Summary of Contents for BeaconMedaes HTM02-01

- Page 1 Operation and Maintenance Instructions Emergency Reserve Manifold - ERM HTM02-01 Part number 2005715 Revision 05 May 24, 2019...

- Page 2 Operation and Maintenance Manual Emergency Reserve Manifold This unit is purchased from: Date purchased: Model number: Serial number: Option(s) included: Any information, service or spare parts requests should include the serial number and be directed to: BeaconMedæs Telford Crescent, Staveley Derbyshire S43 3PF Telephone: +44 (0) 1246 474242 Email: gbn.info@beaconmedaes.com Website Contacts: www.beaconmedaes.com BeaconMedæs reserves the right to make changes and improvements to update products sold previously without notice or obligation. Atlas Copco Ltd. trading as Atlas Copco Medical Unit 18 Nuffield Way, Abingdon, Oxfordshire, UK OX14 1RL Personnel must make themselves familiar with the contents of this manual and the function of the unit before installing, operating or maintaining. Abbreviations Abbreviation Full Description Abbreviation Full Description British Standard Kilo pascals British Standard Pipe Maximum...

-

Page 3: Table Of Contents

Emergency Reserve Manifold Table of Contents 0. Safety Precautions 1. General Information 2. Installation 3. Commissioning 4. Principles of Operation 5. Maintenance Procedures 6. Component Replacement Procedures 7. Recommended Spares Figures 1 - ERM General Arrangement 2 - Schematic Diagram 3 &... - Page 4 Emergency Reserve Manifold Not applicable 0. Safety Precautions 0.6 Cleaning The manifold should be wiped over with a damp This section gives safety, storage and handling cloth frequently to remove any dust or foreign information for the BeaconMedæs Emergency substances Reserve Manifold only.

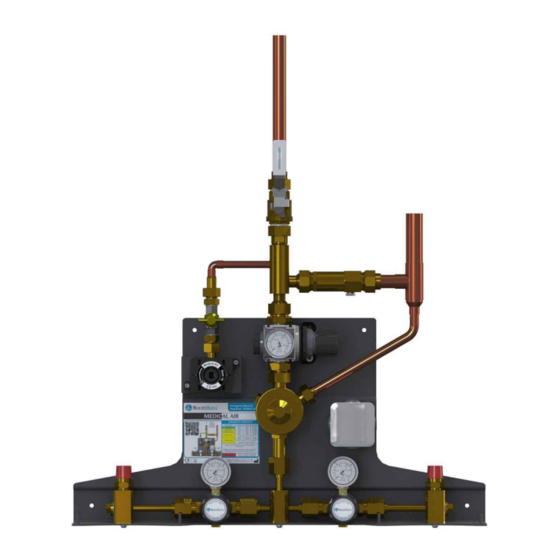

- Page 5 Emergency Reserve Manifold General Information The Emergency Reserve Manifold consists of: - 1. 2 x High Pressure Isolation Valves (1 per cylinder bank. Introduction 2. 2 x Cylinder Pressure Gauges with Contact Alarms (for signalling reserve low alarm fault). 3. 1st Stage Pressure Regulator (c/w inlet filter). The BeaconMedæs Emergency Reserve Manifold 4.

-

Page 6: Relief Valve Set Points

Emergency Reserve Manifold Figure 2 - Schematic Diagram the ERM from feeding the pipeline during normal operation of the primary system. 1st Stage Pressure Regulator For safe operation with regard to performance, mechanical strength, resistance to ignition in pure high pressure oxygen supply and cleanliness, the unit fully conforms to BS EN ISO 10524-2. - Page 7 Emergency Reserve Manifold Tabel 2 - Header extension kits Gas Type Oxygen 8102371280 8102371281 8102371282 8102371283 8102371284 8102371285 Nitrous 8102371286 8102371287 8102371288 8102371289 8102371290 8102371291 Oxide Entonox 8102371292 8102371293 8102371294 8102371295 8102371296 8102371297 O2/N2O Medical Air 8102371298 8102371299 8102371300 8102371301 8102371302 8102371303 Nitrogen...

-

Page 8: Installation

Emergency Reserve Manifold wall structure and selected fasteners are suitable for supporting the 16 kg weight of the ERM. Halogen Free Components 2.1.3 Identify the centre position of the ERM on The ERM contains NO HALOGENATED polymers the wall and mark. located in the gas stream that may experience pressurised oxygen in excess of 3000 kPa (30 Bar) 2.1.4... - Page 9 Emergency Reserve Manifold CAUTION: Supplied fixings are for use with solid masonry type walls only. Typical ERM weight is 16kg. Note - ‘J’ type cylinders typically for Oxygen and Medi- cal Air.‘G’ type cylinders typically for Nitrous Oxide and N2O/O2 mix (Entonox). 2.1.8 The pipework should be secured to the wall using munsen rings (not supplied).

-

Page 10: Reserve Low Alarm Wiring

Emergency Reserve Manifold “Reserve Low” alarm wiring. Figure 5 - Reserve Low Alarm Wiring To primary supplies 2.2.1 Use a flat bladed screw driver to pop the “Reserve Low” alarm input terminal cover at the corners. (Wired on sight) 2.2.2 Wire the reserve low alarm as shown in figure 5. - Page 11 Emergency Reserve Manifold Figure 6 - Cylinder header extension fitting de- tails (upgrade to 2 x 2) 3/8” x 5/8 BSP C/W seals 3/8” BSP plug and bonded seal Wall mounting holes x 4 Header Extension Figure 7 - Typical cylinder header extension layout details (upgrade to 2 x 2), extension kits from table 2.

- Page 12 Emergency Reserve Manifold 2.3.2 Additional Cylinder Header Extensions 2.3.2.3 Secure the previously fitted 5/8” connector (upgrade to 2 x 3 plus manifold). See figure 8 to to the extension header. 2.3.2.4 Repeat 2.3.2.1 & 2.3.2.3 for any additional CAUTION: Ensure that all the header rails header extensions.

- Page 13 Emergency Reserve Manifold Figure 10 - Typical cylinder header extension layout details (upgrade to 2 x 4), extension kits from table 3. Figure 11 - Typical cylinder header extension layout details (upgrade to 2 x 5), extension kits from table 3. 2005715.05...

- Page 14 Emergency Reserve Manifold Figure 12 - Typical cylinder header extension layout details (upgrade to 2 x 6), extension kits from table 3. NOTE - For additional cylinders continue to add the dimensions of the last header kit from either figure 9 or 10 for either single or double racks.

- Page 15 Emergency Reserve Manifold 2.5.7 Repeat the 2.6.3 to 2.6.6 for the right-hand cylinder bank. 2.5.8 Check the reserve low alarm is connected as shown in figure 5. 2.5.9 The installation must now be purged as per HTM 02-01 for UK installations, or as per relevant standards if installed outside the UK.

-

Page 16: Principles Of Operation

Emergency Reserve Manifold Commissioning regulators is a none relieving type. Always leave valve ‘C’ closed when finished. General 3.3.3 Check that the line pressure does not vary outside of the requirements of the installation (see table 4, Section 4 - Principle of Operating, for Commissioning of the ERM must be carried typical values). -

Page 17: Typical Cylinder Bank Changeover Pressure

Emergency Reserve Manifold When the ERM is in operation there is provision for continuous supply (see section 4.4 for bank cycling an alarm output to warn when the running bank procedure). contents is typically below half. The ERM contents gauge should then be locally monitored. The Bank Procedure to cycle banks &... -

Page 18: Maintenance Procedures

Emergency Reserve Manifold Typical Cylinder Handling cylinder key or handwheel where fitted and then turned clockwise a quarter turn. Checklist CAUTION: If there is any leakage of gas CAUTION: Only persons who have had the cylinder should be removed from service and specific training in the safety of medical gases, returned as faulty. - Page 19 Emergency Reserve Manifold Figure 15 - Manifold header Non-Return Valve all system pressures are normal; all alarms are showing “green” normal Inspection. lamps; the automatic manifold main isolating valve is open; and the manifold is supplying the hospital. 5.3.2 Close the isolating valve on the ERM slowly Bodok Seal and confirm that there is no effect on the line pressure to the hospital.

-

Page 20: Component Replacement Procedures

Emergency Reserve Manifold 5.3.9 Open Valve ‘C’ and carefully bleed gas from 6.0.3 Open the sampling outlet valve ‘C’, and the sampling outlet. probe the outlet to depressurise the system. 5.3.10 Observe the falling pressure on the contact CAUTION: When exhausting anaesthetic gauge. and oxygen manifolds ensure that the manifold room is well ventilated and no potential ignition 5.3.11 When the pressure falls to 14 bar for 100... -

Page 21: Sampling Outlet Replacement

Emergency Reserve Manifold Replace Sampling Outlet (See the 2nd fix and check valve capsule. table 6 for part numbers) Fit the new check valve, gas specific socket and locking spring. Secure in place with the 2nd fix Table 5 : Sampling Outlet Part Numbers spring. -

Page 22: 1St Stage Regulator Replacement

Emergency Reserve Manifold 6.3.3 Fully disconnect the two 1” joints as shown 6.4.4 Remove the relief valve and blanking plugs in figure 18 and gently remove the unit by sliding form the old regulator and fit to the new unit. it towards you. -

Page 23: 1St Stage Relief Valve Replacement

Emergency Reserve Manifold Replace High Pressure Bank 6.5.5 Taking care not to damage the O-ring seals replace the new relief valve as shown in figure 20, Valve (P/N: 2005820) and fasten the 2 flat face joints. 6.7.1 Complete steps in section 6.1 before 6.5.7 Follow steps in section 6.11 bring the ERM carrying out any component replacement on the... -

Page 24: Cylinder Header Non-Return Valve Replace

Emergency Reserve Manifold Replace Line Pressure Gauge Replace Cylinder Header Non-return Valves (see table 10 for part numbers) (see table 9 for part numbers) Table 9: Line Pressure Gauge Part Numbers Nominal Line Pressure Part Number Table 8: Header Non-return Valve Part Numbers 4 Bar 2005765... - Page 25 Emergency Reserve Manifold Figure 25 - Reserve Low Contact Gauge Alarm Wiring Note - 14 bar switch point typically used on N2O and CO2. 68 bar switch point typically used for O2, O2/N2O, Medical Air, Surgical Air and N2O. To primary supplies “Reserve Low”...

-

Page 26: Recommended Spares

Emergency Reserve Manifold Recommended Spares and Part Description Accessories Number 2005887 5 Year Overhaul Kit Oxygen 2005888 5 Year Overhaul Kit Nitrous Oxide Spares scheduling 5 Year Overhaul Kit Oxygen/Nitrous 2005889 Oxide The following table is the recommended spares 2005890 5 Year Overhaul Kit Medical Air holding, the number recommended spares for 2005891... - Page 27 Emergency Reserve Manifold Table 11b: Spares scheduling Quan- Quan- tity req./ Part tity req./ Part Item Item Number of Number of Num- ERM Description Num- ERM Description Panels Panels <5 >5 <5 >5 Contact Gauge – 0-315 1826850 Gem 10 2nd fix - Oxygen 2005773 1(2) 2(2)

- Page 28 Tel: +44 (0) 1246 474242 www.beaconmedaes.com Atlas Copco Airpower n.v. Boomsesteenweg 957 2610 Wilrijk - Belgium Atlas Copco Ltd. trading as Atlas Copco Medical 0088 Unit 18 Nuffield Way, Abingdon, Oxfordshire, UK OX14 1RL...

Need help?

Do you have a question about the HTM02-01 and is the answer not in the manual?

Questions and answers