Table of Contents

Advertisement

Quick Links

DK-45 MK2 User Manual

DESCRIPTION

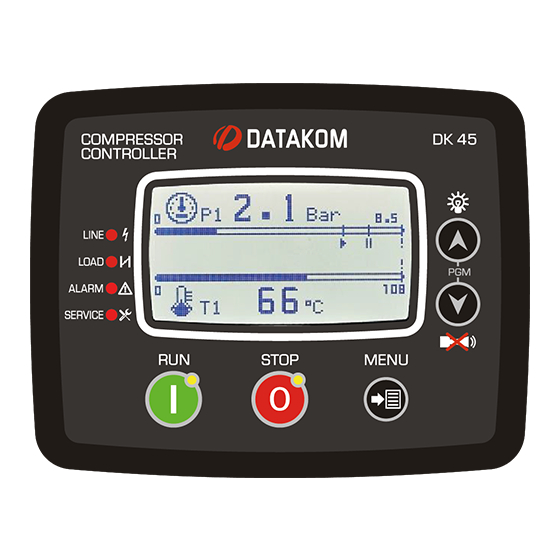

DK-45

MK2

is a high-tech product providing control of

screw or piston type air compressors driven by electric

motors.

The controller incorporates all functions needed in a

compressor control panel; thus, it eliminates the need

for additional modules, resulting in lower panel cost.

The early start function analyzes the air consumption

trend and runs the compressor so that the pressure

never falls below the low limit.

Using the Weekly Schedule and Pressure Calendar

functions, the compressor can be scheduled to work on

given hours and days of the week with given set

pressure values.

The unit is directly supplied from the 380/220V utility

network. It provides fail contact and sensor supplies

internally, removing the need for a supply transformer

in the panel.

Utility mains voltage and frequency can be read on the

unit. It offers low/high voltage and phase order

protection.

The 2.9" wide, 128x64 pixel graphical screen displays

values with graphic support.

RS-485 MODBUS RTU and USB communication ports

allow monitoring and parameter setting via PC.

Optically isolated digital inputs feature noise filtering,

allowing fault-free operation in electrically noisy

environments.

The unit has 5 relays with 5A output current.

The unit may be configured from the front panel or

using the free software Rainbow Plus, available at the

manufacturer's website.

It is possible to monitor and record the unit using the

free RAINBOW+ software.

V1.0 (02.10.2019)

DK-45 MK2

COMPRESSOR

CONTROLLER

FEATURES

● Graphical LCD screen: 128x64 pixels, 2.9"

● Automatic operation from output pressure

● Voltage protection relay function

● Phase order protection function

● Flexible motor hours calculation algorithm

● 0-10V Analog speed control output

● Multiple compressor support

● Early start function against pressure drop

● Dryer control function

● Event records

● 5 independent service counters

● Supports various topologies

● Displays utility mains voltages

● No external transformer needed

● Star / Delta start-up

● Frequency inverter driving capability

● Load solenoid control

● 5 programmable relay outputs

● Optically isolated, programmable digital inputs

● 2 pressure sensor inputs

● 2 temperature sensor inputs

● Adjustable sensor characteristics

● USB communication port

● RS-485 MODBUS communication

● Password protected front panel programming

● Low panel depth, easy installation

● Wide operating temperature range

● Sealed front panel (IP65 with gasket)

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Datakom DK-45 MK2

- Page 1 DK-45 MK2 User Manual V1.0 (02.10.2019) DK-45 MK2 COMPRESSOR CONTROLLER DESCRIPTION FEATURES ● Graphical LCD screen: 128x64 pixels, 2.9” DK-45 is a high-tech product providing control of screw or piston type air compressors driven by electric ● Automatic operation from output pressure motors.

- Page 2 DK-45 MK2 controllers. Follow the advice given in the document carefully. They are often good practices for the installation of compressor controllers to reduce future issues. For all technical queries please contact Datakom at: technical.support@datakom.com.tr QUERIES If additional information to this manual is required, please contact the manufacturer directly at: technical.support@datakom.com.tr...

- Page 3 DK-45 MK2 User Manual V1.0 (02.10.2019) REVISION HISTORY REVISION DATE AUTHOR DESCRIPTION 02.10.2019 First Edition TERMINOLOGY CAUTION: Potential risk of injury or death. WARNING: Potential risk of malfunction or material damage. ATTENTION: Useful hints for the understanding of device operation.

- Page 4 DK-45 MK2 User Manual V1.0 (02.10.2019) ORDER CODES DK-45 MK2 controllers have a variety of options and features. Please use the following tips to order the correct model. DK45-MK2 -G -T -00 Variant 00: standard unit 01...99: customer Controller Code...

- Page 5 DK-45 MK2 User Manual V1.0 (02.10.2019) SAFETY NOTICE Failure to follow the following instructions may result in death or serious injury ▪ Electrical equipment should be installed only by qualified specialist. No responsibility is assured by the manufacturer or any of its subsidiaries for any consequences resulting from the non-compliance to these instructions.

-

Page 6: Table Of Contents

DK-45 MK2 User Manual V1.0 (02.10.2019) TABLE OF CONTENTS 1. INSTALLATION INSTRUCTIONS 2. INSTALLATION 2.1 DIMENSIONS 2.2 SEALING GASKET 2.3 ELECTRICAL CONNECTIONS 3. TERMINAL DESCRIPTIONS 3.1. POWER SUPPLY INPUT 3.2. AC VOLTAGE INPUTS 3.3. DIGITAL INPUTS 3.4. ANALOG TEMPERATURE SENDER INPUTS 3.5. - Page 7 DK-45 MK2 User Manual V1.0 (02.10.2019) 11. ALARMS AND WARNINGS 11.1. SERVICE COUNTER WARNINGS 11.2. ALARMS 11.3. WARNINGS 12. PROGRAMMING 12.1. RESETTING TO FACTORY DEFAULTS 12.2. ENTERING PROGRAMMING MODE 12.3. NAVIGATING BETWEEN MENUS 12.4. MODIFYING PARAMETER VALUE 12.5. EXITING PROGRAMMING MODE 13.

- Page 8 DK-45 MK2 User Manual V1.0 (02.10.2019) 16. DECLARATION OF CONFORMITY 17. MAINTENANCE 18. DISPOSAL OF THE UNIT 19. ROHS COMPLIANCE - 8 -...

-

Page 9: Installation Instructions

DK-45 MK2 User Manual V1.0 (02.10.2019) 1. INSTALLATION INSTRUCTIONS Before installation: ▪ Read the user manual carefully, determine the correct connection diagram. ▪ Remove all connectors and mounting brackets from the controller, then pass the controller through the mounting opening. -

Page 10: Dimensions

DK-45 MK2 User Manual V1.0 (02.10.2019) 2. MOUNTING 2.1. DIMENSIONS Dimensions: 133x107x46mm (WxHxD) Panel cutout: 117x87mm minimum Weight: 350g - 10 -... - Page 11 DK-45 MK2 User Manual V1.0 (02.10.2019) The controller is designed for panel mounting. The user should not be able to access parts of the unit other than the front panel. Mount the unit on a flat, vertical surface. Before mounting, remove the mounting brackets and connectors from the unit, then pass the unit through the mounting opening.

- Page 12 DK-45 MK2 User Manual V1.0 (02.10.2019) One of the following mounting brackets is supplied with the controller: Self-retaining type bracket Screw type bracket Screw type bracket mounting Self-retaining type bracket mounting Do not tighten excessively as it may break the brackets.

-

Page 13: Sealing Gasket

DK-45 MK2 User Manual V1.0 (02.10.2019) 2.2. SEALING GASKET Panel Gasket Controller The sealing gasket provides 60529-IP65 protection if used while mounting the controller on the panel. A short definition of IP protection ratings is given below: 1st Digit Description of Protection Level... - Page 14 DK-45 MK2 User Manual V1.0 (02.10.2019) 2.3. ELECTRICAL INSTALLATION Do not install the unit close to high electromagnetic noise emitting devices like contactors, high current busbars, switchmode power supplies and the like. Although the unit is protected against electromagnetic disturbance, excessive disturbance can affect the operation, measurement precision and data communication quality.

-

Page 15: Terminal Descriptions

DK-45 MK2 User Manual V1.0 (02.10.2019) 3. TERMINAL DESCRIPTIONS 3.1. POWER SUPPLY INPUT 175 - 275VAC or 305 – 460VAC Power supply voltage: Polarity: Indifferent Maximum power: Isolation: 3300VAC 3.2. AC VOLTAGE INPUTS Measurement method: True RMS Sampling rate: 8000 Hz 0 - 300 VAC Ph-N (0 …... -

Page 16: Digital Inputs

DK-45 MK2 User Manual V1.0 (02.10.2019) 3.3. DIGITAL INPUTS Number of inputs: 4 fully configurable inputs Structure: Opto-isolated inputs Function selection: From function list Contact type: Normally open or normally closed (programmable) Switching: To the 24VAC_OUT terminal Low threshold: < 1VAC High threshold: >5VAC... -

Page 17: Pressure Sender Inputs

DK-45 MK2 User Manual V1.0 (02.10.2019) 3.5. PRESSURE SENDER INPUTS Number of inputs: 2, additional 12V (PRES+) sender supply Structure: 50-ohm resistor to ground Measurement method: Analog DC current measurement Function: The measured current value is converted to pressure via programmed values. - Page 18 DK-45 MK2 User Manual V1.0 (02.10.2019) 3.8. RS-485 PORT Structure: RS-485, non-isolated. Connection: 3 wires (A-B-GND). Half duplex Data transmission speed: 2400-115200 baud, adjustable. Data type: 8 bit data, no parity, 1 bit stop Termination: An external 120-ohm termination resistor is required.

-

Page 19: Usb Port

The USB port is designed to connect the controller to PC. Programming, control, and monitoring of the compressors can be done using the RainbowPlus program. RainbowPlus software can be downloaded from www.datakom.com.tr. The connector on the controller is USB type B. Thus, a USB cable type A to B must be used. It is the same type of cable used to connect printers to PC. -

Page 20: Topologies

DK-45 MK2 User Manual V1.0 (02.10.2019) 4. TOPOLOGIES If the controller will not be used in a 3-phase power grid, it should be specified in the order. Various topologies may be chosen from the program parameters. 4.1. 3 PHASES - 20 -... -

Page 21: Phase

DK-45 MK2 User Manual V1.0 (02.10.2019) 4.2. 2 PHASES 4.3. 1 PHASE Single phase controllers are custom made upon request. The standard controller can not be used in single phase connection. - 21 -... -

Page 22: Connection Diagram

DK-45 MK2 User Manual V1.0 (02.10.2019) 5. CONNECTION DIAGRAM - 22 -... - Page 23 DK-45 MK2 User Manual V1.0 (02.10.2019) Terminal Function Technical Data Description If the supply voltage is within 305 – 460 VAC, connect the phase terminal of the 305 – 460 VAC AC power supply to this terminal. If the supply input...

- Page 24 DK-45 MK2 User Manual V1.0 (02.10.2019) Terminal Function Technical Data Description 1 k-ohm – 10 k-ohm TEMP.2/PTC Connect one terminal of KTY/NTC/PTC resistance type temperature sender to this terminal. measurement input. The other terminal of the sender should be connected to the GROUND terminal.

-

Page 25: Technical Specifications

DK-45 MK2 User Manual V1.0 (02.10.2019) 6. TECHNICAL SPECIFICATIONS 305 – 460 VAC Supply Input: 175 - 275VAC Supply Frequency: 50 - 60Hz nominal (± %10) Power Consumption: < 4 VA Measuring inputs: Voltage: 20 - 520 V AC (Ph-Ph) -

Page 26: Description Of Controls

DK-45 MK2 User Manual V1.0 (02.10.2019) 7. DESCRIPTION OF CONTROLS 7.1. FRONT PANEL FUNCTIONALITY Graphical LCD LINE Screen (MAIN relay) Move to status indicator previous measurement screen. LAMP TEST LOAD Relay status indicator Fault condition indicator Move to next measurement Service screen. -

Page 27: Pushbutton Functions

DK-45 MK2 User Manual V1.0 (02.10.2019) 7.2. PUSHBUTTON FUNCTIONS PUSHBUTTON FUNCTION Enter RUN mode. Compressor starts. Enter STOP mode. Compressor stops. The controller will be reset if held pressed for 15 seconds. Moves to next measurement screen. Press and hold to mute alarms. -

Page 28: Display Screen Organization

DK-45 MK2 User Manual V1.0 (02.10.2019) 7.3. DISPLAY SCREEN ORGANIZATION The controller measures multiple electrical and compressor parameters. The parameters are viewable in measurement screens. Shows the next measurement screen each time button is pressed. Moves to the first measurement screen after the last measurement screen is reached, in a loop. -

Page 29: Measured Parameters

DK-45 MK2 User Manual V1.0 (02.10.2019) 7.4. MEASURED PARAMETERS The controller displays below AC measurements: The measured electrical parameters are listed below: Mains voltage between phase L1 and Neutral Mains voltage between phase L2 and Neutral Mains voltage between phase L3 and Neutral... -

Page 30: Led Lamps

DK-45 MK2 User Manual V1.0 (02.10.2019) 7.5. LED LAMPS LINE (MAIN relay) status indicator işareti LOAD Relay status indicator Alarm indicator Service request indicator RUN mode STOP mode indicator indicator STATUS LEDS: LINE (MAIN RELAY): If RUN mode is selected and the compressor is free to run, main relay is energized and this LED turns on. -

Page 31: Event Logs

DK-45 MK2 User Manual V1.0 (02.10.2019) 8. EVENT LOGS The controller records over 400 events with date, time, and measurement values. Event logs include the following: -event order -event type / error definition (refer below for different event sources) -date and time... - Page 32 DK-45 MK2 User Manual V1.0 (02.10.2019) When viewing event logs: button displays the next piece of information related to the same event. button displays the previous piece of information related to the same event. button displays the same piece of information in the previous event. Pressing it for 2 seconds exits the Event Logs screen.

-

Page 33: Statistical Counters

DK-45 MK2 User Manual V1.0 (02.10.2019) 9. STATISTICAL COUNTERS The controller offers a series of counters for statistical use. The counters are listed below: -total running hours -loaded running hours -number of Motor starts - Service-A remaining hours - Service-B remaining hours... -

Page 34: Modes Of Operation

DK-45 MK2 User Manual V1.0 (02.10.2019) 10. MODES OF OPERATION 10.1. SELECTION OF OPERATION MODE When energized, the controller starts in STOP mode and the STOP LED turns on. The compressor starts after receiving REMOTE START signal or by pressing the RUN button. -

Page 35: Starting The Compressor

DK-45 MK2 User Manual V1.0 (02.10.2019) 10.3. STARTING THE COMPRESSOR The controller switches to running mode by pressing the RUN button or by sending the Remote START/STOP command if enabled. In this phase, the controller activates the compressor if the output pressure (main pressure) is lower than Starting Pressure (or pressure switch closes). -

Page 36: Alarms And Warnings

DK-45 MK2 User Manual V1.0 (02.10.2019) 11. ALARMS AND WARNINGS If any of the measured parameters go outside the predefined limits, an ALARM occurs. If a fault condition occurs, the alarm pop-up screen is displayed and the alarm function is activated. To control various systems, the alarm condition may be assigned to a relay output. -

Page 37: Service Counter Warnings

DK-45 MK2 User Manual V1.0 (02.10.2019) 11.1. SERVICE COUNTER WARNINGS The service LED is used to help remind the periodic services for the compressor. Periodic services are done upon completion of specified Motor running hours (2000 hours for example). The device has 5 independent service timers (hours). When any one of them is up, the service LED turns on. -

Page 38: Alarms

DK-45 MK2 User Manual V1.0 (02.10.2019) 11.2. ALARMS ALARM DESCRIPTION HIGH / LOW VOLTAGE Occurs when phase voltages are outside the programmed limits for the related Alarm Duration. The alarms are: High Voltage Alarm, Low Voltage Alarm HIGH / LOW FREQUENCY Occurs when the frequency is outside the programmed limits. - Page 39 DK-45 MK2 User Manual V1.0 (02.10.2019) ALARM DESCRIPTION If the compressor is running under load and the main pressure measurement is higher than Start Pressure parameter, the pressure alarm is checked. Otherwise, Pressure Difference Alarm is not checked. PRESSURE DIFFERENCE...

-

Page 40: Warnings

DK-45 MK2 User Manual V1.0 (02.10.2019) 11.3. WARNINGS WARNING DESCRIPTION HIGH TEMPERATURE A warning is given if temperature values exceed the programmed warning limits. Each temperature sender produces a different warning. These are the warnings: High Temperature-1, High Temperature-2. WAIT 1 HOUR BEFORE If the Motor starts Hourly Max. - Page 41 DK-45 MK2 User Manual V1.0 (02.10.2019) WARNING DESCRIPTION If Take Load Command Source parameter is set to “1: Digital Input” and one DIGITAL INPUT TAKE digital input function is set as “Take Load Command”, this warning is given LOAD COMMAND when the “take load”...

-

Page 42: Programming

DK-45 MK2 User Manual V1.0 (02.10.2019) 12. PROGRAMMING 12.1. RESETTING TO FACTORY DEFAULTS In order to return to factory settings: - Press and hold buttons for 5 seconds, - The screen will display “RETURN TO FACTORY DEFAULTS”, - Press and hold button for 5 seconds, - The controller will be reset to factory defaults. -

Page 43: Navigating Between Menus

DK-45 MK2 User Manual V1.0 (02.10.2019) 12.3. NAVIGATING BETWEEN MENUS The programming mode is designed as a two-level menu system. The main menu is made up of program groups. Program parameters are in the groups. When programming mode is entered, the program groups list will be displayed. Use the buttons to move between groups. -

Page 44: Program Parameter List

DK-45 MK2 User Manual V1.0 (02.10.2019) 13. PROGRAM PARAMETER LIST 13.1. CONTROLLER CONFIGURATION GROUP Parameter Definition Unit Factory Description Default This parameter adjusts the contrast of LCD Contrast the LCD display. Select the value to ensure optimum visibility. 0: English 1: Turkish. - Page 45 DK-45 MK2 User Manual V1.0 (02.10.2019) 13.1. CONTROLLER CONFIGURATION GROUP (cont.) Parameter Definition Unit Factory Description Default 0: No event record is made upon PGM Mode Event entering Programming mode. Record 1: An event record is made upon entering Programming mode.

-

Page 46: Electrical Parameters Group

DK-45 MK2 User Manual V1.0 (02.10.2019) 13.2. ELECTRICAL PARAMETERS GROUP Parameter Definition Unit Min Factory Description Reset Voltage transformer ratio. This ratio is multiplied by the voltage measurement Voltage Transformer Ratio 5000.0 reading values. If no transformer is used, this parameter should be set to 1.0. -

Page 47: Compressor Paremeters Group

DK-45 MK2 User Manual V1.0 (02.10.2019) 13.3. COMPRESSOR PARAMETERS GROUP Parameter Definition Unit Max Factory Description Default 0: Disabled Pressure Sender-1 1: Pressure Switch Control Setting 2: Pressure Sender Pressure Sender-1 The upper measurement limit of the 1 99.9 16.0 Upper Limit pressure sender must be entered here. - Page 48 DK-45 MK2 User Manual V1.0 (02.10.2019) 13.3. COMPRESSOR PARAMETERS GROUP (cont.) Parameter Definition Unit Factory Description Default 0: Disabled 1: Absolute Temperature 2: Temperature Difference Temperature Sender-2 °C 3: Motor PTC (If the resistance value Setting measured by the sender input is higher than Motor PTC Alarm Limit, MPTC High Temperature alarm is raised.)

- Page 49 DK-45 MK2 User Manual V1.0 (02.10.2019) 13.3. COMPRESSOR PARAMETERS GROUP (cont.) Parameter Definition Factory Description Default When Service A is reset, it syncs to this Service A Hours (Timer) Hours 32767 2000 value. If this parameter is set to 0, no Service A warning is issued.

- Page 50 DK-45 MK2 User Manual V1.0 (02.10.2019) 13.3. COMPRESSOR PARAMETERS GROUP (cont.) Parameter Definition Unit Factory Description Default 0: Disabled Pressure Sender-2 1: Pressure Switch Control Setting 2: Pressure Sender pressure sender upper Pressure Sender-2 99.9 16.0 measurement limit must be entered Upper Limit here.

- Page 51 DK-45 MK2 User Manual V1.0 (02.10.2019) 13.3. COMPRESSOR PARAMETERS GROUP (cont.) Parameter Definition Unit Factory Description Default Temperature Difference Delay timer for Temperature Difference Alarm Delay Alarms. Pressure Difference Delay timer for Pressure Difference Alarm Delay Alarms. Pressure and 0: non-latching...

- Page 52 DK-45 MK2 User Manual V1.0 (02.10.2019) 13.3. COMPRESSOR PARAMETERS GROUP (cont.) Parameter Unit Max Factory Description Definition Default Loaded Water The Water Drainage relay is active for this 6500 Drainage Timer duration while the compressor is loaded. Loaded Water The Water Drainage relay is inactive for this...

- Page 53 DK-45 MK2 User Manual V1.0 (02.10.2019) 13.3. COMPRESSOR PARAMETERS GROUP (cont.) Parameter Unit Max Factory Description Definition Default 0: No effect Reset All 1: Resets all service counters. The service Service counters are set to the related Service Hours Counters (Timer) parameter.

-

Page 54: Adjust Date And Time

DK-45 MK2 User Manual V1.0 (02.10.2019) 13.4. ADJUST DATE AND TIME Date-time info is received from the battery supported real time clock in the controller. Parameter Definition Unit Description Day of the month Month Month info Year Last 2 digits of the year... -

Page 55: Pressure Calendar

DK-45 MK2 User Manual V1.0 (02.10.2019) 13.6. PRESSURE CALENDAR 16 different pressure calendar records can be set in the device. Starting day, hour, minute, duration, Start Pressure, and Stop Pressure can be set independently for each pressure calendar record. Start Pressure and Stop Pressure cannot be set higher than (High Pressure-1 Alarm Limit - 0.2) bar. -

Page 56: Sender Configuration

DK-45 MK2 User Manual V1.0 (02.10.2019) 13.7. SENDER CONFIGURATION The controller has 2 4-20mA pressure sender inputs and 2 analog temperature sender inputs. Each sender has a 16-point programmable curve. One of the analog temperature senders’ curve parameters are described below. The other analog temperature sender has identical parameters. - Page 57 DK-45 MK2 User Manual V1.0 (02.10.2019) Parameter Definition Unit Factory Description Default Sender Curve-1 mA 512.0 Point-1 mA value Sender Curve-1 pressure 3000.0 Point-1 pressure value Sender Curve-2 mA 512.0 Point-2 mA value Sender Curve-2 pressure 3000.0 Point-2 pressure value Sender Curve-3 mA 512.0...

-

Page 58: Input Configuration

DK-45 MK2 User Manual V1.0 (02.10.2019) 13.8. INPUT CONFIGURATION The controller has 4 digital inputs. One of the digital inputs’ parameters are described below. The other digital inputs have identical parameters. The name of the input function can be entered using the RainbowPlus software from the USER INPUT TAGS parameter group. -

Page 59: Digital Output (Relay) Configuration

DK-45 MK2 User Manual V1.0 (02.10.2019) 13.9. DIGITAL OUTPUT (RELAY) CONFIGURATION The following parameters define the functions of the controller’s programmable digital outputs (relays). The controller offers 5 programmable digital outputs (relays). Parameter Definition Factory Terminal Description Default number Relay-01... - Page 60 DK-45 MK2 User Manual V1.0 (02.10.2019) OUTPUT FUNCTION LIST Description Description Horn User input alarm-6 Phase order fault alarm User input alarm-7 Alarm User input alarm-8 Warning Up Arrow button simulation Low voltage alarm Down Arrow button simulation High voltage alarm...

-

Page 61: Motor Serial Number

DK-45 MK2 User Manual V1.0 (02.10.2019) 13.10. SITE ID STRING Site ID String can be used to distinguish the compressor on which the controller is installed. A line of up to 20 characters can be entered here. 13.11. ENGINE SERIAL NUMBER Motor serial number can be used to distinguish the compressor on which the device is installed. -

Page 62: Software Features

DK-45 MK2 User Manual V1.0 (02.10.2019) 14. SOFTWARE FEATURES 14.1. REMOTE START The device can be programmed to switch to RUN mode when an external Remote Start signal is given, and switch to STOP mode when the signal is turned off. - Page 63 DK-45 MK2 User Manual V1.0 (02.10.2019) 14.5. VARIABLE SERVICE HOURS SELECTION The controller offers the option to calculate the service hours using a variable coefficient determined by the main temperature measurement. Variable coefficient use can be selected from Variable Service Hours parameter. If this parameter is not active, the service counters are calculated with constant coefficient 1.00 and independently of main...

-

Page 64: Preventing Pressure Loss

DK-45 MK2 User Manual V1.0 (02.10.2019) 14.6. PREVENTING PRESSURE LOSS If the main pressure measurement is higher than Start Pressure for the duration of Unload Timer, the controller stops the motor. If the main pressure measurement decreases below Start Pressure while the motor is not running, the motor is restarted. -

Page 65: Variable Unload Timer

DK-45 MK2 User Manual V1.0 (02.10.2019) 14.7. VARIABLE UNLOAD TIMER This feature is designed to prevent energy consumption by excessive unloaded operation in low air demand situations. When the main pressure value reaches the set pressure, the LOAD relay disengages first, then the motor keeps running for Safety Timer or Unload Timer (whichever is longer), and finally stops. -

Page 66: Multiple Compressor Operation

DK-45 MK2 User Manual V1.0 (02.10.2019) 14.10. MULTIPLE COMPRESSOR OPERATION Multiple operation mode is designed for situations which require parallel operation of many compressors. Multiple operation mode prevents excessive energy consumption by operating only the required number of compressors in low air demand and enables equal aging among compressors. -

Page 67: Modbus Communications

DK-45 MK2 User Manual V1.0 (02.10.2019) 15. MODBUS COMMUNICATION The controller offers MODBUS in the following ways: -RS485 serial port, adjustable data transmission rate between 2400 and 115200 baud The controller’s MODBUS features: -Data transfer mode: RTU -Serial data: adjustable baud rate, 8 bit data, no parity, 1 bit stop... -

Page 68: Parameters For Rs-485 Modbus Operation

DK-45 MK2 User Manual V1.0 (02.10.2019) 15.1. REQUIRED PARAMETERS FOR RS-485 MODBUS OPERATION Modbus Address: Select a value between 1 and 254. RS-485 Communication Rate: Adjustable between 2400 and 115200 bauds. Each device in the network must have the same communication rate. - Page 69 DK-45 MK2 User Manual V1.0 (02.10.2019) The records which can be read through Modbus are listed below. ADDRESS Read Size Coefficient Description (decimal) Write 10240 32bit Phase L1 voltage 10242 32bit Phase L2 voltage 10244 32bit Phase L3 voltage 10246...

- Page 70 DK-45 MK2 User Manual V1.0 (02.10.2019) ADDRESS Read Size Coefficient Description (decimal) Write 10371 32bit Reserved 10373 16bit Number of devices running under load in the multiple operation group 10374 16bit Total number of devices in the multiple operation group...

- Page 71 DK-45 MK2 User Manual V1.0 (02.10.2019) DIGITAL INPUT STATUS BITS DESCRIPTION DESCRIPTION Digital input-1 status Digital input-2 status Digital input-3 status Digital input-4 status DIGITAL OUTPUT (RELAY) STATUS BITS DESCRIPTION DESCRIPTION Digital output-1 status Digital output-2 status Digital output-3 status...

- Page 72 DK-45 MK2 User Manual V1.0 (02.10.2019) WARNING STATUS BITS DESCRIPTION DESCRIPTION Digital input-1 warning Service B Timer Warning Digital input-2 warning Service C Timer Warning Digital input-3 warning Service D Timer Warning Digital input-4 warning Service E Timer Warning Digital input-5 warning...

- Page 73 DK-45 MK2 User Manual V1.0 (02.10.2019) RELAY (DIGITAL OUTPUT) FUNCTION STATUS BITS DESCRIPTION DESCRIPTION DESCRIPTION Input 2 Simulation Horn Pressure Alarm Sender-1 Pressure Alarm Sender-2 Input 3 Simulation Phase Order Fault Alarm Input 4 Simulation Alarm Temperature Sender Error Warning...

-

Page 74: Commands

DK-45 MK2 User Manual V1.0 (02.10.2019) 15.3. COMMANDS ADDRESS Read Size Coefficient Description (decimal) Write 8192 16bit Password (In order to change the calibration coefficients through Modbus, the calibration password must be entered to this address.) 8193 16bit Button simulation. If the following Hexadecimal numbers are entered here, the device will respond as if the corresponding buttons have been pressed. - Page 75 DK-45 MK2 User Manual V1.0 (02.10.2019) ADDRESS Read Size Coefficient Description (decimal) Write 8204 16bit The value typed into this address is added to Service A hours. 8205 16bit The value typed into this address is subtracted from Service A hours.

- Page 76 DK-45 MK2 User Manual V1.0 (02.10.2019) ADDRESS Read Size Coefficient Description (decimal) Write 8216 16bit The controller enters boot mode 8217 16bit The value typed into this address controls the user outputs. To activate user output 1 relay function, type 0x0001 (1); to deactivate, type 0x8001 (32769).

- Page 77 DK-45 MK2 User Manual V1.0 (02.10.2019) 15.4. EVENT LOGS MEMORY STRUCTURE ADDRESS Read Size Coefficient Description (decimal) Write 32bit 32 bit date time information Bit_0..4: seconds/2 (0-29) Bit_5..10: minute (0-59) Bit_11..15: hour (0-23) Bit_16..20: day (1-31) Bit_21..24: month (1-12) Bit_25..31: year-2000 (0..127=2000..2127)

-

Page 78: Real Time Clock

DK-45 MK2 User Manual V1.0 (02.10.2019) 15.5. REAL TIME CLOCK ADDRESS Read Size Coefficient Description (decimal) Write 5120 16bit Year (0-4096) 5121 16bit Month (1-12) 5122 16bit Day (1-31) 5124 16bit Hour (0-23) 5125 16bit Minute (0-59) 5126 16bit Second (0-59) - Page 79 DK-45 MK2 User Manual V1.0 (02.10.2019) 16. DECLARATION OF CONFORMITY The unit conforms to the following EU directives: -2014/35/EC (Low Voltage Directive) -2014/30/EC (Electromagnetic Compatibility) Norms of Reference: EN 61010 (safety requirements) EN 61326 (EMC requirements) The CE mark indicates that this product complies with the European requirements for safety, health, environmental, and customer protection.

Need help?

Do you have a question about the DK-45 MK2 and is the answer not in the manual?

Questions and answers