BeaconMedaes Lifeline Installation, Operation And Maintenance Instructions

Lifeline medical systems. liquid by high pressure fully-automatic manifold

Hide thumbs

Also See for Lifeline:

Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for BeaconMedaes Lifeline

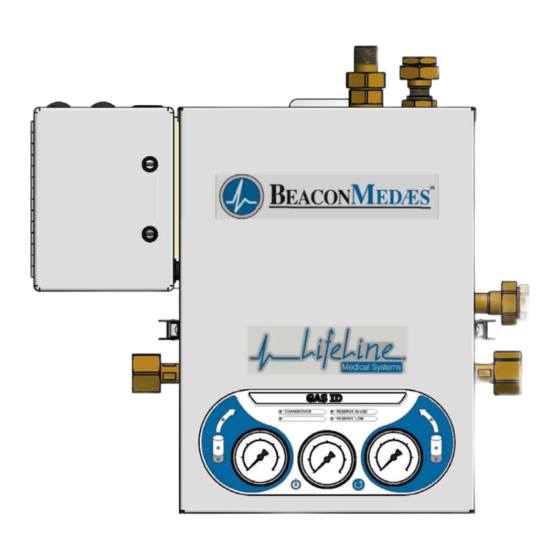

- Page 1 Installation, Operation and Maintenance Instructions LQ x HP Liquid x High-Pressure Models Liquid x High-Pressure Models Lifeline Medical Systems Liquid by High Pressure Fully-Automatic Manifold Basic/TAE NFPA Part number 4107 9013 95 Revision 04 28 March 2018 U.S. Design Patent No. D734,854...

- Page 2 Installation, Operation and Maintenance Manual Lifeline Medical Systems High Pressure Fully-Automatic Manifold This unit is purchased from: Date purchased: Model number: Serial number: Option(s) included: Any information, service or spare parts requests should include the machine serial number and be directed to: BeaconMedæs...

-

Page 3: Table Of Contents

Liquid by High Pressure Manifold Table of Contents 1.0 Introduction 1.1 Audience 1.2 Abbreviations 1.3 Definition of Statements 1.4 Product Description 1.5 Environmental Considerations 1.6 Environmental Declarations 2.0 Installation 2.1 Precautions 2.2 Manifold System Components 2.3 Wall Mounting Instructions 2.4 Floor Mounting Instructions 2.5 Wall Mounting HP Reserve Header 2.6 Main Outlet and Relief Valve Connection 2.7 HP Reserve Header Connection... - Page 4 Liquid by High Pressure Manifold Table of Contents (continued) 4.0 Testing and Adjustments 4.1 Performance Verification 4.2 Bank Regulator Pressure Adjustment 4.3 Line Regulator Pressure Adjustment 4.4 Reserve Header Regulator Adjustment 4.5 Changeover Pressure Switch Adjustment 4.6 Reserve in Use Pressure Switch Adjustment 4.7 Secondary Low Pressure Switch Adjustment 4.8 Reserve Low Pressure Switch Adjustment 5.0 Service Procedures...

-

Page 5: Introduction

A typical This manual provides information related to the manifold system consists of a manifold control module installation and operation of the Lifeline Liquid x High with two banks. Liquid containers are connected to the Pressure manifold manufactured by BeaconMedæs. -

Page 6: Environmental Considerations

BeaconMedæs tries to understand, address, and The Lifeline manifold is designed in accordance with minimize the negative environmental effects that the National Fire Protection Association (NFPA) 99. the products and services may have, when being manufactured, distributed, and used, as well as at 1.5 Environmental Considerations... -

Page 7: Installation

Liquid by High Pressure Manifold 2.0 Installation 2.2 Manifold System Components 2.1 Precautions The manifold system may be shipped in more than one carton, depending on the number of cylinder WARNING: connections. The main carton contains the following items: • Tampering with gas specific connections shall be prohibited. -

Page 8: Wall Mounting Instructions

Liquid by High Pressure Manifold 2.3 Wall Mounting Instructions 1. Remove manifold control module from shipping 4. Mark wall 77-1/2” from finished floor in location carton and place face up on cardboard packaging where manifold will be mounted. Convert mark insert. - Page 9 Liquid by High Pressure Manifold Wall Mounting Instructions (cont.) Place bracket flat against wall as shown in Figure 2 and align top of bracket with level horizontal WARNING: line. Vertical center line of bracket will be vertical center line of installed manifold. Mounting top of Do not attempt to lift manifold alone.

- Page 10 Liquid by High Pressure Manifold Wall Mounting Instructions (cont.) Figure 3 4107 9013 95.04...

- Page 11 Liquid by High Pressure Manifold Wall Mounting Instructions (cont.) Hang manifold control module on tab of mounting bracket as shown in Figure 3. Using M8 hex bolt, attach manifold to wall bracket through slots in black plate (4 places). CAUTION: Do not use thread sealant on header or pigtail connections.

- Page 12 Liquid by High Pressure Manifold Wall Mounting Manifold Control (cont.) 11. Install large nut and plug on end of last header Assemble u-bolt and bracket hardware as extension. Tighten large nut. shown. Tighten u-bolt nuts. 10. Additional header extensions may be attached end to end if required.

-

Page 13: Floor Mounting Instructions

Liquid by High Pressure Manifold 2.4 Floor Mounting Instructions For floor mounting the manifold control panel and 7. Position entire assembly in desired manifold headers, a manifold control panel stand kit and an mounting location. Mark location of eight base appropriate number of manifold header stand kits mounting holes. - Page 14 Liquid by High Pressure Manifold Each header extension is shipped with a header Stand Kit, Manifold Control Panel bracket. Each header bracket shouldbe attached to a manifold header stand. Assemble each P/N 6-135000-KT header stand by attaching a post base to one end of 66-inch channel as shown in Figure 8, Detail A.

- Page 15 Liquid by High Pressure Manifold CAUTION: Manifold Control And Header Stand Kit Assembly Each header segment must be supported by a header bracket before additional header segments are added. DETAIL C DETAIL B DETAIL A Figure 8 4107 9013 95.04...

-

Page 16: Wall Mounting Hp Reserve Header

Liquid by High Pressure Manifold 2.5 Wall Mounting HP Reserve Header High pressure reserve header components may be 6. One more wall bracket should be installed to shipped in several cartons. One carton will contain support left side of reserve header assembly as the control section assembly consisting of regulator shown in Figure 11. - Page 17 Liquid by High Pressure Manifold Wall Mounting HP Reserve Header (cont.) Regulator Assembly Reserve Low Pressure Switch Figure 9 Top of bracket aligned with horizontal line on wall. NOTE: Distance between wall brackets to be determined by installer. Depending upon reserve header configuration, multiple brackets may be required.

- Page 18 Liquid by High Pressure Manifold Wall Mounting HP Reserve Header (cont.) Header Extesions Attach wall bracket at this location in order to support control section. Nut & Plug Figure 11 NOTE: Configuration and number of header extensions will vary depending upon size of high-pressure reserve header assembly (5-cylinder model shown).

-

Page 19: Main Outlet And Relief Valve Connection

Liquid by High Pressure Manifold 2.6 Main Outlet and Relief Valve 2.9 Reserve Low Pressure Switch Connection Wiring The reserve low pressure switch is located on the Manifold’s main outlet and relief valve outlet are high pressure reserve header assembly (Figure 9) supplied with zero clearance, O-ring sealed unions. - Page 20 Liquid by High Pressure Manifold Top View Alarm Power Data Neutral Three 1/2” conduit knockouts for AC power input Ground Line and alarm output field wiring 100-250 VAC Input Power Connection Terminals for Remote Alarm (Refer to wiring diagram) Figure 12 Standard Electronics Shown 4107 9013 95.04 2-14...

-

Page 21: Pigtail/Cylinder Connection

Liquid by High Pressure Manifold 2.12 Initial Power-Up and 2.11 Pigtail/Cylinder Connection Operational Testing 72” black flex pigtails are connected between manifold control panel left bank and liquid containers (Figure 13 See Figures 17, 18, and 19. and 15). Remove plastic shipping caps from manifold control panel inlets. - Page 22 Liquid by High Pressure Manifold 24” Stainless-Steel Flex 72” Flex Pigtail 24” Stainless-Steel Flex Pigtail Pigtail Figure 13 Figure 14 72” Flex Pigtail Rigid Copper Pigtail Rigid Copper Pigtail Figure 15 Figure 16 4107 9013 95.04 2-16...

- Page 23 Liquid by High Pressure Manifold • Yellow “RESERVE IN USE” and “SECONDARY LOW” lights turn off. 1. Release two latches on sides of manifold control module cover (one on each side). • If connected to a master alarm panel, “RESERVE IN USE” and “SECONDARY LOW” 2.

-

Page 24: Leak Test

Liquid by High Pressure Manifold 13. Close high-pressure cylinder on right side 22. Close high-pressure cylinder on right side of of manifold. Slightly open vent valve. Verify manifold and reserve header. following: 23. Wait 15 minutes. • Right bank contents gauge drops slowly. As right contents gauge drops below 1500 psi 24. - Page 25 Liquid by High Pressure Manifold Initial Power-Up and Operational Testing (cont.) Reserve In Use (Yellow) Reserve Low (Red) Changeover (Yellow) Secondary Low In Use (Green) (Yellow) Ready (Green) Empty (Red) Reset Manual Changeover Figure 17 4107 9013 95.04 2-19...

- Page 26 Liquid by High Pressure Manifold NFPA Version Shown 3/4” Source Shut- Off Valve Vent Valve Line Regulator Isolation Valve Master Valve Right Bank Contents Gauge Left Bank Contents Figure 18 Gauge Reserve Header Contents Gauge Reserve Header Master Valve Bleed Valve Reserve Low Pressure Switch Figure 19...

- Page 27 Liquid by High Pressure Manifold 4. Slowly open one liquid container on left and 13. Eliminate leaks by tightening or replacing right bank of manifold. connections or tubing. Retest and verify all leaks have been eliminated. 5. Slowly open one high-pressure cylinder on reserve header assembly.

-

Page 28: Operation

3.1 Precautions All Lifeline Manifold systems are designed in accordance with the current revision of NFPA 99 and WARNING: ISO 7396-1. There are three categories of Lifeline manifolds depending upon the delivery pressure. • Tampering with gas-specific connections shall be prohibited. Do not alter, remove or modify gas-specific connections. -

Page 29: Flow Characteristics

Liquid by High Pressure Manifold Manifold Specifications (cont.) NOTE: In order to ensure proper manifold switchover operation, do not set delivery pressure (line regulators) less than 40 PSI. OXYGEN OXYGEN OXYGEN NITROGEN ARGON ARGON 100 PSI 180 PSI Parameter (psi) 55 PSI 55 PSI 55 PSI... -

Page 30: Manifold Components

Liquid by High Pressure Manifold 3.4 Manifold System Components Refer to Figures 17, 20 and 21. Activation of switch indicates both manifold banks Master Valve Multi-turn high pressure valves allow have been depleted and flow is being provided by the flow from cylinders to be shut off. - Page 31 Liquid by High Pressure Manifold Manifold System Components (Cont.) Control Board Installed in NEMA 4 enclosure pre- Source Shutoff Valve, 1/4 turn valve used to isolate mounted to the back bracket. The electronic circuit manifold from hospital piping for repair. board that controls manifold switchover.

- Page 32 the property of pose for which it aconMedæs Engineering. Liquid by High Pressure Manifold Manifold System Components (cont.) NOTE: Some components not shown for clarity. 3/4” Shut-Off Valve Service Valve Line Relief Valve Relief Vent Outlet Control Board Vent Valve Fuse Line Regulator Power Supply...

- Page 33 Liquid by High Pressure Manifold Manifold System Components (cont.) NOTE: Some components not shown for clarity. Zero Clearance O-ring Sealed Union Reserve Header High-Pressure Regulator Bleed Valve Master Valve Reserve Low Pressure Switch/Transducer Figure 21 Revised: Date: Drawn: Date: 7/16/2013 Scale: UNLESS OTHERWISE SPECIFIED ALL DIMENSIONS ARE IN INCHES AND TOLERANCES ARE:...

- Page 34 Liquid by High Pressure Manifold NOTE: Dome regulators not used on oxygen manifolds design for 55 PSI delivery pressure. Figure 22 4107 9013 95.04...

- Page 35 Liquid by High Pressure Manifold Figure 23 4107 9013 95.04...

-

Page 36: Gas Flow Through The Manifold

Liquid by High Pressure Manifold 3.5 Gas Flow Through the Manifold Outlet pressure is routed to a dome regulator reducing pressure to 40 PSI at solenoid valve. Refer to Figure 22 and 23. Solenoid valve switches 40 PSI (dome bias pressure) Gas is provided to left manifold bank inlet via liquid to one of bank regulators. - Page 37 Liquid by High Pressure Manifold After left side liquid containers have been depleted, If a situation occurs where both banks are depleted, pressure falls to left bank pressure switch setting (100 normally closed reserve in use switch will open and PSI).

-

Page 38: Testing And Adjustments

Liquid by High Pressure Manifold 4.0 Testing and Adjustments 5. Verify the following: • Only left bank green “IN USE” and right bank WARNING: green “READY” lights are illuminated. If necessary, most service, adjustment, and testing • Yellow “CHANGEOVER,” yellow “RESERVE IN can be performed while manifold is in service. - Page 39 Liquid by High Pressure Manifold 18. Close vent valve. If manifold is connected to a master alarm panel, verify “CHANGEOVER” NOTE: “SECONDARY LOW” and “RESERVE IN USE” alarms are activated. Line regulator values listed in Table 1 are nominal factory settings. Actual customer settings may vary. 19.

-

Page 40: Bank Regulator Pressure Adjustment

Liquid by High Pressure Manifold • If connected to a master alarm panel, “RESERVE components called out in this procedure. IN USE” and “SECONDARY LOW” alarms cancel. 1. Remove front cover to expose manual changeover • If connected to a master alarm panel, buttons located on the overlay (Figure 17). -

Page 41: Line Regulator Pressure Adjustment

Liquid by High Pressure Manifold 4.4 Reserve Header Regulator 15. Slowly open all high-pressure cylinders on reserve header. Adjustment 16. Open service valve. The following procedure describes process of setting reserve header high-pressure regulator. 17. Install and secure front cover using the two latch This procedure should only need to be performed hinges if regulator setting was not within acceptable limits... -

Page 42: Reserve In Use Pressure Switch Adjustment

Liquid by High Pressure Manifold 4.6 Reserve in Use Pressure Switch The Changeover Pressure Switch is a normally open type that closes when pressure in excess of Adjustment switch setting is applied. When pressure is applied to the Left Bank of manifold, the pressure switch he following procedure describes process of setting is closed. -

Page 43: Secondary Low Pressure Switch Adjustment

Liquid by High Pressure Manifold 4.7 Secondary Low Pressure Switch Adjustment Adjustment Barrel The following procedure describes process of setting “SECONDARY LOW” pressure switch. This procedure Collar should only need to be performed if the secondary low switch setting was not within acceptable limits during the performance verification procedure. -

Page 44: Reserve Low Pressure Switch Adjustment

Liquid by High Pressure Manifold listed in Table 1 (Secondary Low Pressure Switch 6. Note reserve regulator high-pressure gauge reading when red “RESERVE LOW” light Setting). illuminates. Recommended settings are listed in Table 1 (Reserve Low Pressure Switch). 7. Close vent valve. 8. -

Page 46: Service Procedures

Liquid by High Pressure Manifold 5.0 Service Procedures 5.2 Routine Maintenance 5.1 Precautions Daily: WARNING: • Visually inspect manifold for normal operation. Record front panel indicator status (e.g. left with gas-specific connections • Tampering bank “IN USE,” right bank “READY”). shall be prohibited. -

Page 47: Techniques For Leak-Tight Connections

5.3 Techniques for Leak-Tight 5.4 Pressure Switch / Transducer Connections Replacement Lifeline manifold utilizes three different types of Following procedure describes process of replacing connection between internal components. pressure switch/ transducer. If necessary, pressure switch replacement can be performed while manifold •... -

Page 48: Bank Regulator Maintenance

Liquid by High Pressure Manifold 5.5 Bank Regulator Maintenance 11. Discard Seat Ring w/O-ring. 12. Remove Piston Sub-Assembly and discard. See Figure 25 IMPORTANT: Vent all inlet pressure and 13. Verify the Piston Spring remains in place within outlet pressure to 0 psig prior to servicing the regulator body. - Page 49 Liquid by High Pressure Manifold 21) Put Locknut on Adjustment Screw and assemble to Spring Chamber. 22) Turn Adjustment Screw until desired set pressure is reached. Tighten Locknut. 1. Adjustment Screw O-ring Locknut Spring Chamber (50 FT-LBS) Spring Button Spring Piston Diaphragm 2.

-

Page 50: Line Regulator Maintenance

Liquid by High Pressure Manifold 5.6 Line Regulator Maintenance See Figure 26. 14. Insert new Seat Ring, remove spring pressure from seat ring during installation by pressing on the piston sub-assembly while screwing in the IMPORTANT: Vent all inlet pressure and outlet seat ring, and torque to 30 ft-lbs. - Page 51 Liquid by High Pressure Manifold Adjustment Screw Locknut Spring Chamber (50 FT-LBS) Spring Spring Buttons Piston Diaphragm 1. Piston Diaphragm O-ring 2. Seat Ring w/O-ring (30 FT-LBS) 3. Piston Sub-Assembly Pusher Post Button Seat Spring 4. Regulator/ Body O-ring Shaded Items Included in Kit Figure 26: NFPA version HP x HP Manifold Shown.

-

Page 52: Reserve Header Regulator Maintenance

Liquid by High Pressure Manifold 5.7 Reserve Header Regulator Maintenance 12. Verify the Piston Spring remains in place within IMPORTANT: Vent all inlet pressure and outlet pres- regulator body. sure to 0 psig prior to servicing the regulator. Make sure assembly is performed in a clean environment 13. - Page 53 Liquid by High Pressure Manifold Adjustment Screw Locknut Spring Chamber (50 FT-LBS) Spring Button Spring Piston 2. Seat Ring w/O-ring (30 FT-LBS) Diaphragm 1. Piston Diaphragm O-ring 3. Piston Sub-Assembly Pusher Post Button 4. Regulator/ Body O-ring Seat Spring Shaded Items Included in Kit Figure 27: Reserve Regulator Exploded View.

-

Page 54: Check Valve/Ball Valve Replacement

Liquid by High Pressure Manifold 5.8 Check Valve/Ball Valve 12. Verify manifold operation. Replacement Line Regulator Check Valve Replacement See Figures 28 and 29. 1. If replacing left side check valve, remove SAE-12 Plug to gain access to the Check Valve. If replacing IMPORTANT: Check Valve/Ball Valve replacement will the right side checkvalve, remove Outlet Adapter. - Page 55 3) Follow steps 4-8 above. Liquid by High Pressure Manifold 4) Re-assemble item(s) from Step 2. Retaining Rings Bank Regulator Section Ball Valves Retaining Rings Check Valves Check Valves Line Regulator Section Screws (2) Remove Only if Replacing Bracing Bar Banks Check Valves Figure 28: Check Valve Removal.

-

Page 56: Reserve Low Pressure Switch/Transducer Replacement

Liquid by High Pressure Manifold 5.9 Reserve Low Pressure Switch/ Transducer Replacement The following procedure describes process of replacing high-pressure reserve header, reserve low switch/transducer. If necessary, reserve low switch/ transducer replacement can be performed while manifold is in service. However, this should only be done by qualified technicians experienced in servicing medical equipment. -

Page 57: Control Board Replacement

Liquid by High Pressure Manifold 5.10 Control Board Replacement See Figure 30. Following procedure describes process of replacing manifold’s electronic control circuit board. necessary, control board replacement can be performed while manifold is in service. However, this should only be done by qualified technicians 5. -

Page 58: Wiring Diagrams

Liquid by High Pressure Manifold 5.11 Wiring Diagram Basic Electronics Figure 31 5-13 4107 9013 95.04... - Page 59 Liquid by High Pressure Manifold 5.11 Wiring Diagram TAE Electronics Figure 32 4107 9013 95.04 5-14...

-

Page 60: Totalalert Embedded (Tae)

Liquid by High Pressure Manifold 6.0 TotalAlert Embedded (TAE) 6.1 Remote Monitoring 1. Place the IP Address Selector Switch in the Left- hand position. 2. Using a Cat5 Ethernet cable, connect the mani- CAUTION: The information systems personnel fold to an Ethernet switch or hub. Connect the should be notified before changing any of the net- cable to the Customer’s Ethernet Connection on work settings. -

Page 61: Log In To Setup

Liquid by High Pressure Manifold 6.5 Log in to Setup Pages 6.6 Device Setup Figure 34: Manifold Home Page Figure 36: Device Setup This Device Setup page (Figure 36) is used to config- ure the manifold name, location, facility name, and contact information. -

Page 62: Network Setup

Liquid by High Pressure Manifold 6.7 Network Setup 6.8 System Trend Setup Figure 38: System Trend Setup This System Trend Setup page (Figure 38) is used to Figure 37: Network Setup configure the trend log for the website and to allow the data to be cleared. -

Page 63: Electronic Notification Setup

Liquid by High Pressure Manifold 6.9 Electronic Notification Setup 6.10 Navigating the Website Figure 39: Electronic Notification Setup Figure 40: Status Page The TotalAlert Embedded website allows the user to This Electronic Notification Setup page (Figure 39) is easily view the status of all activity pertaining to the used to configure the Electronic Notification feature manifold air system. - Page 64 Liquid by High Pressure Manifold 6.10 Navigating the Website Cont. Figure 40: System Trend Figure 44: System Trend Page The System Trend Page (Figure 44 displays mulitple items on the system, measured at specified time intervals. These items may include Left Bank Pres- sure, Right Bank Pressure, Delivery Pressure and Figure 42: Network Devices Bank in Use.

- Page 66 1059 Paragon Way Rock Hill, SC 29730 (888) 4-MEDGAS (888) 463-3427 Fax (803) 817-5750 www.beaconmedaes.com...

Need help?

Do you have a question about the Lifeline and is the answer not in the manual?

Questions and answers