Danfoss 51 Series Service Manual

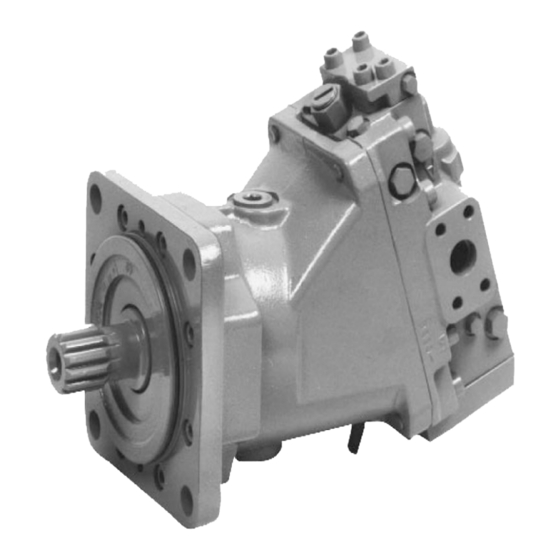

Bent axis motors

Hide thumbs

Also See for 51 Series:

- Service manual (48 pages) ,

- Repair instructions (36 pages) ,

- Service kit instructions (2 pages)

Table of Contents

Advertisement

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Danfoss 51 Series

- Page 1 Service Manual Bent Axis Motors Series 51 and 51-1 powersolutions.danfoss.com...

- Page 2 11009442 is correct number for Series 51 two position controls manual April 2009 remove list of manuals February 2009 Frame size 60 - Minimum displacement range to 36 ccm December 2007 First edition 11008567 | AX00000013en-US0202 © Danfoss | March 2016...

-

Page 3: Table Of Contents

Series 51 and 51-1 Motors Contents Introduction Overview......................................5 Ordering replacement parts and service..........................5 Safety precautions....................................5 Symbols used in Danfoss literature............................6 General instructions..................................7 Keep it clean....................................7 Inspect for system contamination............................7 Replace the O-rings and gaskets............................7 Lubricate all moving parts............................... 7 Torque procedure.................................. - Page 4 Minimum angle adjustment screw............................51 Disassembly....................................51 Inspection....................................51 Reassembly....................................52 4-Way valve and threshold springs............................52 4-Way valve....................................52 Disassembly...................................52 Inspection....................................54 Reassembly....................................54 Threshold adjustment screw and springs........................54 Disassembly...................................54 Inspection....................................56 Reassembly....................................57 Assembling the 4-way valve..............................57 11008567 | AX00000013en-US0202 © Danfoss | March 2016...

-

Page 5: Overview

It discusses those minor repairs you can perform without removing the motor’s end cap. These repairs will not affect the unit’s warranty. Major repairs require removing the motor’s end cap. This manual does not describe them. Only Danfoss Authorized Service Centers and / or original equipment manufacturers trained by Danfoss should perform these repairs. -

Page 6: Symbols Used In Danfoss Literature

Warning Hydraulic fluid contains hazardous material. Avoid prolonged contact with hydraulic fluid. Always dispose of used hydraulic fluid according to state, and federal environmental regulations. Symbols used in Danfoss literature WARNING may result in injury Tip, helpful suggestion CAUTION may result in damage to product or... -

Page 7: General Instructions

A servo piston changes the angle of the rotating group and varys the displacement of the motor. Decreasing displacement increases speed. Increasing displacement decreases speed. Several hydraulic and electrohydraulic controls are available. 11008567 | AX00000013en-US0202 | 7 © Danfoss | March 2016... -

Page 8: Series 51-1 Motors

The Series 51-1 control feeds servo pressure directly to the servo piston. Low system loop pressure for two-position controls, and high system loop pressure for pressure compensating controls actuates the servo piston. Rotating hardware and housing components are common between Series 51 and Series 51-1. 11008567 | AX00000013en-US0202 © Danfoss | March 2016... -

Page 9: Closed Circuit

In a closed circuit, hydraulic lines connect the main ports of the pump to the main ports of the motor. Fluid flows in either direction from the pump to the motor and back to the pump. Either of the hydraulic lines can be under high pressure. 11008567 | AX00000013en-US0202 | 9 © Danfoss | March 2016... -

Page 10: Open Circuit

(3) motor displacement. The machine load determines the system pressure. The directional valve routes fluid returning from the motor to the reservoir. Additional components may be necessary to provide dynamic breaking and to deal with overrunning loads. 11008567 | AX00000013en-US0202 10 | © Danfoss | March 2016... -

Page 11: Shafts

W40x2x30x18x9g per DIN 5480 — — — — — — W45x2x30x21x9g per DIN 5480 — — — — — — W50x2x30x24x9g per DIN 5480 — — — — — — 11008567 | AX00000013en-US0202 | 11 © Danfoss | March 2016... -

Page 12: Operation

The orificed relief cartridge controls flushing flow under most conditions. A combination of orifice size and charge pressure will produce a specific flushing flow. You may exchange the orificed relief cartridge for one with a different flow rating. 11008567 | AX00000013en-US0202 12 | © Danfoss | March 2016... -

Page 13: Displacement Limiters

P101 265E Displacement limiters Series 51 and Series 51-1 motors incorporate mechanical displacement limiters. You can set a specific displacement range by limiting the travel of the valve segment/rotating group. 11008567 | AX00000013en-US0202 | 13 © Danfoss | March 2016... -

Page 14: Mounting Configurations

V, C, or D following the number 51 in the model code. The designations represent: • V = SAE C, D, or E mounting flange • C = Cartridge style mounting • D = DIN ISO 3019/2 mounting flange 11008567 | AX00000013en-US0202 14 | © Danfoss | March 2016... - Page 15 Service Manual Series 51 and 51-1 Motors Operation SAE configuration P101 197 Cartridge configuration P101 198 DIN configuration P101 199 11008567 | AX00000013en-US0202 | 15 © Danfoss | March 2016...

-

Page 16: Speed Sensors

The output changes its high/low state as the north and south poles of the permanently magnetized speed ring pass by the face of the sensor. The digital signal is generated at frequencies suitable for microprocessor-based controls. 11008567 | AX00000013en-US0202 16 | © Danfoss | March 2016... -

Page 17: Controls

Complete functional description, maintenance, and repair procedures for 2-position controls are covered in detail in these supplements to this manual: • 11009442 Series 51 Hydraulic and Electrohydraulic Two-position Controls Types: N2, HZ, E1-E2, F1-F2, G1-G2, S1 11008567 | AX00000013en-US0202 | 17 © Danfoss | March 2016... - Page 18 11009443 Series 51-1 Controls Service Instructions Types: N1, E1-E2-E7, B1-B2-B7, T1, T2, T7, TA, TH Two-position control G3 6 G4 2 G3 8 G4 2 2 G3 8 M16A M18A M18A M16A M18A P101 268 11008567 | AX00000013en-US0202 18 | © Danfoss | March 2016...

-

Page 19: Pressure-Compensator Controls

Complete functional description, maintenance, and repair procedures for pressure-compensator controls are covered in detail in the supplement to this manual: • 11009442 Series 51 Two Position Controls Service Manual Types: T1, T2, TH, TA, PC, PD 11008567 | AX00000013en-US0202 | 19 © Danfoss | March 2016... -

Page 20: Proportional Controls

• 11009447 Series 51 Dual Input Hydraulic Proportional Controls Types: HP, HC, JA • 11009448 Series 51 Electrohydraulic Proportional Controls Types: EP, EQ, ER, ES, L1-L2, L7, A7, D7, D8 11008567 | AX00000013en-US0202 20 | © Danfoss | March 2016... -

Page 21: Technical Specifications

Displacement limiter All Series 51 motors incorporate mechanical minimum and maximum displacement limiters Shaft configuration Splined ANSI or DIN shaft Case pressure Rated pressure Maximum pressure (cold start) Minimum pressure 11008567 | AX00000013en-US0202 | 21 © Danfoss | March 2016... -

Page 22: Fluid Specifications

4,000 3,600 3,200 2,700 at minimum displacement 7,000 6,250 5,600 5,000 4,250 Contact your Danfoss representative for maximum speed at displacements between maximum and minimum displacement. Theoretical torque Frame size Displacement condition at maximum N•m/bar 0.95 1.28 1.75 2.56 3.98 displacement [lbf•in/1000 psi]... -

Page 23: Pressure Measurements

System pressure port A 600 bar [10,000 psi] 9/16-18 O-ring fitting System pressure port B 600 bar [10,000 psi] 9/16-18 O-ring fitting Servo pressure minimum angle 600 bar [10,000 psi] 9/16-18 O-ring fitting 11008567 | AX00000013en-US0202 | 23 © Danfoss | March 2016... - Page 24 System pressure A+B Guage port M1+M2 P107 758E Gauge information System pressure port A 600 bar [10,000 psi] 9/16-18 O-ring fitting System pressure port B 600 bar [10,000 psi] 9/16-18 O-ring fitting 11008567 | AX00000013en-US0202 24 | © Danfoss | March 2016...

- Page 25 60 bar [500 psi] gauge for 2-position control 9/16-18 O-ring fitting Servo supply pressure maximum angle 600 bar [10,000 psi] 60 bar [500 psi] gauge for 2-position control 9/16-18 O-ring fitting 11008567 | AX00000013en-US0202 | 25 © Danfoss | March 2016...

-

Page 26: Fluid And Filter Maintenance

Hydraulic fluid contains hazardous material. Avoid contact with hydraulic fluid. Always dispose of used hydraulic fluid according to state, and federal environmental regulations. Fluid and filter change interval Reservoir type Max. oil change interval Sealed 2000 hours Breather 500 hours 11008567 | AX00000013en-US0202 26 | © Danfoss | March 2016... -

Page 27: Initial Startup Procedures

Troubleshooting on page 29. Caution Low charge pressure may affect the operators ability to control the machine. 13. Shut down the prime mover. 14. Connect the external control input signal. 11008567 | AX00000013en-US0202 | 27 © Danfoss | March 2016... - Page 28 20. Remove gauges. 21. Plug the gauge ports. 22. Check reservoir level. 23. Add filtered fluid to the reservoir, if needed. The motor / transmission is now ready for operation. 11008567 | AX00000013en-US0202 28 | © Danfoss | March 2016...

-

Page 29: Troubleshooting

Excessive leakage will cause lower charge pressure Install loop flushing defeat option and monitor case and affect performance. flow. If case flow is excessive, motor may require major repair. Contact your Danfoss service provider. System operating hot Check Cause Corrective action Oil level Insufficient hydraulic fluid will cause overheating. -

Page 30: Motor Operates Normally In One Direction Only

Excess internal leakage causes lower charge Install loop flushing defeat option and monitor case pressure and affects system performance including flow. If case flow is excessive, motor may require major output speed. repair. Contact your Danfoss Service Provider. Low output torque Check Cause Corrective action... - Page 31 Excess internal leakage causes charge pressure to Install loop flushing defeat option and monitor case decay, reducing output torque. flow. If case flow is excessive, motor may require major repair. Contact your Danfoss Service Provider. 11008567 | AX00000013en-US0202 | 31 © Danfoss | March 2016...

-

Page 32: Adjustments

Clockwise rotation of the plug increases the setting, and counterclockwise rotation decreases the setting. The charge pressure setting will be reduced or increased at a rate of approximately 3.4 bar [50 psi] per turn. 11008567 | AX00000013en-US0202 32 | © Danfoss | March 2016... -

Page 33: Minimum Displacement Limiter

Warning Adjustment of the minimum displacement limiter can result in undesirable or unsafe speed conditions. Consult with the Original Equipment Manufacturer or your Danfoss representative before changing the minimum displacement setting. After adjustment, verify minimum displacement setting by using an appropriate test apparatus. - Page 34 [in³/rev] 12 - 29 [.73 - 1.77] M10 x 65 [2.56] 1.5 [.09] 30 - 36 [1.83 - 2.20] M10 x 80 [3.15] 11008567 | AX00000013en-US0202 34 | © Danfoss | March 2016...

-

Page 35: Maximum Displacement Limiter

Warning Adjusting the maximum displacement limiter can result in undesirable or unsafe speed conditions. Consult with the Original Equipment Manufacturer or your Danfoss representative before changing the maximum displacement setting. Limit the maximum displacement by setting the stroke of the servo piston. A stop screw and spacer is on the servo piston to limit the maximum displacement of the motor to less than 100%. -

Page 36: Series 51 Motors

(See the chart on the next page). Series 51-1 motors F10* F20* Control P101 222E 1. Remove the 4 screws (M16) retaining the control assembly using an 8 mm hex wrench. 11008567 | AX00000013en-US0202 36 | © Danfoss | March 2016... -

Page 37: Speed Sensor Installation And Adjustment

110 N•m [81 lbf•ft] for 250cm³ motor using a 10mm hex wrench. Caution Do not overtorque screws. Speed sensor installation and adjustment DIN and SAE flange units 1. Loosen locknut. Keep all old parts until you receive and inventory new parts. 11008567 | AX00000013en-US0202 | 37 © Danfoss | March 2016... - Page 38 Shaft 1/2 inch centerline wrench flats 22° 22° 3. Thread sensor (CW) into motor housing by hand until bottom end touches the speed ring. 4. Back out (CCW) 1/2 turn. 11008567 | AX00000013en-US0202 38 | © Danfoss | March 2016...

-

Page 39: Cartridge Units

11/16 in. 22.9 [0.90] 12.7 [0.50] flats 9/16-18UNF-2A thread Speed ring Orientation Air gap to be notch 1.52mm [0.060 in.] max. approximate Speed sensor 2-3 turn of thread P101 333E 11008567 | AX00000013en-US0202 | 39 © Danfoss | March 2016... -

Page 40: Minor Repair

5. Lubricate with petroleum jelly and install new O-ring (L050) to the groove in the flange. 6. Install the flange (L35) to the housing, using a seal protection sleeve on the shaft. 7. Install the 8 socket head capscrews (L70). 11008567 | AX00000013en-US0202 40 | © Danfoss | March 2016... -

Page 41: Cartridge Flanged Motors

7. Discard the shaft seal (L40) from the seal carrier (L75) after making certain that the new one fits. Caution Do not damage the seal carrier during removal. Inspection 1. Inspect the seal carrier (L75) and housing bore for damage. 11008567 | AX00000013en-US0202 | 41 © Danfoss | March 2016... -

Page 42: Reassembly

7. Remove the shaft seal protection sleeve. Loop flushing shuttle valve Disassembly 1. Thoroughly clean all external surfaces before disassembly. 2. Using an 11/16 inch hex wrench, remove the two hex plugs (G20) from the endcap. 11008567 | AX00000013en-US0202 42 | © Danfoss | March 2016... -

Page 43: Inspection

7. Place the K14 springs in to the hex plugs. 8. Install the hex plugs. 9. Torque the hex plugs to 41 N•m [30 lbf•ft] using an 11/16 hex wrench. Caution Do not overtorque hex plugs 11008567 | AX00000013en-US0202 | 43 © Danfoss | March 2016... -

Page 44: Charge Relief Valve

3. Install the spring (K70) to the poppet. 4. Install a new O-ring (K50) to the adjustment screw (K10). 5. Install the adjustment screw in the cavity. 6. Hand tighten the locknut (K90). 11008567 | AX00000013en-US0202 44 | © Danfoss | March 2016... -

Page 45: Orificed Style

8. Discard the O-ring after inspecting the new one to make certain that it fits. 9. Remove spring (K70). 10. Remove poppet (K80). Orificed charge relief valve K95A K000 P101 227 11008567 | AX00000013en-US0202 | 45 © Danfoss | March 2016... -

Page 46: Inspection

1. Install a new O-ring to the plug. 2. Install the plug into the cavity. 3. Torque plug (K90) to 40 N•m [30 lbf•ft] using a 1 inch wrench. Caution Do not overtorque plug 11008567 | AX00000013en-US0202 46 | © Danfoss | March 2016... -

Page 47: Maximum Angle Stop - Series 51 Motors

8mm internal hex wrench for 60cm³ motors. • a 10mm internal hex wrench for 80cm³, 110cm³, 160cm³ and 250cm³ motors. 6. If equipped, remove the spacer (F20) from the servo piston end. 11008567 | AX00000013en-US0202 | 47 © Danfoss | March 2016... -

Page 48: Inspection

10 mm internal hex wrench 110 N•m [81 lbf•ft] for 250 cm³ motors for F10 use an 8 mm internal hex wrench 23 N•m [17 lbf•ft] for 60 cm³ motors for F10 11008567 | AX00000013en-US0202 48 | © Danfoss | March 2016... -

Page 49: Reassembly

1. Remove the 4 screws (M16) retaining the control assembly using an 8mm internal hex wrench. 2. Remove the control assembly. Series 51-1 maximum displacement limiter F10* F20* Control P101 222E Legend 11008567 | AX00000013en-US0202 | 49 © Danfoss | March 2016... -

Page 50: Inspection

6. Install the control. 7. Install the control screws (G24). 8. Torque the control screws (M16) to 78 N•m [58 lbf•ft] using an 8mm hex wrench. Caution Do not overtorque screw 11008567 | AX00000013en-US0202 50 | © Danfoss | March 2016... -

Page 51: Minimum Angle Adjustment Screw

Warning Improper adjustment of the minimum displacement limiter can result in undesirable or unsafe speed conditions. Consult with the original equipment manufacturer or your Sauer-Danfoss representative before changing the minimum displacement setting. After adjustment, verify the minimum displacement setting by testing: using an appropriate test apparatus. -

Page 52: Reassembly

1. Remove screws (M22) from the control using: • 10 mm hex wrench for 60 cm³, 80 cm³, 110 cm³ motors • 12 mm hex wrench for 160 cm³ and 250 cm³ motors. 11008567 | AX00000013en-US0202 52 | © Danfoss | March 2016... - Page 53 1/8 inch hex wrench for G30 plugs. 6. Remove the O-rings (G12A and G30A) from plugs. 7. Discard the O-rings after inspecting the new one to make certain that it fits. 11008567 | AX00000013en-US0202 | 53 © Danfoss | March 2016...

-

Page 54: Inspection

5. Remove orifices (T7 and T8) from the sleeve (F32) using a 2.5 mm internal hex wrench. Threshold adjustment screw and springs Disassembly 1. Remove threshold spring guide (J20) from the cavity. 2. Remove the threshold spring(s) (S10). 11008567 | AX00000013en-US0202 54 | © Danfoss | March 2016... - Page 55 7. Turn the motor over to access the threshold adjustment screw (J90). 8. Loosen locknut (J70). 9. Loosen the mounting sleeve (J60) holding the threshold adjustment screw (J40) using a 13 mm wrench. 11008567 | AX00000013en-US0202 | 55 © Danfoss | March 2016...

-

Page 56: Inspection

P101 231 1. Clean all parts. 2. Inspect all parts. 3. Replace any part, as necessary, discarding old or worn parts only after making certain you have the correct replacement(s). 11008567 | AX00000013en-US0202 56 | © Danfoss | March 2016... -

Page 57: Reassembly

4-way valve, in that order: 1. Install orifices (T7 and T8) in appropriate cavities in the 4-way valve sleeve using a 2.5mm hex wrench. 11008567 | AX00000013en-US0202 | 57 © Danfoss | March 2016... - Page 58 2.5 mm hex wrench for 60 cm³, 80 cm³, 110 cm³, 160 cm³, 250 cm³ motors 4 N•m [2.95 lbf•ft] 3. Install new O-rings (F324) on to the 4-way valve sleeve (F32). 11008567 | AX00000013en-US0202 58 | © Danfoss | March 2016...

- Page 59 12. Torque the cavity plugs (G12) to 37 N•m [27 lbf•ft] using a ¼-inch hex wrench. 13. Torque the cavity plugs (G30) to 6 N•m [4 lbf•ft] using a 1/8-inch wrench. 11008567 | AX00000013en-US0202 | 59 © Danfoss | March 2016...

- Page 60 78 N•m [57.6 lbf•ft] using a 10 mm internal hex wrench for 60 cm³, 80 cm³, 110 cm³ motors. • 110 N•m [81 lbf•ft] using a 12 mm internal hex wrench for 160 cm³ and 250 cm³ motors. Caution Do not overtorque screws. 11008567 | AX00000013en-US0202 60 | © Danfoss | March 2016...

- Page 61 Service Manual Series 51 and 51-1 Motors 11008567 | AX00000013en-US0202 | 61 © Danfoss | March 2016...

- Page 62 Service Manual Series 51 and 51-1 Motors 11008567 | AX00000013en-US0202 62 | © Danfoss | March 2016...

- Page 63 Service Manual Series 51 and 51-1 Motors 11008567 | AX00000013en-US0202 | 63 © Danfoss | March 2016...

- Page 64 Phone: +86 21 3418 5200 Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products already on order provided that such alterations can be made without changes being necessary in specifications already agreed.

Need help?

Do you have a question about the 51 Series and is the answer not in the manual?

Questions and answers