Table of Contents

Advertisement

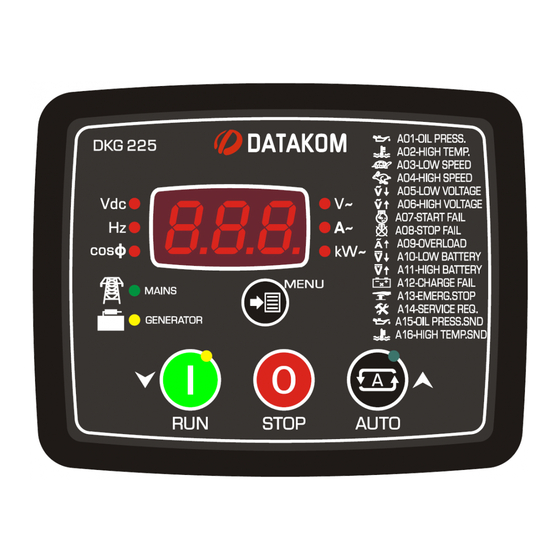

DKG-225 User Manual

DESCRIPTION

DKG-225, is a low cost AMF controller for 12V-DC

gensets, featuring an internal battery charger. Internal

fuel and crank relays are rated at 40Amps@12V-DC

and do not require external relays.

Thus a typical transfer panel will simply consist on one

DKG-225 and two contactors, reducing material cost,

panel size and production time.

The unit supports also current transformer connections

allowing detailed power measurements from both mains

and genset sides. The standard unit supports 1A and

5A secondary CTs. A special version supports low cost

and small 0.1A secondary CTs allowing more compact

panel design.

Thanks to the DKG-225, automatization of small

gensets has become easy and cost effective.

In AUTO position, the unit monitors 3 phases of the

mains, runs and stops the genset automatically and

performs load transfer. When the engine is running, it

monitors internal protections and alarm inputs.

The 1Amp @12V-DC rated battery charger is sufficient

for the float charging of the engine start battery.

Timers, threshold levels, input and output configurations

are digitally programmable. Programs are modified

through front panel pushbuttons and do not require an

additional unit.

The fault conditions are considered in 2 categories as

Warnings and Alarms. Measured values have separate

programmable limits for warning and alarm conditions.

DKG-225

AUTOMATIC MAINS

FAILURE UNIT

WITH INTERNAL

FEATURES

•

Automatic mains monitoring

•

Automatic load transfer

•

Automatic starting and stopping

•

Automatic stopping in fault condition

• Gas engine support

•

Test mode available

•

Emergency backup mode

• 3 phase mains voltage inputs

• 3 phase genset voltage inputs

•

3 phase mains/genset CT inputs

• 2 configurable analog sender inputs

• 3 configurable digital inputs

•

Detailed AC measurements and protections

•

Internal battery charging rectifier

•

40 Amp rated Fuel and Crank outputs

•

Front panel adjustable parameters

•

Stop, preheat and choke output capability

•

Survives cranking voltage dropouts

•

Compact dimensions, panel mounted

MEASUREMENTS

Mains Volts: L1-N, L2-N, L3-N, L1-L2, L2-L3, L3-L1

Genset Volts: L1-N, L2-N, L3-N, L1-L2, L2-L3, L3-L1

Load Currents: L1, L2, L3

Load total kW, kVA, kVAr, cosΦ

Genset Frequency

Battery Voltage

Oil pressure

Coolant temperature

Engine run Hours

Service Counters

Firmware V-01

CHARGER

Advertisement

Table of Contents

Summary of Contents for Datakom DKG-225

- Page 1 FAILURE UNIT WITH INTERNAL CHARGER DESCRIPTION FEATURES • DKG-225, is a low cost AMF controller for 12V-DC Automatic mains monitoring gensets, featuring an internal battery charger. Internal • Automatic load transfer fuel and crank relays are rated at 40Amps@12V-DC •...

- Page 2 DKG-225 family units. Follow carefully advices given in the document. These are often good practices for the installation which reduce future issues. For all technical queries please contact Datakom at below e-mail address: datakom@datakom.com.tr QUERRIES If additional information to this manual is required, please contact the manufacturer directly at below e- mail address: datakom@datakom.com.tr...

- Page 3 DKG-225 User Manual Firmware V-01 SPARE PARTS Screw Type Bracket Spring Type Bracket Stock Code=J10P01 (1 unit) Stock Code=K16P01 (1 unit) Watertight Gasket, Stock Code= K96P01 - 3 -...

- Page 4 DKG-225 User Manual Firmware V-01 SAFETY NOTICE Failure to follow below instructions will result in death or serious injury Electrical equipment should be installed only by qualified specialist. No responsibility is assured by the manufacturer or any of its subsidiaries for any consequences resulting from the non-compliance to these instructions.

-

Page 5: Table Of Contents

DKG-225 User Manual Firmware V-01 TABLE OF CONTENTS 1. INSTALLATION INSTRUCTIONS 2. MOUNTING 2.1 DIMENSIONS 2.2 SEALING, GASKET 2.3 ELECTRICAL INSTALLATION 3. TERMINAL DESCRIPTIONS 3.1. BATTERY VOLTAGE INPUT / OUTPUT 3.2. AC VOLTAGE INPUTS 3.3. AC CURRENT INPUTS 3.4. DIGITAL INPUTS 3.5. - Page 6 DKG-225 User Manual Firmware V-01 TABLE OF CONTENTS (continued) 12. SOFTWARE FEATURES 12.1. REMOTE START OPERATION 12.2. MAINS SIMULATION 12.3. DELAYED MAINS SIMULATION, BATTERY CHARGING 12.4. SERVICE REQUEST DISPLAY 12.5. ENGINE HOUR METER 12.6. SOFTWARE VERSION DISPLAY 12.7. GAS ENGINE FUEL SOLENOID CONTROL 12.8.

-

Page 7: Installation Instructions

DKG-225 User Manual Firmware V-01 1. INSTALLATION INSTRUCTIONS Before installation: Read the user manual carefully, determine the correct connection diagram. Remove all connectors and mounting brackets from the unit, then pass the unit through the mounting opening. ... -

Page 8: Mounting

DKG-225 User Manual Firmware V-01 2. MOUNTING 2.1. DIMENSIONS Dimensions: 133x107x46mm (5.25”x4.2”x1.9”) Panel cutout: 117x87mm minimum (4.6”x3.43”) Weight: 200g (0.45 lb) WALL 117mm min 60mm 40mm Mount the unit on a flat, vertical surface. Before mounting, remove the mounting brackets and connectors from the unit, then pass the unit through the mounting opening. - Page 9 DKG-225 User Manual Firmware V-01 The module will come with one of below bracket types: Spring type bracket Screw type bracket Screw type bracket installation Spring type bracket installation Do not tighten too much, this may break the unit. - 9 -...

-

Page 10: Sealing, Gasket

DKG-225 User Manual Firmware V-01 2.2. SEALING, GASKET Panel Gasket Module The rubber gasket provides a watertight means of mounting the module to the genset panel. Together with the gasket, 60529-IP65 protection can be reached from the front panel. A short definition of IP protection levels is given below. -

Page 11: Electrical Installation

DKG-225 User Manual Firmware V-01 2.3. ELECTRICAL INSTALLATION Do not install the unit close to high electromagnetic noise emitting devices like contactors, high current busbars, switchmode power supplies and the like. Although the unit is protected against electromagnetic disturbance, excessive disturbance can affect the operation, measurement precision and data communication quality. -

Page 12: Terminal Descriptions

DKG-225 User Manual Firmware V-01 3. TERMINAL DESCRIPTIONS 3.1. BATTERY VOLTAGE INPUT / OUTPUT Battery terminals are both internal battery charger outputs and battery supply inputs. When AC mains supply is available, the unit charges the battery. When mains voltages fail, the unit continues operation through the engine battery. -

Page 13: Ac Current Inputs

The CT accuracy class should be selected in accordance with the required measurement precision. The accuracy class of the Datakom controller is 1.0%. Thus 1.0% class CTs are advised for the best result. Current Transformers must be used for current measurement. -

Page 14: Phase L1

DKG-225 User Manual Firmware V-01 CONNECTING CTs: Be sure of connecting each CT to the related phase input with the correct polarity. Mixing CTs between phases will cause faulty power and pf readings. Many combinations of incorrect CTs connections are possible, so check both order of CTs and their polarity. - Page 15 DKG-225 User Manual Firmware V-01 EFFECT OF POLARITY REVERSAL The generator is still loaded with 10 kW On each phase. The load Power Factor (PF) is 1. PF in phase L2 will show -1,00 due to reverse CT polarity. The result is that total generator power displayed by the controller is 10 kW.

-

Page 16: Digital Inputs

DKG-225 User Manual Firmware V-01 3.4. DIGITAL INPUTS Contact type: Normally open or normally closed (programmable) Switching: Battery negative or battery positive (programmable) Structure: 47 k-ohms resistor to battery positive, 110k-ohms to battery negative. Measurement: Analog voltage measurement. Open circuit voltage:... -

Page 17: Charge Input Terminal

DKG-225 User Manual Firmware V-01 3.6. CHARGE INPUT TERMINAL The Charge terminal is both an input and output. When the engine is ready to run, this terminal supplies the excitation current to the charge alternator. The excitation circuit is equivalent to a 2W lamp. -

Page 18: Connection Diagram

DKG-225 User Manual Firmware V-01 4. CONNECTION DIAGRAM - 18 -... -

Page 19: Terminal Description

DKG-225 User Manual Firmware V-01 5. TERMINAL DESCRIPTION Term Function Technical data Description CRANK Relay Output CRANK output, capable of driving the 40A/12V-DC starter motor directly. BATTERY POSITIVE +12 V-DC The positive terminal of the DC Supply. FUEL Relay Output... - Page 20 DKG-225 User Manual Firmware V-01 Term Function Technical data Description Connect the generator current transformer CURR_1+ Current transformer terminals to these inputs. inputs, 5A-AC Do not connect the same current CURR_1- transformer to other instruments otherwise a unit fault will occur.

-

Page 21: Technical Specifications

DKG-225 User Manual Firmware V-01 6. TECHNICAL SPECIFICATIONS Alternator Voltage: 0-300 V-AC (Phase-Neutral) Alternator Frequency: 0-100 Hz. Mains Voltage: 0-300 V-AC (Phase-Neutral) Mains Frequency: 0-100 Hz. Topology: 1 or 3 phases with neutral Cranking Dropouts: survives 0V for 100ms. Fuel and Crank Relay Outputs: 40 A / 12V-DC... -

Page 22: Description Of Controls

DKG-225 User Manual Firmware V-01 7. DESCRIPTION OF CONTROLS 7.1. FRONT PANEL FUNCTIONALITY Mimic Diagram (system status) Menu selection button RUN mode AUTO mode STOP mode button button button 7.2. PUSHBUTTON FUNCTIONS BUTTON FUNCTION Selects RUN mode. The genset runs off-load. -

Page 23: Display Screen Organization

DKG-225 User Manual Firmware V-01 7.3. DISPLAY SCREEN ORGANIZATION The unit measures a large number of electrical and engine parameters. The display of the parameters is organized as a list which can be scanned by pressing the MENU button. Each depression of the button will cause the display to switch to the next parameter. -

Page 24: Led Indicators

DKG-225 User Manual Firmware V-01 7.5. LED INDICATORS Display unit Display unit leds leds Mains led. Flashes when mains is OK, turns-on steady when load is fed by mains. Genset led. Flashes when genset is running, turns-on steady when load is fed by the genset. -

Page 25: Operation Of The Unit

DKG-225 User Manual Firmware V-01 8. OPERATION OF THE UNIT 8.1. QUICK START GUIDE STOPPING THE GENSET: Press STOP button STARTING THE GENSET: Press RUN button AUTOMATIC OPERATION: Press AUTO button. Mode can be changed anytime without negative effect. Changing the operation mode while the genset is running will result into a behavior suitable for the new operating mode. -

Page 26: Auto Moden

DKG-225 User Manual Firmware V-01 8.4. AUTO MODE The AUTO mode is entered by pressing the button. The AUTO mode is used for the automatic transfer between genset and mains. The controller will constantly monitor the mains availability. It will run the engine and transfer the load when a mains failure occurs. -

Page 27: Protections And Alarms

DKG-225 User Manual Firmware V-01 9. PROTECTIONS AND ALARMS The unit provides 3 different protection levels, being warnings, loaddumps and shutdown alarms. 1- SHUTDOWN ALARMS: These are the most important fault conditions and cause: The display to show the alarm code,... -

Page 28: Service Request Alarm

DKG-225 User Manual Firmware V-01 9.1. SERVICE REQUEST ALARM The SERVICE REQUEST led is designed to help the periodic maintenance of the genset to be made consistently. The periodic maintenance is basically carried out after a given engine hours (for example 200 hours), but even if this amount of engine hours is not fulfilled, it is performed after a given time limit (for example 12 months). -

Page 29: Alarms

DKG-225 User Manual Firmware V-01 9.2. ALARMS A01-LOW OIL PRESSURE SWITCH: Set if a signal is detected at the Low Oil Pressure Switch. This fault will be monitored with Holdoff Timer delay after the engine is running. A02-HIGH TEMPERATURE SWITCH: Set if a signal is detected at the High Temperature Switch input. -

Page 30: Programming

DKG-225 User Manual Firmware V-01 10. PROGRAMMING The program mode is used to program timers, operational limits and the configuration of the unit. To enter the program mode, hold pressed the MENU button for 10 seconds. When the program mode is entered, if the MENU button is pressed, the display will indicate the program parameter number. - Page 31 DKG-225 User Manual Firmware V-01 Parameter Name Unit Std. Description Current Transformer This is the rated value of current transformers. P_00 Ratio All transformers must have the same rating. The secondary of the transformer will be 5 Amps. Fuel output type...

- Page 32 DKG-225 User Manual Firmware V-01 Parameter Definition Unit Fact.Set Description If one of the generator phase voltages goes under Genset Low Voltage this limit when feeding the load, this will generate a P_15 Shutdown Limit GENSET LOW VOLTAGE shutdown alarm and the engine will stop.

- Page 33 DKG-225 User Manual Firmware V-01 Parameter Definition Unit Fact.Set Description This is the period after the mains contactor has Genset Contactor P_32 been deactivated and before the generator Timer contactor has been activated. This is the period after the generator contactor has...

- Page 34 DKG-225 User Manual Firmware V-01 Parameter Definition Unit Fact.Set Description If the oil pressure measured from the analog input Low Oil Pressure P_49 falls below this limit, this will generate a LOW OIL Warning PRESSURE SENDER warning. If the oil pressure measured from the analog input...

- Page 35 DKG-225 User Manual Firmware V-01 Oil Pressure Sender Characteristics Parameter Definition Unit Factory Set Description P_53 Oil Pressure Sender point 1, ohm value Oil Pressure Sender Ohms -1 Oil Pressure Sender point 1, bar value P_54 Oil Pressure Value -1...

- Page 36 DKG-225 User Manual Firmware V-01 The parameters below define the function of the auxiliary relay output. The relay function is selected from below list. Program Group: Relay Definitions Parameter Definition Unit Fac.Set Description RELAY-1 function selected from list P_83 Relay 01 Definition...

-

Page 37: Crank Cutting

DKG-225 User Manual Firmware V-01 11. CRANK CUTTING In order to insure fast and reliable crank cutting, the unit uses various resources for engine running condition detection. Cranking is stopped when at least one of below conditions is met: - Crank timer expired: The crank timer is adjusted through programming menu. -

Page 38: Software Features

DKG-225 User Manual Firmware V-01 12. SOFTWARE FEATURES 12.1 Remote Start Operation The unit offers the possibility of REMOTE START mode of operation. The SPARE input may be assigned as Remote Start Input using the program parameter P_45. The REMOTE START signal may be a NO or NC contact, switching to either battery positive or battery negative. -

Page 39: Delayed Mains Simulation, Battery Charging

DKG-225 User Manual Firmware V-01 12.3 Delayed Mains Simulation, Battery Charging The Delayed Mains Simulation feature is used in battery backed up telecom systems where batteries are able to supply the load during a certain period. The genset is requested to run only when battery voltage drops below the critical level. -

Page 40: Service Request Display

DKG-225 User Manual Firmware V-01 12.4 Service Request Display This led is designed to help the periodic maintenance of the genset to be made consistently. The periodic maintenance is basically carried out after a given engine hours (for example 200 hours), but even if this amount of engine hours is not fulfilled, it is performed after a given time limit (for example 12 months). - Page 41 DKG-225 User Manual Firmware V-01 12.7 Gas Engine Fuel Solenoid Control The unit provides a special function for the fuel solenoid control of a gas engine. The fuel solenoid of a gas engine is different from a diesel engine. It should be opened after the cranking has been started and should be closed between crank cycles.

-

Page 42: Declaration Of Conformity

ROHS directive. However Datakom is not using any ROHS uncompliant electronic components in the production. Only the solder contains lead. The switching to unleaded solderin is in progress. - 42 -... -

Page 43: Troubleshooting

DKG-225 User Manual Firmware V-01 17. TROUBLESHOOTING Below is a basic list of most often encountered troubles. More detailed investigation may be required in some cases. The genset operates while AC mains are OK or continues to operate after AC mains are OK: -Check engine body grounding. - Page 44 Some program parameters are skipped: These parameters are reserved for factory setting and cannot be modified. DATAKOM Electronics Ltd. Tel: +90-216-466 84 60 Fax: +90-216-364 65 65 e-mail: datakom@datakom.com.tr http: www.datakom.com.tr - 44 -...

Need help?

Do you have a question about the DKG-225 and is the answer not in the manual?

Questions and answers