Advertisement

Quick Links

Advertisement

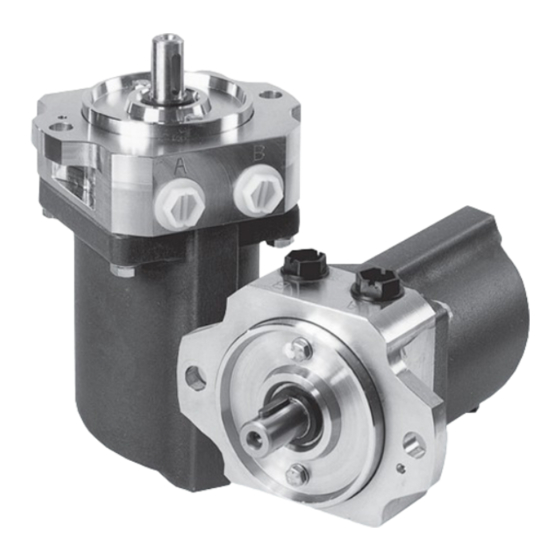

Summary of Contents for Danfoss MAH Series

- Page 1 Service guide MAH motor MAH 6.3 - 12.5 Disassembling and assembling hpp.danfoss.com...

- Page 2 Service guide | Disassembling and assembling MAH 6.3 - 12.5 Table of Contents Introduction ............................2 Disassembling the motor ......................... 3 Inspection .............................. 7 Assembling the motor ........................8 Service kit for MAH 6.3 ........................13 4.1. Service kit for MAH 12.5 ........................14 Exploeded view MAH 6.3 ........................

- Page 3 Service guide | Disassembling and assembling MAH 6.3 - 12.5 Disassembling the motor 1. Remove parallel key and unscrew front 2. Dismantle front cover using a vice. cover. 4. Remove the two small O-rings from flange. Remove seal from front cover using a screwdriver.

- Page 4 Service guide | Disassembling and assembling MAH 6.3 - 12.5 7. Remove pistons and retaining plate from 8. Remove retaining guide. cylinder barrel. 9. Remove pins and springs. 10. Remove cylinder barrel. 11. Remove port plate from fl ange. 12. Remove guide pin. 180R9152 | AX357937856579en-000402 | 07.2021...

- Page 5 Service guide | Disassembling and assembling MAH 6.3 - 12.5 13 Remove O-ring from flange.. 14. Remove O-ring from port. 15. Loosen thrust plate using a screwdriver. 16. Remove swash plate from housing. Place screwdriver in slot of thrust plate. 17.

- Page 6 Service guide | Disassembling and assembling MAH 6.3 - 12.5 18. Parts Thrust plate with sealing Swash plate Housing Flange Cylinder barrel Pistons Retaining guide Front cover Port plate Retaining plate Pins and springs O-rings Pins Seal Screws and washers Shaft seal Washer Spring...

- Page 7 Service guide | Disassembling and assembling MAH 6.3 - 12.5 Inspection 2.1. Port plate and thrust plate 2. Hold a ruler against the surface of the 1. Neither port plate nor thrust plate must plates and check the tightness against a show any sign of wear.

- Page 8 Service guide | Disassembling and assembling MAH 6.3 - 12.5 Assembling WARNING: Important: Do not use silicone when assembling the It is essential that the motoris serviced in motor. Do not reuse disassembled O-rings; conditions of absolute cleanliness. All parts they might be damaged.

- Page 9 Service guide | Disassembling and assembling MAH 6.3 - 12.5 1.5 - 2.5 mm 5. Mount thrust plate with seals on cylinder 6. Check that the gap between the cylinder barrel. barrel and the thrust plate is 1.5-2.5 mm. 7. Mount the cylinder barrel in the flange. 8.

- Page 10 Service guide | Disassembling and assembling MAH 6.3 - 12.5 11. Mount the retaining plate on the retainer 12. Insert the pistons. guide with plain surface pointing upwards. 13. Mount swash plate. 14. Mount housing using pin as guide. 15. Tighten screws to a torque of 13 Nm. 16.

- Page 11 Service guide | Disassembling and assembling MAH 6.3 - 12.5 17. Mount washer with edge pointing 18. Mount spring. upwards. 19. Fit hollow bush onto shaft. 20. Wet shaft seal and mount/slide it over bush. 22. Press shaft seal in position. 21.

- Page 12 Service guide | Disassembling and assembling MAH 6.3 - 12.5 23. Mount O-ring on front cover. 24. Wet shaft seal with water and mount it in front cover. . 25. Press shaft seal into front cover using 26. Mount front cover and align it to screw shaft seal tool.

-

Page 13: Unit Designation

Service guide | Disassembling and assembling MAH 6.3 - 12.5 Service kit list for MAH 6.3 Pos. Qnt. Unit Designation Material Shaft bush, torpedo Press tool for 18 mm shaft Mounting screw Housing with bearing (welded) AISI317Mg/PEEK Pcs. Screw (M6 x 22 mm) Pcs. - Page 14 Service guide | Disassembling and assembling MAH 6.3 - 12.5 4.1. Service kit list for MAH 12.5 Pos. Qnt. Unit Designation Material Shaft bush, torpedo Press tool for 18 mm shaft Mounting screw Housing with bearing (welded) AISI317Mg/PEEK Pcs. Screw (M8x25 mm) Pcs.

- Page 15 Service guide | Disassembling and assembling MAH 6.3 - 12.5 Exploded view MAH 6.3 180R9152 | AX357937856579en-000402 | 07.2021...

- Page 16 5.1. Exploded view MAH 12.5 Danfoss A/S High Pressure Pumps Nordborgvej 81 DK-6430 Nordborg Denmark 180R9152 | AX357937856579en-000402 | 16 © Danfoss | DHS (im) | 2021.07...

Need help?

Do you have a question about the MAH Series and is the answer not in the manual?

Questions and answers