Additional Accessories 10-Apr-13 Page12 Updated step motor timing diagram Page 16 Updated pin out assignment Updated Chapter 5. ELM205-V10 - Technical Manual - Rev. F Page 2...

-

Page 3: Table Of Contents

Advanced Printing Systems TABLE OF CONTENTS Sec. Page 1. INTRODUCTION .......................4 1.1 ELM205-V10 F ....................4 EATURES 2. GENERAL CHARACTERISTICS ..................5 3. THERMAL HEAD AND PRINTING CONFIGURATION ..........7 3.1 O ..........................7 UTLINES 3.2 T ..............7 HERMAL LECTRICAL HARACTERISTICS 3.3 T ........................8... -

Page 4: Introduction

Advanced Printing Systems 1. INTRODUCTION The ELM205-V10 printer has been designed to be the smallest, wide low voltage range (from 2.7V to 8.5V) and high efficiency (20% less consumption than standard 5V mechanisms) easy loading printer on the market. The unique easy loading APS concept makes the ELM205-V10 an ultra compact, reliable and cost- effective mechanism. -

Page 5: General Characteristics

Head-up detection Photo-interrupter (obtained with the paper end sensor) Paper end detection Photo-interrupter Recommended Operating voltage range ELM205-V10-LV Dots : 2.7-8.5 / Logic: 3.0- 5.25 ELM205-V10-HS Dots : 4.5-8.5 / Logic: 3.0- 5.25 Current consumption(LV) At printing (5V): 3.2 A (Head dots) (64 dots 0.5 A (Motor) - Page 6 - Room temp.: 20 Max. resistance value pulse resistance ~ 25°C ( ) of any dot, - Head temp.: Abrasion/wear 100 km of paper from its initial 65°C max. resistance value - Rated energy ELM205-V10 - Technical Manual - Rev. F Page 6...

-

Page 7: Thermal Head And Printing Configuration

(LA) Latch hold time t h (LA) Data out delay time t d (S O) STB setup time t s u (S TB) Driver out delay time t d (DO) µs ELM205-V10 - Technical Manual - Rev. F Page 7... -

Page 8: Timing Chart

• If print cycle is less than 2.5 ms/line (above 50 mm/s) then maximum supply energy value is decreased. For these applications, please contact A.P.S. for more information. This condition satisfies the print density as defined in section 3.5 ELM205-V10 - Technical Manual - Rev. F... -

Page 9: Typical Printing Conditions

N is the number of dots energized simultaneously is the common resistance (0.05 ) is the driver saturated resistance (11.7 ) is the lead resistance (10 ) ELM205-V10 - Technical Manual - Rev. F Page 9... -

Page 10: Thermistor

• The first bit of data (dot 1) entered is the first bit of data printed (FIFO), left side of TPH, top view (gearing side of the printer). • STB 1 to STB 6 are driving one sixth of the print-head, starting from dot 1. ELM205-V10 - Technical Manual - Rev. F... - Page 11 Advanced Printing Systems ELM205-V10 - Technical Manual - Rev. F Page 11...

-

Page 12: Operating Precautions

To prevent any dot element damage: At power up, make sure that logic voltage (Vdd) is present simultaneously or before VH. At power down, make sure that VH is at 0 V before removing logic voltage. ELM205-V10 - Technical Manual - Rev. F... -

Page 13: Stepper Motor

Coil resistance is 12 ; rated current is 300 mA (5V) per phase while feeding at 10mm/s. In case of high voltage or continuous printing application, please contact A.P.S. for current application circuitry. ELM205-V10 - Technical Manual - Rev. F... -

Page 14: Paper Feed Speed Versus Voltage

On the above example, if the ELM205-V10 works consecutively for 15 seconds, it must rest for 22.5s to allow the motor to cool down. ELM205-V10 - Technical Manual - Rev. F Page 14... -

Page 15: How To Optimize Speed, Consumption And Max. Peak Current

MaxPS will be the invert of the activation time multiplied by the number of blocks the head is divided into. Example: at 6.5 V with the ELM205-V10, let’s set the activation time as 1.76ms. If the maximum current available for the head is 2.4A, the maximum number of dots to be simultaneously activated will be 2.4A/(6.5V/176 )=64 dots. -

Page 16: Sensors

6.2 End of Paper Sensor The ELM205-V10 has an end of paper sensor achieved by a photo-transistor. Arrange the circuitry so that no energy is applied to the head when there is no paper. If the head is energized when there is no paper and the head is in the down position, then both roller and head may be strongly damaged. -

Page 17: Pin Out Assignment

Advanced Printing Systems 7. PIN OUT ASSIGNMENT One flexible cable is gathering all signals. The pitch at the end of the flexible cable is 1mm. FPC connector can be: JST 27FMN-BMT-TF ELM205-V10 Pin Number Signal Name Function Collector of photo-transistor... -

Page 18: Mechanical And Housing

To avoid any twist and mechanical stress on the cover and more generally on the customer plastic housing, APS has developed a unique and patented feature to ease the opening of the door that makes the mechanism very easy to open, not requiring any access to the cover’s sides, giving more flexibility and ergonomics to the customer design. -

Page 19: Ordering Code

Advanced Printing Systems Please contact A.P.S. to obtain the application notes and for any assistance in designing the lever. 9. ORDERING CODE Type Product name Ordering code ELM205-V10 Low Voltage (from 2.7V) ELM205-V10-LV 90200571 ELM205-V10 High Speed (95mm/s) ELM205-V10-HS 90200572 10.

Need help?

Do you have a question about the ELM205-V10 and is the answer not in the manual?

Questions and answers