Table of Contents

Advertisement

Quick Links

D-100 MK2 User Manual

DESCRIPTION

The D-100 MK2 is a next generation genset control

units combining multi-functionality and wide

communication possibilities together with a reliable

and low cost design.

The unit complies and mostly exceeds world's

tightest safety, EMC, vibration and environmental

standards for the industrial category.

Software features are complete with easy firmware

upgrade process through USB port.

The Windows based PC software allows monitoring

and programming through USB, serial and GPRS.

The PC based Rainbow Scada software allows

monitoring and control of an unlimited number of

gensets from a single central location.

FUNCTIONALITIES

AMF unit with uninterrupted transfer

ATS unit with uninterrupted transfer

Remote start controller

Manual start controller

Engine controller

CTs at genset or load side

D-100 MK2

ADVANCED

GENSET

CONTROLLER

COMMUNICATIONS

•

GSM Modem (2G-3G-4G) *

•

Ethernet 10/100Mbits *

•

Wi-Fi *

•

RS-485 isolated (2400-38400baud) *

•

RS-232 isolated (2400-38400baud) *

•

USB Device

•

J1939 CANBUS

•

Central Monitoring through internet *

•

SMS message sending *

•

PC software: Rainbow Plus

•

Central monitoring *

•

Modbus RTU through RS-485 *

•

Modbus TCP/IP *

*Optional with plug-in module

TOPOLOGIES

3 phases 4 wires, star

3 phases 3 wires, 3 CTs

3 phases 3 wires, 2 CTs (L1-L2)

3 phases 3 wires, 2 CTs (L1-L3)

2 phases 3 wires, L1-L2

2 phases 3 wires, L1-L3

3 phases 4 wires, delta

1 phase 2 wires

Firmware V-6.3

Advertisement

Table of Contents

Summary of Contents for Datakom D-100 MK2

- Page 1 Firmware V-6.3 D-100 MK2 ADVANCED GENSET CONTROLLER DESCRIPTION COMMUNICATIONS • The D-100 MK2 is a next generation genset control GSM Modem (2G-3G-4G) * • units combining multi-functionality and wide Ethernet 10/100Mbits * • Wi-Fi * communication possibilities together with a reliable •...

- Page 2 D-100 family units. Follow carefully advices given in the document. These are often good practices for the installation of genset control units which reduce future issues. For all technical queries please contact Datakom at below e-mail address: technical.support@datakom.com.tr QUERRIES...

- Page 3 D-100 MK2 User Manual Firmware V-6.3 REVISION HISTORY REVISION DATE AUTHOR DESCRIPTION 16.09.2019 First edition, firmware version 6.3 TERMINOLOGY CAUTION: Potential risk of injury or death. WARNING: Potential risk of malfunction or material damage. ATTENTION: Useful hints for the understanding of device operation.

- Page 4 D-100 MK2 User Manual Firmware V-6.3 ORDERING CODES The D-xxx family units are available in various options and peripheral features. Please use below information for ordering the correct version: D-100 MK2 -M2 -G -T -00 Variant Family Code 00: standard unit PLUG-IN MODULE 01...99: customer...

- Page 5 D-100 MK2 User Manual Firmware V-6.3 SAFETY NOTICE Failure to follow below instructions will result in death or serious injury Electrical equipment should be installed only by qualified specialist. No responsibility is assured by the manufacturer or any of its subsidiaries for any consequences resulting from the non-compliance to these instructions.

-

Page 6: Table Of Contents

D-100 MK2 User Manual Firmware V-6.3 TABLE OF CONTENTS 1. INSTALLATION INSTRUCTIONS 2. MOUNTING 2.1 DIMENSIONS 2.2 SEALING, GASKET 2.3 ELECTRICAL INSTALLATION 3. TERMINAL DESCRIPTIONS 3.1. BATTERY VOLTAGE INPUT 3.2. AC VOLTAGE INPUTS 3.3. AC CURRENT INPUTS 3.4. DIGITAL INPUTS 3.5. - Page 7 D-100 MK2 User Manual Firmware V-6.3 5. FUNCTIONALITIES 5.1. CT LOCATION SELECTION 5.2. AMF FUNCTIONALITY 5.3. ATS FUNCTIONALITY 5.4. REMOTE START FUNCTIONALITY 5.5 ENGINE CONTROLLER FUNCTIONALITY 5.6. - 5.7. - 6. CONNECTION DIAGRAMS 6.1. AMF FUNCTIONALITY, CTs AT LOAD SIDE 6.2.

- Page 8 D-100 MK2 User Manual Firmware V-6.3 14. PROTECTIONS AND ALARMS 14.1. DISABLING ALL PROTECTIONS 14.2. SERVICE REQUEST ALARM 14.3. SHUTDOWN ALARMS 14.4. LOADDUMP ALARMS 14.5. WARNINGS 14.6. NON-VISUAL WARNINGS 15. PROGRAMMING 15.1. RESETTING TO FACTORY DEFAULTS 15.2. ENTERING THE PROGRAMMING MODE 15.3.

- Page 9 D-100 MK2 User Manual Firmware V-6.3 25. SOFTWARE FEATURES 25.1. LOAD SHEDDING / DUMMY LOAD 25.2. LOAD ADD / SUBSTRACT 25.3. FIVE STEP LOAD MANAGEMENT 25.4. REMOTE START OPERATION 25.5. DISABLE AUTO START, SIMULATE MAINS 25.6. BATTERY CHARGING OPERATION, DELAYED SIMULATE MAINS 25.7.

-

Page 10: Installation Instructions

D-100 MK2 User Manual Firmware V-6.3 1. INSTALLATION INSTRUCTIONS Before installation: Read the user manual carefully, determine the correct connection diagram. Remove all connectors and mounting brackets from the unit, then pass the unit through the mounting opening. -

Page 11: Mounting

D-100 MK2 User Manual Firmware V-6.3 2. MOUNTING 2.1. DIMENSIONS Dimensions: 133x107x46mm (5.25”x4.2”x1.9”) Panel Cutout: 117x87mm minimum (4.6”x3.43”) Weight: 250g (0.55 lb) K96D01-EN - 11 -... - Page 12 D-100 MK2 User Manual Firmware V-6.3 The unit is designed for panel mounting. The user should not be able to access parts of the unit other than the front panel. Mount the unit on a flat, vertical surface. Before mounting, remove the mounting brackets and connectors from the unit, then pass the unit through the mounting opening.

- Page 13 D-100 MK2 User Manual Firmware V-6.3 Two different types of brackets are provided: Self retaining type bracket Screw type bracket Installation of screw type bracket Installation of self retaining type bracket Do not tighten too much, this may break the unit.

-

Page 14: Sealing, Gasket

D-100 MK2 User Manual Firmware V-6.3 2.2. SEALING, GASKET Panel Gasket Module The rubber gasket provides a watertight means of mounting the module to the genset panel. Together with the gasket, 60529-IP65 protection can be reached from the front panel. A short definition of IP protection levels is given below. -

Page 15: Electrical Installation

D-100 MK2 User Manual Firmware V-6.3 2.3. ELECTRICAL INSTALLATION Do not install the unit close to high electromagnetic noise emitting devices like contactors, high current busbars, switchmode power supplies and the like. Although the unit is protected against electromagnetic disturbance, excessive disturbance can affect the operation, measurement precision and data communication quality. -

Page 16: Terminal Descriptions

D-100 MK2 User Manual Firmware V-6.3 3. TERMINAL DESCRIPTIONS 3.1. BATTERY VOLTAGE INPUT Supply voltage: 8 to 36VDC Cranking dropouts: Survives 0VDC during 100ms. The voltage before surge should be 8VDC minimum Overvoltage protection: Withstands 150VDC continuously. Reverse voltage: -33VDC continuous Maximum operating 500mA @ 12VDC. -

Page 17: Ac Voltage Inputs

D-100 MK2 User Manual Firmware V-6.3 3.2. AC VOLTAGE INPUTS Measurement method: True RMS Sampling rate: 8000 Hz Harmonic analysis: up to 31th harmonic Input voltage range: 14 to 300 VAC Minimum voltage for 15 VAC (Ph-N) frequency detection: Supported topologies:... -

Page 18: Ac Current Inputs

SELECTING THE CT ACCURACY CLASS: The CT accuracy class should be selected in accordance with the required measurement precision. The accuracy class of the Datakom controller is 0.5%. Thus 0.5% class CTs are advised for the best result. K96D01-EN - 18 -... - Page 19 D-100 MK2 User Manual Firmware V-6.3 Current Transformers must be used for current measurement. No direct connection allowed. No common terminals or grounding allowed. CONNECTING CTs: Be sure of connecting each CT to the related phase input with the correct polarity. Mixing CTs between phases will cause faulty power and pf readings.

- Page 20 D-100 MK2 User Manual Firmware V-6.3 EFFECT OF POLARITY REVERSAL The generator is still loaded with 100 kW On each phase. The load Power Factor (PF) is 1. PF in phase L2 will show -1,00 due to reverse CT polarity. The result is that total generator power displayed by the controller is 100 kW.

-

Page 21: Digital Inputs

D-100 MK2 User Manual Firmware V-6.3 3.4. DIGITAL INPUTS Type of inputs: all configurable Function selection: from list Contact type: Normally open or normally closed (programmable) Switching: Battery negative or battery positive (programmable) Structure: 47 k-ohms resistor to battery positive, 110k-ohms to battery negative. -

Page 22: Charge Input Terminal

D-100 MK2 User Manual Firmware V-6.3 3.6. CHARGE INPUT TERMINAL The Charge terminal is both an input and output. When the engine is ready to run, this terminal supplies the excitation current to the charge alternator. The excitation circuit is equivalent to a 2W lamp. -

Page 23: Port (Plug-In Module)

The RS-485 port features MODBUS-RTU protocol. Multiple modules (up to 128) can be paralleled on the same RS-485 bus for data transfer to automation or building management systems. The Modbus register list is available at Datakom technical support. The RS-485 port provides also a good solution for distant PC connection where RainbowPlus program will enable programming, control and monitoring. -

Page 24: J1939-Canbus Port

The RainbowPlus software can be downloaded from www.datakom.com.tr website. The connector on the module is of USB-B type. Thus A to B type USB cable should be used. This is the same cable used for USB printers. - Page 25 D-100 MK2 User Manual Firmware V-6.3 3.15. GSM MODEM (optional with plug-in module) The optional internal GSM modem offers the advantage of being internally powered and is fully compatible with the unit. It does not require any special setup. The 1800/1900 MHz magnetic antenna together with its 2 meter cable is supplied with the internal modem option.

-

Page 26: Ethernet Port (Plug-In Module)

D-100 MK2 User Manual Firmware V-6.3 3.16. ETHERNET PORT (PLUG-IN MODULE) Data Flow Link Established Ethernet Slot STANDARD ETHERNET CABLE Description: IEEE802.3 compliant, 10/100 Base-TX RJ45 ethernet port with indicating leds Data rate: 10/100 Mbits/s, auto detecting Connector: RJ45 Cable type:... -

Page 27: Wi-Fi (Plug-In Module)

D-100 MK2 User Manual Firmware V-6.3 3.17. Wi-Fi (PLUG-IN MODULE) Wi-Fi Slot Wi-Fi protocols: 802.11 b/g/n Frequency range: 2.4 GHz ~ 2.5 GHz (2400M ~ 2483.5M) Network Protocols: IPv4, TCP/UDP Security: WPA/WPA2 Functionality: Web Client, Modbus TCP_IP K96D01-EN - 27 -... -

Page 28: Topologies

D-100 MK2 User Manual Firmware V-6.3 4. TOPOLOGIES Various topologies are selectable through program parameter. The topology is independently selectable for both genset and mains sections. In following drawings, the connections are shown for the alternator. Current transformers are supposed connected to the alternator side. -

Page 29: Phase, 4 Wire, Star

D-100 MK2 User Manual Firmware V-6.3 4.2. 3 PHASE, 4 WIRE, STAR 4.3. 3 PHASE, 3 WIRE, DELTA K96D01-EN - 29 -... -

Page 30: Phase, 4 Wire, Delta

D-100 MK2 User Manual Firmware V-6.3 4.4. 3 PHASE, 4 WIRE, DELTA 4.5. 3 PHASE, 3 WIRE, DELTA, 2 CT (L1-L2) K96D01-EN - 30 -... -

Page 31: Phase, 3 Wire, Delta, 2 Ct (L1-L3)

D-100 MK2 User Manual Firmware V-6.3 4.6. 3 PHASE, 3 WIRE, DELTA, 2 CT (L1-L3) 4.7. 2 PHASE, 3 WIRE, DELTA, 2 CTs (L1-L2) K96D01-EN - 31 -... -

Page 32: Phase, 3 Wire, Delta, 2 Cts (L1-L3)

D-100 MK2 User Manual Firmware V-6.3 4.8. 2 PHASE, 3 WIRE, DELTA, 2 CTs (L1-L3) 4.9. 1 PHASE, 2 WIRE K96D01-EN - 32 -... -

Page 33: Functionalities

D-100 MK2 User Manual Firmware V-6.3 5. FUNCTIONALITIES The same unit provides different functionalities through parameter setting. Thus a single stock item will fulfill various duties, minimizing stock cost. 5.1. CT LOCATION SELECTION CTs may be placed at alternator or load busbars. The CT location selection is configured with Controller Configuration >... -

Page 34: Engine Controller Functionality

D-100 MK2 User Manual Firmware V-6.3 5.5 ENGINE CONTROLLER FUNCTIONALITY When the Engine Controller functionality is selected, genset electrical measurements and protections will be disabled. The unit is supposed to control an engine without alternator. When the Engine Control Mode is activated: -the unit will not display genset AC parameters (volts, amps, kW and pf). -

Page 35: Connection Diagrams

D-100 MK2 User Manual Firmware V-6.3 6. CONNECTION DIAGRAMS 6.1. AMF FUNCTIONALITY, CTs AT LOAD SIDE K96D01-EN - 35 -... -

Page 36: Amf Functionality, Cts At Alternator Side

D-100 MK2 User Manual Firmware V-6.3 6.2. AMF FUNCTIONALITY, CTs AT ALTERNATOR SIDE K96D01-EN - 36 -... -

Page 37: Ats Functionality

D-100 MK2 User Manual Firmware V-6.3 6.3. ATS FUNCTIONALITY K96D01-EN - 37 -... -

Page 38: Remote Start Functionality

D-100 MK2 User Manual Firmware V-6.3 6.4. REMOTE START FUNCTIONALITY K96D01-EN - 38 -... -

Page 39: Engine Control Functionality

D-100 MK2 User Manual Firmware V-6.3 6.5. ENGINE CONTROL FUNCTIONALITY K96D01-EN - 39 -... - Page 40 D-100 MK2 User Manual Firmware V-6.3 6.6. - K96D01-EN - 40 -...

-

Page 41: Terminal Description

D-100 MK2 User Manual Firmware V-6.3 7. TERMINAL DESCRIPTION Term Function Technical data Description BATTERY POSITIVE +12 or 24VDC The positive terminal of the DC Supply. BATTERY NEGATIVE O VDC Power supply negative connection. DIGITAL OUTPUT 1 Protected This relay has programmable function, Semiconductor selectable from a list. - Page 42 D-100 MK2 User Manual Firmware V-6.3 Term Function Technical data Description DIGITAL INPUT 1 Digital Inputs, The input has programmable function. Factory set as LOW OIL PRESSURE 0-30Vdc SWITCH. DIGITAL INPUT 2 The input has programmable function. Factory set as HIGH TEMP SWITCH.

-

Page 43: Technical Specifications

D-100 MK2 User Manual Firmware V-6.3 8. TECHNICAL SPECIFICATIONS DC Supply Range: 9.0 to 36.0 V-DC. DC power consumption: 300 mA-DC max. @12V-DC 150 mA-DC max. @24V-DC Alternator voltage: 0 to 330 V-AC (Ph-N), 0 to 570V Ph-Ph Alternator frequency: 0-100 Hz. -

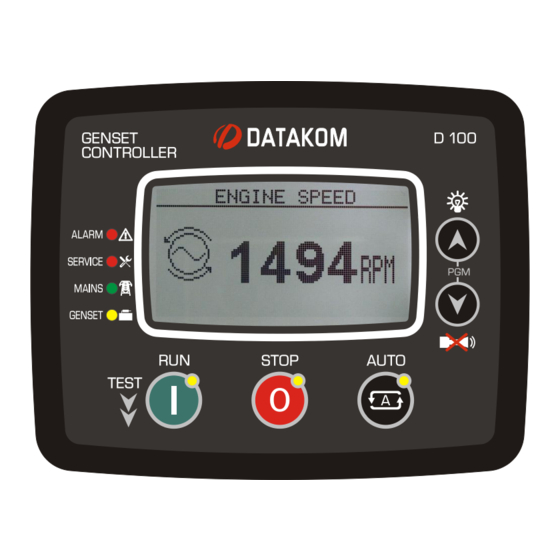

Page 44: Description Of Controls

D-100 MK2 User Manual Firmware V-6.3 9. DESCRIPTION OF CONTROLS 9.1. FRONT PANEL FUNCTIONALITY Graphic LCD screen Fault condition Next screen indicators group. LAMP TEST if held pressed Mimic Diagram Next screen in (sysem status) the same group. ALARM Mute... -

Page 45: Pushbutton Functions

D-100 MK2 User Manual Firmware V-6.3 9.2. PUSHBUTTON FUNCTIONS BUTTON FUNCTION Selects RUN mode. The genset runs off-load. If held pressed for 5 seconds, selects TEST mode. In TEST mode the genset runs and takes the load. Selects AUTO mode. The genset runs when necessary and takes the load. -

Page 46: Display Screen Organization

D-100 MK2 User Manual Firmware V-6.3 9.3. DISPLAY SCREEN ORGANIZATION The unit measures a large number of electrical and engine parameters. The display of the parameters is organized as PARAMETER GROUPS and items in a group. Navigation between different groups are made with button. -

Page 47: Measured Parameters

D-100 MK2 User Manual Firmware V-6.3 9.5. MEASURED PARAMETERS The unit performs a detailed set of AC measurements. Mains currents and power parameters (listed in blue color) are measured and displayed only if CTs are placed at load side. please see connection diagrams section for more details. -

Page 48: Led Lamps

D-100 MK2 User Manual Firmware V-6.3 9.6. LED LAMPS Alarm indicator Service request indicator FLASH: mains available ON: Mains Contactor On FLASH: Genset available ON: Genset Contactor on STOP mode AUTO mode RUN mode indicator indicator indicator STATUS LEDS: ALARM: Turns on when a fault condition exists. -

Page 49: Displaying Event Logs

D-100 MK2 User Manual Firmware V-6.3 10. - 11. DISPLAYING EVENT LOGS The unit features more than 400 event logs with date-time stamp and full snapshot of measured values at the moment that the event has occurred. Stored values in an event record are listed below:... - Page 50 D-100 MK2 User Manual Firmware V-6.3 Remote Start/Remote Stop events: recorded when mains status is changed Engine started/stopped events: recorded when engine status is changed Genset on_load/off_load events: recorded when the genset loading status is changed Event logs are also displayed within the main screen. Press button to find event record screen.

-

Page 51: Statistical Counters

D-100 MK2 User Manual Firmware V-6.3 12. STATISTICAL COUNTERS The unit provides a set of non-resettable incremental counters for statistical purposes. The counters consist on: -total genset kWh -total genset kVArh inductive -total genset kVArh capacitive -total genset export kWh... -

Page 52: Operation Of The Unit

D-100 MK2 User Manual Firmware V-6.3 13. OPERATION OF THE UNIT 13.1. QUICK START GUIDE STOPPING THE ENGINE: Press STOP button STARTING THE ENGINE: Press RUN button LOAD TEST: Hold pressed RUN button for 5 seconds. The genset will run and take the load. -

Page 53: Auto Mode

D-100 MK2 User Manual Firmware V-6.3 13.3. AUTO MODE The AUTO mode is entered by pressing the button. The AUTO mode is used for the automatic transfer between genset and mains. The controller will constantly monitor the mains availability. It will run the engine and transfer the load when a mains failure occurs. -

Page 54: Run Mode, Manual Control

D-100 MK2 User Manual Firmware V-6.3 13.4. RUN MODE, MANUAL CONTROL The RUN mode is entered by pressing the button. When the RUN mode is selected, the engine will be started regardless of the mains availability. The starting sequence is as described below: ... -

Page 55: Protections And Alarms

D-100 MK2 User Manual Firmware V-6.3 14. PROTECTIONS AND ALARMS The unit provides 3 different protection levels, being warnings, loaddumps and shutdown alarms. 1- SHUTDOWN ALARMS: These are the most important fault conditions and cause: The ALARM led to turn on steadily,... -

Page 56: Disabling All Protections

D-100 MK2 User Manual Firmware V-6.3 14.1. DISABLING ALL PROTECTIONS The unit allows any digital input to be configured as “Disable Protections”. This input configuration is used in cases where the engine is required to run until destruction. This may be the case under critical conditions like firefighting or other emergency cases. - Page 57 D-100 MK2 User Manual Firmware V-6.3 14.3. LIST OF ALARMS Alarms are displayed with their numbers. Thus, a reference list is necessary to decrypt the alarm details. The unit has 256 shutdown alarms, 256 loaddump alarms and 256 warnings. Thus, a total of 768 different alarms may be displayed.

- Page 58 D-100 MK2 User Manual Firmware V-6.3 ALARM # LOADDUMP# WARNING# DESCRIPTION 0-47 256-303 512-559 DIGITAL INPUT ALARM: Alarm becomes active when a fault is detected from the related digital input. Digital inputs are programmable for the switching polarity, NO/NC contact, latching and detection delay.

- Page 59 D-100 MK2 User Manual Firmware V-6.3 ALARM # LOADDUMP# WARNING# DESCRIPTION HIGH OIL PRESSURE: Set if the oil pressure value measured from the sender is above the programmed limit. Warning and shutdown limits are independently programmable. This fault will be monitored Holdoff Timer delay after the engine is running.

- Page 60 D-100 MK2 User Manual Firmware V-6.3 ALARM # LOADDUMP# WARNING# DESCRIPTION J1939 ECU FAIL: Set if no information has been received during Message Absence Timer from the ECU of the electronic engine. This fault condition is only controlled when fuel is on.

-

Page 61: Non-Visual Warnings

D-100 MK2 User Manual Firmware V-6.3 ALARM # LOADDUMP# WARNING# DESCRIPTION SERVICE-2 REQUEST: Set if at least one of the service-2 counters has expired. In order to reset the service counters please hold pressed both buttons during 5 seconds. The screen will display “Completed!”... -

Page 62: Programming

D-100 MK2 User Manual Firmware V-6.3 15. PROGRAMMING The program mode is used to adjust timers, operational limits and the configuration of the unit. Although a free PC program is provided for programming, every parameter may be modified through the front panel, regardless of the operating mode. -

Page 63: Entering The Programming Mode

D-100 MK2 User Manual Firmware V-6.3 Although a free PC program is provided for programming, every parameter may be modified through the front panel, regardless of the operating mode. When modified, program parameters are automatically recorded into a non-erasable memory and take effect immediately. -

Page 64: Modifying Parameter Value

D-100 MK2 User Manual Firmware V-6.3 15.4. MODIFYING PARAMETER VALUE Increase parameter value Previous parameter Decrease parameter Long Press: value Return to the upper menu Next parameter 15.5. PROGRAMMING MODE EXIT To exit the program mode press STOP button. If no button is pressed during 2 minutes the program mode will be cancelled automatically. -

Page 65: Program Parameter List

D-100 MK2 User Manual Firmware V-6.3 16. PROGRAM PARAMETER LIST Factory Description Parameter Definition Unit This parameter is used to set LCD 001-LCD Contrast contrast. Adjust for the best viewing angle. This parameter defines the delay after 002-Fault Holdoff Timer the engine runs and before the fault monitoring is enabled. - Page 66 D-100 MK2 User Manual Firmware V-6.3 Factory Description Parameter Definition Unit This parameter provides the mains and genset voltage limits with a hysteresis feature in order to prevent faulty decisions. For example, when the mains are 018-Hysteresis Voltage V-AC present, the mains voltage low limit will be used as the programmed low limit.

- Page 67 D-100 MK2 User Manual Firmware V-6.3 Factory Description Parameter Definition Unit This parameter is useful to invert all CT 029-Reverse CT polarities at the same time. Direction 0: normal CT polarity assumed. 1: reverse CT polarity assumed. 0: AMF functionality. The unit controls both engine and load transfer.

- Page 68 D-100 MK2 User Manual Firmware V-6.3 Factory Description Parameter Definition Unit This parameter adjusts the time zone of the controller, in order to allow internal 042-Time Zone -720 +720 real time clock to be synchronized to the UTC time. 0: no location information from GSM...

- Page 69 D-100 MK2 User Manual Firmware V-6.3 Factory Description Parameter Definition Unit If the mains phase voltages are outside limits, but not more than this parameter (with reference to nominal voltage), then the genset will run without 056-Instant Mains releasing the mains contactor. When...

- Page 70 D-100 MK2 User Manual Firmware V-6.3 Factory Description Parameter Definition Unit If the genset frequency goes over this 067-Genset High limit when feeding the load, this will F-100 F+100 F+15% generate a GENSET HIGH Frequency Warning Limit FREQUENCY warning. If the genset frequency goes over this...

- Page 71 D-100 MK2 User Manual Firmware V-6.3 Factory Description Parameter Definition Unit If the genset power is negative and 080-Genset Reverse 50000 goes above this limit then a REVERSE Power Loaddump Limit POWER loaddump will be generated. If the genset power is negative and over...

- Page 72 D-100 MK2 User Manual Firmware V-6.3 Factory Description Parameter Definition Unit This is the minimum delay required for a 092-Load Subtract-Add load_add pulse after a load_substract pulse. Review chapter “Load Shedding” Delay for more details. This is the time between the mains...

- Page 73 D-100 MK2 User Manual Firmware V-6.3 Factor Description Parameter Definition Unit y Set If a mains MCB feedback input is 101-Mains MCB Fail defined and if the mains MCB fails to Timer change position before the expiration of this timer, then a fault condition occurs.

- Page 74 D-100 MK2 User Manual Firmware V-6.3 Factor Description Parameter Definition Unit y Set If the genset active power goes above 116-Excess power 50000 this limit then the controller will give an Warning Limit Excess Power Warning. The nominal value of engine rpm. Low-...

- Page 75 D-100 MK2 User Manual Firmware V-6.3 Factory Description Parameter Definition Unit This is the maximum delay after the ATS controller issues a Remote Start 131-Start Request Timer 1800 command and genset voltage are established. This is the time after the fuel solenoid is...

- Page 76 D-100 MK2 User Manual Firmware V-6.3 Factory Description Parameter Definition Unit The gas solenoid of the gas engine (if 144-Gas Solenoid Delay assigned by Relay Definitions) will be opened after this delay during cranking. The crank relay output is deenergized...

- Page 77 D-100 MK2 User Manual Firmware V-6.3 Factory Description Parameter Definition Unit The SERVICE REQUEST led indicator will turn on after this quantity of engine 159-Service-1 Engine hours from the last service. If the period hours 5000 is set to ‘0’ no SERVICE REQUEST will...

- Page 78 D-100 MK2 User Manual Firmware V-6.3 Factory Description Parameter Definition Unit 0: GENERIC 1: CUMMINS 2: DETROIT DIESEL 3: DEUTZ 4: JOHN DEERE 5: PERKINS 169-J1939 Engine Brand 6: VOLVO 7: CATERPILLAR 8: SCANIA 9: IVECO 10: MTU-MDEC 11: BOSCH...

- Page 79 D-100 MK2 User Manual Firmware V-6.3 Factory Description Parameter Definition Unit This parameter adjusts the speed of an 171-J1939 Speed Adjust -100 +100 ECU controlled engine by +/- 8%. If the battery voltage goes below this 172-Battery Charge Run limit the engine will be automatically V-DC 35.0...

-

Page 80: Adjust Date And Time

D-100 MK2 User Manual Firmware V-6.3 16.4. ADJUST DATE AND TIME These parameters allow adjusting the battery backup real time clock of the module. Once set, the clock will continue to run even if DC power is removed from the unit. -

Page 81: Exerciser Schedule

D-100 MK2 User Manual Firmware V-6.3 16.6. EXERCISER SCHEDULE The unit provides 7 independent automatic exerciser programs. Automatic exercise may be done in weekly or monthly basis. If monthly exercise is selected, the week, day and hour is adjustable for each exercise item. -

Page 82: Sender Configuration

D-100 MK2 User Manual Firmware V-6.3 16.7. SENDER CONFIGURATION The unit has 3 analog sender inputs. Only parameters of one sender are explained below. Other senders have identical parameter set. Each sender has 16 step programmable curves. The sender name and reading unit is freely programmable, thus the sender can be adapted to any type through programming. - Page 83 D-100 MK2 User Manual Firmware V-6.3 Factory Description Parameter Definition Unit Sender Curve-1 ohm ohms 5000 Point-1 ohm value Sender Curve-1 value 10000 Point-1 reading Sender Curve-2 ohm ohms 5000 Point-2 ohm value Sender Curve-2 value 10000 Point-2 reading Sender Curve-3 ohm...

-

Page 84: Digital Input Configuration

D-100 MK2 User Manual Firmware V-6.3 16.8. DIGITAL INPUT CONFIGURATION The unit has 5 digital inputs. Only parameters of one input are explained below. Other inputs have identical parameter set. The input name is freely programmable, thus the input can be adapted to any functionality through programming. - Page 85 D-100 MK2 User Manual Firmware V-6.3 INPUT FUNCTION LIST Description Description Description User Defined Function Over Resonance Low Oil Press. Switch Short-Circuit Alarm High Temp. Switch Reset Service 1 Alm Coolant Level Switch Reset Service 2 Alm Rectifier Fail Switch...

-

Page 86: Output Configuration

D-100 MK2 User Manual Firmware V-6.3 16.9. OUTPUT CONFIGURATION The parameters below define the functions of relay outputs. The unit has 5 relay outputs. All relays have programmable functions, selected from a list. Parameter Definition Factory Terminal Description number Relay-01... - Page 87 D-100 MK2 User Manual Firmware V-6.3 OUTPUT FUNCTION LIST Description Description Description Fuel Pgm Mode Active Remote Control Out 11 Horn Engine Running Remote Control Out 12 Crank Genset Voltage Ok Remote Control Out 13 Stop Solenoid Alarm Check Enable...

-

Page 88: Site Id String

D-100 MK2 User Manual Firmware V-6.3 16.10. SITE ID STRING The site identity string is designed to identify the current controller. This is the site Id string sent at the beginning of SMS messages and web page headers for the identification of the genset sending the message. -

Page 89: Gsm Modem Parameters

D-100 MK2 User Manual Firmware V-6.3 16.13. GSM MODEM PARAMETERS Parameter Definition Description The APN (access point name) username may be required by the GSM operator. However some GSM operators may allow access without APN User Name username. The exact information should be obtained from the GSM operator. - Page 90 D-100 MK2 User Manual Firmware V-6.3 16.14. TCP/IP PARAMETERS Parameter Definition Factory Set Description This is the IPv4 (internet protocol version 4) address that the unit will require from the DHCP (dynamic host control protocol) server. Network IP Address 0.0.0.0 If this parameter is set to 0.0.0.0 then the unit will...

-

Page 91: Wifi Parameters

D-100 MK2 User Manual Firmware V-6.3 16.15. Wi-Fi PARAMETERS Wi-Fi parameter can be configured only from PC software. Parameter Definition Factory Set Description This is the name of wireless network that you want to ………...…. SSID connect. This is the password of wireless network that you want ………...…. -

Page 92: Wi-Fi Configuration

D-100 MK2 User Manual Firmware V-6.3 18. Wi-Fi CONFIGURATION Related parameters are: Parameter Definition Factory Set Description This is the name of wireless network that you want to ………...…. SSID connect. This is the password of wireless network that you want ………...…. -

Page 93: Gsm Configuration

D-100 MK2 User Manual Firmware V-6.3 19. GSM CONFIGURATION Related parameters are: Parameter Definition Factory Set Description 0: SMS messages disabled SMS Enable 1: SMS messages enabled GPRS Connection 0: GPRS disabled Enable 1: GPRS enabled This parameter controls SMS sending when mains SMS on Mains voltages status is changed. -

Page 94: Crank Cutting

D-100 MK2 User Manual Firmware V-6.3 20. CRANK CUTTING In order to insure fast and reliable crank cutting, the unit uses various resources for engine running condition detection. Cranking is stopped when at least one of below conditions is met: - Crank timer expired: The crank timer is adjusted through Engine Parameters >... -

Page 95: Overcurrent Protection (Idmt)

D-100 MK2 User Manual Firmware V-6.3 21. OVERCURRENT PROTECTION (IDMT) The unit offers a programmable IDMT protection function in order to protect the alternator against excessive currents. The IDMT (Inverse Definite Minimum Time) protection function has such tripping characteristics that the tripping time varies inversely with the value of current. - Page 96 D-100 MK2 User Manual Firmware V-6.3 Below is a table showing the tripping delay in function of the percent load level (with TMS=36): 100% unlimited 170% 73s 240% 18s 110% 3600s 180% 56s 250% 16s 120% 900s 190% 44s 260% 14s...

-

Page 97: Motorized Circuit Breaker Control

D-100 MK2 User Manual Firmware V-6.3 22. MOTORIZED CIRCUIT BREAKER CONTROL The unit offers full control for any brand and model of motorized circuit breakers (MCB). The MCB control is performed through 3 digital output functions, namely Open, Close and Undervoltage coil controls. - Page 98 D-100 MK2 User Manual Firmware V-6.3 MCB modules can be operated by 2 different ways. The unit supports both configurations. Below is the terminology used: M: gear motor PF: ready to close contact XF: close coil MX: open coil MN: undervoltage trip (release)

-

Page 99: J1939 Canbus Engine Support

Type parameter should be set accordingly. The list of available engines is given at the programming section. Please contact DATAKOM for the most current list of engines. If the J1939 port is enabled then the oil pressure, coolant temperature and the engine rpm information are picked up from the ECU unit. - Page 100 D-100 MK2 User Manual Firmware V-6.3 The electronic engine fault codes are displayed in text within the alarm list table, together with their SPN-FMI codes. The complete list of fault codes is given in the engine manufacturer’s user manual. Below is a basic list of fault conditions (x denotes any FMI)

- Page 101 D-100 MK2 User Manual Firmware V-6.3 DESCRIPTION Incorrect ECM software Engine magnetic speed sensor fault ECU internal +5V fail Preheating relay fault Injector power supply fault ECU hardware fail ECU memory fail Fuel injector valve fault Camshaft sensor Flywheel sensor ECU memory fail External speed comm.

- Page 102 D-100 MK2 User Manual Firmware V-6.3 Below is a basic list of FMI codes. Please be aware that these codes may differ slightly depending on the engine brand and model. DESCRIPTION Value too high” Valid data, but above the normal working range “Value too low”...

-

Page 103: Sms Commands

D-100 MK2 User Manual Firmware V-6.3 24. SMS COMMANDS SMS messages are accepted only from phone numbers recorded in the Communication>GSM>Message Numbers tab. Answers to SMS messages will be sent to all phone numbers in the list. SMS messages must be written exactly as below, without any preceding blanks. -

Page 104: Software Features

D-100 MK2 User Manual Firmware V-6.3 25. SOFTWARE FEATURES 25.1. LOAD SHEDDING / DUMMY LOAD The load shedding feature consists on the disconnection of the least crucial loads when the genset power approaches to its limits. These loads will be supplied again when the genset power falls below the programmed limit. -

Page 105: Load Add / Substract

D-100 MK2 User Manual Firmware V-6.3 25.2. LOAD ADD / SUBTRACT The load add/subtract output functions are designed to provide control signals for an external, multi-step load adding/subtracting system. This external system will add either linearly or by small steps a dummy load that will prevent the genset from running below the minimum required load level. -

Page 106: Five Step Load Management

D-100 MK2 User Manual Firmware V-6.3 25.3. FIVE STEP LOAD MANAGEMENT The controller is able to manage the supply of up to 5 prioritized loads. The loads are supplied starting from the number #1 (highest priority) and unloaded from the highest number (lowest priority) available. -

Page 107: Remote Start Operation

D-100 MK2 User Manual Firmware V-6.3 25.4. REMOTE START OPERATION The unit offers the possibility of Remote Start mode of operation. Any digital input may be assigned as Remote Start Input using Input Function Select program parameters. The Remote Start signal may be a NO or NC contact, switching to either battery positive or battery negative. -

Page 108: Battery Charging Operation, Delayed Simulate Mains

D-100 MK2 User Manual Firmware V-6.3 25.6. BATTERY CHARGING OPERATION, DELAYED SIMULATE MAINS The Delayed Mains Simulation feature is used in battery backed up telecom systems where batteries are able to supply the load during a certain period. The genset is requested to run only when battery voltage drops below the critical level. -

Page 109: Dual Genset Mutual Standby Operation

If a Priority input is defined, then the system will work in priority mode. If the priority signal is applied, the unit will become master after each mains failure. If the priority signal is not applied, then the unit will become the slave one and the other genset will start. Please contact DATAKOM for a complete application manual. K96D01-EN... -

Page 110: Multiple Voltage And Frequency

D-100 MK2 User Manual Firmware V-6.3 25.8. MULTIPLE VOLTAGE AND FREQUENCY The unit offers 3 sets of voltage and frequency protection limit values. The user is allowed to switch between these 3 sets anytime. This feature is especially useful in multiple voltage or frequency gensets for easy switching between different operating conditions. -

Page 111: Automatic Exerciser

D-100 MK2 User Manual Firmware V-6.3 25.11. AUTOMATIC EXERCISER The unit offers 7 independent automatic exercisers. The exercise operation may be done on a weekly or monthly basis. The start day and time of the exercise is programmable as well as its duration. The exercise may be done with or without load following programming. -

Page 112: Engine Heating Operation

D-100 MK2 User Manual Firmware V-6.3 25.13. ENGINE HEATING OPERATION Especially on engines without a body heater, or with a failing one, it may be desired that the genset should not take the load before reaching a suitable temperature. The unit offers 2 different ways of engine heating. -

Page 113: Fuel Pump Control

D-100 MK2 User Manual Firmware V-6.3 25.16. FUEL PUMP CONTROL The unit is able to provide a digital output function in order to drive the fuel pump motor. The fuel pump is used to transfer fuel from the large capacity main tank (if exists), to the genset daily tank which is generally integrated in the chassis and has a limited capacity. -

Page 114: Charging The Engine Battery

D-100 MK2 User Manual Firmware V-6.3 25.19. CHARGING THE ENGINE BATTERY The controller offers an automatic charge cycle for the engine battery. When the engine battery weakens, the genset will run automatically during programmed period in an unloaded state in order to charge the engine battery, protecting it from total discharge when the genset has not run for a long time. -

Page 115: Resetting The Controller

D-100 MK2 User Manual Firmware V-6.3 25.22. RESETTING THE CONTROLLER When necessary, the controller may be manually reset by holding the STOP button pressed for 30 seconds. The manual reset will cause the hardware to be configured following new settings. -

Page 116: Zero Power At Rest

D-100 MK2 User Manual Firmware V-6.3 25.24. ZERO POWER AT REST In a manual genset, it is possible to reduce the current consumption of the unit down to true zero Amperes, in order to prevent the battery from discharging. For “zero power at rest operation”, an external relay and “wake-up” pushbutton is necessary. -

Page 117: Modbus Communications

D-100 MK2 User Manual Firmware V-6.3 26. MODBUS COMMUNICATIONS This chapter is a brief description of the Modbus properties of the controller. For a complete documentation please use “D- 500 D-700 Modbus Application Manual” The unit offers the possibility of MODBUS communication through below carriers:... -

Page 118: Parameters Required For Rs-485 Modbus Operation

D-100 MK2 User Manual Firmware V-6.3 26.1. PARAMETERS REQUIRED FOR RS-485 MODBUS OPERATION Modbus Slave Address: may be set between 1 and 240 RS-485 Enable: must be set to 1 (or checkbox enabled) RS-485 Baud Rate: selectable between 2400 and 38400 bauds. All devices in the same network must use the same Baud Rate. - Page 119 D-100 MK2 User Manual Firmware V-6.3 Below is a shortlist of available Modbus registers. For complete register map please refer to D-500/700 Modbus Application Manual. ADDRESS R / W DATA COEFF. DESCRIPTION (decimal) SIZE 8193 16bit Pushbutton simulation BIT 0.Simulate Stop button BIT 1.Simulate Manual button...

- Page 120 D-100 MK2 User Manual Firmware V-6.3 ADDRESS R / W DATA COEFF. DESCRIPTION (decimal) SIZE 10504- 256bit Shutdown alarm bits. Bit definitions are given at the end of the 10519 document. 10520- 256bit Loaddump alarm bits. Bit definitions are given at the end of the 10535 document.

-

Page 121: Declaration Of Conformity

“Monitoring and control instruments including industrial monitoring and control instruments” and exempted from ROHS directive. However Datakom is not using any ROHS uncompliant electronic components in the production. Only the solder contains lead. The switching to unleaded soldering is in progress. K96D01-EN... -

Page 122: Troubleshooting Guide

D-100 MK2 User Manual Firmware V-6.3 31. TROUBLESHOOTING GUIDE Below is a basic list of most often encountered troubles. More detailed investigation may be required in some cases. The genset operates while AC mains are OK or continues to operate after AC mains are OK: -Check engine body grounding. - Page 123 D-100 MK2 User Manual Firmware V-6.3 The engine does not run after the first start attempt, then the unit does not start again and OIL PRESSURE EXISTS ! message is displayed: -The oil pressure switch closes very lately. As the unit senses an oil pressure, it does not start. When oil pressure switch closes the unit will start.

Need help?

Do you have a question about the D-100 MK2 and is the answer not in the manual?

Questions and answers